W'UMAB

D',EsiELE Utr',NE

M a r i n eA u x i l i a r yE n g i n e

6Nf8(AlL-\/sE'rrEs

,/

t/

//''-

OPERATION

]YIANUAL

Be sureto readthis OperationManualfor you to use

this productsafelyandcorrectly.

Evenafter readingit, carefullykeep it, makingclearto

all personnelconcemedwhere it is kept so that the

operator,mechanicor supervisorwill havean accessto it

wheneverhe wantsto reador referto it.

\-

@YANMAI

2003.12.10R

Ea,.,LTD.

YArMAB

6]||8(A)L-lf

CONTENTS

Page

....0-1

PREFACE

. . . . . . . . . . . . . .0

. .-.1. .

1. Foreword

0-3

..............

2. Terms& SymbolMarks

on Safety

3. Precautions

3-1.BasicPrecautions

3-2.Precautions

on Operation

( 1 )P r i otro S t a r i nogf t h eE n g i n e. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(2)During

a Run

(3)WhenStopping

theEngine

................

3-3.Precautions

on Maintenance

(1) Precautions

................

Priorto Maintenance

Servicing

(2) Precautions

Servicing

DuringMaintenance

(3) Precautions

Servicing

at Completion

of Maintenance

0-4

..................

.................0-4

.....0-7

................0-7

...................0-7

................0-8

....0-9

............0-8

........0-10

...........0-11

O-12

..................

4. Listof SafetyLabels

....0-13

for Engine

5. LiftingProcedures

EE S C R I P T I O. N

.........

1 . E N G T ND

1-1.EngineSpecification

& Attachments

1-2.Typesof Accessories

1-3.SectionalView

of theEngine...............

................

& Device

Anangement

1-4.EngineOutline

. . . . . . . . . . . . . . .1. .-.1. . .

...........1-1

......1-3

....14

......1-5

...,,...,...,,.2.1

OF MAJORPARTS

2. STRUCTURE

........

3 . T A B L EO F E N G I N E

S T A N D A RA

DD J U S T M E N T.S

. . . . . . . . . . . . .3. .-.1.

4. oPERATION

...............

4-1.OperationalPreparation

...........

4-1-1.Lubricating

Oilsystem

4 - 1 - 2F. u e l O i l s y s t e m

................;.

4 - 1 - 3C

. o o l i nW

g a t eS

r ystem

4-1-4.BoostAir System

4-1-5.Starting

Air System

4-1-6.Controland

Protective

Devices

4-2.Starting

procedures

1) Starting

operation

2) Conectiveactionsto be takenin startingfailure

3) Checksto be madeimmediately

afterstiarting

4 - 3 .R u n n i n g. . . . . . . . . . . . . .

'1)lnitialRunning-in

Operation

(Routine)

Running

2) Steady

4 - 4 .S t o p p i n.g. . . . . . . . . . . . . .

4-4-1.Stopping

in NormalRunning

4-4-2.Emergency

Stop....,.....

Stop..........

4-4-3.Disposal

Afteran Emergency

.................4-1

..............4'1

.................4'2

.........44

.................4'7

.......4-7

....4-8

....4-8

.............4-8

............4-8

....4-9

.....4'10

..............4-10

..............4-10

...............4-10

.............4-12

.......4-12

..............4-13

.....4'13

5 . FUELOIL,LUB.OIL& COOLINGWATER

5 - 1 .F u e l O i .l . . . . . . . . . . .

2002.12.25R

F-1

... 5.1

....................5-1

CONTENTS

YAX'',AF

5 - 1 - 1Q. u a n t i tCy r i t e r ioaf F u e l O i l. . . . . . . . . . . .

5-1-2.Quality

Criteria

of Blended

FuelOil

5-1-3.Properties

of FuelOilat the Enginelnlet

5-1-4.Howto FindouttheHeavyFuelOilHeating

Temperature

5-1-5.Howto FindouttheViscosity

of Blended

Oil ............

5-2.Lubricating

Oil

5 - 2 - 1C. h o o s i nt gh eL u b .O i l

5-2-2.Control

on Lub.Oil ............

3) Control

Criteria

4) OilChange

Criteria

5-2-3.Listof Lub.OilBrands

5-3.Cooling

Water(EngineJacketWater)

5-3-1.Criteria

on Cooling

FreshWater

5-3-2.Selection

of andControlon Corrosion

Inhibitor

6ilT8(A)L.Y

...............5-1

................5-2

.........5-2

..................5-5

.........5-6

....5-T

.................5-7

..........5-g

...............S-g

..........5-g

.................S-9

...5-10

...................5-10

..............S-10

6 . M A I N T E N A N CCEH E C K I N G

......6-1

6-1.Precautions

in Maintenance

Checking

.......................6-1

6-2.Tableof Periodical

Checking

..................6-2

1)Tableof Routine

Maintenance

Checking

...............6-2

2) Checking

Tablefor EngineUsingMarineDieselOit .............

......................6-3

3) Checking

Tablefor EngineUsingHeavyFuetOit(R.W.No.1at...)

............6-6

6-3.Routine

Maintenance

Checking

& Adjusting

Procedures

.............6-9

6-3-1.Measurement

of Running

Performance

..............

.............6-9

6-3-2.Measurement

of Max.Combustion

(Pmax)

Pressure

.....6-10

6-3-3.Regulation

of Fuellnjection

Votume(RackScale)

..........6-11

6-3-4.Adjustment

of FuelInjection

Timing

.............6-12

6-3-5.Checking

of FuelInjection

Valve& Adjustment

of lnjectionPressure...................6-13

6-3-6.Adjustment

of Suc./Exh.

ValveHeadCtearance

.............6-19

6-3-7.Adjustment

of Lub.OilPressure

...................6-19

6-3-8.Adjustment

of Lub.OilTemperature

..........

..6-20

6-3-9.Adjustment

of FuelOilPressure

...................6-22

6-3-10.Checking

of Cyl.JacketCoolingWaterThermostatic

Valves

..........6-23

6-3-1

1.Cleaning

of Lub.OilBypassstrainer

...........6-24

6-3-12.Cleaningof Lub.Oil Strainer

....6-27

6-3-13.

Cleaning

of FuelOilFilter

........6-29

6-3-14.

Cleaning

of Strainer/Filter

Element...............

...............6-31

6-3-15.

Washing

of Turbocharger

Blower

..............6-31

6-3-16.

Maintenance

of Pressure

Gauge

...............6-32

6-3-17.

Measurement

of Crankshaft

Deflection

............

............6-34

6-3-18.Adjustment

of FuelInjectionPumpPinionLubricating

Volume

( f o rE n g i n e

U s i n gH . F . O) . . . . . . . .

...........6-37

6-3-19.

Maintenance

of FuetOitSealPot(forEngineUsingH.F.O.)..............................6-37

6-3-20.Check& Replacement

of Anticorrosive

Zinc .........

........6-3g

7. MAINTENANCE

SERVICING

.,...7-1

7-0.Precautions

in Maintenance

Servicing

.....7-1

1) Precautions

on Safety

......7-1

2) Precautions

in Dismantling,

Servicing

& Reassembly

............

....................7-3

3) Precautions

at Completion

of Maintenance

Servicing

.............74

4) Handling

Procedures

for TurningGearDevice

......7-4

5) Handling

Procedures

for hydrautic

Jack..........

......7-s

7-1.Cylinder

Head& ltsAccessories

.........

..7-10

7-1-1.Cylinder

Head

.........7-10

7-1-2.Suction& Exhaust

Valves

..........7-15

7-1-3.Suc./Exh.

ValveSeat .........

........7-16

7-14.Suc./Exh.

ValveGuide

...............7-1g

7-1-5.Suc./Exh.

ValveBridge& ttsGuide

..............7-19

7-1-6.ValveRotator

...........7-19

2002.12.25R

F-2

CONTENTS

YA}//'',AR 61II8(A)L-Y

7-2.Piston& Connecting

Rod

....7-20

7-2-1.Piston& PistonPin ...........

........7-20

7 - 2 - 2 . C o n n e c tR

i nogd. . . . . . . . . . .

..............7-Zg

7-2-3.CrankPinMetal

......7-24

7-24. Connecting

RodBolt

.................,7-24

7-3.Cylinder

Block& Cylinder

Liner.........

...7-26

7-3-1.Cylinder

Block

.........7-26

7-3-2.Cylinder

Liner

.........7-26

7-4.MainBearing

& Crankshaft

..............

.....7-29

7-4-1.MainBearing

..........7-29

7-4-2.Crankshaft

.........

.....7-36

7-5.TimingGear,Camshaft

& Suc./Exh.

SwingArm ..........

..............7-37

7 - 5 - 1T. i m i n g

Gear

.............7-37

7-5-2.Camshaft

...........

......7-39

7-5-3.Suc./Exh.

SwingArm ..........

.......7-40

7-6.FuelInjection

Pump& PumpDriver

.......7-41

7 - 6 - 1F. u e l n j e c t i oPnu m p. . . . . . . .

...........7-41

7 - 6 - 2 . F u Ienl j e c t i oPnu m pD r i v e .r . . . . . . . . . . . . . .

............7-44

7-7.Governor

& Governor

Gear

...................7-45

7-7-1.Governor..........

(Seethe separate-vol.

manualon hydraulicgovernor.)

7-7-2.Governor

Gear

........7-45

7-7-3.Coupling

Adjustment

of Governor

Gear .........

