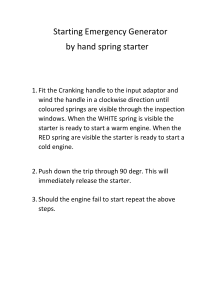

Diesel power station Abdugafforova D.O. Bisengalieva A. The diesel power plant consist of following components: 1. engine) 2. fuel system 3. Intake system 4. Exhaust system 5. Cooling system 6. Lubrication system 7. Starting and stopping system 8. Governing system 9. Generator of alternator 1.Engine: This is the main component of the power plant. The function of engine is to develop mechanical power for generator. The diesel engines used for diesel power plants may be four stroke or two stroke engines. A two stroke engine is rugged and compact in construction simple in mechanical design. Cheaper in cost, smaller flywheel required and develops more power for same speed and piston displacement. However, a four stroke engine has lower specific fuel consumption and more effective lubrication, more flexibility, less noisy exhaust, simple and better cooling, better scavenging and higher efficiency than a two stroke engine. Generally two stroke engines are favoured only for diesel electric power mainly due to high power output, uniform turning moments, compactness and less capital cost. Nowadays, high diesel oil price and hence high operating cost of two stroke engine is favoured to use four stroke diesel engines for diesel electric power plants. The diesel engines are available in size from 75 KW to 40MW. The size and number of engines depends upon plant capacity, purpose for which plant is being set up and the load characteristics. 2. Fuel system: It consist of fuel storage tank, daily consumption tank fuel transfer pump, strainer, fuel filters, and fuel injection pump. The fuel oil may be supplied at plant site by truck rail road, tank, cars etc. The function of fuel system are 1. To transfer fuel from storage tank to dail consumption tank, 2. To filter 3. To increase pressure of fuel 4. To measure and control the fuel supply 5. To inject and atomize ( spray in form of small particles) the fuel in the engine cylinders. 3.Intake system: It consists of air supply pipe, filters, and supercharge in case of supercharge engine. The function of air intake system are 1. To clean air, 2. To supply air for supercharging in case of supercharge engine, and 3. To reduce the noise of air intake. 4.Exhaust system: In consists of piping from engine to a point where exhaust gases may be discharged without danger or annoyance. A silencer is usually incorporated in this system to reduce the noise level. 5. Cooling system: The function of cooling system is to provide a proper amount water circulation all around the engines to remove the part of heat from engine cylinder keeping the low temperature at predefined level. The cooling system consists of water jacket, jacket water pump, surge tank, cooling tower, raw water pump and heat exchanger. 6. Lubricating system: It consists of lubricating oil tank, pumps, filters and lubricating coil cooler. The function of lubricating system is to provides a proper amount of oil to minimise friction and wear of the rubbing parts. The oil cooler is installed in order to keep the temperature or lubricating oil low in order to sustain the property of lubricating oil. 7.Starting and stopping system: The starting system is used to rotate the engine initially while starting until firing starts and unit runs in its own power. Small diesel engine plants are usually started manually by handles but for large capacity engine the compressed air system is mostly used for starting system. Battery driven motors can also be used for starting the diesel engine. The engine can be stopped by stopping fuel supply to the injection pump or stopping the action of injection pump 8. Governing system The system of government is the relationship of authority, power and function between two or more state organs and government on a reciprocal basis. 9. Electric Generator: The function of generator or alternator is to convert the mechanical energy (shaft power) of engine into electric energy. The generator shaft is coupled with engine shaft. They are provided with automatic voltage regulators to allow close voltage regulation and satisfactory parallel operation The alternators used in diesel electric power plants are of rotating fields, salient pole construction, speed ranging from 214 to 1000 rpm (poles 28 to 6) and capacities ranging from 25 to 5000 KVA at 0.8 power factor lagging. thank you for your attention