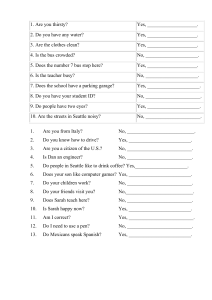

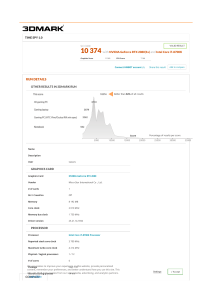

energies Article The Effect of Distributed Parameters on Conducted EMI from DC-Fed Motor Drive Systems in Electric Vehicles Li Zhai 1,2, *, Liwen Lin 1,2 , Xinyu Zhang 3 and Chao Song 1,2 1 2 3 * National Engineering Laboratory for Electric Vehicle, Beijing Institute of Technology, Beijing 100081, China; [email protected] (L.L.); [email protected] (C.S.) Co-Innovation Center of Electric Vehicles in Beijing, Beijing Institute of Technology, Beijing 100081, China Beijing Institute of Radio Metrology and Measurement, Beijing 100854, China; [email protected] Correspondence: [email protected]; Tel.: +86-10-6891-5202 Academic Editor: Joeri Van Mierlo Received: 18 August 2016; Accepted: 12 December 2016; Published: 22 December 2016 Abstract: The large dv/dt and di/dt outputs of power devices in DC-fed motor drive systems in electric vehicles (EVs) always introduce conducted electromagnetic interference (EMI) emissions and may lead to motor drive system energy transmission losses. The effect of distributed parameters on conducted EMI from the DC-fed high voltage motor drive systems in EVs is studied. A complete test for conducted EMI from the direct current fed(DC-fed) alternating current (AC) motor drive system in an electric vehicle (EV) under load conditions is set up to measure the conducted EMI of high voltage DC cables and the EMI noise peaks due to resonances in a frequency range of 150 kHz–108 MHz. The distributed parameters of the motor can induce bearing currents under low frequency sine wave operation. However the impedance of the distributed parameters of the motor is very high at resonance frequencies of 500 kHz and 30 MHz, and the effect of the bearing current can be ignored, so the research mainly focuses on the distributed parameters in inverters and cables at 500 kHz and 30 MHz, not the effect of distributed parameters of the motor on resonances. The corresponding equivalent circuits for differential mode (DM) and common mode (CM) EMI at resonance frequencies of 500 kHz and 30 MHz are established to determine the EMI propagation paths and analyze the effect of distributed parameters on conducted EMI. The dominant distributed parameters of elements responsible for the appearing resonances at 500 kHz and 30 MHz are determined. The effect of the dominant distributed parameters on conducted EMI are presented and verified by simulation and experiment. The conduced voltage at frequencies from 150 kHz to 108 MHz can be mitigated to below the limit level-3 of CISPR25 by changing the dominant distributed parameters. Keywords: electric vehicle; DC-fed; motor drive system; conducted electromagnetic interference (EMI); distributed parameter 1. Introduction In the face of the worldwide demand for reduction in greenhouse gas emissions and PM2.5 production [1], recently many countries have adopted policies, mainly in the form of tax incentives for the purchase, to increase the number of electric vehicles (EVs) and thus reduce pollutant emissions and improve the air quality, especially in urban areas [2–5]. Electromagnetic interference (EMI) considerations in EVs have become increasingly important, as the electromagnetic compatibility (EMC) regulations for EVs (typically defined from 10 kHz to 30 MHz) have become more stringent [6]. The DC-fed motor drive system of EVs, consisting of the electric motor, power inverter, and electronic controller has an essential role in EVs [7]. Large dv/dt and di/dt due to high-speed switching of power devices within a DC-fed voltage-type pulse width modulation (PWM) inverter of high-power-density Energies 2017, 10, 1; doi:10.3390/en10010001 www.mdpi.com/journal/energies Energies 2017, 10, 1 2 of 17 and high-efficiency motor drive system always introduce unwanted higher-order harmonics currents and high frequency noise currents through parasitic/distributed parameters of the motor system [8–10], and are mainly responsible for the conducted and/or radiated electromagnetic interference (EMI) emissions which will greatly affect the behavior of low voltage supply electronic equipment (such as board bus system, sensors, vehicle control units (VCUs), battery management systems (BMSs), power batteries, and the drive motor in EVs [6,11]. Additionally, the unwanted higher-order harmonics current from the motor drive system due to the switching of insulated gate bipolar transistors (IGBTs) can not only generate common mode (CM) EMI and differential mode (DM) EMI emissions, but also increase the motor losses, which may lead to energy transmission losses and thermal problems in the power inverter system. 1.1. Literature Review Much valuable work involving the EMI emissions of the motor drive system for conventional industrial applications has been widely conducted by many researchers [12–14]. However, the EMI from the drive motor system under varying load conditions for EVs is different from that of a conventional industrial motor with no load or invariant load conditions. Previous studies on EMI emissions from vehicle components are based on the measurements specified in the EMC standard CISPR25 (International Special Committee on Radio Interference 25) [15,16], which are implemented for low voltage components in EVs and not suitable for the high voltage applications in EVs (e.g., motor system, charging system), so we cannot correctly predict the EMI emissions from the high voltage motor system in EVs due to the fact few EMC laboratories have the dynamometer needed to study EVs under varying loading conditions, so the present study on the EMI mechanism and propagation path of the motor system is much less than that on the total EMC performance of EVs [17,18]. The EMI emissions from the high voltage cables of the AC motor drive system of EVs under load condition have not been considered in previous works. Various parasitics and distributed parameters exist inside the motor system and they play a very important role in the generation of EMI. The high-frequency leakage currents flowing to the ground could be generated through distributed parameters between the components of the motor drive system (such as the motor, inverter, cables, etc.) and the chassis of the body of the EV at high frequency, and introduce the radiation of power cables, shaft voltage and bearing currents in the motor [19,20]. Additionally the EMI emission peaks due to resonances caused by distributed parameters may cause some energy losses of the motor drive system and decrease the efficiency of the system [21–23], so the distributed parameters at high frequency in the system should not be neglected anymore for EVs. Therefore, the effect of the distributed parameters on EMI emissions is important for identification of EMI propagation paths and the critical distributed parameters of elements responsible for EMI, and mitigation of EMI emissions [24]. Models of the motor drive system are necessary to analyze and predict the EMI sources and propagation inside the motor drive system to find the elements responsible for the EMI. Since the most basic and widely applied full-wave models based on the “black box” approach cannot show the location of the noise source or the propagation path inside the motor power inverter [20,25], some terminal modeling techniques for a two-port network were proposed to predict the conducted EMI [14,21,26]. However, there has never been a theoretical analysis of the parasitic effects of the distributed parameters on EMI noise suppression. An equivalent simulation program with integrated circuit (SPICE)-based model is a better approach to find the parts and elements of the motor inverter system responsible for EMI [12] and analyze the effects of the distributed parameters on the EMI noise. A rather simple measurement-based SPICE model of the motor power inverter has been presented [12] to quickly identify the parts responsible for EMI and help predict resonances between the two ports of the motor power inverter by a straightforward correlation between the system geometry and the parasitic circuit elements [27]. A detailed analysis of current paths and the equivalent circuits at three important resonance frequencies have been presented to determine the EMI propagation path in the Energies 2017, 10, 1 3 of 17 motor drive system [6]. A combination of mitigation strategies was designed to mitigate the CM conducted emission by IGBT switching and the radiated emissions of AC cables. Most of the above work focuses on analyses of CM and DM EMI propagation paths in the system based on a “black box” approach, terminal modeling techniques and SPICE-based models, which have not considered the effect of the distributed parameters of the high voltage motor drive system in EVs on EMI noise, so the previous equivalent circuits of the EMI could not be correctly proposed to accurately and effectively predict the actual source and propagation of the EMI in the system. The effects of the distributed parameters on the conducted EMI noise have not been adequately considered previously because of a lack of the modeling of the conducted EMI from the high voltage motor drive system with suitable parameters and better analysis methods. 