Surface plasmon resonance and coloration in stainless steel with a 2D periodic texture

реклама

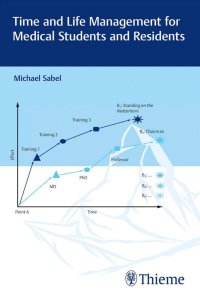

Applied Physics A (2019) 125:624 https://doi.org/10.1007/s00339-019-2926-9 Surface plasmon resonance and coloration in stainless steel with a 2D periodic texture Minseok Seo1 · Myeongkyu Lee1 Received: 10 March 2019 / Accepted: 9 August 2019 © Springer-Verlag GmbH Germany, part of Springer Nature 2019 Abstract Although stainless steel (STS) is an alloy commonly used in both daily life and the industrial field, little is known about its plasmonic behavior. In this study, we investigated the surface plasmon resonance (SPR) phenomenon in two-dimensionally (2D) textured STS. A 2D periodic grating with a 500 nm pitch was fabricated by imprinting combined with electrochemical etching on the surface of 316L STS plates. Since the fabricated surface texture gave rise to SPR absorption peaks and structural colors, its resonance behavior was characterized in terms of light incident direction and polarization state; the dependence of the SPR wavelengths on these two parameters was theoretically calculated based on the grating-assisted lightcoupling mechanism. The experimental results were in good agreement with the theoretical calculations. Grating-coupled SPR can be an effective tool to generate structural colors in STS and may be used in many applications including surface decoration, product identification, and anti-counterfeiting. 1 Introduction The widespread use of metals in vehicles, electronic devices, machines, and tools is attributed to their superior mechanical and electrical properties. Although the mechanical performances of metals are still of primary interest, their optical properties have also drawn increasing attention [1–6]. With the rapidly growing application of metals for mobile electronics, home appliances, and building interiors, their esthetics becomes increasingly significant; surface decoration with sensuous colors is an essential feature to improve the appearance of materials. Over the past decade, metal plasmonics has received great attention due to its promising applicability in many different areas, including solar cells [7, 8], displays [9, 10], sensors [11], color filters [12], art/ decoration, and anti-counterfeiting [13]. It benefits from the coupling of light with charges such as electrons in metals. Surface plasmons are charge oscillations propagating along a metal–dielectric interface. Surface plasmon resonance (SPR) is the resonant oscillation of free electrons excited by incident light, which is coupled into a metal–dielectric interface to generate the oscillation. Thus far, SPR studies have been * Myeongkyu Lee [email protected] 1 Department of Materials Science and Engineering, Yonsei University, Seoul 120‑749, South Korea carried out mostly with precious metals like gold and silver, which are both known as good plasmonic materials. Stainless steel (STS) is one of the most widely used metals in daily life. Several different methods have been investigated to color or decorate the surface of STS, including direct current anodization [14], surface passivation with an oxide layer [15–17], and laser-direct surface structuring [18–22]. However, they all present some drawbacks: although anodic films can produce different colors depending on the anodization conditions, they are easily cracked on drying; forming a passivation layer with uniform thickness and coloration on an STS surface is still challenging; and the surface structures obtained by laser processes are only statistically reproducible. In contrast, SPR provides an effective way to manipulate the absorption and reflectance of light in a specific wavelength range, producing structural colors. We have recently demonstrated SPR on bulk STS having a one-dimensional (1D) surface texture [23], but it was supported only when the incident light had a polarization parallel to the grating vector, showing colors under this transverse magnetic (TM) polarization. In this study, we investigated SPR in STS with a two-dimensional (2D) periodic texture, aiming to produce colors under both transverse electric (TE) and TM polarizations. A 2D texture