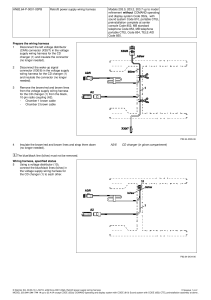

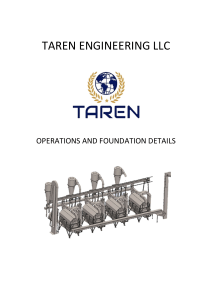

Attachment—Redekop™ Seed Control Unit Seed Control Unit INSTALLATION INSTRUCTIONS 5RKSC00201 12MAY20 S780, S780HM, S785, S785HM, S790, S790HM Deere & Company (XG) 5RKSC00201 (12MAY20) PRINTED IN U.S.A. COPYRIGHT © 2020 DEERE & COMPANY European Office Mannheim All rights reserved. A John Deere ILLUSTRUCTION ™ Manual 5RKSC00201-19-12MAY20 (ENGLISH) Seed Control Unit Check Status of Installation Instructions the Installation Instructions available in the Technical Information Store. See https://techpubs.deere.com. IMPORTANT: Before starting installation work, check if there is a newer version of AK53658,0000CB6 -19-23AUG19-1/1 Recognize Safety Information This is a safety-alert symbol. When you see this symbol on your machine or in this manual, be alert to the potential for personal injury. T81389 —UN—28JUN13 Follow recommended precautions and safe operating practices. DX,ALERT -19-29SEP98-1/1 Understand Signal Words DANGER; The signal word DANGER indicates a hazardous situation which, if not avoided, will result in death or serious injury. TS187 —19—30SEP88 WARNING; The signal word WARNING indicates a hazardous situation which, if not avoided, could result in death or serious injury. CAUTION; The signal word CAUTION indicates a hazardous situation which, if not avoided, could result in minor or moderate injury. CAUTION may also be used to alert against unsafe practices associated with events which could lead to personal injury. A signal word—DANGER, WARNING, or CAUTION—is used with the safety-alert symbol. DANGER identifies the most serious hazards. DANGER or WARNING safety signs are located near specific hazards. General precautions are listed on CAUTION safety signs. CAUTION also calls attention to safety messages in this manual. DX,SIGNAL -19-05OCT16-1/1 Carefully read all safety messages in this instruction. Read the product operators manual for operating instructions and safety messages. Do not let anyone operate without instruction. (A copy of the operators manual may also be available from the Service ADVISOR™ application.) TS201 —UN—15APR13 Follow Safety Instructions Service ADVISOR is a trademark of Deere & Company DX,READ,INS -19-23JUN09-1/1 5RKSC00201 (12MAY20) 1 052020 PN=3 Seed Control Unit Park Machine Safely Before working on the machine: TS230 —UN—24MAY89 • Lower all equipment to the ground. • Stop the engine and remove the key. • Disconnect the battery ground strap. • Hang a "DO NOT OPERATE" tag in operator station. DX,PARK -19-04JUN90-1/1 Overview of Trademarks PowerCast™ Trademark of Deere & Company Redekop™ Trademark of Redekop Manufacturing Company OUCC002,000651C -19-10MAY20-1/1 General Information CAUTION: When performing the work described below, comply with the safety instructions in the relevant technical manuals. NOTE: Due to the variety of combine types and materials used, it is not possible to describe and illustrate all the different methods of installation in these installation instructions. NOTE: For related work, refer to the relevant Technical Manual. NOTE: If torques for screws and screw fittings are not specified here, refer to the relevant Repair Technical Manual. OUCC002,00063B3 -19-17JAN20-1/1 5RKSC00201 (12MAY20) 2 052020 PN=4 Seed Control Unit Metric Bolt and Screw Torque Values TS1742 —UN—31MAY18 4.8 8.8 9.8 10.9 12.9 4.8 8.8 9.8 10.9 12.9 Class 4.8 Bolt or Screw Size M6 M8 M10 Hex Head a Class 8.8 or 9.8 Flange Headb a Hex Head Class 10.9 Flange Headb N·m lb·in N·m lb·in N·m lb·in N·m lb·in 3.6 31.9 3.9 34.5 6.7 59.3 7.3 64.6 8.6 76.1 9.4 83.2 16.2 143 17.6 156 