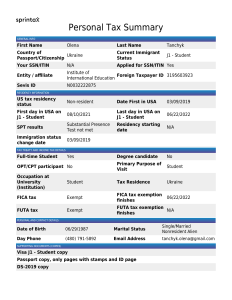

Journal of Physics: Conference Series You may also like PAPER • OPEN ACCESS New efficiencies of energy-saving facade paints based on a combined film-forming agent - Performance analysis of the MICRO-V (Multifunctional, Integrated, Climateresponsive, Opaque, and Ventilated) façade with different ventilation modes SS Soudian Shahrzad and UB Berardi Umberto To cite this article: Olmahon Gadoeva et al 2022 J. Phys.: Conf. Ser. 2388 012136 - Perspectives in double-skin façade (DSF) advantages and disadvantages E A N Al-awag and I A Wahab View the article online for updates and enhancements. - Dynamic facade module prototype development for solar radiation prevention in high rise building Muhammad Sega Sufia Purnama and Dalhar Sutanto This content was downloaded from IP address 84.54.70.253 on 14/12/2022 at 00:30 APITECH-IV - 2022 Journal of Physics: Conference Series 2388 (2022) 012136 IOP Publishing doi:10.1088/1742-6596/2388/1/012136 New efficiencies of energy-saving facade paints based on a combined film-forming agent Olmahon Gadoeva, Sardorbek Fatiloev, Zarina Fayzullaeva and Yoqub Yaxshiyev Bukhara Engineering Technological Institute, Bukhara, Uzbekistan E-mail: [email protected] Abstract. This article discusses new nano-technological building materials for facade backgrounds and energy-saving efficiencies in the construction of new buildings. Recently, a lot of new materials and their economic efficiency for modern construction have been developed in construction. In nano technologies applying facade paints and semi-thermal energy-saving paints for the utilization of the house and efficiency in new housing and this is very relevant in new construction, and this has grown a lot of development is underway based on a combined filmforming agent from local materials Keywords: building materials, granular PVC, paint coatings (LCP), facade paints, film-forming substances, vapor permeability, hydrophobic additive. 1. Introduction The development of new building materials has recently become very relevant and use them in nontechnology construction. Plasters of various compositions, decorative plasters, including crumbs of natural stone, cement and ceramic tiles, facing bricks are traditionally used for facades of urban buildings in Western Europe, Russia and the Republic of Belarus. Such surfaces are painted with various paints, both inorganic and based on polymer binders of various nature. Water in the form of precipitation (droplet moisture) and water vapor are the main factors leading to the destruction of paint coatings (LCP). Construction of 1 million cubic meters of modern and energy-efficient building materials (an increase of 2.9 times) of aerated concrete blocks, 25 thousand tons of basalt and glass-wool thermal insulation boards, 2.5 thousand tons of basalt fiber composite reinforcement, 114 thousand tons of pipes and fittings made of granular PVC material. In general, production facilities aimed at fully providing the domestic market with basic construction materials will be created this year. Drip moisture enters the structure mainly during precipitation, as well as through the basement and roof of the building with insufficient waterproofing and violation of the current drainage system. Water vapor in the premises has a biogenic origin, or is formed during the operation of household and industrial equipment; it penetrates into the walls, where it can condense in the cold season. Increased humidity of the walls increases heat loss in winter, promotes the growth of algae (on the facade of the building), fungi and mold (inside the building). Cyclic freezing of water in the capillaries of artificial stone material (freezing-thawing) leads to the appearance of internal stresses, a decrease in strength and the formation of cracks [1]. The humidity level must be taken into account when determining the timing of the painting of facades, both in new construction and during major repairs of buildings and structures, when replacing the roof, plaster and restoring the loss of masonry. As a consequence, one of the main requirements for the LCP is sufficient permeability for water vapor. At the same time, the facade paintwork should Content from this work may be used under the terms of the Creative Commons Attribution 3.0 licence. Any further distribution of this work must maintain attribution to the author(s) and the title of the work, journal citation and DOI. Published under licence by IOP Publishing Ltd 1 APITECH-IV - 2022 Journal of Physics: Conference Series 2388 (2022) 012136 IOP Publishing doi:10.1088/1742-6596/2388/1/012136 prevent the ingress of droplet moisture inside during precipitation, that is, it should have hydrophobic properties [2]. 