.................7-47

7-8.Lub.OilPump,Lub.OilPressure

Regulating

Vatve& Lub.OitCooter

..........7-49

7 - 8 - 1L. u b O

. ilPump

..........7-48

7-8-2.Lub

O.i l C o o l e r

.........7-50

7-9.Cooling

WaterPump

...........7-52

7 - 1 0F

. u e l O iFl e e dP u m p

..........7-53

7-11.Suction/Exhaust

System

...7-54

7-11-1.

BoostAirCooler

.....7-54

7 - 1 1 - 2E. x h a u sMt a n i f o l d

....................7-56

7-11-3.

Turbocharger

..............

(Seethe separate-vol.

manualon turbocharger.)

7 - 1 2A

. i M o t o r. . . . . . . .

..................7-57

7-13.Electromagnetic

Pickup

.....7-Sg

7-14.Stopping

AirPiston

..........7-59

8. PRINCIPAL

DIMENSIONS

& PARTMASSFOR DESASSEMBLY

& SERVICING..............8-1

9. TABLEOF TIGHTENING

TORQUESOF MAJORBOLTS

10. CLEARANCES

& WEARLIMITSOF MAJORPARTS

1 1 . T R O U B L E S H O O T I&

NG

COUNTERMEASURES

PartsList& Figure

..................

1O-1

,.....11-1

. Appended

ATTACHED

ServiceManualfor the EngineAir Starters

YanmarServiceNetworks

2002.12.25R

...............9-1

F-3

PREFACE(Foreword)

YAnrrAn 6Illg(A)L-Y

PREFACE

Thankyou for purchasinga YANMARDieselEngine.

1. Foreword

This OperationManualhas beenpreparedfor yoursafeandeffectiveuse of the engine.Readthorough

regardingthe operaand precautions

the safetyprecautions

this OperationManualandfully understand

beforeusingthisengine.

tion,checkingandservicing

placeaccessible

for the operatorto referto it at

(1) Keepthis OperationManualat a clearlyidentified

anytime.

Manualmaypartlydisagreewithenginesof somespeci(2) The textand illustrations

of thisOperation

fications.

and FinalDocumentwe have submittedyou

For such engines,referto the EngineSpecification

separately.

Also note that this OperationManualis subjectto changefor improvingthe qualityand performancesof engineor for safety.

manualsseparatelyattached.

operation

(3) For the followingdevices,referto thecorresponding

Turbocharger

Hydraulicgovernor

of specialspecifications

Otherattachments

Systemof Units).

(4) In this manual,the numerical

valuesare basedon the Sl system(lnternational

given

in brackets.

are

also

unit

system

conventional

on

the

numericalvalues

based

However,the

your nearest

part

parts.

to

parts

a

Order

or specified

(5) Replacementpartsshouldbe our genuine

salesor serviceagentof Yanmar'sparts.Whenorderinga part,clearlyspecifythe PartName(part

SerialNo.of the engine.

and PartNo.,andthe Modelandmanufacture's

description)

Manual,or if you haveanyquestionsand advice,

(6) lf you shouldhavelostor damagedthisOperation

"YANpleasecontactus or yournearestsalesor serviceagent(shownin the servicenetworklist

to thismanual).

MARWorldwideService"appended

(7) lf you transferthis engine,alsotransferthis OperationManual,FinalDocumentand Recordsof

ShopTrialwiththe engineto the nextowner.

(8) lf you usethis enginefor an application

or underserviceconditionotherthanthosespecified,or if

Manual,an accidentor a failuremaybe caused.

you handleit not in accordance

withthisOperation

your

agent

beforechanginganytechnicaldataof the

or

service

nearestsales

Pleasecontactus or

Nevermodifythe enginewithoutconsulttheengineafierit hasbeendelivered.

engineor modifying

ing us.

0-l (Volume:14pages)

safe useof your engine)

PREFACEFoT

YATITUAB 6]II8(A)L-Y

For safe use of your engine.

WARNINGsand CAUTIONsdescribedin this Manual.

Be sureto abideby A -markedDANGERs,

particularly

importantparts of instructions.

are

they

As far as safetyis concerned,

Manualand

in thisOperation

showsthesafetymarksusedfor cautionindications

o Thefollowing

product

meaning.

their

and

explains

to this

safetylabelsattached

l\onruoenIt indicates that a danger of

possible death or serious injury is very great

when the proper precautions is not followed.

WARNING It indicatesthat there is a danger of resulting in death or serious

is notfollowed.

injury whentheproperprecautions

CAUTION It indicatesthat there is the possibilityof resultingin injuryor serious

damage to the engine when an advice on safety handlingor the

proper precautions is not followed.

r Wherethesafetylabelsare postedis shownin pageO-12.

for safe

marf in this OperationManualare especiallyimportant

with the A

o The cautionsprefixed

performances

or

of

handingof this product.A failureto observethis cautionmay incura deterioration

of thisproduct.Therefore,be sureto observethe items.

trouble/accident

0-2

& SymbolMarks)

PREFAC(Terms

YANM,AN 6]IT8(AL-Y

2. Term& SymbolMarks

1) The major terms used in this Operation Manual are defined as follows:

Front part of engine: Part oppositeto the flywheel end

Rearpartof engine: Part on the flywheelend

Operatingside:

Left side as viewed form the flywheelend (fuel injectionpump side)

Non-operating

side: On the rightas viewedfrom the flywheelend (exhaustpipe side)

CWrotation:

CCWrotation:

No:

Cylinder

Clockwise

rotationas viewedfromthe flywheelend

Counterclockwise

rotationas viewedfromthe flywheelend

Assigned

in the ascending

orderfromthe cylindernearestto theflywheel

end

Non-operatingSide

F

Fuel InjectionPump

OperatingSide

2) The following symbol marks are used in the safety labels shown in this Operation Manual and

posted on the engine.

(1)Cautionmarksand signalwords

l\onrucen It indicates that a danger of possible death or serious injury is very great

when the proper precautions is not followed.

l\wnnulruc It indicatesthat there is a danger of

resultingin death or serious

injury whenthe properprecautions

is not followed.

l\clunont

It indicatesthat there is the possibilityof resultingin injuryor serious

damageto the engine when an advice on safety handling or the

proper precautions is not followed.

l_\

lt indicates a handing caution which, if not observed, may incur a deterioration of performance or a trouble/accident of this product.

(2)Symbolmarks

(a)Caution

marks

(b)Others

ru

Caution

on explosion

Cautionon

rotatingpart

Cautionon fire

Cautionon

high temperature

Cautionon

hazardousnoise

0-3

. Refer to anotherpage,

sectionor chapterof this

OperationManualor other

document.

/ BasicPrecautions)

PREFAC(SafetyPrecautions

YAttroAB 6lll8(A)L-v

WARNINGAn accident may occur if the safetyrules are not followed.

3. Precautionson Safety

3-1.Basic Precautions

Strict Observanceof the SafetyRules

. When runningthe engineor servicingit for its maintenance,

observethe safetyrules,precautionson

safetyandworkprocedures.

. Whencarryingout a joint work,workaccordingto the predeterminedsigns.

Way of pre-workarrangement

(1) Accordingto kindof work required

(2) Everyoneto contemplate

and consider

(3) Everyoneto understand

well

( ) Fixthe mostsuitableway to work

. Wear the proper protectivegarment. Don't wear oil

smudgedwork clothesbecausethey are proneto catch

fire.

. Wear protectorssuch as helmet,safety goggles,safety

shoes, protectivemask, protectiveglove, life-line,etc.,

dependingon the natureof workrequired.

When workingon the engine,use the specifiedengine

tools.Usejigs or toolssuitablefor particularworkbecause

useof a wrongtoolcausesan injury.

%

f

sarewFrRsr

(1) Safety has priorityover

all the works.

(2) Safety is more important than any other

duties.

(3) lt is needless to say

"Safety First"

that

means that safety has

priority over working

efficiency.

(4) Safetyis the foundation

for working efficiency.

Safety is never contradictory to working efficiency.

. While at work, do not jump on and off the engine.

. For working,installa work bench fitted to the size of your engineto securea good footing.Don't work

in a dangerousposition.

0-4

PREFAC(Safety Precautions/ Basic Precautions)

YA)rruAn 6Ill8(A)L-V

I\CAUTION

Yanmarcannotbe responsible

for an accior serviceagentin advance.

fromunauin injuryor deathor an enginetroubleresulted

dentresulting

thorizedmodification.

. Yourengineand its safetydeviceshave been sealedfor the sake of

safety.Don'tbreakor tamperwitha sealindiscreetly.

. lf a sealingis missing,takea properstepof promptlycontacting

us or

your nearestsalesor serviceagentfor ensuringthe properinitialsetting.

A

ro*osoFF!

I \ W A R N IN GObserve the precautions for ensuring safety.

Check of Safety Devices

. Checkthe all the safetydevicesof your enginehave been set normally.

. lf a safetydeviceis wronglyused,it leadsto a seriousaccidentresultingin injuryor death.

. Promptlyrepaira cover a rotating part, a heat shieldingcover for exhaust pipe, a protectivecoverof

the heatingregionor the like,if found damaged.

. Neverrun the enginewhilethe coverof a rotatingpartis removed.Otherwise

dur-

mwAr-,rc-l ingoperation,

part,resultyourhand,bodyor clothingmaybe caughtin therotating

ingin yourinjury.

f---r'--..l

|

, { . J l

t.tYl

ItVtl

l\caunoru

Spot

or High-pressure

Be Cautiousof Handlingof a High-temperature

- Take care not to get burnt. . Duringrunningand immediatelyafterthe enginehas stopped,the wholeengineis heated.Takecare

not to get burnt.