N·m lb·ft N·m lb·ft N·m lb·ft 18.4 13.6 31.9 23.5 34.7 25.6 a Hex Head Class 12.9 Flange Headb N·m lb·in N·m lb·in Hex Heada N·m Flange Headb lb·in N·m lb·in 9.8 86.7 10.8 95.6 11.5 102 12.6 112 N·m lb·ft N·m lb·ft N·m lb·ft N·m lb·ft 23.8 17.6 25.9 19.1 27.8 20.5 30.3 22.3 46.8 34.5 51 37.6 55 40.6 60 44.3 16.9 150 N·m lb·ft M12 — — — — 55 40.6 61 45 81 59.7 89 65.6 95 70.1 105 77.4 M14 — — — — 87 64.2 96 70.8 128 94.4 141 104 150 111 165 122 M16 — — — — 135 99.6 149 110 198 146 219 162 232 171 257 190 M18 — — — — 193 142 214 158 275 203 304 224 322 245 356 263 M20 — — — — 272 201 301 222 387 285 428 316 453 334 501 370 M22 — — — — 365 263 405 299 520 384 576 425 608 448 674 497 M24 — — — — 468 345 518 382 666 491 738 544 780 575 864 637 M27 — — — — 683 504 758 559 973 718 1080 797 1139 840 1263 932 M30 — — — — 932 687 1029 759 1327 979 1466 1081 1553 1145 1715 1265 M33 — — — — 1258 928 1398 1031 1788 1319 1986 1465 2092 1543 2324 1714 M36 — — — — 1617 1193 1789 1319 2303 1699 2548 1879 2695 1988 2982 2199 The nominal torque values listed are for general use only with the assumed wrenching accuracy of 20%, such as a manual torque wrench. DO NOT use these values if a different torque value or tightening procedure is given for a specific application. For lock nuts, for stainless steel fasteners, or for nuts on U-bolts, see the tightening instructions for the specific application. Replace fasteners with the same or higher property class. If higher property class fasteners are used, tighten these to the strength of the original. • Make sure that fastener threads are clean. • Apply a thin coat of Hy-Gard™ or equivalent oil under the head and on the threads of the fastener, as shown in the following image. • Be conservative with the amount of oil to reduce the potential for hydraulic lockup in blind holes due to excessive oil. • Properly start thread engagement. TS1741 —UN—22MAY18 a Hex head column values are valid for ISO 4014 and ISO 4017 hex head, ISO 4162 hex socket head, and ISO 4032 hex nuts. Hex flange column values are valid for ASME B18.2.3.9M, ISO 4161, or EN 1665 hex flange products. b DX,TORQ2 -19-30MAY18-1/1 5RKSC00201 (12MAY20) 3 052020 PN=5 Seed Control Unit Unified Inch Bolt and Screw Torque Values TS1671 —UN—01MAY03 SAE Grade 1a Bolt or Screw Size 1/4 5/16 3/8 Hex Head c SAE Grade 2b Flange Headd Hex Head c SAE Grade 5, 5.1 or 5.2 Flange Headd c Hex Head Flange Headd N·m lb·in N·m lb·in N·m lb·in N·m lb·in N·m lb·in N·m lb·in 3.1 27.3 3.2 28.4 5.1 45.5 5.3 47.3 7.9 70.2 8.3 73.1 6.1 10.5 54.1 93.6 6.5 11.5 57.7 102 10.2 90.2 10.9 96.2 SAE Grade 8 or 8.2 Hex Headc N·m lb·in Flange Headd N·m lb·in 11.2 99.2 11.6 103 N·m lb·ft N·m lb·ft 22.2 16.4 23.7 17.5 15.7 139 16.8 149 N·m lb·ft N·m lb·ft 27.3 20.1 29.7 21.9 38.5 28.4 41.9 30.9 60.6 44.7 66.8 49.3 17.6 156 19.2 170 N·m lb·ft N·m lb·ft 27.8 20.5 30.6 22.6 43 31.7 47.3 34.9 16.7 148 18.4 163 N·m lb·ft N·m lb·ft 1/2 25.9 19.1 28.2 20.8 43.1 31.8 47 34.7 66.6 49.1 72.8 53.7 94 69.3 103 75.8 9/16 36.7 27.1 40.5 29.9 61.1 45.1 67.5 49.8 94.6 69.8 104 77 134 98.5 148 109 5/8 51 37.6 55.9 41.2 85 62.7 93.1 68.7 131 96.9 144 106 186 137 203 150 3/4 89.5 66 98 72.3 149 110 164 121 230 170 252 186 325 240 357 263 7/8 144 106 157 116 144 106 157 116 370 273 405 299 522 385 572 422 1 216 159 236 174 216 159 236 174 556 410 609 449 785 579 860 634 1-1/8 305 225 335 247 305 225 335 247 685 505 751 554 1110 819 1218 898 1-1/4 427 315 469 346 427 315 469 346 957 706 1051 775 1552 1145 1703 1256 1-3/8 564 416 618 456 564 416 618 456 1264 932 1386 1022 2050 1512 2248 1658 1-1/2 743 548 815 601 743 548 815 601 1665 1228 1826 1347 2699 1991 