1.2. Motivation and Innovation This study proposes a new method to analyze the effect of distributed parameters on conducted EMI from the DC-fed high voltage motor drive systems in EVs. A complete test for conducted EMI emissions from the AC motor drive system of an EV under load conditions will be set up to measure the conducted EMI of high voltage DC cables and EMI noise peaks due to resonances in a frequency range of 150 kHz–108 MHz. The corresponding equivalent circuits for DM and CM EMI at the resonance frequencies of 500 kHz and 30 MHz are established to determine the EMI propagation paths and analyze the effect of distributed parameters on conducted EMI. The dominant distributed parameters of elements responsible for the resonances appearing at 500 kHz and 30 MHz will be determined. The effect of the dominant distributed parameters on conducted EMI will be verified by simulations and experiments. 1.3. Organization of the Paper The organization of this study is as follows: Section 2 illustrates the structure of the complete test setup for conducted EMI emissions from the AC motor drive system of an EV. Then, the corresponding current paths and equivalent circuits of DM and CM EMI at resonance frequencies of 500 kHz and 30 MHz, and the effect of distributed parameters on CM EMI will be presented in Section 3. After that, the simulation verification and discussion will be illustrated in Section 4. The experiment verification will be discussed in Section 5. Finally, conclusions are provided in Section 6. 2. System Conducted Emission Measurement 2.1. Conducted EMI Emission Setup The complete test setup for conducted EMI emissions from the DC-fed AC motor drive system on an EV in an EMI laboratory is shown in Figure 1 and mainly consists of a DC power supply such as a Li-ion battery, DC cables, a DC-fed voltage-type PWM three-phase power inverter, AC cables, and an AC motor. Measurements were performed to comply with the CISPR 25 standard which provides conducted EMI emission limits for vehicle components in a frequency range of 150 kHz to 108 MHz [28]. Two standard line impedance stabilization networks (LISNs) terminated with 50 Ω resistances provide DC power from a battery or DC power supply to the three-phase power inverter using two shielded cables (2 m). The power inverter with 330 V DC input is connected to a 50 kW/100 kW permanent magnet synchronous motor (PMSM) using three shielded cables (1 m). As required by the EMC regulations of CISPR 25, all components are connected to a large copper sheet as ground reference plane, except for the AC motor which is located on an insulated bench covered with ferrite material and connected to an electric dynamometer supplying a mechanical load. The output speed and torque of the AC motor can be measured by a meter between the dynamometer and the insulated output shaft of the AC motor. With this configuration, the total conducted EMI noise voltage signals in DC cables can be picked up by any one of the line impedance stabilization network (LISN) impedances connected to an EMI receiver [29]. Energies 2017, 10, 1 4 of 17 Energies 2016, 10, 1 4 of 17 Energies 2016, 10, 1 Energies 2016, 10, 1 4 of 17 4 of 17 Figure 1. Conducted EMI emission system test setup for the AC motor drive system. Figure 1. Conducted EMI emission system test setup for the AC motor drive system. 2.2. Conducted EMI Experiment Results Figure 1. Conducted EMI emission system test setup for the AC motor drive system. 2.2. Conducted EMI Experiment Results 1. Conducted emission system test setup for the AC motor driveand system. The ACFigure motor is operatedEMI continuously at 2000 rpm speed with no-load 60 N·m loaded The ACasmotor is Experiment operated continuously at 2000 rpm speed with no-load 60 N·mEMI loaded 2.2. Conducted EMI Results torque, shown in Figure 2. Figure 3 shows the experimental comparison in and conducted 2.2. EMI Experiment Resultsand load conditions. This experimental result indicates that the emission levels between the no-load torque, asConducted shown in Figure 2. Figure 3 shows the experimental comparison in conducted EMI emission The AC motor is operated continuously at 2000 rpm speed with no-load and 60 N·m loaded conducted EMI noiseis voltage of continuously the power inverter is rpm dominant aresult frequency range ofN·m 150 kHz to TheasAC motor operated atThis 2000 speedinwith no-load and 60 levelstorque, between the no-load and load conditions. indicates that theloaded conducted shown in Figure 2. Figure 3 shows theexperimental experimental comparison in conducted EMI 108 MHz and is not compliant with CISPR25, as shown in Table 1. Therefore the conducted EMI torque, aslevels shown in power Figure 2. Figure shows theinexperimental comparison conducted EMI EMI noise voltage ofbetween the inverter is3dominant a frequency range of 150inindicates kHz to 108 emission the no-load and load conditions. This experimental result thatMHz the and emission levels levels between in the load areload more severe and higher than those in the no-loadthat mode. the condition no-load and conditions. This experimental result indicates is notemission compliant with CISPR25, asthe shown ininverter Table 1. conducted EMI conducted EMI noise voltage of power is Therefore dominant inthe a frequency range of emission 150 kHzthe tolevels Two noise voltage peaks at frequency around 500 kHz and 30 MHz can be observed and may mainly conducted EMI noise voltage of the power inverter is dominant in a frequency range of 150 kHz to MHz and is not withand CISPR25, shown in Table Therefore the conducted in the108 load condition arecompliant more severe higherasthan those in the1.no-load mode. Two noiseEMI voltage be caused by PWM switching harmonics or parasitic resonances due1.toTherefore the distributed parameters of 108 MHz levels and isinnot with CISPR25, shown inhigher Table EMI thecompliant load condition are more as severe and thanmay those inthe theconducted no-load mode. peaksemission at frequency around 500 kHz and 30 MHz can be observed and mainly be caused by the motor system [30]. It is critical to analyze the source and propagation mechanism of EMI toPWM emission levels in peaks the load condition around are more severe and30 higher than those in theand no-load mode. Two noise voltage at frequency 500 kHz and MHz can be observed may mainly switching harmonics or parasitic resonances to kHz the distributed parameters of parameters the motor system predict thevoltage conducted EMI emissions anddue determine the 30 dominant distributed of the [30]. Two noise at frequency around 500 and MHz be observed and may mainly be caused by PWMpeaks switching harmonics or parasitic resonances duecan to the distributed parameters of It is critical to analyze the source and propagation mechanism of EMI to predict the conducted EMI elements in the motor system responsible for the resonances. be PWM[30]. switching harmonics or parasitic resonances to the distributed parameters thecaused motor by system It is critical to analyze the source and due propagation mechanism of EMI of to emissions and determine the dominant distributed parameters of the elements in the motor system the motor [30]. EMI It is emissions critical to and analyze the source and propagation mechanism of EMI to predict thesystem conducted determine the dominant distributed parameters of the responsible for the resonances. predict the conducted EMI emissions and determine the dominant distributed parameters of the elements in the motor system responsible for the resonances. elements in the motor system responsible for the resonances. Figure 2. The test platform for conducted EMI emission. Figure 2. The test platform for conducted EMI emission. Figure 2. 