with a 500 nm pitch was fabricated by imprinting and electrochemical etching on the surface of STS plates. The resonance behavior of the surface texture and the obtained colors were characterized 13 Vol.:(0123456789) 624 Page 2 of 9 M. Seo, M. Lee in terms of light incident angle and polarization. The SPR positions were theoretically calculated using the measured dielectric function of the STS alloy tested, and they were compared with the experimental results. This study may provide a design rule for producing SPR-based structural colors in STS. 2 Materials and methods The samples used for this study were prepared from commercial 316L STS plates (thickness = 1 mm, super mirror polished), which were cut into 20 mm × 20 mm pieces. The refractive index, N = n + ik, of 316L STS was measured as a function of the photon energy by ellipsometry using a polished sample. The dielectric function ε of the sample was derived from the relation of ε = εm + iεm′ = N2 = (n + ik)2, where εm and εm′ are the real and imaginary dielectric constants, respectively. εm depends on both the real and imaginary refractive indices as εm = n2 − k2; the measured refractive indices are plotted in Fig. 1 along with the derived εm. The central areas (~ 10 mm × 10 mm each) of the samples were textured by imprinting combined with etching. Figure 2 shows a schematic illustration of the fabrication process. An SU-8 photoresist (PR) layer was deposited onto the STS surface by spin coating and successively imprinted using a polyurethane acrylate (PUA) mold, which was cast from a Si master stamp having a 2D square-lattice pattern fabricated by photolithography and wet etching of a (100)-oriented Si wafer. The pattern pitch was 500 nm, which is the minimum scale obtainable with conventional photolithography. The imprinted PR layer was cured by ultraviolet (UV) light, Fig. 1 Measured refractive indices and derived real dielectric constant 13 Fig. 2 Schematic of the texture patterning process of stainless steel (STS) plates baked at 150 °C, and then partially removed via reactive ion etching (RIE) so that the STS surface was locally exposed. Then, the exposed STS surface was etched using two different methods: acid etching, with an HCl solution, and electrochemical etching. The latter was performed according to the method described in a literature report [24]; the sample and a Cu block were immersed in an aqueous solution of oxalic acid and, respectively, used as anode and cathode. Finally, the residual PR layer was removed using a piranha solution. The microstructural analysis of PUA mold, PR layer, and final texture was performed using a field-emission scanning electron microscope (SEM) (JSM-7001F, JEOL Inc. 15 kV). The texture heights were measured with an atomic force microscope (AFM). Reflectance spectra were measured by a UV–visible spectrophotometer using a halogen lamp as the light source. The polarization of light was controlled by a linear polarizer. The incident angle of light was varied from 10° to 30° with respect to the normal to the sample surface. The camera images of the samples were taken using a digital camera. A sheet polarizer was placed between the camera and the sample. Full-wave electromagnetic simulation was performed using finite-difference time-domain (FDTD) simulation software (www.lumeri cal.com). A plane-wave source in the wavelength range from 300 to 800 nm was incident onto the sample surface. The incident angle of light was varied from 0° to 40°. The spectral reflectance was measured by a power monitor placed above the sample. The electric- and Surface plasmon resonance and coloration in stainless steel with a 2D periodic texture magnetic field distributions were obtained by placing a field profile monitor at the cross-section of the sample. 