2962 2185 7/16 The nominal torque values listed are for general use only with the assumed wrenching accuracy of 20%, such as a manual torque wrench. DO NOT use these values if a different torque value or tightening procedure is given for a specific application. For lock nuts, for stainless steel fasteners, or for nuts on U-bolts, see the tightening instructions for the specific application. Replace fasteners with the same or higher property class. If higher property class fasteners are used, tighten these to the strength of the original. • Make sure that fastener threads are clean. • Apply a thin coat of Hy-Gard™ or equivalent oil under the head and on the threads of the fastener, as shown in the following image. • Be conservative with the amount of oil to reduce the potential for hydraulic lockup in blind holes due to excessive oil. • Properly start thread engagement. TS1741 —UN—22MAY18 a Grade 1 applies for hex cap screws over 6 in (152 mm) long, and for all other types of bolts and screws of any length. Grade 2 applies for hex cap screws (not hex bolts) up to 6 in (152 mm) long. Hex head column values are valid for ISO 4014 and ISO 4017 hex head, ISO 4162 hex socket head, and ISO 4032 hex nuts. d Hex flange column values are valid for ASME B18.2.3.9M, ISO 4161, or EN 1665 hex flange products. b c DX,TORQ1 -19-30MAY18-1/1 5RKSC00201 (12MAY20) 4 052020 PN=6 Seed Control Unit Disconnect Battery LX000872 —UN—19SEP94 CAUTION: Disconnect the negative terminal first. When reconnecting, do the positive terminal first. Always pay attention to the positive/negative markings on the battery. CAUTION: Comply with safety instructions on how to handle batteries. See Technical Manual, Section 10, Group 05. OUCC002,00063B4 -19-17JAN20-1/1 Summary of Attachments Attachment Seed Control Unit Designation Tractors Model Year Attachment—Redekop™ Seed Control Unit S780, S780HM, S785, S785HM, S790, S790HM From S.N 115000- OUCC002,000651A -19-09MAY20-1/1 Overview of Additional Parts That Are Required NOTE: The parts listed are not included in the scope of supply; if necessary, they must be ordered separately through normal parts channels. Extra Parts Required for Attachment Seed Control Unit Part Number. Designation Combine Quantity AN233321 Axle Stop S780, S780HM, S785, S785HM, S790, S790HM 2 OUCC002,00063E4 -19-11FEB20-1/1 5RKSC00201 (12MAY20) 5 052020 PN=7 Seed Control Unit Upgrade the Combine Straw Chopper with Vane Tailboard or PowerCast™ Tailboard Only ZX387488 —UN—21JAN20 IMPORTANT: The purpose of this attachment is to upgrade the original straw chopper with vane tailboard or PowerCast™ tailboard. If the straw chopper is equipped with an Advanced PowerCast™ tailboard, then additional parts are required to convert. If necessary, order the parts through the regular parts channel. Contact your John Deere dealer. IMPORTANT: For all adjustment and removal/installation procedure, always refer to the relevant combine Repair Technical Manual and Operator’s Manual. ZX387489 —UN—21JAN20 NOTE: Installation procedure is for a S700 Series Combine with a PowerCast™ tailboard and must be followed for any other system. If equipped with an Advanced PowerCast™ tailboard, then the tailboard must be removed but the hydraulic parts must remain on the machine. If converted to a vane tailboard only, upgrade the straw chopper as follows: 1. Remove both covers (A) and (B). ZX387490 —UN—21JAN20 IMPORTANT: To allow removal of the hydraulic components without draining the hydraulic oil reservoir, use the vacuum pump D15032NU. Contact your John Deere dealer. 2. Disconnect the hydraulic hoses (C) and (D) from the hydraulic block (E). 