2.The for conducted conductedEMI EMI emission. Figure Thetest testplatform platform for emission. Figure 3. Comparison of measurement with load and measurement without load. Figure 3. Comparison of measurement with load and measurement without load. Figure 3. Comparison ofofmeasurement withload loadand andmeasurement measurement without Figure 3. Comparison measurement with without load.load. Energies 2017, 10, 1 5 of 17 Table 1. CISPR25 class3-peak limits for conducted disturbances. Service Band Frequency/MHz Limit/dB (µv) Broadcast 0.15–0.30 0.53–1.80 5.9–6.2 41–88 76–108 90 70 65 46 50 Mobile services 26–28 30–54 68–87 56 56 50 3. System Conducted Emission Analysis 3.1. Noise Source Figure 1 shows the circuit of a full bridge IGBT-based inverter in the motor controller model. The DC-fed PWM power inverter is designed to have a rated 250 V output voltage. The DC bus input voltage is 330 V. The six switches S1 –S6 in the inverter are 1200 V/600 A full bridge IGBT modules (Infineon) with sinusoidal pulse width-modulation (SPWM) control. Although control methods (like space vector pulse width modulation (SVPWM), direct torque control (DTC), indirect field oriented control (IFOC), etc.) have better characteristics for mitigating harmonics, this is not the case for the EMI noise at high frequency. Therefore, we focus on the effect of characteristics of the trapezoidal wave for PWM on the EMI. We just take SPWM as an example for explaining the principle of the spectrum of the trapezoidal wave. The switching frequency of IGBT was set to 20 kHz and the line frequency for the AC motor was 400 Hz. The SPWM control signals are generated by compared a sinusoidal reference with a 20 kHz triangular carrier signal as illustrated in Figure 4a, which shows the PWM waveforms in a half-period, which have nine duty cycles corresponding to nine pulses with different pulse-widths. The noise source due to the SPWM control is often simplified by assuming a trapezoidal shape for the switching transients [26]. Each PWM pulse can be described as a trapezoidal pulse by an amplitude A, a frequency f, a pulse rise-time τr , a pulse fall-time τ f and a pulse-wide τ. T represents the period of the trapezoidal pulse. The continuous envelope spectrum for a trapezoidal pulse can be given by the following equations [31]: Envelope = 2A τ sin(πτ f ) sin(πτr f ) T πτ f πτr f 20 log10 (envelope) = 20 log10 (2A Tτ ) + 20 log10 ( (πτr f ) ) +20 log10 ( sinπτ rf (1) sin(πτ f ) πτ f ) (2) The τ is smaller under unloaded operation conditions than that under load operation by SPWM control, as shown in Figure 4. Then from (1) and (2) the magnitude of the EMI noise voltage decreases as the value of τ decreases, and is lower under unloaded operation than that under load operation. From (1) and (2), the first break point in the frequency spectral bound is related to τ and is 1/πτ. The higher the τ, the wider the span related to the DC term, as shown in Figure 4b. The τ is smaller under unloaded operation conditions. Then the magnitude of the EMI noise voltage is lower under unloaded operation than that under load operation, as shown in Figure 3. The second breakpoint in the frequency spectral bound is related to rise/fall time and is 1/πτr .The smaller the rise/fall time, the larger the high-frequency spectral content, as shown in Figure 4c. The frequency band of the EMI noise source due to IGBT switching is from 0 Hz to 1 GHz. Then the resonances could be caused up to 1 GHz by parasitic distributed parameters of the AC motor system and may result in peak voltages exceeding the limit levels specified in the CISPR25 standard, as shown in Table 1. Energies 2016, 10, 1 6 of 17 result voltages exceeding the limit levels specified in the CISPR25 standard, as shown in 6 of 17 Energies 2017,in 10,peak 1 Table 1. 1 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 0.5 0 -0.5 -1 0 0.2 0.4 0.6 0.8 Time/(s) 1 1.2 1.4 1.6 -3 x 10 (a) 1 0.5 0 -0.5 -1 0 0.2 0.4 0.6 0.8 Time/(s) 1 1.2 1.4 1.6 -3 x 10 1.2 1.4 1.6 -3 x 10 1 0.5 0 -0.5 -1 0 0.2 0.4 0.6 0.8 Time/(s) 1 (b) (c) Figure 4. Spectral bounds for a trapezoidal wave: (a) SPWM in half-period; (b) The effect of Figure 4. Spectral bounds for a trapezoidal wave: (a) SPWM in half-period; (b) The effect of pulse-width; pulse-width; (c) The effect of rise-time. (c) The effect of rise-time. 3.2. Analysis of the Current Path of Conducted Emissions 3.2. Analysis of the Current Path of Conducted Emissions The self-inductance and mutual inductance are equivalent to one inductance in order to simplify the equivalent circuit for analyzing EMI propagation path. The motor drive system is constructed in DM and CM situation, as shown in Figure 5 and Figure 7, where, S1 –S6 represent six IGBTs in the inverter, C1 –C6 represent the distributed capacitance between the collector and emitter of S1 –S6 , Energies 2016, 10, 1 7 of 17 The Energies 2017,self-inductance 10, 1 and mutual inductance are equivalent to one inductance in order to 7 of 17 simplify the equivalent circuit for analyzing EMI propagation path. The motor drive system is constructed in DM and CM situation, as shown in Figures 5 and 7, where, S1–S6 represent six IGBTs CY1 and CY2 represent the filter Y capacitors between the positive/negative DC cable and chassis, in the inverter, C1–C6 represent the distributed capacitance between the collector and emitter of S1– LY1 and LY2 represent the equivalent series inductances (ESLs) of CY1 and CY2 , CX represents the S6, CY1 and CY2 represent the filter Y capacitors between the positive/negative DC cable and chassis, filter X capacitor between the DC buses, LX represents the equivalent series resistance (ESR) of CX . LY1 and LY2 represent the equivalent series inductances (ESLs) of CY1 and CY2, CX represents the filter Two LISNs can be represented by the circuit composed of RL1 , CL1 , RL2 , CL2 , C7 , C8 and C9 to represent X capacitor between the DC buses, LX represents the equivalent series resistance (ESR) of CX. Two the distributed capacitance from the collector and emitter of the IGBT to the chassis, C10 represents the LISNs can be represented by the circuit composed of RL1, CL1, RL2, CL2, C7, C8 and C9 to represent the distributed motor and chassis. LM IGBT represents inductance of the motor distributedcapacitance capacitancebetween from thethe collector andthe emitter of the to thethe chassis, C10 represents the phase winding, L and L represent the DC bus bars’ inductance, which includes DC bus bar+ bar− and the chassis. LM represents the inductance distributed capacitance between DC thebusmotor of the self-inductance and mutual inductance between two DC bus bars, so its value is larger than that of the motor phase winding, LDC bus bar+ and LDC bus bar− represent the DC bus bars’ inductance, which includes lead stray inductance of IGBT, which is smaller andtwo can DC be ignored, compared the inductance of the self-inductance and mutual inductance between bus bars, so its value is larger than thatDC of bus bars. C and C represent the DC cables’ capacitance, L and L represent the DC cables’ DC+ DC − DC+ DC − the lead stray inductance of IGBT, which is smaller and can be ignored, compared the inductance of inductance, RDC1 Cand RDC2 represent the DC cables’ resistance. The main distributed parameters’ the DC bus bars. DC+ and CDC− represent the DC cables’ capacitance, LDC+ and LDC− represent the DC values are measured by in Table EMI noise propagation pathsdistributed based on cables’ inductance, RDC1VNA and and RDC2shown represent the 2.DCThe cables’ resistance. The main distributed parameters and the equivalent circuits of DM and CM noise current are respectively parameters’ values are measured by VNA and shown in Table 2. The EMI noise propagation paths presented follows. parameters and the equivalent circuits of DM and CM noise current are based on as distributed respectively presented as follows. Table 2. Parameters in the motor drive system. Parameter Table Value 2. Parameters in the motor drive system. Parameter LY1 , LY2 Parameter LY1, LY2 C7 C7 C8 C8 C9 C9 C10 C10 CY1 , CY2 LDC+ , LDC− CY1, CY2 RDC+ , RDC−LDC+, LDC− RDC+, RDC− 200 nHValue 30 pF200 nH 20 pF 30 pF 20 pF 20 pF 200 pF 20 pF 100 pF200 pF 50 nH100 pF 0.0002 Ω50 nH 0.0002 Ω Parameter CX CX LX LX6 C1 –C –CL2 6 RL1C,1R RL1 , RL2 CL1 ,C L2 CLL1, CL2 M CDC+ , LCMDC− CDC+ DC− LDC bus bar+ , L, C DC bus bar− LDC bus bar+, LDC bus bar− Value Value 1028 µF 1028 µF20 nH 20 nH 20 pF 20 pF 50 Ω 50 Ω0.47 µF 0.47 µF1 mH 1 mH100 nF 100 nF104 nH 104 nH 3.2.1. Analysis of the DM Current Path for 500 kHz 3.2.1. Analysis of the DM Current Path for 500 kHz The DM EMI emission from the phase node P between the two IGBTs of one phase bridge leg The DM EMI emission from the phase node P between the two IGBTs of one phase bridge leg can be equivalent to a DM noise current source IDM between the phase node P and DC bus minus the can be equivalent to a DM noise current source IDM between the phase node P and DC bus minus the distributed parameters of the inner elements of the motor system, as shown in Figure 5a. The DM distributed parameters of the inner elements of the motor system, as shown in Figure 5a. The DM current loop can be illustrated by calculating the impedance of each circuit element ignoring the current loop can be illustrated by calculating the impedance of each circuit element ignoring the distributed parameters at 500 kHz, so the DM current flows though the distributed parameters of distributed parameters at 500 kHz, so the DM current flows though the distributed parameters of the the motor system is shown in Figure 5b. IDM acts as a driving force to form the following three motor system is shown in Figure 5b. IDM acts as a driving force to form the following three current current loops: loops: • current loop I: IDM →C4 →LDC bus bar− →RDC2 →LX →CX →RDC1 →LDC bus bar+ →C1 →IDM • current loop I: IDM→C4→LDC bus bar−→RDC2→LX→CX→RDC1→LDC bus bar+→C1→IDM • current loop II: IDM →LM →C6 →LDC bus bar− →RDC2 →LX →CX →RDC1 →LDC bus bar+ →C1 →IDM • current loop II: IDM→LM→C6→LDC bus bar−→RDC2→LX→CX→RDC1→LDC bus bar+→C1→IDM •• current →LM →C2 →L busbus →→L RDC2 →LX →CX →RDC1 →LDC bus bar+ →C1 →IDM bar−DC2 current loop loop III: III: IIDM DM→LM→C2→LDCDC bar−→R X→CX→RDC1→LDC bus bar+→C1→IDM IDM (a) (b) Figure 5. 