3 Results and discussion 3.1 Fabrication of textured STS surface Figure 3 shows a 2D texture formed on the surface of STS, together with its fabrication steps. Since the Si stamp used had inverse pyramidal trenches, the PUA mold cast from it exhibited sharp tips. However, these mold tips could not reach the top surface of the STS samples by imprinting alone, even with the application of a high pressure. This is the reason for employing the intermediate RIE step to expose the STS surface. The width of the texture grooves was also affected by the RIE time, although it depended predominantly on the STS etching time. The final texture morphology was influenced by many experiment factors. First of all, to produce texture patterns of high quality and uniformity, the PUA mold should be a perfect replica of the Si stamp; to this end, the PUA solution must uniformly coat the stamp. On the contrary, when the features formed on the PUA mold have nonuniform heights, the resulting STS Page 3 of 9 624 texture is irregular, as shown in Fig. 4a. For the imprinting, the PUA mold was placed on top of the PR-coated sample and pressed with a mechanical press. However, this direct pressing often broke the mold. This problem was solved by inserting a polydimethylsiloxane (PDMS) plate between the mold and the press, which was attributed to the higher softness and ductility of PDMS compared to PUA. The exposed STS surface was first etched with an HCl solution. But the residual PR layer was easily damaged by this etchant, resulting in holes with irregular shapes (Fig. 4b). On the other hand, 2D textures with uniform feature sizes were obtained by electrochemical etching, as shown in Figs. 3 and 4c. Hence, the sample shown in Fig. 4c was used for the current SPR analysis. The height of the 2D texture, measured by AFM, was ~ 60 nm. 3.2 Theory of grating‑coupled SPR For a light wave with wavelength λ travelling in free space, the relation between its wave vector magnitude Klight (= 2π/λ) and angular frequency ω is linear: Klight = ω/c, where c is the light speed in free space. On the contrary, surface plasmons propagating on a planar metal surface have a nonlinear dispersion relation [25–27]: Fig. 3 Scanning electron microscope (SEM) images showing the steps used to fabricate a two-dimensional texture on a STS surface 13 624 Page 4 of 9 M. Seo, M. Lee Fig. 4 SEM images of 2D textures on STS plates obtained using a a PUA mold with nonuniform heights b by typical acid etching with an HCl solution, and c by electrochemical etching. All scale bars are 1 μm 𝜔 Ksp = c √ 𝜀m . 1 + 𝜀m (1) Since εm is frequency-dependent and has negative values in the visible range, the wave vector (i.e., the momentum) of light is always smaller than that of surface plasmons at a given ω value (i.e., Klight < Ksp). For SPR to occur, both energy and momentum should be conserved (i.e., ωlight = ωsp and Klight = Ksp). A promising way to modify the momentum of incident light and consequently support SPR is to form a diffraction grating on the metal surface [27–29]. Before discussing SPR based on a 2D grating, we will describe the resonance condition of a 1D grating. Consider the 1D grating with pitch d shown in Fig. 5a, where the y-direction is parallel to the grating grooves and the x-direction is parallel to the grating vector G, whose magnitude is given by G = 2π/d. Suppose that a light wave with wave vector Ki impinges on the grating at an angle Fig. 5 a Light diffraction by a 1D grating. b Vector representation of the momentum-matching condition. c Dispersion relations of light and surface plasmons on a planar metal surface. d Dispersion relations of light and surface plasmons when a diffraction grating with pitch d is present 13 θi with the surface normal in the x–z plane. The incident light is diffracted into multiple beams according to the following diffraction relation [30]: ) ( Ki sin𝜃m − sin𝜃i = mG. (2) Here, m represents the diffraction order (m = 0, ± 1, ± 2,..) and θm is the diffraction angle. The m = ± 1 terms can induce a strong diffraction effect. The diffracted beams have a wave vector component tangential to the surface given by Ki sin θm. If this component equals the wave vector (i.e., the momentum) of the surface plasmons, both energy and momentum can be conserved. This condition is mathematically given by ±Ksp = Ki sin𝜃m = Ki sin𝜃i + mG and alternatively expressed as ±Ksp − mG = Ki sin𝜃i . (3) (4) Surface plasmon resonance and coloration in stainless steel with a 2D periodic texture The ± sign is added to Ksp because surface plasmons can propagate either in the positive or negative x-direction. Figure 