1-a--_-_::-t . When changing cooling water, lubricatingoil or filter immediatelyafter the enginehas

qfry

stopped,proceedto work only after the temperaturehas lowered.

. Do not touch a high-temperatureregion such as the exhaustpipe or pressureindicator

cock of enginewith bare hands.

. Do not touch the heater and heated sectionsof fuel oil systemwith bare hands.

. Since the pressure indicatorbecomes hot, be sure to wear gloves when taking reading. lf you uncap the radiatoror fresh water tank, vapor or hot water may blow up, causing

you to get burnt.

. Stop the engineand wait untilthe temperaturehas dropped.Then, wrap the cap with

cloth and slowly loosen it to releasethe internalpressure.After that, removethe cap.

0-5

PREFAC(SafetyPrecautions/ BasicPrecautions)

YANM,AB 6NI8(A)L'Y

f\oarucen

Be Cautious of Handling of Fuel & LubricatingOil.

Z6-o_,**-l

\-

. lf fire is broughtcloseto fuel andior lubricatingoil, there is the possibilityof catching

Ilfe.

(Particularlythe fuel is highly flammable and dangerous.)

. Fire shouldbe strictlyprohibitedin the engineinstalledplace(engineroom).

. Check for leak of fuel oil and lubricatingoil. lf you find a defectivepoint,repairit and

wipe out leakedfuel or lubricatingoil.

. Store the fuel oil and lubricatingoil at the specifiedplace and do not allow persons

otherthan thoseconcernedto handlethem.

. Unnecessaryflammablesin the engineinstalledplace(engineroom) may cause fire.

Therefore,store theseflammablesin anotherspecifiedplace.

. If Exhaustgas is leading,promptlyrepair such a leaking Ventilatewell to preventgas intoxication.

pointat the exhaustpipe.

. Ventilatewell the indoor engine installedplace (and/orthe

engineroom.)

- )- r^\

. Take care that the room does not fall short of the air (oxylr

gen) becausethe turbochargertakes in a great volumeof

air.

i?--)^Fl*

.+ --+Tf

<,4..)r-l- '^\

'drA

(l ( )<d

f-A;"'n*-l

M

. Whilechargingthe battery,

thereis dangerof

catchingfire becausehydrogengas is gen. Inhaling

exhaustgas is verydangerous.

erated.

. Whenworkingindoors,sufficiently

ventilate

the room.

FIHE

it.

. Fix a safekeepingplace for a first-aidkit, and installit there.

. Fix the actionsto be taken when fire or an accidenthas occurred.

. Establisha means of reportingto emergencymedicalinstitutionsuch

as an emergency hospital,and have its telephonenumber written

down.

EXTINGUISHER

-

-e-

lt

lt

r t

r

r

-

-

FIRST-AIDKIT

0-6

on Operation)

PREFACE(SafetyPrecautions/Precautions

vAnnAB

61ll81a)L-yr

WARNINGObservethe precautionsfor ensuringsafety.

3-2.Precautionson Operation

(1)Priorto Startingof the Engine

Startthe EngineafrerSignaling

. Check if no one is aroundthe engine.

. lf someoneis foundnearthe engine,give him a signthatthe enginewill be

started.Only then start it.

. Check the holdingcapacitiesof fuel, oil, air, etc.

. Be sure to detach the tuming device once the engine is started,and keep

f

sorewFrRsr

it at it'sfixedhousingspot.

. Turnon the powersupplyof the engineprotection

up theengine.

devicebeforestiarting

. Afterthe enginehas beenstoppedfor a longtimeor afterthe enginehas beenserviced,be sure to

startup theengineat theengineside.

. lf the rotationalspeedrisesextremelyrapidlyor if you findan usualsoundor fume,immediately

set

leverin the STOPpositionto stopthe engine.

the starUstop

GheckAfter the Enginels Started

. Checkif pressurevaluesof eachinstrumenVgauge

boardare normal.

. Checkif thereare no unusualsoundandabnormal

heatbuildup.

. Checkfor any leakagesof fuel,oil,air,etc.,andif a leakageis found,promptlyrepair.

. Exceptin caseof emergency,

applythe loadaftera warming-up.

(2)Duringa Run

. Keepwatchingthe pressureandtemperature

or checkfor unusualsoundandabnormalheatbuildup.

. Checkwhethertheenginefullyshowsits properperformances

and recordthecheckresults.(Referto

the Recordsof ShopTrial,thenrecordthe checkresultson the EngineLog.)

f-A* ""*l

Takecare not to be caught in a rotating part.

. Neverallowyourhands,.body

andclothingto makecontactor bringcloseto any rotating part.

Takecare not to get burnt.

mcArntolrl

tA*"""il]

2003.10.20R

. During running and immediatelyafter the engine has stopped,the whole engine is

heated. Therefore, take care not to get burnt.

. Take care not to allow your hands, body and clothingto make contactwith the turbocharger,exhaust manifold,exhaustpipe and/orengine as whole.

. lf any abnormalityis detected,immediatelystop the engine and repair it.

Takecare not to get hearing loss.

. Putan ear protection

duringrunning,becausecancausehearingloss.

in engine-room

0-7

Precautions

/ Precautions

on Operation)

PREFAC(Safety

,AXMAE

6NtB1a)L-yz

f\wnnrulrucAn accidentmay occur if the safety rules are not followed.

(3) When Stopping the Engine

.

.

.

.

Do not stopthe enginesimultaneously

with load shutoff.

Exceptin caseof emergency,keep runningthe enginewithoutload after load shutoff.

Keepthe enginereadyfor beingstartedup.

Promptlyrepairthe pointsthat have been troublingduringa run.

. Do not open the side cover of crankcasefor at least 10 minutesafter havingstopped

the engine.Otherwise,the entryof externalair may resultin explosion.

m"*"*1

M

M

l-A;.,fi]

Take care not to get burnt.

. lmmediatelyafterthe enginehas stopped,the whole engineis heated.Therefore,take

care not to get burnt.

Takecare not to allowyour hands,body and clothingto make contactwith the turbocharger,exhaustmanifold,exhaustpipe and engineas a whole.

. lf you attemptto drain oil while the engine is still hot, take care not to get burnt with

splashof oil.

. lf you disassemblethe coolingwater systemwhile the engine is still hot, vapor or hot

watermay blow out, causingyou to get burnt.

Waituntilthe enginebecomescool,then wrap the disassemblingpartwith clothor the

likeand slowlyloosenit.

0-B

Precautions

/ Precautions

on Maintenance)

PREFACqSafety

'AI,IUAR

6lllg{AL-V

O bservethe precautionsfor ensuringsafety.

l\wnnrurruc

3-3.Precautionson Maintenance

(1) PrecautionsPrior to MaintenanceServicing

lndication of Warnings in Checking and Servicing

. Whilecheckingand/ormaintenanceservicingthe engine,post a notice

on a warningindicatingboardfor dangerprevention.

. Strivefor safety,maintaininga close contact with the respectiveparties

concerned.

. Striveto preventa dangerfrom emerging,forbiddingotherthan the parties concernedto enter the engine installedplace (and/orthe engine

room),for instance.

A

KEEPour!

A

,* woRKrNG

lmmediately After an Engine Stop

m;-G*-.t

M

m*fi* I

ffi

. Do not open the side cover of crankcasefor at least 10 minutesafterhavingstopped

the engine.Otherwise,entry of externalair may resultin explosion.

Take care not to get burnt.

. lmmediatelyafterthe enginehas stopped,the whole engineis heated.Therefore,take

care not to get burnt.

Takecare not to allow your hands, body and clothing to make contactwith the turbocharger,exhaustmanifold,exhaustpipe and engineas a whole.

. lf you attemptto drain oil while the engine is still hot, take care not to get burntwith

splashof oil.

. lf you disassemblethe coolingwater systemwhile the engine is stillhot,vapor or hot

watermay blow out, causingyou to get burnt.

. Wait untilthe enginebecomescool,then wrap the disassemblingpartwith clothor the

like and slowlyloosenit.

Preparation Prior to Working

.

.

.

.

put it in good order.

Sincea workingareawill be stained/smudged,

Prepareenginejigs and tools readyto use.

Prepareoil,genuineparts,waste cloth,wire, etc. accordingto the natureof work to be done.

Securea work benchfittedto the heightof the engine.

\,

0-9

on Maintenance)

/ Precautions

PREFAC(SafetyPrecautions

tO"-O"

6X|8(A)L-Yz

l\WARNTNG An accident may occur if the safety rules are not followed.

(2) Precautions During MaintenanceServicing

Gheck in Course of Work

. For a jointwork strivefor elimination

of a possibledangerby keeping

alertto the surroundings.

. Tie suchan accessorydetachedin workto a stablepostor spotso that

it willnotfall down.

. Fora workat a height,puton the safetybeltor life-line.

. Accordingto the conditionof working,wearprotectors.

. Be carefulof oil stainedor smudgedprotective

glovebecauseworking

parts

injury

or a personal

glove

of

lead

to

a

damage

might

withsucha

your

apt

to

slip.

handsare

as

. Wipeoff or mopup spilledfuel or oil at oncebecause,

if leftalone,it is

it

a

sliP.

dangerous

as causes

. Preparea boxto accommodate

removedpartsin advanceso thattheywillnotbe lostnordamaged.

it in

. lf necessaryprovidesettingmarksbeforedisassembling

the engineso thatyoucan reassemble

sequence.

theproperreassembling

. Reassemble

the settingmarkedportionswithreferenceto the settingmarks.