5. (a) (a) Equivalent Equivalent circuit circuit for for DM; DM; (b) (b) DM DM interference interference propagation propagation path path at at 500 500kHz. kHz. Figure Energies 2016, 10, 1 8 of 17 Energies 2017, 10, 1 8 of 17 3.2.2. Analysis of DM Current Path for 30 MHz The impedance of each circuit element at 30 MHz is calculated as shown in Figure 6. IDM acts as 3.2.2. Analysis of DM Current Path for 30 MHz a driving force to form the following three current loops at 30 MHz: The impedance of each circuit element at 30 MHz is calculated as shown in Figure 6. IDM acts as a • current loop I: IDM→C4→LDC bus bar−→RDC2→LX→CX→RDC1→LDC bus bar+→C1→IDM driving force to form the following three current loops at 30 MHz: • current loop II: IDM→C4→C6→C3→C1→IDM • • • • current loop III: IDM→C4→C2→C5→C1→IDM current loop I: I →C4 →LDC bus bar− →RDC2 →LX →CX →RDC1 →LDC bus bar+ →C1 →IDM Energies 2016, 10, 1DM 8 of 17 The loop harmonic content ofCthe DM current at 500 kHz and 30 MHz flowing through the 50 Ω current II: IDM →C4 → 6 →C3 →C1 →IDM impedance of LISN is also very smallfor the filtering effect of the X capacitor. Then the resonant 3.2.2. loop Analysis DM →Current C4 →C2Path →C5due →30CtoMHz current III: of IDM 1 →IDM peak at about 500 kHz and 30 MHz is not dominated by the DM current. The impedance of each circuit element at 30 MHz is calculated as shown in Figure 6. IDM acts as a driving force to form the following three current loops at 30 MHz: • • • current loop I: IDM→C4→LDC bus bar−→RDC2→LX→CX→RDC1→LDC bus bar+→C1→IDM current loop II: IDM→C4→C6→C3→C1→IDM current loop III: IDM→C4→C2→C5→C1→IDM The harmonic content of the DM current at 500 kHz and 30 MHz flowing through the 50 Ω impedance of LISN is also very small due to the filtering effect of the X capacitor. Then the resonant peak at about 500 kHz and 30 MHz is not dominated by the DM current. Figure6.6.DM DMinterference interference propagation at at 30 30 MHz. Figure propagationpath path MHz. 3.2.3. Analysis of CM Current Path for 500 kHz The harmonic content of the DM current at 500 kHz and 30 MHz flowing through the 50 Ω TheofCM noise is always generated high frequency and through the distributed impedance LISN is current also very small due to theatfiltering effect of theflows X capacitor. Then the resonant parameters to the ground [32]. The CM emission from the phase node P of two IGBTs of one phase peak at about 500 kHz and 30 MHz is not dominated by the DM current. bridge leg can be equivalent to a CM voltage source UDM between the phase node P and chassis with ignored distributed parameters of inner elements of the motor system, as shown in Figure 7a,b. The 3.2.3. Analysis of CM Current Path for 500 kHz CM current loop can be illustrated calculating the impedance of each circuit element with Figure 6. DMby interference propagation path at 30 MHz. The CM noise currentatis500 always high force frequency flows through the shown distributed distributed parameters kHz. Ugenerated CM acts as a at driving to formand three CM current loops 3.2.3.to Analysis of current CM Current Path for 500 kHz in Figure 7c, where loop1 (red line), currentfrom loop2 (blue line)node and current loop3 (purple line)phase parameters the ground [32]. The CM emission the phase P of two IGBTs of one areleg considered parallel. The current flowing pathsU at 500 kHz are composed of a DC side path The be CMin noise current generated at high frequency and flows through the distributed bridge can equivalent toisCM aalways CM voltage source between the phase node P and chassis DM and an AC side path. The effective impedance of inductance for one branch of the current loop (red) parameters to the ground [32]. The CM emission from the phase node P of two IGBTs of one phase with ignored distributed parameters of inner elements of the motor system, as shown in Figure 7a,b. dominatedleg by LDCbe busequivalent bar+ or LDC bus is voltage about j0.32 ΩU and the effective impedance capacitance to abar− CM source DM between the phase P of and chassis withfor The CMbridge current can loop can be illustrated by calculating the impedance ofnode each circuit element with parameters of inner elements of system, as shown inisFigure TheΩ. oneignored branchdistributed of the current loop (red) dominated bythe themotor DC cable capacitance about7a,b. −j0.32 distributed parameters at 500 kHz. U acts as a driving force to form three CM current loops shown CM current loopvoltage can beatillustrated calculating impedance of each circuit element with Therefore the peak aboutCM 500 by kHz is mainlythe caused by the series resonance in the current in Figure 7c, where current loop1 (redUline), current loop2 (blue line) andCM current (purple line) parameters at 500 kHz. CM acts as a driving force to form three currentloop3 loops shown loopdistributed (red). are considered The CM current flowing 500line) kHz arecurrent composed of a DC side path in Figurein 7c,parallel. where current loop1 (red line), currentpaths loop2 at (blue and loop3 (purple line) are considered in parallel. The CM current flowing paths at 500 kHz are composed of a DC side path and an AC side path. The effective impedance of inductance for one branch of the current loop (red) and by an AC path. The effective impedance of inductance for one branch of the current loop (red) dominated LDCside bus bar+ or LDC bus bar− is about j0.32 Ω and the effective impedance of capacitance dominated by LDC bus bar+ or LDC bus bar− is about j0.32 Ω and the effective impedance of capacitance for for one branch of the current loop (red) dominated by the DC cable capacitance is about −j0.32 Ω. one branch of the current loop (red) dominated by the DC cable capacitance is about −j0.32 Ω. Therefore the peak at about 500500 kHz causedbyby series resonance the current Therefore the voltage peak voltage at about kHzisismainly mainly caused thethe series resonance in the in current loop (red). loop (red). (a) (b) (a) (b) Figure 7. Cont. Energies 2016, 10, 1 Energies 2017, 10, 1 9 of 17 9 of 17 Energies 2016, 10, 1 9 of 17 (c) (c) Figure 7. (a) Equivalent circuit for CM; (b) Equivalent circuit for CM; (c) CM interference Figure 7.7.(a)(a) Equivalent circuit for CM; Equivalent circuit forcircuit CM; (c) CM interference Figurepropagation Equivalent circuit for (b) CM; (b) Equivalent for CM; (c) CM propagation interference path at 500 KHz. path at 500 KHz. propagation path at 500 KHz. The elements responsible for the resonance at 500 kHz mainly are the capacitance between the DC cables andresponsible the chassis, and inductance of thekHz DC bus bar ofare IGBT. resonance peak Theelements elements forthe thestray resonance at 500 500 mainly theThe capacitance between the the The responsible for the resonance at kHz mainly are the capacitance between at about 500 kHz is mainly dominated by the CM current. The effect of the current loop2 (blue line) DCcables cablesand and the thechassis, chassis, and and the the stray stray inductance inductance of of the the DC DC bus bus bar bar of of IGBT. IGBT. The The resonance resonance peak peak DC and current loop3 (purple line) is smaller and can be ignored in the equivalent circuit of CM current atabout about 500kHz kHz mainly dominated bythe theCM CM current. current. The The effect effect of of the the current current loop2 loop2 (blue line) at kHz isismainly dominated by at500 500 shown in Figure 8. andcurrent currentloop3 loop3(purple (purpleline) line)isissmaller smallerand andcan canbebeignored ignored the equivalent circuit CM current and inin the equivalent circuit of of CM current at at 500 kHz shown in Figure 500 kHz shown in Figure 8. 