5b illustrates the relationship between three vectors Kll, G, and Ksp, where Kll is the component of Ki tangential to the surface and Ksp is the wave vector of surface plasmons. Since the magnitude of Kll is Kll = Ki sin θi, the vector form of Eq. (4) is ± Ksp − mG = Kll. In the absence of a grating (i.e., G = 0), Ksp is always larger than Ki sin θi = (ω/c) sin θi at the same energy (i.e., at the same ω), because, as mentioned above, εm has negative values in the visible range. This is graphically depicted in Fig. 5c, where ω/c is drawn as a function of the x-component of the momentum Kx for both light (i.e., Kx = Ki sin θi) and surface plasmons (i.e., Kx = Ksp). The in-plane momentum (i.e., the tangential component of the wave vector) of light is modified by a diffraction grating. This is equivalently viewed as a shift of the dispersion relation of surface plasmon by mG, as described in Eq. (4) and illustrated in Fig. 5d. Hence, as shown, SPR occurs at two different frequencies ω1 and ω2, which means that, for a given incident angle, two different light wavelengths λ1 (= 2πc/ω1) and λ2 (= 2πc/ω2) can be coupled with surface plasmons and, thus, strongly absorbed. As the incident angle changes, the slope of the “Kx/sin θi” line also changes, consequently shifting the wavelengths at which SPR occurs. The SPR wavelengths also depend on εm and d. The above derivations of Eq. (1) through (3) are purely based on grating-coupled SPR, where one wave vector is taken from the diffraction theory of a periodic structure and the other is taken from the surface plasmon theory of a flat metal surface without periodicity. Today, there exists a deeper understanding of the nature of resonances on optical gratings. The resonances are explained via the existence of specific poles of the field function, associated with the so-called grating modes of periodic open resonators [31, 32]; these grating modes exist even if there is no substrate. Nevertheless, the simpler grating-coupled SPR mechanism may also predict fairly correct resonant wavelengths for the surface texture described in the current study. Now, we go back to the 2D grating case. A 2D squarelattice texture can be regarded as a superposition of two orthogonal 1D gratings. Consider the 2D texture shown in Fig. 6a, where two orthogonal grating vectors are oriented in the x- and y-directions and have the same magnitude G = 2π/d. Here, we consider the case where the y–z plane is the plane of incidence; however, the result using the x–z plane would be the same due to a rotational symmetry. With respect to the geometry shown in Fig. 6a, the x-component of the momentum is Kx = m1 G and the y-component is Ky = Ki sin𝜃i + m2 G, (5) (6) Page 5 of 9 624 where m1 and m2 are integers representing the diffraction order for each grating. Energy and momentum can be simultaneously conserved if Ksp equals the vector summation of these two components (i.e., Ksp = (Kx2 + Ky2)1/2), leading to √ ( ) ) ( 𝜀m m1 𝜆 2 m2 𝜆 (7) − ± . sin𝜃i = − d 1 + 𝜀m d Equation (7) can be solved unless m1 and m2 are both zero. 3.3 Reflection spectra and revealed colors The reflectance spectra were measured as a function of θi using the 2D texture shown in Fig. 4c. Figure 6b shows the experimental spectra obtained under TE-polarized light, where the electric field of light is parallel to the x-direction. The TE-polarized light exhibited a strong resonance peak whose position depended on the incident angle. The resonance peak shifted toward shorter wavelengths as θi increased. For a 1D grating, SPR does not occur under TE polarization and thus no color is observed [23]. The TMpolarized light, having the electric field lying in the plane of incidence, generated two prominent resonance peaks (Fig. 6c). These two absorption peaks were more widely separated with an increasing incident angle. The TE-spectra revealed an additional set of weak peaks in a shorter wavelength range, which were also observed under TM light. They slightly red-shifted as θi increased. These secondary peaks overlapped stronger main peaks at some incident angles, making it difficult to define their positions precisely. In a 1D grating, the diffraction order m supporting SPR is