. Tightenthe boltsand nutsto the specifiedtorqueor hydraulicpressure.

Useof the ProperTools

.

.

.

.

.

Use the specifiedenginetools to preventthe damage of the respectiveboltsand nuts of the engine.

When handlinga heavything,followthe slinger'sinstructions.

In advanceof usingexclusivetools,checkthe functionof thesetools.

Carefullycheck for any damagesto rubberhose and jointsof hydraulicjacks.

Use the specified lifting gear, hook, rope, etc.; and pay attentionto safety when handling a heavy

thing particularly.

%

n

B

Z,,R\

t\2.1

V

A

toots

Precautions in Use of Fire

rA;'{GER-I

. In such works with welder, electricaltools

and grinder,be carefulof sparking.

Since there is the possibilityof catching

fire, try not to leave combustiblessuch as

fuel, lubricatingoil and usedwasteclothin

a workingarea.

ttu

0-l 0

tl"^rnables

oootronflo

Precautions

/ Precautions

on Maintenance)

PREFACESafety

l\wenunc

yAmUAB

61118(A)L-yz

Observethe precautionsfor ensuringsafety.

l\onrucen

Precautionsin Gheckingthe ElectricalSystem

-a

-._::-t

I /I\ DANGER I

rr.i)-=j:::::j_J

. Shutoff the powersupplybeforestartingthework.Otherwise,

a fire mayoccuror you

mav receive elgctric shock.

. When checkingthe batterysystem,be sure to disconnectthe earth cable

(-) terminal.Othenruise,

the negativeterminalmay be short-circuitedby mistake,

resultingin fire.

. The strong acid batteryelectrolyteput on your skin or eyes will cause inflammation.lf

the battery electrolyteshould be put on your skin or eyes, immediatelyflush it with

fresh water,then consulta physician.

Precautionsfor Using Organic Solvent

. Since an organicsolventis highlyvolatile,liableto be gasifiedand absorbedby workerthroughhis

when handlingit.

breathingas it vaporized,pay closeattentionto ventilation

. Since a highly concentratedorganic solvent has the propertyof dissolvingfats and oils and is

absorbedby workerthroughhis skins,be carefulof handlingit.

. When workingwith such a solvent,be sure to wear rubbergloves.

A

*=or PRorEcroRs

(3) Precautions at Gompletion of Maintenance Servicing

Check of Work Finish

. Check if detached parts have been refitted at the specifiedspots in the total

number.

. Check if the damaged parts have been replacedwith the good ones.

. Returntools, liftinggear, hook, rope,etc. used to the formersafekeepingplace.

. Removefuel and oil from the engineinstalledplace(and/orthe engineroom).

. Keep the engine installedplace (and/orthe engineroom)in orderand tidy so

that it will not interferewith daily operation.

. Beforestartingthe engine, check variousparts to see if there is no abnormality.

Refer back lo 3-2. Precautions on Operation, (1) Prior to Starting of the

Engine.

. Proceedt a load run, and check that the performancedoes not differfrom that

existedpriorto the maintenanceservicing.

Refer back to 3-2. Precautionson Operation,(2) Duringa Run.

. As soon as a load run is completed,enter recordsof performanceas well as

the natureof maintenanceservicingin your EngineLog. (Keepingof records

and then reportingof work completion)

. Remove such as a standingsignboard,and contactthe respectivepartiesconcerned for reportingthe completionof work.

0-11

PREFACESafetyPrecautions/ List of Safety Labels)

6]|I8(A)L-V

YAM'AN

4. List of SafetyLabels

a

.9

u 5 9

o ( E v

€ 8B

o

'

6 ) x

o =

v t r

=

( =

6 -

g

* 9

"\

o

+

b f r

)y-

3 3 € :

P

S

E

- 4 )

o

! v l l ;

. P { I

l!.:i!

+ i { s ;

3

E * h

F<$,.i

. e 4g ( &

E

I

(!:

o o )

o

X

=

J

g

a

f

3=

@

>

L

x o )

.eg

*i ;

=';

;iE

;E

:

JI

.:

6 s to =

6 E - , ^e

o.E:

i-I

z E

S J

o o

€N

c Eb 9

;i

:3

I F

o = 6 *

; : o):

@

ij XY E

;=

k :

>. oii

o.

.:c

i

i:

.!:5!z i

{,;:;i

.

.

; - i t

s"!:;

:i

--i$

r ! - : t !

o

i f i f

do

z

AH$*6

;

i . -

3 5

o

! :

:

::E

E i= = c

€ ; . 9 1 a "

: ; .

: : '

: : B l

=ir

!i ::as

" c ;

i-: ; :ii F

0

0

-

:l=:!5ii!

; ' : .

@

- ?

r 3 ;

_!i:

!i-:! ii M

o

iil

j

::

: ! E - :

-iil:

(E

q 6 s ; P

\

:"

?- t : :l i : 9! -1P !"

*€ fei3i'eF ;E

- € > o ' Y

t:

:::

i . : t l E: ! e i : l

- : : 3 . a : :

a

+z

'-

s*

=

@

o

,, ]

E

o

TL

.9-

w = Z

- r

35eig

s

O

- #

w

F = =

E.;;E*

* UH ! :

xg EU-

a

o H ' 6g ' =

,5

;35aE

"i=

9 ( o i oO - ^

o (Q9

:F;=19

\t

E

E

-

-

-

:

j

i:

"

Ei :'c

:!

;:

;

b, ij';i;

: :: !

-i "i:

i

:a -!:!:-

:

i6

:

!I

i. :

!

J

::

,

.:r.

ii:j!i

i B : : :: i ! , i - i ' i : " - :i i - ' t

:;::*3;;il

l ; ; , ii s :; 'r- r;il{:p=

i!3;it::;'i

. =i i i l i r

.-=

:: i: i 'Ii. iE:i"ti.1: 3 ,:;,;1it r:"; : i :Bt S

I

'- i':

;-!

i : : : :

o

@

iN

=

?

I

: Y

ie

q -

0

2002.8.30R

o

@

0 t

@

0-12

lil rlj

9 6 ; : t

8 l s ; 6 8 : ; i

@

o o

@ @

j

!i i!

3 ; : a ;

@ @

PREFACqsafetyPrecautions/ LiftingProceduresEngine)

YA}'NAR

6I[T8(A)L'V

5. Lifting Proceduresfor Engine

WARNING

Fallingof the engineor generatingset duringits liftingor carriageis very dangerousif so happened.

ln time of a load liftingwork, observethe followingitems in order to preventan accident:

. Use the liftingwire rope,shackle,etc. that are suitablefor liftingweight.

. Choosethe wire rope lengthso that the engineor commonbed does not lean to one side duringlifting.

. Put a cushioningmatedalsuch as paddingbetweenthe wire rope and the engineor drivenmachine

(generator,for instance)whichthe wire rope comes into contactwith otherwise.

. Choosesuch a cushioningmaterialas will not be damagednot removedduringlifting,then attachit

not to allowits contactswith the engineor drivenmachineto be damaged.

. Do not enteran area belowthe liftingload.

Lifting sling attaching points

1) Common bed set

The "Hang up This Point"labelshave been

stuckon the commonbed.

2) Enginesingly

o Fit the (optionallyavailable)exclusive lifting

slings to cylinderhead clamping bolts of the

No. 2 and No. 5 cylinderscloseto the centerof

the engine.

o Haul up the cylinderheadsunderthe specified

hydraulicpressuretightenedstate.

o Keep the liftingangle of the wire rope within 60

degrees.

3) Driven machines(generator,pump, etc.)

o For the wire rope attachingpoints, refer to the

respectiveOperationManuals.

0-13

1.

Specification)

ENGINEDESCRIPTION(Engine

YAmuAa 6tr€l(AlL-V

1 . E N G I N ED E S C R I P T I O N

1-1.EngineSpecification(1121

Unit

Model

Type

6N181-DV I 6N181-UV I 6N181-SV I 6N1BL-EV

4-cycledieselengine

Vertical,water-cooled,

Directinjectiontype

Combustionchamber

No. of cylinders

o

Cylinderbore

mm

180

Stroke

mm

280

42.75

Totalcylinderdisplacement

16.5

Compressionratio

Rated speed of revolution

minj(rpm)

Directionof rotationof

crankshaft

720or 750

Counterclockwiseas viewedfrom the flywheelend (XL)

Operatingside

On the left as viewedfrom the flywheelend

Order of firing

1-4-2-6-3-5-1

e ri t)ha i rc o o l e r

E x h a u sgta st u r b i n seu p e r c h a r g( et ur r b o c h a r gw

Superchargingsystem

Dualfreshwaterline cooling.

Coolingsystem

Forcedlubrication

(systemoil also usedas turbochargerlub.oil)

(systemoil also usedas rockerarm lub.oil)

Lubricating

system

Lubricating

oilsumpsystem

in commonbed

Sump incorporated

Air motorstarting

Startingsystem

Dimensions

Overalllenoth

mm

2,696

Overallwidth

mm

1, 3 1 5

Overallheight

mm

1,935

kg

6,500

(mayvaryas depending

on specification)

Mass(of enginesingly)

Constitutionof Model Designation

J- No. of cylinders

I

f Engineseries

t

t

|

|

;- Cyl. bore (in cm)

i-]

of Cylinders)

IConfiguration

="1

EINL,'

lb_lH-t

WO"A":ZZOor 750min-1

_l

I

M'A': 900or 1000min-1

I

Marine auxiliary/Landuse J

I

I

I

@o@@@o

Flywheel

Degreeof superchargingJ

2003.4.17R

1-1 (Volume:6pages)

1.