8. I1 I1I 2 I 2 Figure 8. Equivalent circuit of CM interference at 500 KHz. The CM current at about 500 kHz flowing on LISN can be expressed by the following equation: Z 1U CM lim I1 = x→ ∞ Figure 8. Equivalent circuit of CM interference at 500 KHz. ( Z ZCM Figure 8. Equivalent circuit1 +of 2 ) Z 3interference at 500 KHz. (3) where Z1 denotes series-parallel impedance of RL1, CL1 and CDC+, Z2 denotes series impedance of LDC The CM DC1 current at about 500 kHz flowing on of LISN can be expressed by the following equation: bus CM bar+, Rcurrent and Cat 1, Z 3 denotes series impedance RL1 can and C The about 500the kHz flowing on LISN beL1.expressed by the following equation: Z 1U CM = Z U lim I 1 MHz 3.2.4. Analysis of CM Current Path for 30 (3) CM) Z x → ∞ I1 = ( Z 11+ Z (3) 2 3 lim x →∞ shown in Figure 9. It is difficult to Z2 ) Z3 loops UDM acts as a driving force to form the( ZCM 1 +current where determine Z1 denotes impedance of Relements L1, CL1 and CDC+, Zfor 2 denotes series at impedance theseries-parallel main CM current loop and the responsible the resonance 30 MHz of LDC where Z series-parallel impedance of RL1 ,circuit CL1 , Z denotes series impedance of 1 denotes because complexity CM current equivalent dominated bus bar+, R DC1 andofCthe 1, Z 3 denotesof the series impedance of RL1and andCCDC+ L1. by 2C1, C4, LDC bus bar+ , LDC bus bar−, DC2,, R , Rand DC2, LC DC+ LDC− , CY1, LY1, the CY2, series LY2, C7,impedance C8 and C9. The of the LDC bus R RDC1 of model RL1 and CL1CM . current equivalent DC1 1, Z 3 denotes bar+ circuit is of essential to studyPath the main CM current loop at 30 MHz to determine the 3.2.4. Analysis CM Current for 30dominated MHz distributed responsible resonance peak at 30 MHz. 3.2.4. Analysis of parameters CM Current Path forfor30the MHz The as equivalent circuit of CM at 30CM MHz is shown in Figure 10 and CM current 30 UDM acts a driving force to current form the current loops shown in the Figure 9. It isat difficult to UDM acts as a through drivingthe force toresistor form can thebeCM current loops shownequation: in Figure 9. It is difficult to MHz flowing LISN expressed by the following determine the main CM current loop and the elements responsible for the resonance at 30 MHz determine the main CM current loop and the elements responsible for the resonance at 30 MHz because because of the complexity of CM current equivalent circuit dominated by C1, C4, LDC bus bar+ , LDC bus bar−, of the complexity of CM current equivalent circuit dominated by C1 , C4 , LDC bus bar+ , LDC bus bar− , RDC2, RDC1, RDC2, LDC+, LDC−, CY1, LY1, CY2, LY2, C7, C8 and C9. The model of the CM current equivalent RDC2 , RDC1 , RDC2 , LDC+ , LDC− , CY1 , LY1 , CY2 , LY2 , C7 , C8 and C9 . The model of the CM current circuit is essential to study the main dominated CM current loop at 30 MHz to determine the equivalent circuit is essential to study the main dominated CM current loop at 30 MHz to determine distributed parameters responsible for the resonance peak at 30 MHz. the distributed parameters responsible for the resonance peak at 30 MHz. The equivalent circuit of CM current at 30 MHz is shown in Figure 10 and the CM current at 30 MHz flowing through the LISN resistor can be expressed by the following equation: I2 = Z1UCM (Z1 + ZC1 )(Z2 + Z3 )Z4 (4) Z1 denotes series-parallel impedance of C8, LDC bus bar+, RDC1, LDC+, CY1, LY1, CL1and RL1. Z2 denotes Energies 2016, 10, 1 of LDC bus bar+ and RDC1. Z3 denotes series-parallel impedance of LDC+, CL1, RL1, CY110and of 17 series impedance Energies 2017, 10, 1 10 of 17 LY1. Z4 denotes series impedance of LDC+, CL1 and RL1. I2 = Z1UCM (Z1 + ZC1 )(Z2 + Z3 )Z4 (4) Z1 denotes series-parallel impedance of C8, LDC bus bar+, RDC1, LDC+, CY1, LY1, CL1and RL1. Z2 denotes series impedance of LDC bus bar+ and RDC1. Z3 denotes series-parallel impedance of LDC+, CL1, RL1, CY1 and LY1. Z4 denotes series impedance of LDC+, CL1 and RL1. Figure Figure 9. 9. CM CM interference interference propagation propagation path at 30 MHz. The equivalent circuit of CM current at 30 MHz is shown in Figure 10 and the CM current at 30 MHz flowing through the LISN resistor can be expressed by the following equation: I3 Z1 UCM ( Z1 + ZC1 )( Z2 + Z3 )path Z4 at 30 MHz. Figure 9. CM interference propagation I2 = (4) I4 I3 Figure 10. Equivalent circuit of CM interference at 30 MHz. From Equation (3), CDC+, LDC bus bar+, CDC− and LDC bus bar− are the dominant distributed parameters I causing the series resonance at 500 kHz and the effect on the CM current I1. Therefore C1 and C4 have a very small effect on I1 and can be ignored. Changing of any parameter among CDC+, LDC bus bar+, CDC− and LDC bus bar+ can reduce the value of I1 at 500 kHz. From Equation (4), LDC+, CY1, LY1, LDC−, CY2, LY2, C8 and C9 are the effective distributed parameters at 30 MHz and with an effect on I1. Figure10. 10.Equivalent Equivalent circuitof ofCM CMinterference interferenceat at 30MHz. MHz. Figure The effect from distributed parameterscircuit on conducted voltage UR30 according to above equivalent circuits andEquation calculation kHz and 30 MHz is shown in Table 3. In a motor drive system, the From (3),atC500 DC+, LDC bus bar+, CDC− and LDC bus bar− are the dominant distributed parameters Z1 denotes series-parallel impedance of C8 , Lcannot ,controlled, RDC1 , LDC+and , CY1 , LY1the , CL1 and RL1 . parameters such as C 1–C6, CX, L X and LM usually beCM only distributed DCon busthe bar+ causing the series resonance at 500 kHz and the effect current I1. Therefore C1 and C4 have Z2 denotes series of LC series-parallel impedance of Lwith parameters busimpedance bar+, LDC bus bar− DC+ , Cbar+ DC−,and CChanging 8, R CDC1 9, L.Y1Z , of Y2, CY1, C Y2 could be changed along 3Ldenotes DC+ , DC bus a very smallLDC effect on I1 and can, be ignored. any parameter among CDC+, LDC bus bar+, CDC− C , R , C and L . Z denotes series impedance of L , C and R . different arrangements, L1 LL1 Y1 Y1 4filtering and shielding. DC+ L1 L1 and DC bus bar+ can reduce the value of I1 at 500 kHz. From Equation (4), LDC+, CY1, LY1, LDC−, CY2, LY2, C8 From Equation (3), CDC+ , LDC bus bar+ , CDC− and LDC bus bar− are the dominant distributed and C9 are the effective distributed parameters at 30 MHz and with an effect on I1. Table 3.the Theseries effect of the main at distribution parameter on conducted EMI emission. parameters causing resonance 500 kHz and the effect on the CM current I1 . Therefore C1 The effect from distributed parameters on conducted voltage UR according to above equivalent and C4 have a very small effect on I1 and can be ignored. Changing of any parameter among CDC+ , circuits and calculation atChanging 500 kHzof and 30 MHz is shown in Table 3. In a motor drive system, the Parameters Current Voltage LDC bus bar+ , CDC− and LDC bus bar+ can reduce the value of I1 at 500 kHz. From Equation (4), LDC+ , CY1 , parameters such as C1–C6, CXL, DCLXbusand bar+ ↑ L orM ↓usually cannot I1 ↓ be controlled, UR ↓ and only the distributed LY1 , LDC− , CY2 , LY2 , C8 and C9 are the effective distributed parameters at 30 MHz and with an effect parameters LDC bus bar+, LDC bus bar− CDC+ DC−↓, C8, C9, LY1, IL be changed along with LDC, bus bar−, ↑Cor 1 Y2 ↓ , CY1, CY2Ucould R ↓ on I1 . DC+ ↑shielding. or ↓ I1 ↓ UR ↓ different arrangements, filteringCand The effect from distributed parameters URUaccording to above equivalent CDC−↑ or ↓ on conductedI1voltage ↓ R ↓ circuits and calculation at 500 kHz and 30 MHz is shown in Table 3. In a motor drive system, 8 ↑ I2 ↓ on conducted UR ↓ EMI emission. Table 3. The effect of theCmain distribution parameter the parameters such as C1 –C6 , CX , LCX9 and ↑ LM usually cannot I2 ↓ be controlled, UR ↓ and only the distributed Changing, of Parameters Current Voltage parameters LDC bus bar+ , LDC C , C , C , C , L , L , C , CY2 could be changed along DC+ DC − 8 9 Y1 Y2 Y1 bus bar− LDC bus bar+ ↑ or ↓ I1 ↓ UR ↓ with different arrangements, filtering and shielding. 4 LDC bus bar− ↑ or ↓ CDC+ ↑ or ↓ CDC−↑ or ↓ C8 ↑ C9 ↑ I1 ↓ I1 ↓ I1 ↓ I2 ↓ I2 ↓ UR ↓ UR ↓ UR ↓ UR ↓ UR ↓ Energies 2017, 10, 1 11 of 17 Table 3. The effect of the main distribution parameter on conducted EMI emission. Changing of Parameters LDC bus bar+ ↑ or ↓ LDC bus bar− ↑ or ↓ CDC+ ↑ or ↓ CDC− ↑ or ↓ C8 ↑ C9 ↑ LY1 ↑ LY1 ↑ LY2 ↑ LY2 ↑ CY1 ↑CY1 ↑ CY2 ↑ CY2 ↑ LDC bus bar+ ↑ L DC bus bar+ ↑ LDC bus bar− ↑ Energies 2016, 10, 1 LDC bus bar− ↑ Current I1 I1 I1 I1 I2 I2 I2 I2 I2 I2 I2 I2 ↓ ↓ ↓ ↓ ↓ ↓ ↓I2 ↓ ↓I2 ↓ ↓I2 ↓ ↓I2 ↓ ↓ ↓I2 ↓ I2 ↓ Voltage UR UR UR UR UR UR URU↓R URU↓R URU↓R URU↓R U URU↓R R UR ↓ ↓ ↓ ↓ ↓ ↓ ↓ ↓ ↓ ↓ ↓ ↓ ↓ 11 of 17 4. Simulation of the Effect of Distributed Parameters 4. Simulation of the Effect of Distributed Parameters 4.1. System System Conducted Conducted EMI EMI Modeling Modeling 4.1. According to the structure of the system and the distributed parameters, the power inverter system was modeled as a simplified single-arm bridge of the power inverter system using the EMC simulation software “Computer Simulation Simulation Technology” (CST) (CST) that predicts the noise in the entire simulation conducted emissions range from 150 kHz to 108 MHz, as conducted emissions range from MHz, as illustrated illustrated in in Figure Figure 11. 