3. Disconnect the hydraulic hoses (F) and (G) from the hydraulic block (E). 4. Install the hydraulic hose 5RKHH122 (H) with one swivel fitting 5RKH38 (I) on original union fittings (J) and (K) of the hydraulic block (E) as shown. A—Cover—Upper B—Cover—Lower C—Hydraulic Hose D—Hydraulic Hose E—Hydraulic Block F— Hydraulic Hose G—Hydraulic Hose IMPORTANT: Make sure that O-rings are present on all fittings. 5. Install the hydraulic hose 5RKHH123 (L) on original elbow fittings (M) and (N) of the hydraulic block (E), creating a loop as shown. Continued on next page 5RKSC00201 (12MAY20) 6 H—Hydraulic Hose —5RKHH122 I— Swivel Fitting—5RKH38 J— Union Fitting (original) K—Union Fitting (original) L— Hydraulic Hose —5RKHH123 M—Elbow Fitting (original) N—Elbow Fitting (original) OUCC002,0006517 -19-12MAY20-1/12 052020 PN=8 Seed Control Unit 6. Disconnect the spreader wiring harness (A) from the spreader and the arms, but keep it connected to the hydraulic block (B). Tie up wiring harness (A) as shown. B—Hydraulic Block ZX387491 —UN—12MAY20 A—Wiring Harness OUCC002,0006517 -19-12MAY20-2/12 7. Machine without XFC (X-tra Fine Cut) Chopper Only: b. Disconnect plate (E) from bracket (F). c. Remove attaching screws (G), then remove the hydraulic pump (C) from the drive sheave (H). Keep all parts for further use. E—Plate F— Bracket G—Screws (2 used) H—Drive Sheave ZX387494 —UN—21JAN20 A—Hydraulic Hose B—Hydraulic Hose C—Hydraulic Pump D—Cover ZX387492 —UN—21JAN20 a. Disconnect hydraulic hoses (A) and (B) from fittings of the hydraulic pump (C), then remove cover (D). Continued on next page 5RKSC00201 (12MAY20) 7 OUCC002,0006517 -19-12MAY20-3/12 052020 PN=9 Seed Control Unit 8. On Combine with 3-Rib Chopper Jackshaft Belt Only: To allow the drive belt (A) removal, remove the shields, brackets, hoses, and other necessary components. Refer to the relevant Section of the combine Repair Technical Manual. NOTE: Keep all removed components for further use. a. Loosen tensioner, then remove and discard the 3-rib drive belt (A). IMPORTANT: Check that a 4-rib jackshaft drive belt can be installed on the PTO drive sheave (B). If it is not the case, order and install the corresponding drive sheave through the regular parts channel. b. Loosen tensioner, then remove the inner chopper drive belt (C). NOTE: Keep the inner chopper drive belt (C) for further use. ZX387495 —UN—06FEB20 c. Loosen tensioner, then remove and discard the outer chopper drive belt (D). d. Remove the attaching hardware (E), then remove and discard the 3-groove drive sheave (F). Refer to the relevant Section of the combine Repair Technical Manual. NOTE: Keep hardware (E) for further use. e. Install the 4-groove drive sheave H227595 (G) with the original hardware, then tighten the nut (H) to 308 N·m (225 lb·ft). F— 3-Groove Drive Sheave G—4-Groove Drive Sheave—H227595 H—Nut (original) I— 4-Rib Drive Belt—H240899 ZX387499 —UN—06FEB20 A—Chopper Jackshaft Drive Belt B—PTO Drive Sheave C—Chopeer Drive Belt—Inner D—Chopper Drive Belt—Outer E—Attaching Hardware ZX387496 —UN—06FEB20 f. Install the 4-rib drive belt H240899 (I), then adjust the tensioner (I). Continued on next page 5RKSC00201 (12MAY20) 8 OUCC002,0006517 -19-12MAY20-4/12 052020 PN=10 Seed Control Unit 1. The 2-rib drive belt 5RKBE2C112K (B) onto large set of grooves on jackshaft sheave (A). 2. The beater drive belt (C) onto middle set of grooves on sheave jackshaft (A) up to the beater sheave. 