(EngineSpecification)

ENGINEDESCRIPTION

!'A}/,TUAN6NT8(A)L'V

(212)

1-1.EngineSpecification

Unit

Model

6N18ALHV

6N18ALDV

6N18ALUV

6N 18AL.

SV

6N18ALEV

Vertical,water-cooled,4-cycle d iesel eng ine

Type

Direct injectiontype

Combustionchamber

No. of cylinders

Cylinderbore

mm

180

Stroke

mm

280

0

42.75

Totalcylinderdisplacement

ratio

Compression

16.5

Ratedsoeed of revolution

900or 1,000

min-1(rpm)

Directionof rotationof

crankshaft

Counterclockwiseas viewed from the flywheelend (XL)

On the left as viewed from the flywheelend

Operatingside

1-4-2-6-3-5-1

Order of firing

(turbocharger)

with

Exhaustgasturbinesupercharger

air cooler

Supercharging

system

Dual freshwater line coolino.

Coolingsystem

Forced lubrication

(systemoil also used as turbochargerlub.oil)

(systemoil also used as rockerarm lub.oil)

Lubricating

system

Sump incorporatedin common bed

Lubricating

oil sumpsystem

Startingsystem

Dimensions

Air motor stariing

Overalllength

mm

Overallwidth

mm

Overallheight

mm

'1,935

kg

6,500

(mayvaryas depending

on specification)

Mass (of enginesingly)

2,696

'1,315

Constitution

of ModelDesignation

No. of cylinders

Engineseries

I

f

[Configurationof Cylinders)

5-

I

I

J-

cyl.bore(incm)

EEtrEE-tr

wlo-'n.

z-zo

orF.in-iT

@@@@@o

Flywheel

l-

W/'A":900or 1000min-1

|

Marineauxiliary/Landuse J

|

I

Degree of stiperchargingJ

2003.4.17R

1-2

(Typesof Accesories

& Attachments) vAn''Aa

1. ENGINEDESCRIPTION

6;518(A)L'yz

1-2.Typesof Accessories& Attachments

Accessory/Attachment

Supercharger

Boostair cooler

Governor

pump

Fuelinjection

Fuelvalve

M.D.O.feedpump

Fueloilfilter

Lub.oilpump

Lub.oilcooler

Lub.oilstrainer

Lub.oilby-passstrainer

Lub.oiltank

Coolingwaterpump

Lub.oilprimingpump

Air motor

Remarks

Type

exhaustgas turbine

Air-cooled

Platefinnedmultitubular

Hydraulic

Bosch

perforated

Non-cooled

For marinedieseloil

Gear

Heat-insulating,

manualback-washing,

notchwire

duplex,

changeover

Forengineinlet

Gear

Pressureregulatingvalveintegrated

Lowfinnedtubemultitubular

valve

control

temperature

dautomatic

notchwire

Duplex,changeover

Manualback-washing

Centrifugal

Tankincorporatedin common bed

Centrifugal

Screw

Turbine

1-3

jacketside,coolerside

Cylinder

1.

of the Engine)

ENGINEDESCRIPTION(SectionalView

YAI{/IOAB 6][I8(A)L-V

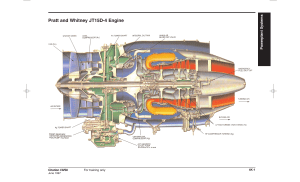

1-3.SectionalView of the Engine

OPERATING

SIDE

NON-OPERATING

SIDE

ValvePush Rod

Suc./Exh.Valve

Cyl. Head

Exh.Manifold

Pump HousingCover

Swing Arm

Lub.Oil Cooler

Camshaft

ConnectingRod

MainBrg.Bolt

OilPan

Mounting

Foot

1-4

Outline& DeviceArrangement)

1. ENGfNEDESCRIPTION(Engine

VanM,aB 6lf|8(A)L-Y7

1-4.(112)EngineOutline& DeviceArrangement

EngineRearEnd

Turbocharger

Fuel InjectionPump

StartingSwitch

StarVStopLever

Governor

Control Position

Selector Switch

Air Motor

Cam Case Cover

TurningDevice

1-4.(2|2)EngineOutline& DeviceArrangement

EnqineFrontEnd

ino Side

Exh. ManifoldCover

Lub.OilThermostatic

Valve

HotWater

ThermostaticValve

FuelFilter

BoostAir Cooler

Fuel Oil Pressure

RegulatingValve

Cold WaterPump

(on CoolerSide)

Hot WaterPump

(on Cly.JacketSide)

Lub.Oil Cooler

Lub.Oil Pressure

Valve

Regulating

Lub.OilPump

Crankcase SafetyValve

',

Lub.Oil Bypass Strainer

Lub.Oil PrimingPump

Lub. Oil Strainer

1998.10.20R

1-5

Pump

M.D.O.Feed

2.

STRUCTUREOF MAJOR PARTS(Outlineof Structure)

YA]{/TUAR6]II8(A)L-Y

OF MAJORPARTS

2. STRUCTURE

2-1. Outlineof Structure

This engine is designedto be a crankcaseintegrated,suspensionmetalstructureas shown in the below

sectionalview.

there are the fixed supportingto fix it directlyon the commonbed and the antivibration

For its installation,

supportingto fix the mountingfoot and generatoron the commonbed via rubbervibrationinsulators.

Drawing2-1.

SIDE

NON-OPERATING

SIDE

OPERATING

ValvePush Rod

RockerArm

Suc./Exh.Valve

Cyl.Head

InjectionPipe Joint

ProtectionRing

Exh. Manifold

Fuel InjectionPump

Piston

BoostAir BoostChamber

' Cyl. Liner

PumpHousing

Cover

SwingArm

Lub.Oil Cooler

Camshaft

Rod

Connecting

Lub.Oil Strainer

Crankshaft

Cyl.Block

MainBrg

Oil Pan

MountingFoot

2-1 (Volume:6pages)

2.

of MajorParts)

STRUCTUREOF MAJORPARTS(Structure

YAN',,AB 6]|T8(A}L'Y

2-2.Structureof MajorParts

1) Cylinder block

Providedwith side coverson both the operatingside and the non-operatingside, the cylinderblock is a

duplexwall structuremadeof castingintegratingthe boostair manifold(boostair chamber),main lubricating oil pipeand maincoolingwaterpipe.

2) Cylinder liner

Made of a specialcast iron,the cylinderlinerhas the specialthermaltreatedsurface. The innerface is

finishedwith precisionhoning.On the upper part of inner diameterof the liner, an anti-polishring is

mounted.

3) Cylinder head

The cylinder head is of the 4-valve type equipped with two suction valves and two exhaust valves and

arrangedwith a fuel injectionvalve at the center.The cylinderhead is clamped by tighteningfour bolts

underthe hydraulicpressure.

The exhaustvalveseat is watercooled,and the fuel injectionvalve is mountedwith a sleeve.

4) Piston and piston rings

The pistonis specialcast iron.lts upperpartsis cooledby the cocktailshakermethodusing lubricatingoil

that passesthroughthe connectingrod and pistonpin. The skirtis providedwith specialcoating.

The pistonrings are two compressionrings,and their slidingsurfaceis chrome-plated.Besides,there is

one oil ringcombinedwith a coil expanderwhose slidingsurfaceis also chrome-plated.

5) Connecting rod

The big end of a connectingrod is an obliquelysplit structure,and its matingsurfacesare serrated.The

connectingrod boltsare two tap boltstightenedto the specifiedangle'

6) Grankshaft and main bearings

A balanceweightis attachedto eacharm of the crankshaftby tighteningthe balanceweightclampingbolts

to the specifiedangle.

The main bearingis of the suspensionmetaltype. At the flywheel-sidetiminggear case of the No.1 main

bearing,the No.Omainbearingis provided,and it is attachedwith thrustmetaland journalmetal.

Each bearingcap is fixed with two mountingbolts and two side bolts on both the operatingside and nonoperatingside. The mountingboltsare tightenedto the specifiedhydraulicpressure.(Theside bolt of the

side.)

No.0 mainbearingcap is equippedonlyon the non-operating

7) Gamshaft

The suction/exhaustcam and fuel cam form a monoblockstructurewith the camshaft. lt is split in two at

the bearingpart betweenthe No.3& No.4cylinders.

8) Fuelinjectionpump

The fuel injectionpump is of the Boschtype. The deliveryvalve is a pressureequalizingvalve, and the

plungerbarrel is of the top closedtype.

The fuel injectiontimingis adjustedby means of the adjustingbolt of tappet of pump driving gear.

9) Fuel injection valve

The type usingthe highviscosityfuel oil is cooledwith the coolingwater runningthroughthe fuel injection

sleevemountedon the cylinderhead.A heat transferbush (copper)is installedbetweenthe fuel injection

nozzleand the injectionvalve sleeve,thus indirectlycoolingthe injectionnozzle.The engine using the MD

oil does not use the indirectcoolingsystemnor a heat transferbush. The injectionpressureis adjusted

with the spring shoe fastenedwith the adjustingnut.