11. The conducted emission (CE) voltage on the resistor of the LISN in the DM and CM network equivalent circuits can time-domain simulation, followed by fast transform(FFT) in the designer be obtained obtainedbybyusing using time-domain simulation, followed byfourier fast fourier transform(FFT) in the platform provided in the CST software. The CM EMI source is equivalent to an ideal trapezoidal designer platform provided in the CST software. The CM EMI source is equivalent to an shape ideal wave and theshape EMI voltage measured by avoltage probe Pmeasured emission voltage. The EMI trapezoidal wave and the EMI by a conducted probe P1 is the positive conducted 1 is the positive voltage simulation result shown in Figure 12.result Tableis 3shown and Figure 12 suggest that3 the emission voltage. The EMIis voltage simulation in Figure 12. Table andconducted Figure 12 EMI voltage spectrum of theEMI motor drivespectrum system inofEV be divided into two frequency suggest that the conducted voltage thecan motor drive system in different EV can be divided ranges: low frequency range around 500 frequency kHz that isrange dominated DC cables’ capacitance into twothe different frequency ranges: the low aroundby 500 kHz that is dominatedand by DC bus bars, and the high frequency range around 30 MHz that is related to parasitic resonances due cables’ capacitance and DC bus bars, and the high frequency range around 30 MHz that is to the distributed parameters of due Y capacitors and distributed capacitance from the IGBT node related to parasitic resonances to the distributed parameters of Y capacitors and phase distributed to the chassis. Thethe EMIIGBT voltage peaks obtained in Figure 12 correspond to those capacitance from phase node to the through chassis. simulation The EMI voltage peaks obtained through of measurements at 500 and 30 to MHz. There are some larger between results simulation in Figure 12 kHz correspond those of measurements at errors 500 kHz and 30simulation MHz. There are and measurement because the measurement voltage is the totalbecause of the EMI from the some larger errorsresults between simulation results and EMI measurement results the noise measurement threevoltage arms ofisthe power Conversely, the simulated EMI is obtained from a single-arm. EMI the total inverter. of the EMI noise from the three arms ofvoltage the power inverter. Conversely, the It can be seen the model is efficient enough to be used to predict thethat CM the current paths and the simulated EMIthat voltage is obtained from a single-arm. It can be seen model is efficient elementstoresponsible the EMI. enough be used to for predict the CM current paths and the elements responsible for the EMI. Figure Figure 11. 11. CM CM circuit circuit model model of of single-arm single-arm bridge bridge of of power power inverter. inverter. 100 Vp/(dBμV) 80 60 40 Energies 2017, 10, 1 12 of 17 Figure 11. CM circuit model of single-arm bridge of power inverter. 100 Vp/(dBμV) 80 60 40 20 0 Simulation Measurement -20 10 0 frequency/(MHz) Energies 2016, 10, 1 10 1 2 10 12 of 17 Figure 12. Comparison of measurement and simulation. Figure 12. Comparison of measurement and simulation. 4.2. The Effect Effect of of Distributed Distributed Parameters Parameters 4.2. The DC bus and LDCLDC bus bar− 4.2.1. The Effect of LDC and busbar+ bar+ bus bar− According to toTable Table3,3,changing changing value DC bus bar+and andLDC LDCbus bus bar bar−−can According thethe value of LofDCLbus canmitigate mitigatethe the resonance bar+ low frequency. frequency. Therefore, and reduce the conducted emissions at low Therefore, the the EMI voltage peak due to resonance at at 500 500kHz kHzcould couldbe besuppressed. suppressed.The Thevoltage voltagevalue value conducted emission kHz resonance ofof conducted emission at at 500500 kHz cancan be be rapidly decreased about 50 dB increasing value bar+ and and LLDC DC bus 104104 nHnH to rapidly decreased by by about 50 dB by by increasing thethe value of LofDCLDC busbus bar+ busbar− barfrom − from 220220 nHnH to to comply with thethe limit level-3 of of CISPR25 regulatory standards, as as shown in in Figure 13.13. It to comply with limit level-3 CISPR25 regulatory standards, shown Figure suggests that two CM inductors It suggests that two CM inductorscan canbebeplaced placedon onthe theDC DCbus busbar barof of the the power power inverter inverter of the AC current and and conducted conducted emission emission at at 500 500 kHz. kHz. motor to reduce the CM current 100 Vp/(dBμV) 80 60 40 20 0 -20 LDC bus bar+ =104nH and LDC bus bar- LDC bus bar+ =220nH and LDC bus bar- =104nH =220nH 0 10 frequency/(MHz) 10 1 Figure 13. Positive conducted emission(CE) voltage after LDC bus bar+ and LDC bus bar− were increased. Figure 13. Positive conducted emission(CE) voltage after LDC bus bar+ and LDC bus bar− were increased. 4.2.2. The Effect of LY1 and LY2 4.2.2. The Effect of LY1 and LY2 According to Table 3, LY1 and LY2 can be increased to mitigate the resonance and reduce the According to Table 3, LY1 and LY2 can be increased to mitigate the resonance and reduce the conducted emission at high frequency. Therefore, the EMI voltage peak due to resonance at 30 MHz conducted emission at high frequency. Therefore, the EMI voltage peak due to resonance at 30 MHz could be suppressed. The voltage value of conducted emission at 30 MHz can be rapidly decreased could be suppressed. The voltage value of conducted emission at 30 MHz can be rapidly decreased by by about 64 dB by increasing the value of LY1 and LY2 from 200 nH to 300 nH to comply with the about 64 dB by increasing the value of LY1 and LY2 from 200 nH to 300 nH to comply with the level-3 level-3 limit of CISPR25, as shown in Figure 14. It suggests that the equivalent series inductance of Y limit of CISPR25, as shown in Figure 14. It suggests that the equivalent series inductance of Y capacitor capacitor can affect the conducted EMI at 30 MHz. A better design of the parameters of the Y can affect the conducted EMI at 30 MHz. A better design of the parameters of the Y capacitor can capacitor can reduce the conducted emissions at high frequency. reduce the conducted emissions at high frequency. 100 Vp/(dBμV) 80 60 40 20 0 -20 LY1=200nH and LY2=200nH LY1=300nH and LY2=300nH 10 0 frequency/(MHz) 10 1 10 Figure 14. Positive CE voltage after LY1 and LY2 were increased. 2 conducted emission at high frequency. Therefore, the EMI voltage peak due to resonance at 30 MHz could be suppressed. The voltage value of conducted emission at 30 MHz can be rapidly decreased by about 64 dB by increasing the value of LY1 and LY2 from 200 nH to 300 nH to comply with the level-3 limit of CISPR25, as shown in Figure 14. It suggests that the equivalent series inductance of Y capacitor the Y Energies 2017,can 10, 1affect the conducted EMI at 30 MHz. A better design of the parameters of 13 of 17 capacitor can reduce the conducted emissions at high frequency. 100 Vp/(dBμV) 80 60 40 20 0 -20 LY1=200nH and LY2=200nH LY1=300nH and LY2=300nH 10 0 frequency/(MHz) 10 1 10 2 Figure 14. Positive CE voltage after LY1 and LY2 were increased. Figure 14. Positive CE voltage after LY1 and LY2 were increased. 4.2.3. The Effect of Combination of LDC bus bar+, LDC bus bar−, LY1 and LY2 4.2.3. The Effect of Combination of LDC bus bar+ , LDC bus bar− , LY1 and LY2 Increasing of the value of LDC bus bar+, LDC bus bar− (each 220 nH) and LY1, LY2 (each 300 nH) can Increasing of the value of LDC bus bar+ , LDC bus bar− (each 220 nH) and LY1 , LY2 (each 300 nH) can decrease the conduced emissions at frequencies from 150 kHz to 108 MHz to below the limit level-3 decrease the conduced emissions at frequencies from 150 kHz to 108 MHz to below the limit level-3 of of CISPR25. Then there are no resonances previously caused by LDC bus bar+ and LDC bus bar− at 500 kHz, CISPR25. Then there are no resonances previously caused by LDC bus bar+ and LDC bus bar− at 500 kHz, LY1 and LY2 at 30 MHz. Although there still is a resonance point at around 55 MHz, the value of LY1 and LY2 at 30 MHz. Although there still is a resonance point at around 55 MHz, the value of conducted voltage is decreased below the level-3 limit of CISPR25, as shown in Figure 15. conducted is decreased below the level-3 limit of CISPR25, as shown in Figure 15. Energies 2016,voltage 10, 1 13 of 17 100 80 Vp/(dBμV) 60 40 20 0 L L -20 DC bus bar+ DC bus bar+ =104nH and L =220nH and L DC bus barDC bus bar- 10 =104nH,L =200nH and L =200nH Y1 Y2 =220nH,L =300nH and L =300nH Y1 0 f/(MHz) Y2 10 1 10 2 Figure Positive voltage after DC bus bar+, LDC bus bar−, LY1 and LY2 were increased. Figure 15. 15. Positive CE CE voltage after LDCLbus bar+ , LDC bus bar− , LY1 and LY2 were increased. 