2. Materials and methods Domestic and imported paints are also in demand. Thanks to modern equipment and foreign experience, you can hear such trademarks as "Yaroslavl paints", "Ancient", "Aquatex", "Additionally". In each company you can find compositions for exterior and interior work, as well as a rich palette of shades. Acrylic paints for works of art appeared much later. It can be called an invention of modernity. The first copies had a limited number of colors, while it was necessary to choose a special shade. But if everything is properly selected and mixed, the paint will dry quickly. It was very difficult to find the right shades. Photochemical aging of the LCP, manifested in a change in its color and chalking, causes solar radiation. Heating of the facade of the building due to solar radiation intensifies the evaporation of water from the structure, significantly increasing the load on the paintwork.Thus, the purpose of using facade paints is to decorate the building and protect its exterior surface from atmospheric influences. The effect of ultraviolet radiation on the paintwork affects the loss of mass (chalking), a decrease in gloss, an increase in fragility, but the first signs of a decrease in weather resistance are a decrease in the initial color characteristics, including a change in the appearance and color of the paintwork. [3]. "nanotechnology products" means industrial and consumer products created using nanomaterials/nanotechnology. As a rule, there are three groups of nanotechnology products: • primary nanotechnology products - products (nanoobjects, nanosystems, especially pure substances) created directly with the use of nanotechnology, including basic raw materials and semi-finished products for the nanoindustry (in particular, nanopowders and nanomaterials); • nano–containing products - products (goods) containing nanotechnological components (nanoobjects, nanosystems and especially pure substances), including those produced using primary nanotechnological products; • nanotechnological works and services – works and services, carrying out (rendering) which is carried out using nanotechnologies or technologies of application of primary nanotechnological and (or) containing nanoproducts. Thus, the primary nanoproduct is actually nanomaterials, which form the core of the nanomarket. They are used in the production of end-use goods, which, in turn, are secondary nanoproducts. Figure 1. Combined film-forming paint for facades. 2 APITECH-IV - 2022 Journal of Physics: Conference Series 2388 (2022) 012136 IOP Publishing doi:10.1088/1742-6596/2388/1/012136 3. Results and discussion The use of nanotechnology in construction is increasing, the water resistance of the facade of the house and the need to use paints, as well as the convenience of nano-coatings in that they are an energy-saving tool. For example, one of the properties of translucent nanocoats is that they collect solar energy. These films are placed on the windows and sides of the building: nanocoats can work as solar cells, adding modernity to the appearance of the building and are important for saving electricity., The convenience of nanocoats is that they are energy efficient. For example, one of the properties of translucent nanocoats is that they collect solar energy. These films are placed on the windows and on the sides of the building: nanocoats can work as solar panels, giving the building a modern look, and play an important role in saving electricity. Currently, the most light-resistant, mainly natural and synthetic inorganic pigments are used in the development of formulations of high-quality facade paints. Dust, dirt, fatty contamination, acid rain destroy the mineral substrate and create conditions for the development of microorganisms in cracks and on the surface of facades, which leads to bio-damage to the structure. High-quality facade paint should contain a balanced complex of biooccides, providing long-term durability of the paintwork. The use of modern film-forming substances prevents the softening of the coating with an increase in temperature, thus reducing the retention of impurities on the surface of facades. It is important that the facade paint forms a paintwork with sufficient hardness and abrasion resistance, since these indicators indicate the ability of the coating to resist wind erosion. Traditional water-dispersion paints for outdoor work differ from each other in the content of the film-forming agent and the volume concentration of the pigment (OKP). Compositions with a low OKP and a high content of film-forming agent have good water resistance, but low vapor permeability, since the formed coating is insufficiently porous. Compositions with high OKP and low film-forming agent content have sufficient vapor permeability, but the water absorption of LCP based on them is too high [4]. The authors developed and optimized the formulation of water-dispersion facade paint based on a combined filmforming agent: 50% styrene acrylic dispersion of anionic type obtained by emulsion co polymerization of styrene and methyl methacrylate, and silicone emulsion [5, 6, 7]. Natural calcium carbonate (marble powder) of various fractional composition and micro talc were chosen as fillers to increase the hiding power of the paintwork, titanium dioxide of rutile form obtained by the chloride method was used as a pigment. Table 1. Average chemical composition of basalt raw materials (in % by weight). country name and gender SiO2 Chinese 48,03 basalt Basalt of 48,2 Uzbekistan TiO2 Al2O3 Components (minerals) Fe2O3 FeO MgO CaO Na2O 2,85 12,59 3,88 8,15 5,47 10,5 2,32 0,60 11,8 4,12 6,20 9,15 13,3 1,452,2 3 K2O 2,68 APITECH-IV - 2022 Journal of Physics: Conference Series 2388 (2022) 012136 IOP Publishing doi:10.1088/1742-6596/2388/1/012136 Composition of basalt fiber sample 1 Figure 2. Basalt fiber. The fiber used is basalt fiber. Basalt fiber differs from metal reinforcement in the following advantages: • environmentally friendly material, has a natural formula of basalt stone; • without carcinogenic and toxic-toxicological substances; • resistant to mold and microorganisms; • thermal conductivity is zero; • bending strength 1200 MPa; • does not lose strength from -70°С to +100°С; • fiber diameter 10-21 microns; • fiber length 15-20 mm. • absolute incombustibility at high temperature, continuous use temperature is high – 700 °С, with short-term use - up to 900 °С; durable up to; • due to the natural formula, the service life is more than 50 years; • basalt composites replace steel and fiberglass reinforced plastics possible [3] durable up to; • due to the natural formula, the service life is more than 50 years; • basalt composites replace steel and fiberglass reinforced plastics possible [3]. Titanium dioxide of this brand is characterized by increased whiteness due to surface treatment with aluminum oxides, silicon and zirconium compounds, as well as high resistance to photo-oxidative degradation. The formulation contains a complex of functional additives: a dispersant, a rheology agent, a coalescent, a container preservative, an algicide that provides bio-protection of the paintwork, a foam extinguisher and a deaerator (for removing foam in 67% of the paint). The pH of the composition was regulated with an aqueous ammonia of 25% concentration [7]. To obtain a coating with the effect of rolling drops (the "lotus" effect), a hydrophobic additive is included in the composition. The OKP of the developed composition is 75%. The optimized formulation of water-dispersion eco-friendly facade paint is shown in Table 1. Tests of water-dispersion eco-friendly facade paint and cured paintwork were carried out according to known methods [8]. Table 1 – Optimized formulation of water-dispersion eco-friendly facade paint Component name Component content, mass.% Styrene acrylic dispersion 12.0 Silicone emulsion 7.0 Sodium polyphosphate (water softener) 0.2 Hydroxymethylcellulose (rheology agent) 0.3 pH regulator (technical water ammonia) 0.05 Coalescent (butyldiglycolacetate) 0.7 Hydrophobizer 1.30 Dispersant 0.4 Silicone-based defoamer 0.2 Deaerator 0.3 Container preservative 0.2 Algicide (film biosecurity) 0.2 Polyurethane thickener 0.15 Titanium dioxide 12.0 Microtalk (Ø cf.= 2 microns) 6.0 Micromramor powder (Ø cf.=5 microns) 20.0 Micromramor powder (Ø cf.=1.8-1.5 microns) 16.0 Water 23.0 The degree of grinding of the facade 4 APITECH-IV - 2022 Journal of Physics: Conference Series 2388 (2022) 012136 IOP Publishing doi:10.1088/1742-6596/2388/1/012136 paint was determined according to the grindometer (the "Wedge" device). The hardness of the LCP film was tested with the U-1 device, adhesion to the concrete base was tested by the separation method [8]. Additionally, the water absorption of LCP on inert glass substrates was investigated. Water absorption (W) as a percentage was calculated by the formula: W = (m2 – m1) * 100 / (m1 –m0), where m0 is the mass of the clean plate, g; m is the mass of the plate with the LCP before the test, g; m2 is the mass of the plate with the LCP after the test, g. The vapor permeability of the LCP was evaluated by a