either 1 or − 1. According to Eq. (7), however, some different combinations of m1 and m2 are possible in a 2D texture and the curves resulting from its solution are plotted in Fig. 7. The experiment results agreed fairly well with these curves. The data corresponding to the curve having m1 = ± 1 and m2 = 1 were not marked due to the absence of any noticeable peaks, which may be because the corresponding resonance peaks were either inherently too weak to be detected or located outside of the operation range (350–1000 nm) of the spectrophotometer used. The curve corresponding to m1 = ± 1 and m2 = 0 was produced by the grating vector parallel to the x-direction when the incident light was TEpolarized. Since m2 = 0, the grating with the vector parallel to the y-direction had no contribution to the resonance peaks of this curve. By the same token, two branches corresponding to m1 = 0 and m2 = ± 1 and the resulting SPR peaks arose from the grating with the vector parallel to the y-direction. In this case, the SPR was supported by TM polarization. When both gratings contribute to the resonance, m1 and m2 are both non-zero, which produces another set of branches starting 13 624 Page 6 of 9 Fig. 6 a Schematic of light incidence into a 2D squarelattice texture. Reflectance spectra obtained from the 2D texture shown in Fig. 4c under b TE-polarized light and c TMpolarized light 13 M. Seo, M. Lee Surface plasmon resonance and coloration in stainless steel with a 2D periodic texture Fig. 7 Experimental results compared with the theoretical curves predicted by Eq. (7) at a shorter wavelength (~ 395 nm). The color of an opaque object is determined by its reflectance spectrum. Using colorimetric transformations, the measured reflectance spectra were mapped as points on a CIE chromaticity diagram, as shown in Fig. 8a. Unlike the 1D grating case, the fabricated 2D texture exhibited colors under both polarizations, which were incident angle-dependent. For comparison, Fig. 8b shows the camera images of the sample captured apparently at the same angles. The marked angle represents the angle between the line connecting the camera to the sample and the normal to the sample surface. Polarized images were obtained with a sheet polarizer placed between the camera and the sample. The slight discrepancies observed in the color appearance may have two reasons; first, while the spectrophotometer measures the incident angle precisely, Page 7 of 9 624 accurately defining the incident angle when taking camera images is very difficult; second, an object may exhibit slightly different colors under different light sources, and the images shown in Fig. 8b were captured under illumination by a fluorescent lamp in the laboratory. For normal incidence (i.e., at θi = 0°), the reflectance spectrum and color are the same for both polarizations. In other words, there is no distinction between TE and TM polarizations. This is obvious from the curves shown in Fig. 7, although the reflectance at θi = 0° cannot be measured experimentally. As described above, the experimental results obtained using the fabricated 2D grating were well predicted by Eq. (7). This implies that the SPR wavelengths and the revealed colors may be tailored by varying the grating pitch over a certain range. Figure 6 shows that the positions of the resonance peaks depend on the polarization of light. This indicates that the observed spectra and colors are due to SPR, not diffraction. To confirm this, FDTD simulation was performed for a 2D texture structure. The pitch, height, and aspect ratio of the simulated structure were 500 nm, 60 nm, and 0.5, respectively. Figure 9a shows the reflectance spectra of TMpolarized light simulated at three different incident angles (θi) of 10°, 20°, and 30°. The peak positions in the simulated spectra were fairly consistent with the experimental results (Fig. 6c). Figure 9b shows the magnetic field (H-field) profiles observed at θi = 20°. At λ = 750 nm where no absorption occurs, the field profile appears like a typical reflection profile. At the peak wavelengths of 685 and 470 nm, the fields are highly localized and enhanced on the surface of the grating (i.e., at the air–metal