4.2.4. The The Effect Effect of of C CDC+ and CDC− 4.2.4. DC+ and CDC− From Table Table3,3,the thedistributed distributedcapacitances capacitancesfrom fromDC DCcables cables(C(CDC+, ,CCDC−)) can affect the conducted From DC+ DC− can affect the conducted emissions. Changing the value of C DC+ and CDC− can mitigate the resonance at 500 kHz and reduce emissions. Changing the value of CDC+ and CDC− can mitigate the resonance at 500 kHz and reduce the conducted conducted emission emissionatatlow lowfrequency. frequency.The Thevoltage voltagevalue value conducted emission at 500 kHz the ofof conducted emission at 500 kHz cancan be be decreased by about 25 dB by increasing the value of C DC+ and CDC− from 100 nF to 250 nF to decreased by about 25 dB by increasing the value of CDC+ and CDC− from 100 nF to 250 nF to comply comply with level-3 the limit level-3 ofasCISPR25, shown Figure 16. suggests that filteringofand with the limit of CISPR25, shown inas Figure 16. in It suggests thatItfiltering and shielding the shielding of the DC input of the power inverter of the AC motor can be used to change the DC input of the power inverter of the AC motor can be used to change the distributed parameters distributed of DC the CM current at lowthe frequency and suppress of DC cablesparameters to reduce the CMcables currenttoatreduce low frequency and suppress EMI voltage peak duethe to EMI voltage peak dueFor to resonance kHz. For example, a Ybetween capacitor be added between resonance at 500 kHz. example, aatY 500 capacitor could be added thecould DC cable and chassis to the DCconducted cable and chassis to reduce conducted emissions, the Yground capacitor may cause a high reduce emissions, although the Y capacitor mayalthough cause a high leakage current. ground leakage current. comply with the limit level-3 of CISPR25, as shown in Figure 16. It suggests that filtering and shielding of the DC input of the power inverter of the AC motor can be used to change the distributed parameters of DC cables to reduce the CM current at low frequency and suppress the EMI voltage peak due to resonance at 500 kHz. For example, a Y capacitor could be added between the DC2017, cable chassis to reduce conducted emissions, although the Y capacitor may cause 14 a high Energies 10, and 1 of 17 ground leakage current. Figure16. 16.Positive PositiveCE CEvoltage voltageafter afterCDC+ CDC+and andCCDC DC−−were Figure wereincreased. increased. 4.2.5. The The Effect Effect of of the the Combination Combination of of CCY1 Y1,, C , C8 and C9 4.2.5. CY2 Y2 , C8 and C9 From Table Table3,3,the the capacitances of the Y capacitors , CY2) and the distributed capacitance From capacitances of the Y capacitors (CY1(C , CY1 Y2 ) and the distributed capacitance from from the collector and emitter of the IGBT to the chassis (C 8 , C can affect the conduced emissions at the collector and emitter of the IGBT to the chassis (C8 , C9 ) can9)affect the conduced emissions at high high frequency. The voltage value of conducted emissions at high frequency can be decreased to frequency. The voltage value of conducted emissions at high frequency can be decreased to comply comply with CISPR25 by increasing of CY1 and CY2 from 100 nF to 500 nF and the value of with CISPR25 by increasing the value the of Cvalue Y1 and CY2 from 100 nF to 500 nF and the value of C8 and C9 C 8 and C 9 from 20 pF to 100 pF, as shown in Figure 17.that It shows thatvalue the peak value of the conducted from 20 pF to 100 pF, as shown in Figure 17. It shows the peak of the conducted voltage is voltage is 20 dB at about 30 MHz.YTherefore, capacitors could be added betweenand the reduced byreduced 20 dB atby about 30 MHz. Therefore, capacitors Y could be added between the collector collector and emitter of the IGBT and chassis, and between DC input and chassis to reduce emitter of the IGBT and chassis, and between DC input and chassis to reduce conducted emissions at conducted emissions at high frequency. high frequency. Energies 2016, 10, 1 14 of 17 100 80 Vp/(dBμV) 60 40 20 0 -20 CY1=100nF,CY2=100nF,C8=20pF and C9=20pF -40 1 10 CY1=500nF,CY2=500nF,C8=100pF and C9=100pF f/(MHz) Figure 17. Positive CE voltage after CY1, CY2, C8 and C9 were increased. Figure 17. Positive CE voltage after CY1 , CY2 , C8 and C9 were increased. 4.2.6. The Effect of the Combination of CDC+, CDC−, CY1, CY2, C8 and C9 4.2.6. The Effect of the Combination of CDC+ , CDC− , CY1 , CY2 , C8 and C9 It is a better mitigation method to change the value of the distributed parameters (CDC+, CDC−, CY1, It is a better mitigation method to change the value of the distributed parameters (CDC+ , CDC− , CY2, C8 and C9) to reduce the conducted emission at frequencies from 150 kHz to 108 MHz defined in CY1 , CY2 , C8 and C9 ) to reduce the conducted emission at frequencies from 150 kHz to 108 MHz defined CISPR25. The conducted voltage is reduced by increasing the capacitances (CDC+ = CDC− = 250 nF, CY1 = in CISPR25. The conducted voltage is reduced by increasing the capacitances (CDC+ = CDC− = 250 nF, CY2 = 500 nF, C8 = C9 = 100 pF), as shown in Figure 18. CY1 = CY2 = 500 nF, C8 = C9 = 100 pF), as shown in Figure 18. 100 80 Vp/(dBμV) 60 40 20 0 -20 C =100nf,C C =250nF,C DC+ DC+ =100nf,C =100nF,C =100nF,C =20pF and C =20pF DC- Y1 Y2 8 9 =250nF,C =500nF,C =500nF,C =100pF and C =100pF DC- Y1 Y2 10 8 0 frequency/(MHz) 9 10 1 10 2 Figure 18. Positive CE voltage after CDC+, CDC−, CY1, CY2, C8 and C9 were increased. 4.2.6. The Effect of the Combination of CDC+, CDC−, CY1, CY2, C8 and C9 4.2.6. The Effect of the Combination of CDC+, CDC−, CY1, CY2, C8 and C9 It is a better mitigation method to change the value of the distributed parameters (CDC+, CDC−, CY1, It is a better mitigation method to change the value of the distributed parameters (CDC+, CDC−, CY1, CY2, C8 and C9) to reduce the conducted emission at frequencies from 150 kHz to 108 MHz defined in CY2, C8 and C9) to reduce the conducted emission at frequencies from 150 kHz to 108 MHz defined in CISPR25. The conducted voltage is reduced by increasing the capacitances (CDC+ = CDC− = 250 nF, CY1 = Energies 2017,The 10, 1conducted voltage is reduced by increasing the capacitances (CDC+ = CDC− = 250 nF, 15CofY117 CISPR25. = CY2 = 500 nF, C8 = C9 = 100 pF), as shown in Figure 18. CY2 = 500 nF, C8 = C9 = 100 pF), as shown in Figure 18. 100 100 Vp/(dBμV) Vp/(dBμV) 80 80 60 60 40 40 20 20 0 0 -20 -20 C =100nf,C =100nf,C =100nF,C =100nF,C =20pF and C =20pF DC+ DCY1 Y2 8 9 CC =100nf,C =100nf,C =100nF,C =100nF,C =20pF and C =20pF =250nF,C =250nF,C DC+ DCY1 Y1=500nF,C Y2 Y2=500nF,C 8 8=100pF and 9 C9=100pF DC+ DCC =250nF,C =250nF,C =500nF,C =500nF,C =100pF and C =100pF 1 0 DC+ DCY1 Y2 8 9 10 10 0 1 frequency/(MHz) 10 10 frequency/(MHz) 2 10 2 10 Figure 18. Positive CE voltage after CDC+ , CDC−,, C CY1,, C Y2, C8 and C9 were increased. Figure 18.18. Positive CECE voltage after CDC+ ,C ,C increased. DC −, CY1 Y1, CCY2 Y2 8 and 9 were Figure Positive voltage after CDC+ ,C DC− ,C 8 and C9Cwere increased. 5. Experimental Verification 5. Experimental Verification Verification According to the above analysis of the effect of distributed parameters on the power inverter According to the above above analysis analysis of the the effect effect of of distributed distributed parameters parameters on the the power power inverter inverter system of AC motors for EVs, changing the combination of CDC+, CDC−, CY1, CY2, C7 and C8 should be a system of AC motors for EVs, changing the combination combination of of C CDC+ ,C , C, Y1 C7 and C8 should ,C DC− ,C CY2, ,CC C8 should be a DC+ DC − Y1 Y27 ,and better way to suppress the voltage peak at 500 kHz and 30 MHz to comply with the limit level-3 of be a better to suppress the voltage at 500 30 MHz to comply with limit level-3 better wayway to suppress the voltage peakpeak at 500 kHzkHz andand 30 MHz to comply with thethe limit level-3 of CISPR 25. A new pair of Y capacitors are added between the collector and emitter of the IGBT and of CISPR 25. A new pair of Y capacitors are added between the collector and emitter of the IGBT CISPR 25. A new pair of Y capacitors are added between the collector and emitter of the IGBT and DC bus bar and the chassis to increase the capacitances between the inverter and the chassis. and chassis increase thecapacitances capacitancesbetween betweenthe theinverter inverterand and the the chassis. DC DC bus bus bar bar andand thethe chassis to to increase the Experimental verification is conducted and the results are shown in Figure 19. The conducted Experimental conducted andand the results are shown in Figure The conducted emission Experimentalverification verificationis is conducted the results are shown in 19. Figure 19. The conducted emission characteristics at around 500 kHz and 30 MHz in Figure 19 are approximately as predicted characteristics at around 500 kHz and 30 MHz in Figure 19 are approximately as predicted by the emission characteristics at around 500 kHz and 30 MHz in Figure 19 are approximately as predicted by the simulation in Figure 18. simulation in Figure 18. by the simulation in Figure 18. 100 100 Vp/(dBμV) Vp/(dBμV) 80 80 60 60 40 40 20 20 0 0 -20 -20 After increasing C ,C ,C ,C ,C and C DC+ DC- Y1 Y2 8 9 After increasing C ,C ,C ,C ,C and C DC- Y1 Y2 8,C and9C Before increasingDC+ C ,C ,C ,C DC+ DC- Y1 Y2 8 9 Before increasing C ,C ,C ,C ,C and C DC+ DC- Y1 Y2 8 9 Limit level 3-CISPR25 0 Limit level 3-CISPR25 100 frequency/(MHz) 10 frequency/(MHz) 1 101 10 2 102 10 Figure 19. Positive CE voltage after CDC+, CDC−, CY1, CY2, C8 and C9 were increased. Figure Positive voltage after CDC+ , CDC−,, C Y1, CY2, C8 and C9 were increased. Figure 19.19. Positive CECE voltage after CDC+ ,C DC− CY1 , CY2 , C8 and C9 were increased. 