10) Starting and stopping devices

The engineis startedby an air motorusingthe compressedairTo stop the engine,the starVstoplever is set in the STOP position.To stop the engine by the remote operposition.

ation,the air pistonis actuatedto set the rack of fuel injectionpump at the non-injection

The starUstoplever and turningdevice are interlockedwith the respectiveswitchesto prevent starting by

erroneousoperation.

2002.8.8R

2-2

2.

OilSystem)

STRUCTUREOF MAJORPARTS(Lubricating

YANTUAE 6]II8(A)L'Y

2-3.LubricatingOil System

oil pumpis a gear pump integratingthe pressureregulatingvalve and safety,valve.

O The lubricating

O The lubricatingoil strainersare a notch-wiretype strainerand a centrifugalbypass strainer.

type fittedwith an automaticthermooil cooleris a unitstructureof the multi-tubular

O The lubricating

staticvalve and a notch-wiretype strainer.

OThe primingpumpis a motoredscrewpumpand is mountedon the commonbed. The deliverypipe

is connectedwith the inlet side of the notch-wiretype strainer.

The lubricatingoil dischargedfrom the pump is regulatedof its pressureto the specifiedvalue by the pressure regulatingvalve.Then,the lub. oil passesthroughthe cooler and strainerand then entersthe main

galleryof the cylinderblock.The lubricatingoil line is branchedat the main gallery.The oil passesthrough

each partand returnsto the oil pan and then the commonbed.

Each lub. oil passagefranchedoff from the main galleryis a drilledhole structure,excludinglines leading

to the pressureregulatingvalveand governordrivinggear.

The oil suctionpart of the pump varies accordingto the engine installationtypes. In the case an engine

installedby the fixed supporting,the fixed suction part is the command bed; in the case of antivibration

supporting,it is oil pan.

Drawing 2-2

(HeavyFuel Oil Spec.

Fuel InjectionPump Pinion

Swing Arm RollerPin

Fuel lnjectionPumpTappetRoller

(ConnectingRod)

Auto. ThermostaticValve

Governor

DrivingGear

MainGallery

Lub. Oil Cooler

Turbocharger

Lub. Oil Strainer

Paper ElementType

EngineMain

Lub. Oil Strainer

Notch-wireType

BypassStrainer,

Centrifugal

CommandBed

PrimingPump

1999.7.2R

2-3

2.

STRUCTUREOF MAJOR PARTS(CoolingWater System)

YANM,AB G]ll8(All.-v

2-4. CoolingWaterPipe System

2-4-1. CoolingWaterHpe System(both freshwater)ineof the mixingtype)

The coolingsystem of this engine is to coof the engine (cylinderliner and cylinderhead) with hot fresh

waterand the lubricatingoil coolerand boost air coolerwith coldfreshwater.This coolingsystemis called

the dual fresh water line coolingsystemof the mixingtype.

O Both the cold water pump and the hot water pump are centrifugalpumpsequippedto the frontal

part of the engine.The hot water pump is such a structureto incorporatethe checkvalvedirectly

to the frontalside gear case throughthe check valve on the deliveryside. (The suctionparts of

both pumpsare caupledin the gear case.)

O The temperatureof hot water is controlledby the pellettype automaticthermostaticvalve.

O The temperatureof cold water is controlled by a thermostaticvalve equippedon the fresh water

coolerside.

The coolingwater dischargedfrom the cold water pump passesthroughthe boostair coolerand lubricating oil cooler,and then returns to the fresh water cooler side. However,a part of the coolingwater passes

throughthe coolingwater passagein the cylinderblockand flows intothe cold watersuctionside through

the automaticthermostaticvalve.

The coolingwater dischargedfrom the hot water pump returnsto the cylinderjacket,cylinderhead and

coolingwater collectingpipe and then to the automaticthermostaticvalvewhich controlsthe temperature

of thus returnedcoolingwater.

The coolingwater flown into the cylinderhead cools the combustionsurfaceand peripheryof fuel injection

valvesleeveand then coolsthe exhaustvalve seat.Afterthat,the coolingwaterflowsintothe coolingpipe.

Tank

Exoansion

Drawing2-3

I

I

I

4l

'j:-i!

, ai - - - CheckValve

a

HotWaterPump

I

I

I

AutomaticThermostaticValve

ColdWater Pump

I

i

.i.

- - -. {i

li

F1i i

;

-a---

i

Fresh

Water

cooler

.t-t

ColdWaterThermostaticValve

I

i

I

I

(SeaWater)

2-4

2.

STRUCTUREOF MAJORPARTS(CoolingWaterSystem)

YA'//'UAE 6TI8(A)L'V

2-4-2.CoolingWaterPipeSystem(coldwaterlineseawaterspec.)

1) The coolingsystemof this engineis to cool the engine(cylinderlinerand cylinderhead)with hot fresh

water and the lubricatingoil coolerand boostair coolerwith cold sea water.

o The coolingsystemis a dual-linesystemconsistingof the cylinderjacketlineand coolerline.

Sea water lines are equippedwith a motor-drivencentrifugalpump mountedin the marineas the

standardprovision,

o The coolingfresh water pump in the cylinderjacketline,the centrifugalpump is drivenvia an idle

gear.

2) The coolingsea water dischargedfrom the cold water pump passesthroughthe boostair coolerand

lubricatingoil cooler.

3) A bypass valve is providedat the coolingwater outletside of boost air cooler.

Openingthe bypassvalve decreasesthe amountof coolingwaterflowingthroughthe boostair cooler

and raisedthe boostair temperature.

4) The coolingwater dischargedfrom the hot water pump returnsto the cylinderjacket,cylinderhead and

coolingwater collectingpipe and then to the coolingwaterexpansiontank tank.

5) The cooling water flown into the cylinder head cools the combustionsurface and peripheryof fuel

injectionvalve sleeveand then cools the exhaustvalveseat.After that,the coolingwaterflows into the

coolingwater coolingpipe.

Drawing2- 4

Fresh(Hot)Water Pump

Fresh (Hot)Water Outlet

(Toexpansiontank)

AutomaticSea Water Valve

FreshWater lnlet

By-passValve

SeaWaterOutlet

2000.10.6R

2-5

Sea Water Pump

(mountin marine)

3. TABLEoF ENGINESTANDARD

ADJUSTMENTS

yermee

6J|!B(A)L-V

3. TABLEOF ENGINESTANDARD

ADJUSTMENTS

3-1.AssemblyAdjustmentValues

Item

Pistontop clearance(A)

z

Beginsto open(before

T.D.C.)

E

Ends closing(afterB.D.C)

Valve head clearance(B)

s

@

Beginsto open(before

B.D.C)

I

Ends closing(afterT.D.C)

Valveheadclearance(B)

u

AdjustmentValue

mm

Remarks

2.0 + 0.2

68

deg.

50

0.3

68

58

mm

deg.

o.4

mm

q)

In the cold state

ln the coldstate

o

o

q)

o

.E

tr

Adjust B after

setting it to zero

pumpbeginsto

Fuelinjection

deliver(before

T.D.C)

Injectionpressure,fuel injectionvalve

deg.

*

Referto Recordsof Shop

Traial.

MPa(kgf/cmz) 34.0-r-0.5(347-f 5)

3-2. Pressure& TemperatureSettingValues

Item

SettingValiie

Remarks

0 . 4 9 - 0 . 5 4 ( 5 . 0 - 5 . 5 ) Marinediseloil(M.D.O)

Referto Chapter5,5-1-3 Heavyfuel oil(H.F.O.)

Fuelfeedpressure

Maximum

pressure(Pmax)

combustion

*

Refer to Records of Shop

Trial.

0 . 3 9 - 0 . 4 4 ( 4 . 0 - 4 . 5 ) Engineinlet(cooler

outlet)

O . 2 5 - 0 . 4 4 ( 2 . 5 - 4 . 5 )Turbocharger

inlet

Valuesmarked

withX areper.

E

missible

cooling

waterpresMPa(kgf/cm2)

C"

0

.

1

5

0

.

2

5

l

X

0

.

3

9

sure

of

central

cooling

system

waterpressure(jacket

o Cooling

coolingline

- 2 . 5 t N 4 . 0 ) whenthepressurized

(

1

.

5

E

water

(L

inletpressure

or tankhead

pressure

areimposed

0.15-0.25lX0.39

Coolingwaterpressure(cooler

coolingline

( 1 . 5- 2 . 5 t N 4 . 0 \

Startingairtank

Startingair

2.94(30)

Lowerlimit1.18(12)

pressure

Afierdecompression

0 . 6 9 - 0 . 9 8 ( 7 - 1 0 ) At the air motorinlet

Coolingwaterengineoutlettemperature

358+4(85+4)

Coolingwaterair coolerinlettemperature

Below311(below38)

Lub.oil Dressure

o

(E

L

Lub.oilengine inlettemperature(cooler

outlet)

o)

o.

Exhausttemperature(at

eachcylinderoutE le0

P

Exh.gasturbocharger

inlettemp.

323-338(50-65)

K('C )

*

*

Referto Recordsof Shop

Trial.

Referto Recordsof Shoo

Trial.

Note:Fora star( * ) givenabove,referto the Recordsof ShopTrialand enterthe obtainedvalue here

becauseit variesaccording

to theenginespecification

and output.

200't.2.28R

3-1 (Volume:2pages)

YANM,AN 6]|I8(A)L-Y

TABLE OF ENGINESTANDARDADJUSTMENTS

3.