method based on determining the amount of water vapor that passed through 1 cm 2 of the surface of the free film during the day at a temperature of (20 ± 2) ° C. The results of laboratory tests of the LCP are shown in Table 2. Accelerated climatic tests were carried out in RUE BelNIIS (Minsk) according to the standard method [8], simulating the effect on the LCP of a combination of climatic factors of a moderate climate (variable cyclic effect of UV radiation, irrigation with water, freezing-thawing). The studied coatings were applied to cement-sand substrates in two layers, having previously primed the surface with acrylic dispersion diluted with drinking water in a ratio of 1:7. The thickness of the dried paintwork was 70-80 microns. Before conducting the studies, the samples with LCP were kept for 72 hours under standard conditions [6, 7]. Laboratory studies have shown that the developed water-dispersion eco-friendly facade paint based on a combined film-forming agent has high vapor permeability and low water absorption, which indicates the formation of a "breathable" paintwork with high hydrophobicity. The combination of such characteristics determines the high weather resistance of the coating – more than 100 cycles, which is 10 conditional years of operation in a temperate climate, and the adhesion of the LCP to the substrate after testing is about 90% of the initial (A100 = 0.9 * A0). The high hiding power of the facade paint is provided by a combination of fillers (ground micro marble and microtalk) and pigment with different particle shapes. Thanks to the combined film-forming agent included in the composition of the facade paint formulation, a high light resistance of the paintwork is achieved, which is the most important indicator characterizing the resistance of the paintwork to atmospheric influences (exposure to ultraviolet radiation, atmospheric oxygen, humidity, acid rain, temperature fluctuations) [7]. Results of laboratory tests of the LCP indicator (actual value of the indicator): 1. Appearance of the film Smooth and homogeneous matte surface; 2. Mass fraction of non-volatile substances, % 62.1; 3. Coverage of the dried film, g/m2 170; 4. pH 9.0; 5. Drying time to degree 3 at a temperature (20±2)° C, min no more than 40; 6. Degree of grinding, microns 40; 7. Resistance of the coating to static effects of water, h more than 72; 8. Conditional light resistance (change in diffuse reflection coefficient) after 168 hours of irradiation, % 1.1 (norm – no more than 5); 9. Film washability (resistance to wet abrasion), g/m2 0.96; 10. Frost resistance of the coating, cycles more than 50; 11. Adhesion of the coating to the base (concrete), MPa 2.4; 12. Resistance of the coating to climatic factors (weather resistance), cycles more than 100; 13. Film hardness of the film according to the device U-1, usl.ed 0.21; 14. Vapor permeability coefficient, mg/m·h·Pa 0.01 (norm - not less than 0.005); 15. Water absorption after 24 hours, % 0.25. 4. Conclusions Thus, as a result of the development of formulations and laboratory studies, an energy-saving (providing optimal operating conditions), environmentally complete formulation of paint coatings without organic solvents, siccatives, toxic components have been developed. We can say that basalt materials are distinguished by their modernity, economy, strength, resistance to climatic conditions, ease of processing. References [1] Brock T et al. 2004 European Guide to paints and coatings (M.: Paint-Media) [2] Okhrimenko I S et al. 1978 Chemistry and technologies of film-forming substances (L.: 5 APITECH-IV - 2022 Journal of Physics: Conference Series 2388 (2022) 012136 IOP Publishing doi:10.1088/1742-6596/2388/1/012136 Chemistry) [3] Yakovlev A D 1981 Chemistry and technologies of paint and varnish coatings (L.: Chemistry) [4] Stoye D et al. 2007 Paints, coverings and solvents (St. Petersburg: Surplus) [5] Tur A S 2016 Investigation of the possibilities of using acrylic and silicone film for developers of water-using environmental facade dyes Collection of competitive sciences. the work of students and undergraduates in 2 parts (Brest, 2016) Part 1 pp 208-12 [6] Karikina M I et al. 1988 Used paint and varnish materials and coatings (M.: Chemistry) [7] Dllaganov A A Possibilities of searching for structures of string plants for architectural monuments of Bukhara [8] Hartmann H 2008 Nanotechnology Window (M.: BINOM) [9] Sodikov G, Gadoeva O P 2019 Temirbeton constructionlarn louichalashda armuraning noelastic [10] Usmonov F B 2021 European Scholar Journal An Open Access , Peer Reviewed Multidisciplinary Journal 2(5) 267-70 6