6. Conclusions This study proposed a new method to analyze the effects of distributed parameters on conducted EMI from the DC-fed high voltage motor drive systems in EVs. The conducted EMI of high voltage DC cables of the motor drive system in a frequency range of 150 kHz–108 MHz and two EMI noise peaks at resonances frequencies 500 kHz and 30 MHz have been measured by a complete test for conducted EMI emissions from the AC motor drive system of an EV under load conditions. The research mainly focuses on the effects of distributed parameters in the inverter and cables on the resonances at 500 kHz and 30 MHz, nor the distributed parameters of the motor due to the high impedance of the motor model at 500 kHz and 30 MHz. The corresponding equivalent circuits for DM and CM EMI at resonance frequencies of 500 kHz and 30 MHz are established to determine the EMI propagation paths and the dominant distributed parameters of elements responsible for the resonances appearing at 500 kHz and 30 MHz. The distributed parameters LDC bus bar+ , LDC bus bar− , CDC+ , CDC− , C8 , C9 , LY1 , LY2 , CY1 and CY2 can affect the EMI emissions from the high voltage motor drive system. The effect of the dominant Energies 2017, 10, 1 16 of 17 distributed parameters on conducted voltage is verified by modeling of the CM circuit of a single-arm bridge of the high voltage motor power inverter. Increasing the value of LDC bus bar+ , LDC bus bar− from 104 nH to 220 nH and LY1 , LY2 from 200 nH to 300 nH or increasing the capacitances (CDC+ , CDC− from 100 nF to 250 nF, CY1 , CY2 from 100 nF to 500 nF, C8 , C9 from 20 pF to 100 pF) can mitigate the two resonance peaks at the frequencies of 500 kHz and 30 MHz and decrease the conduced voltage at frequencies from 150 kHz to 108 MHz to below the limit level-3 of CISPR25. The effect of the combination of CDC+ , CDC− , CY1 , CY2 , C8 and C9 on conducted voltage is verified by experiments. In future work, modeling of a CM circuit of three-arm bridge of the high voltage motor power inverter in EV will be developed. After that the effect of distributed parameters on EMI noise will be further simulated and tested. Acknowledgments: This study is supported by National Natural Science of Foundation of China and Outstanding Talents Project of Beijing. Author Contributions: Li Zhai analyzed the system conducted emission; Liwen Lin and Xinyu Zhang performed the modeling; Li Zhai and Chao Song performed the experiments; Li Zhai and Liwen Lin analyzed the data; Li Zhai wrote the paper. Conflicts of Interest: The authors declare no conflict of interest. References 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. Sun, F.; Xiong, R.; He, H. A systematic state-of-charge estimation framework for multi-cell battery pack in electric vehicles using bias correction technique. Appl. Energy 2016, 162, 1399–1409. [CrossRef] Ferrero, E.; Alessandrini, S.; Balanzino, A.; Yan, J. Impact of the electric vehicles on the air pollution from a highway. Appl. Energy 2016, 169, 450–459. [CrossRef] Hu, X.; Murgovski, N.; Johannesson, L.; Bo, E. Energy efficiency analysis of a series plug-in hybrid electric bus with different energy management strategies and battery sizes. Appl. Energy 2013, 111, 1001–1009. [CrossRef] Chen, Z.; Xiong, R.; Wang, C.; Cao, J. An on-line predictive energy management strategy for plug-in hybrid electric vehicles to counter the uncertain prediction of the driving cycle. Appl. Energy 2016, 185, 1663–1672. [CrossRef] Torresa, J.L.; Gonzalezb, R.; Gimeneza, A.; Lopeza, J. Energy management strategy for plug-in hybrid electric vehicles. A comparative study. Appl. Energy 2014, 113, 816–824. [CrossRef] Zhai, L.; Zhang, X.; Bondarenko, N.; Loken, D.; Doren, T.V.; Beetner, D.G. Mitigation emission strategy based on resonances from a power inverter system in electric vehicles. Energies 2016, 9, 419. [CrossRef] Ehsani, M.; Gao, Y.; Emadi, A. Modern Electric, Hybrid Electric, and Fuel Cell Vehicles: Fundamentals, Theory, and Design; CRC Press: Boca Raton, FL, USA, 2010. Ardon, V.; Aime, J.; Chadebec, O.; Clavel, E. EMC modeling of an industrial variable speed drive with an adapted PEEC method. IEEE Trans. Magn. 2010, 46, 2892–2898. [CrossRef] Lai, J.S.; Huang, X.; Chen, S.; Nehl, T.W. EMI characterization and simulation with parasitic models for a low-Voltage high-current AC motor drive. IEEE Trans. Ind. Appl. 2004, 40, 178–185. [CrossRef] Jettanasen, C.; Costa, F.; Vollaire, C. Common-mode emissions measurements and simulation in variable-speed drive systems. IEEE Trans. Power Electron. 2009, 24, 2456–2464. [CrossRef] Tommasini, R.; Spertino, F. Electric power distribution and environment: Interference of power installation magnetic fields on computer systems. Appl. Energy 1999, 64, 181–193. [CrossRef] Toure, B.; Schanen, J.-L.; Gerbaud, L.; Meynard, T.; Roudet, J.; Ruelland, R. EMC modeling of drives for aircraft applications: Modeling process, EMI filter optimization and technological choice. IEEE Trans. Power Electron. 2013, 28, 1145–1156. [CrossRef] Lai, J.S. Resonant snubber-based soft-switching inverters for electric propulsion drives. IEEE Trans. Ind. Electron. 1997, 44, 71–80. Mutoh, N.; Ogata, M. New methods to control EMI noises generated in motor drive systems. IEEE Trans. Ind. Appl. 2004, 40, 143–152. [CrossRef] Rebholz, H.M.; Tenbohlen, S.; Kohler, W. Time-domain characterization of RF sources for the design of noise suppression filters. IEEE Trans. Electromagn. Compat. 2009, 51, 945–952. [CrossRef] Energies 2017, 10, 1 16. 17. 18. 19. 20. 21. 22. 23. 24. 25. 26. 27. 28. 29. 30. 31. 32. 17 of 17 Reuter, M.; Friedl, T.; Tenbohlen, S.; Köhler, W. Emulation of conducted emissions of an automotive inverter for filter development in HV networks. In Proceedings of the IEEE International Symposium on Electromagnetic Compatibility (EMC), Denver, CO, USA, 5–9 August 2013; pp. 236–241. Trzynadlowski, A.M.; Wang, Z.; Nagashima, J.; Stancu, C. Comparative investigation of PWM techniques for general motor’s new drive for electric vehicles. In Proceedings of the IEEE Industry Applications Conference, Pittsburgh, PA, USA, 13–18 October 2002; pp. 2010–2015. Piazza, M.C.D.; Ragusa, A.; Tine, G.; Vitale, G. A model of electromagnetic radiated emissions for dual Voltage automotive electrical systems. In Proceedings of the IEEE International Symposium on Industrial Electronics, Ajaccio, France, 4–7 May 2004; pp. 317–322. Akagi, H.; Shimizu, T. Attenuation of conducted EMI emissions from an inverter-driven motor. IEEE Trans. Power Electron. 2008, 23, 282–290. [CrossRef] Wang, S.; Maillet, Y.Y.; Wang, F.; Lai, R.; Luo, F.; Boroyevich, D. Parasitic effects of grounding paths on common-mode EMI filter’s performance in power electronics systems. IEEE Trans. Ind. Electron. 2010, 57, 3050–3059. [CrossRef] Bishnoi, H.; Baisden, A.C.; Mattavelli, P.; Boroyevich, D. Analysis of EMI terminal modeling of switched power converters. IEEE Trans. Power Electron. 2012, 27, 3924–3933. [CrossRef] Gong, X.; Ferreira, A.J. Comparison and reduction of conducted EMI in SiC JFET and Si IGBT-based motor drives. IEEE Trans. Power Electron. 2014, 29, 1757–1767. [CrossRef] Revol, B.; Roudet, J.; Schanen, J.L.; Loizelet, P. EMI study of three-phase inverter-fed motor drives. IEEE Trans. Ind. Appl. 2011, 47, 223–231. [CrossRef] Stevanovic, I.; Skibin, S.; Masti, M.; Laitinen, M. Behavioral modeling of chokes for EMI simulations in power electronics. IEEE Trans. Power Electron. 2013, 28, 695–705. [CrossRef] Mutoh, N.; Ogata, M.; Gulez, K.; Harashima, F. New methods to suppress EMI noises in motor drive systems. IEEE Trans. Ind. Electron. 2002, 49, 474–485. [CrossRef] Bishnoi, H.; Mattavelli, P.; Burgos, R.; Boroyevich, D. EMI behavioral models of DC-fed three-phase motor drive systems. IEEE Trans. Power Electron. 2014, 29, 4633–4645. [CrossRef] Bondarenko, N.; Zhai, L.; Xu, B.; Li, G.; Makharashvili, T.; Loken, D.; Berger, P.; Doren, T.P.V.; Beetner, D.G. A measurement-based model of the electromagnetic emissions from a power inverter. IEEE Trans. Power Electron. 2015, 30, 5522–5531. [CrossRef] Australia, S. Vehicle, Boats and Internal Combustion Engines—Limits and Methods of Measurement for the Protection of on-Board Receivers; CISPR25; International Special Committee on Radio Interference: Geneva, Switzerland, 2012. Mihalic, F.; Kos, D. Reduced conductive EMI in switched-mode DC–DC power converters without EMI filters: PWM versus randomized PWM. IEEE Trans. Power Electron. 2006, 21, 1783–1794. [CrossRef] Chen, S.; Nehl, T.W.; Lai, J.-S.; Huang, X.; Pepa, E.; de Doncker, R.; Voss, I. Towards EMI prediction of a PM motor drive for automotive applications. In Proceedings of the Applied Power Electronics Conference and Exposition, Miami Beach, FL, USA, 9–13 February 2003; pp. 14–22. Paul, C.R. Introduction to EMC; Wiley & Sons. Inc.: New York, NY, USA, 1992; pp. 466–474. Mugur, P.R.; Roudet, J.; Crebier, J.C. Power electronic converter EMC analysis through state variable approach techniques. IEEE Trans. Electromagn. Compat. 2001, 43, 229–238. [CrossRef] © 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).