3-3.ProtectiveDeviceSetting Values

AlarmSettingValue

Unit

Item

0.34(3.s)

Lub.oilengineinletpressure

Lub.oilturbochargerinletpressure

MPa(kgf/cm2)

Coolingwaterengineoutlettemoerature

Rotationaloverspeed

* Lub.oilprimingpressure

0.02(o.2)

. Differential

pressure(lub.oil

strainer)

0.0e(o.e)

* Differentialpressure(fuel.oilfilter)

0.oe(0.e)

MPa(kgf/cm2)

373(100)

of the rated

115- 120o/o

sDeed

min-'(rmp)

. Startingair pressure

* Controlair pressure

0.2e(3.0)

0.25(2.5)

368(e5)

K ( " C)

Emer.Stop

SettingValue

0.65(6.6)

0.65(6.6)

. Coolingwaterpressure(acket

coolingline)

- Coolingwaterpressure(cooler

0 . 1 3 (.13 )

0.13(1.3)

coolingline)

. Lub.oilengineinlet(cooler

outlet)

temperature

348(75)

K ( " C)

As for an asterisk("),for equipmentof each item varies as dependedon the specification,refer to the Final

Document.

3-4.HoldingVolumesof LubricatingOil and CoolingWater

Unit:ltr.

HoldingVolume

Item

o

thecooler,strainer&

Engine(incl.inside

piping)

35

morethan1.lLlos

bedtank)

Lub.oilsump(common

" Governor

J

'

Remarks

TypeN261,RHD

1.3

TypePSG

2.0

water)

Cylinderjacket(fresh

75

Cooler

25

As for an asterisk(*),referto the FinalDocumentas the volumemay vary accordingto the specification.

1998.5.29R

3-2

4.

Preparation)

OPERATION(Operational

YADt',,An 6]||8(A)L-Y

4. OPERATION

Duringoperation,the dieselengineruns at a high speed.Also,some partsof the engineare hot, and

the compressedair and such pressurizedfluidsas oil and waterare flowinginsideit. Therefore,thoroughly read the safety precautionsbefore operation,maintenanceand inspectionto handle the

engineproperlynot to cause any accidents.

fLLfi Chapter0,Section3. Precautionson Safety

4-1. OperationalPreparation

Beforethe initialstart of the engine after its installationor beforeits restartafter its overhaulservicing

or a long-termstoppage, sufficientlyperform the following inspectionand operationpreparationin

additionto daily inspectionand operationalpreparation,and make sure there is no abnormalityand

the operationalpreparationhas completed.

(1) Make sure no part nor tool has been left in the crankcase.

(2) Checkfor a part not tightenedyet.

valveheadclearance.

(3) lf you havedisassembledthe valve mechanism,checkthe suction/exhaust

flll llCtrapter6, 6-3-6.Adjustmentof Suc./Exh.ValveHeadClearance

indicator

cocksof allthecylinders.

(4)Operatethelubricating

oil primingpump,andopenthe pressure

fromeachpartof the valve

oil is dropping

Whileturningthe flywheel,makesurethe lubricating

arms.

pins,

and

swing

pins,

main

bearings

piston

sure

crank

rockerarmshafts,

oilstrainer.

(5)Bleedtheairfromthe lubricating

pump.

(6)Bleedtheairfromthefueloil filterandinletpipeof fuelinjection

and makesureit movessmoothly.

(7)Manually

thegovernorlinkage,

lubricate

I Proceduresfor turningthe flywheel]

Be careful not to allow your body to make contact with a moving part while turning the flywheel.

(Neverput you hand into the crankcase.)

4-1 (Volume:14pages)

4.

OPERATION(LubricatingOil System)

YAxi'An

6X!8(A)L-Y

Drawingzt-2.Draining&Air

BleedingPointson Nonoperating

Silde Drawing4-2. Draining & Air Bleedingpoints

Lub.Oil Cooler

AirVentValve

AirVent Plug

AirVentPlug

Chang-over

Cock

Drain Plug

DrainPlug

OilSupplying Points on OperatingSide

Hand Lubricating Points

Manually lubricatethe governorlink and controldevices(circledportions)

Drawing4-4.GovernorDevice

Control Lever

for Gov. output

StarVStop

Lever

Governor

Connector

l i

Oil Level Gauge

1st LeverShaft

Remove the top covel

and supply oil to 2 to

3 mm above the center of oil level gauge.

DrainPlug

Lub.Oil Filler(Systemoil sump)

1999.7.2R

4-3

(Lubricating

OilSystem)

4. OPERATION

YAr/'UAB 6TII8(A)L-V

Turn the flywheel by the following procedures:

Turning Gear Device - - - - - - - - Operationalspec.

(1) Removethe lock bar,loosenthe stopperlock boltand slightlymovethe stopper.

(2) Pressthe turninggear shaftdownto the GEAR lN position.

(3) Fit the stopper into the groove B of the gear shaft,and then tightenthe stopper lock bolt.

(4) Attach the socket and ratchethandlefor turningto the shaft, and then turn the flywheel.

(5) When the turningoperationhas completed,returnthe turninggear shaftto the GEAR OUT position.

Then, fit the stopperintothe grooveA, and tightenthe stopperlock bolt.

(6) Attach the lock bar.

Unless the turning gear is the GEAR OUT position,the turning gear engagemenVdisengagement

switch actures to disablestarting.(optionalspec)

Drawing 4-1 Turning gear device (Optionalspec.)

r-l

TurningGear

L-._l

r N' Ti'

'rt

/41

B

4-1-1.LubricatingOil System

The piping parts of lubricatingoil systemare bandedwith yellow coating.

1) Inspection and oil supply of lubricatingoil sump

(1) Open the drain valve,cock or plugof the followingoil sumpsand devices;and checkthe drain.

Supplythe lubricatingoil to the upperlimitof oil levelgaugeor dipstickin each oil sump;

systemoil sump)

@ Engineoil pan or commonbed (lubricating

Governor

oil

sump

@

@ Lubricatingoil cooler

@ Lubricatingoil strainer

contaminated

of deteriorated,changeit.

(2) Checkthe propertiesof lubricating

oil;and if it is considerably

lLl_flChapter 3. Tableof EngineStandardAdjustment

fl | fltGhapter5. 5-2-2.Control on Lub. Oil

2001.6.15R

4-2

4.

OPERATION(LubricatingOil System)

YAxi'An

6X!8(A)L-Y

Drawingzt-2.Draining&Air

BleedingPointson Nonoperating

Silde Drawing4-2. Draining & Air Bleedingpoints

Lub.Oil Cooler

AirVentValve

AirVent Plug

AirVentPlug

Chang-over

Cock

Drain Plug

DrainPlug

OilSupplying Points on OperatingSide

Hand Lubricating Points

Manually lubricatethe governorlink and controldevices(circledportions)

Drawing4-4.GovernorDevice

Control Lever

for Gov. output

StarVStop

Lever

Governor

Connector

l i

Oil Level Gauge

1st LeverShaft

Remove the top covel

and supply oil to 2 to

3 mm above the center of oil level gauge.

DrainPlug

Lub.Oil Filler(Systemoil sump)

1999.7.2R

4-3

4.

OPERATION(FuelOil SYstem)

YANJUAB 6NI8(A)L'V

2) Primingof lubricatingoil

pump.

primingsystemusinga motor-operated

Thisengineemploysthe continuous

o Keep the control power supply for the motor-operatedpriming pump of this engine switchedON

always.

o SwitchOFF the said powersupplyin a long-termstoppageof the ship and in a restand maintenance

servicingof the powerinstallation.

Afterpriminghas stoppedfor two hoursor longer,performprimingfor about20 minutesor longer.

pressure:

0.02- 0.20MPa(0.2- 2.0kgf/cm2)

Priming

3) Air Bleeding of Lub. Oil Cooler

airfromthe lub.oilcooler,operate

itemsarises,startthe engineafterbleeding

r lf anyof thefollowing

theprimingpump.

r Afterpriminghasstoppedfor two hoursor longer.

& cleaningthelub.oil strainer.

r Afterdisassembling

oil system.

the pipingpartsof lubricating

the lub.oil or disassembling

o Afterchanging

Air Bleeding Procedures

(1) Operatethe primingpump.

(2) Openthe air bleedvalve of the lub. oil cooler.

(3) Dischargethe air,and then closethe air bleedvalve.

o lf you cannotoperatethe motor-operatedpriming pump, performair runningfor about 3 seconds

repeatedlyfive times.

Afterstartingthe engineshouldbe executedthe air ventingagain.

4-1-2.FuelOil System

Thepipingpartsof fueloilsystemarebandedwithredcoating.

(1)Drainthefueloiltankandfueloilfilter.

(2)Supplythefueloil intothefueloiltank,andcheckthefueloil.Then,openor closeeachvalveaccordconditions.

ingto theoperation

turn on the heaterfor the

specifications,

(3) Youusean engineof marinedieseloil (M.F.O)starUstop

proper.

becomes

pipeline,andcontinueheatingtheH.F.O.untilitsviscosity

heavyfueloil(H.F.O.)

make sure the fuel oil temperlf you use an engineof heavyfuel oil (H.F.O.)starUstopspecifications,

proper.

ature(viscosity)at the engine inletis

fLl-[lChapter5, 5-1-3.Propertiesof FuelOil at the EngineInlet

1998.4.21R

4-4

4.

OPERATION(FuelOilSYstem)

YAN',,AB 6]|I8(A)L-Y

(4)Bleeding

airfromoilsystem

long-termstoppageor overhaulof the engine,bleedair from the fuel oil sysAfterengineinstallation,

tem by the followingprocedures:

O Open the bypassvalveof fuel feed pump.