interface), confirming the excitation of SPR. Since the light is incident at 20° with respect to the surface normal, the field enhancement is asymmetric. Figure 9c shows the field profiles observed at θi = 10°. Compared to the peak for λ = 470 nm and θi = 20°, the resonance peak found at λ = 460 nm and θi = 10° is wider, exhibiting a different field-enhancement profile. In Fig. 7, Fig. 8 a Mapping of the reflectance spectra, obtained under TE and TM polarizations, onto a CIE chromaticity diagram. b Camera images of the sample. The size of each image is 5 mm × 5 mm 13 624 Page 8 of 9 M. Seo, M. Lee Fig. 9 a Reflectance spectra of TM-polarized light simulated at three different incident angles (θi) of 10°, 20°, and 30°. b Magnetic field (H-field) profiles observed at θi = 20°. c Field profiles observed at θi = 10° two branches (m1 = ± 1 and m2 = − 1, m1 = 0 and m2 = 1) overlap near θi = 10°. The wider resonance peak and the corresponding field profile may thus result from a combination of two resonance modes. The theoretical derivations given in this work are purely based on grating-coupled SPR. For nanoscale gratings with a pitch much smaller than the wavelength of light, localized SPR (LSPR) may be dominant over the grating-coupled SPR [13, 28, 33]. In such cases, Eq. (7) may not be applicable and the overall plasmonic behaviors should be studied numerically or experimentally because LSPR with metal nanostructures other than spheres cannot be described analytically. 4 Conclusion We theoretically calculated and experimentally demonstrated grating-coupled SPR in 2D-textured stainless steel. A periodic 2D grating with a 500 nm pitch was fabricated on the surface of 316L STS plates by imprinting combined with electrochemical etching and the resulting resonance behavior was characterized in terms of the incident angle of 13 light and its polarization state. The dependence of the SPR wavelengths on these two parameters was theoretically calculated based on the grating-assisted light-coupling mechanism. The experimental results were in good agreement with the calculated ones. Surface texturing and the resulting resonance absorption present a promising method to produce structural colors in stainless steel and may find many applications including surface decoration, product identification, and anti-counterfeiting. Acknowledgements This work was supported by the R&D convergence program of the National Research Council of Science & Technology of Korea (CAP-16-10-KIMS). References 1. A. Kosinova, D. Wang, E. Baradacs, B. Parditka, T. Kups, L. Klinger, Z. Erdelyi, P. Schaaf, E. Rabkin, Tuning the nanoscale morphology and optical properties of porous gold nanoparticles by surface passivation and annealing. Acta. Mater. 127, 108 (2017) 2. X. Zhu, C. Vannahme, E. Nielsen, N. Mortensen, A. Kristensen, Plasmonic colour laser printing. Nat. Nanotechnol. 11, 325 (2016) Surface plasmon resonance and coloration in stainless steel with a 2D periodic texture 3. A. Furrer, R. Spolenak, Colors of thin films of binary and ternary gold- and platinum-based alloys. Acta Mater. 66, 241 (2014) 4. M. Blaber, M. Arnold, M. Ford, A review of the optical properties of alloys and intermetallics for plasmonics. J. Phys. Condens. Matter 22, 143201 (2010) 5. C. Noguez, Surface plasmons on metal nanoparticles: the influence of shape and physical environment. J. Phys. Chem. C 111, 3806 (2007) 6. K. Kelly, E. Coronado, L. Zhao, G. Schatz, The optical properties of metal nanoparticles: the influence of size, shape, and dielectric environment. J. Phys. Chem. B 107, 668 (2003) 7. Z. Wang, Y. Tang, M. Li, Y. Zhu, M. Li, L. Bai, M. Luoshan, W. Lei, X. Zhao, Plasmonic enhancement of the performance of dyesensitized solar cells by incorporating ­TiO2 nanotubes decorated with Au nanoparticles. J. Alloys Compd. 714, 89 (2017) 8. K. Lee, J. Jang, J. Zhang, S. Yang, S. Park, H. Park, Highly efficient colored perovskite solar cells integrated with ultrathin subwavelength plasmonic nanoresonators. Sci. Rep. 7, 10640 (2017) 9. L. Shao, X. Zhuo, J. Wang, Advanced plasmonic materials for dynamic color display. Adv. Mater. 30, 1704338 (2018) 10. X. Duan, S. Kamin, N. Liu, Dynamic plasmonic colour display. Nat. Commun. 