(Fullyturn the bypassvalve handlecounterclockwise)

the air bleedcock of fuel oil filterto bleedair.

Open

@

Drawing 4-6 Air Bleeding Points on Frontal Side

Iten

1

z

Name

Fuel Feed Pumo

Press Reoulat.Valve

Bv-oassHandle

4

5

6

8

9

Chano-overCock

Fuel Filter (NO.2)

Air BleedCock

Fuel lniectionPump

Air BleedPlug

Drain Cock

By-passValve

(Clockwisefor close)

@ Loosenthe air bleedplugson the fuel oil pipe mountof each fuel injectionpumpto bleedair.

Drawing 4-7 Air Bleeding Points on Operating Side

'if-\ixi

Air BleedPlug

f-

@ Bleedthe air from each fuel injectionpump by the followingprocedures:

o Set the starVstopleverin the RUN position,and push the rackof fuel injectionpumpto

the injectionvolumeincreasedirection.

r Attachthe primingtools to the pumptappetwhilethe plungerof fuel injectionpump is at the

lowermostposition.

4-5

4.

SYstem)

OPERATION(FuelOil

No.

ExclusiveToolDescription

YAT{/TUAB6III8(A)L-V

PartNo.

O

Priminglever

146673-92920

@

Leversupport

146673-92930

Drawing 4-8 Priming Procedures

r Move up and down the primingleveruntilyou feel a strongresistance.

r Turn the flywheelto bleedthe air from all of the cylinders.

@ Closethe bypassvalve.

(Fullyturn the bypassvalve handleclockwise.)

Fuel Oil Seal Pot Servicing Procedures(for Engine Using H.F.O.)

Seal potsare equippedto the mountfor fuel oil pressuregaugeand that for the fuel oil differentialpressure

to 1,500-sec.or higherfuel oil).

indicator(optional)of an engineusingthe heavyfuel oil (equivalent

Drawing 4-9 Seal Pot Servicing Procedures

Seal Pot

2002.s.15R

4-6

4.

WaterSystem& BoostAir)

OPERATION(Cooling

YA'j,'frAB 61II8(A}L'V

(1) Removethe fillerplugO and the air vent plug@ .

(2) Pour ethyleneglycolfrom the filleruntilit overflowfromthe air vent plug.

(3) When the seal pot is filledwith ethyleneglycol,securelytightenthe plugsO & @ .

(4) Removethe plug @, and pour ethyleneglycolfromthe filler.When the seal pot is filledwith ethylene

glycol,tightenthe plug.

(5) Periodically(abouteverytwo months)loosenthe plug@ anOplug @, and check if the fuel oil does not

overflow.

4-1-3.CoolingWaterSystem

The piping partsof coolingwatersystemare bandedwith blue coating.

(1) Inspectthe coolingwatertank,and checkwhetherthe coolingwateris not contaminated.lf the cooling

changeit.

water is considerably,

(2) Supply the coolingwater to the upper limit of water level gauge, and add a proper amount of rust

inhibitor.

[LLilCnapter 5, 5-3-2.Brandsof RustInhibitor& AddingQuantity

(3) Open and closeeach valveof the coolingwaterpipe systemaccordingto the operationconditions.

heat the coolingwater in the

(4) lf you use an engineof heavyfuel oil (H.F.O.)starVstopspecifications,

jacket

cylinder

sideto 65 to 75'C .

When you have replacedthe cylinderliner or drawn it out for servicing,remove the cylinderside

cover and make sure no waterleaksinsidecvlinder.

4-1-4.BoostAir System

Open the drain cocksof the followingpointsto drainthem.

Drawing4-10 Boost Air System Draining Points on Non-operatingSide

2002.5.15R

4-7

4.

OPERATION(Starting& ControlAir System / Starting)

YADIM,AB 61118(A)L-V

Air System

4-1-5.Starting

The pipingpartsof fuel oil system are bandedwith white coating.

(1) Drainthe startingair reservoir.

(2) Make sure that the pneumaticpressurein the air reservoiris high enough to start the engine (2.2

MPa{22kgf

I cm2}or higher).

Devices

4-1-6.Controland Protective

(1) Movethe starUstopleverfromthe RUN positionto the STOP positionand vice versa,and makesure

the rackof fuel injectionpump, 1st levershaftof governorlink and connectormove smoothly.

(2) Checkfor excessiveplay of connectorpin.

(3) Set the powerswitchof protectiveand alarm devicesto the ON position.

Unlessthe powerswitch is set in the ON position,the protectiveand alarm devices do not actuate.

4-2.Starting

Thisengineis startedby an air motor.

Pressthe STARTswitch.Then,the pilotair solenoidvalvedirectlyattachedto the air motorwillopenon

the batterypowerto startthe engine.

Duringstartoperation,

do not bringyourfacecloseto the air motor.Dustadheredat the exhaustport

in injury.

of air motormayenteryoureye,resulting

Before the initialstart of the engine after its installationof before its start after its overhaulor longterm stoppage,performair runningby the followingprocedures,and make sure there is no abnormality.Then,startthe engineby the controlpanelon the engineside. lf a largeamountof fuel oil,cooling

"waterhammering"may occur.

wateror lubricating

oil shouldbe entrappedin cylinders,

operationselectorswitchin the ENGINEposition.

o Set the ENGINE/REMOTE

pressure

indicatorcocksof all the cylinders.

o Openthe

e Set the starUstoplever in the STOP position.

o Hold the STARTswitch pressingfor 2 to 3 secondsto effect air running.

1) Starting operation procedures

Start the engineby the followingprocedures.

(1) Makesurethe turninggear is it the GEAR OUT position.

(2) Make sure the pressureindicatorcock is closed.

(3) Set the ENGINE/REMOTE

operationselectorswitchto the ENGINEor REMOTEpositioncorresponting to the controlpanelto be selected.

2002.5.15R

4-8

4.

YATJ',,AB 6I|I8(A)L-Y

OPERATION(Starting)

(4) Set the start/ stop leverin the RUN position.

(5) Make surethe pointerof speedcontrolshaftof governorindicatesthe positionof ordinaryoperation

(ratedspeed).

(6) Open the startingair reservoirvalveand controlair valve.

(7) Hofdthe STARTswitchpressingfor 2Io 3 seconds,and make sure of ignition.Only then releasethe

switch.

Drawing 4-11Start Operating Procedures

v\/v

@@@

SpeedControlKnob

(for Governor)

Speed ControlShaft

ENGINE/REMOTE

OperationSelectorSwitch

ControlAir Valve

2) Corrective actions to be taken in starting failure

gasin thefluemaybe ignited,resulting

combustion

started,

unburnt

lf the enginecannotbe properly

gas

fromthe exhaustgas systembefore

perform

discharge

the

running

to

Therefore,

air

in explosion.

to restarttheengine.

attempting

(1) Make surethe flywheelhas completelystopped,and then pressthe STARTswitch.

(2) lf the batterypower for the STARTswitch has been exhausted(and in case of emergency),press the

manualbuttonof air motorto startthe engine.

Use startingcontrolbasedon the manualbuttononly in emergencybecausethe air motor may rotate

excessivelyas the controlmoduleis not in operationin this case.

Drawing 4-12 Air Motor Manual Button

2002.5.15R

4-9

4.

OPERATION(Running)

YAr/'UAB 6]|I8(A)L-V

3) Checks to be made immediately after starting

Checkthe followingitems.lf any abnormalityis found,stop the engine and repairit.

(1)Valueindicatedby the pressureindicatoron the gaugepanel

(2) Leakfrom each piping

(3) Unusualsoundand abnormalheatgenerationof each part

4-3.Running

partswithbarehands.

aftertheenginestop,nevertouchthefollowing

o Duringa runandimmediately

youmaygetburnt.

Otherwise,

.Turbocharger,

Exhaustpipesystem,boostair pipesystem

.Flueandfunnel

youmay be caughtin,resulting

in injury.

o Duringa run,nevertouchanymovingpart.Otheruvise,

Keepthecontrolairvalveopenedduringa run.

devicescannotactuate.

lf youcloseit, the protective

1) Initial Running-inOperation

To preventinitialabnormalwear of pistonrings and cylinderliner,run the engineon marinedieseloil

(M.D.O)for the followingperiod:

(1) For 10 to 20 hoursafterinstallation.

(2) For 10 to 20 hoursafterreplacementof pistonrings,pistonor cylinderliner

2) Steady (Routine)Running

(1) Makesure the pressureof lubricatingoil, coolingwater and fuel oil has reachedthe specifiedvalue.

(2) Run the enginefor about 10 minutesat the ratedspeedwithoutload to warm it up.

(3) lf the engineis used to drive a cargo pump or the like,which requiresthe controlon rotation,run the

engineat the presetidlingspeedto warm it up.

The criticalspeedthat may causetorsionalvibrationis withinthe normalrotationspeedrange,quickly

avoid it, and set the rotationalspeed to the rated speed.

2002.5.15R

4-10

4.

OPERATION(Running)

YANTOAB 6]II8(A)L-\/

(4) lf you continuerunningthe enginewith a low load for longerthan three hours,observethe following

load factors,othenrvise

combustionworsensand foulingof the combustionchamber,exhaustpipe,

turbocharger,etc. becomes heavy.

or higherloadfactor.

@ ff fuel oil used is the marinedieseloil (M.D.O),run the engineat 15o/o

@ lf fuel oil used is the heavyfuel oil (H.F.O)