8, 14606 (2017) 11. K. Mayer, J. Hafner, Localized surface plasmon resonance sensors. Chem. Rev. 111, 3828 (2011) 12. B. Hwang, S. Shin, S. Hwang, J. Jung, J. Choi, B. Ju, J. Jeong, Flexible plasmonic color filters fabricated via nanotransfer printing with nanoimprint-based planarization. ACS Appl. Mater. Interfaces 9, 27351 (2017) 13. J. Clausen, E. Højlund-Nielsen, A. Christiansen, S. Yazdi, M. Grajower, H. Taha, U. Levy, A. Kristensen, N. Asger Mortensen, Plasmonic metasurfaces for coloration of plastic consumer products. Nano Lett. 14, 4499 (2014) 14. V. Klimas, V. Pakstas, I. Vrublevsky, K. Chernyakova, A. Jagminas, Fabrication and characterization of anodic films onto the Type-304 stainless steel in glycerol electrolyte. J. Phys. Chem. C 117, 20730 (2013) 15. C. Degueldre, L. Fuks, E. Schenker, Pre-oxidation of stainless steel: a study by diffuse reflection spectroscopy. Appl. Surf. Sci. 134, 254 (1998) 16. D. Adams, V. Hodges, D. Hirschfeld, M. Rodriguez, J. McDonald, P. Kotula, Nanosecond pulsed laser irradiation of stainless steel 304 L: oxide growth and effects on underlying metal. Surf. Coat. Technol. 222, 1 (2013) 17. A. Rosenkranz, L. Reinert, C. Gachot, H. Aboufadl, S. Grandthyll, K. Jacobs, F. Muller, F. Mucklich, Oxide formation, morphology, and nanohardness of laser-patterned steel surfaces. Adv. Eng. Mater. 17, 1234 (2015) 18. B. Dusser, Z. Sagan, H. Soder, N. Faure, J. Colombier, M. Jourlin, E. Audouard, Controlled nanostructures formation by ultrafast laser pulses for color marking. Opt. Express 18, 2913 (2010) 19. K. Liu, X. Li, C. Xie, K. Wang, Q. Zhou, R. Qiu, Formation of sub-200 nm nanostructure on Fe film irradiated by femtosecond laser. Opt. Laser Technol. 94, 28 (2017) Page 9 of 9 624 20. G. Li, J. Li, Y. Hu, C. Zhang, X. Li, J. Chu, W. Huang, Femtosecond laser color marking stainless steel surface with different wavelengths. Appl. Phys. A 118, 1189 (2015) 21. F. Luo, W. Ong, Y. Guan, F. Li, S. Sun, G. Lim, M. Hong, Study of micro/nanostructures formed by a nanosecond laser in gaseous environments for stainless steel surface coloring. Appl. Surf. Sci. 328, 405 (2015) 22. G. Lazzini, L. Romoli, F. Tantussi, F. Fuso, Nanostructure patterns on stainless-steel upon ultrafast laser ablation with circular polarization. Opt. Laser Technol. 107, 435 (2018) 23. M. Seo, M. Lee, Grating-coupled surface plasmon resonance on bulk stainless steel. Opt. Express 25, 26939 (2017) 24. M. Shimizu, T. Yamada, K. Sasaki, A. Takada, H. Nomura, F. Iguchi, H. Yugami, Anisotropic multi-step etching for large-area fabrication of surface microstructures on stainless steel to control thermal radiation. Sci. Technol. Adv. Mater. 16, 025001 (2015) 25. L. Novotny, B. Hecht, Principles of Nano-optics (Cambridge University Press, New York, 2006) 26. S. Hayashi, T. Okamoto, Plasmonics: visit the past to know the future. J. Phys. D Appl. Phys. 45, 433001 (2012) 27. D. Sarid, W. Challener, Modern Introduction to Surface Plasmons (Cambridge University Press, New York, 2010) 28. B. Bhatnagar, A. Pathak, D. Menke, P. Cornish, K. Gangopadhyay, V. Korampally, S. Gangopadhyay, Fluorescence enhancement from nano-gap embedded plasmonic gratings by a novel fabrication technique with HD-DVD. Nanotechnology 23, 495201 (2012) 29. F. Ren, K. Kim, X. Chong, A. Wang, Effect of finite metallic grating size on Rayleigh anomaly-surface plasmon polariton resonances. Opt. Express 23, 28868 (2015) 30. E. Hecht, Optics, 2nd edn. (Addition-Wesley, New York, 1990) 31. T. Zinenko, V. Byelobrov, M. Marciniak, J. Čtyroký, A. Nosich, Grating resonances on periodic arrays of sub-wavelength wires and strips: from discoveries to photonic device applications. Contemp. Optoelectron. Mater. Metamater. Device Appl. Springer Ser. Opt. Sci. 199, 65 (2016) 32. V. Yachin, T. Zinenko, S. Mizrakhy, Resonance enhancement of Faraday rotation in double-periodic gyromagnetic layers analyzed by the method of integral functionals. J. Opt. Soc. Am. B 35, 851 (2018) 33. R. Ng, X. Goh, J. Yang, All-metal nanostructured substrates as subtractive color reflectors with near-perfect absorptance. Opt. Express 23, 32597 (2015) Publisher’s Note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations. 13