3. The original low speed chopper drive belt (D) onto set of grooves on sheave jackshaft (A) closest to the side wall. A—Chopper Jackshaft Sheave B—2-Rib Drive Belt—5RKBE2C112K C—Drive Belt—Beater D—Drive Belt—Low Speed Chopper Drive ZX387500 —UN—06FEB20 g. Install belts on the chopper jackshaft sheave (A) in the following order: OUCC002,0006517 -19-12MAY20-5/12 NOTE: If the straw chopper is equipped with an Advanced PowerCast™ tailboard (A), then additional parts are required to convert to vane tailboard. If necessary, order parts through the regular parts channel. Contact your John Deere dealer. C—Quick-Lock Pin (4 used) ZX387502 —UN—06FEB20 A—Advanced PowerCast™ Tailboard B—Chopper ZX387503 —UN—06FEB20 9. To remove the tailboard assembly (A) from the chopper (B), support the tailboard (A) using a pallet and a suitable lifting device, then disconnect the quick-lock pins (C) on both sides and remove tailboard (A). Continued on next page 5RKSC00201 (12MAY20) 9 OUCC002,0006517 -19-12MAY20-6/12 052020 PN=11 Seed Control Unit 10. Remove the chopper assembly as follows: a. Remove the stationary knife bank (A) and handle assembly (B) from the chopper frame (C). ZX387504 —UN—06FEB20 C—Chopper Frame ZX387505 —UN—06FEB20 A—Stationary Knife Bank B—Handle Assembly Continued on next page 5RKSC00201 (12MAY20) 10 OUCC002,0006517 -19-12MAY20-7/12 052020 PN=12 Seed Control Unit b. Fully extend the actuators (A) and set the chopper frame (B) to its utmost rear position as shown. CAUTION: Avoid personal injury, make sure that the chopper frame (A) is securely supported. d. On both sides, remove all hardware retaining hydraulic hoses and wiring harness on the rails (D), then disconnect the speed sensor (E), the chopper position sensor (F), and the actuator connector (G). ZX387506 —UN—06FEB20 c. Support the chopper frame (B) using a pallet and suitable lifting device, then remove both attaching pins (C). e. On both sides, remove all attaching bolts (H) and (I) - see arrows. f. Remove the rails (D) with the actuators still mounted to the rails and the spacer bars (J). NOTE: Keep the rails (D) with the actuators and the spacer bars (J) for further use. g. Remove the chopper frame (B) from the machine. ZX387508 —UN—06FEB20 F— Chopper Position Sensor G—Connector—Actuator H—Attaching Bolt (9 used per side) I— Attaching Bolt (2 used per side) J— Spacer Bar ZX387509 —UN—06FEB20 A—Actuator B—Chopper Frame C—Pin D—Rail E—Speed Sensor ZX387507 —UN—06FEB20 NOTE: Keep all hardware for further use. Continued on next page 5RKSC00201 (12MAY20) 11 OUCC002,0006517 -19-12MAY20-8/12 052020 PN=13 Seed Control Unit 11. Upgrade the original chopper as follows: a. Remove and discard the following components from the chopper frame (A) and keep all attaching hardware for further use: • Drive sheave assembly (B) • Chopper front panel (C) • Chopper knife floor (D) b. Install the chopper floor 5RKCD723GA (E) into the chopper frame (A) using six original flange screws M8x20 and flange nuts (F) as shown. c. Install the counterknife assembly 5RKCD724GA (G) into the chopper frame (A) with the knives through slots of chopper floor (E), then retain on the left-hand side of the chopper floor (E) using one original flange screw M12x35 and washer in hole (H) and one original flange screw M12x35 and washer in adjusting slot (I). ZX387514 —UN—06FEB20 F— Flange Screw and Nut M8x20 (original - 6 used) G—Counterknife Assembly—5RKCD724GA H—Flange Screw M12x35 and Washer—Attaching Hole I— Flange Screw M12x35 and Washer—Adjusting Slot ZX387517 —UN—06FEB20 ZX387516 —UN—06FEB20 A—Chopper Frame B—Drive Sheave Assembly C—Front Panel D—Knife Floor E—Chopper Floor—5RKCD723G Continued on next page 5RKSC00201 (12MAY20) 12 OUCC002,0006517 -19-12MAY20-9/12 052020 PN=14 Seed Control Unit NOTE: Install washers on both sides of the handle (B). NOTE: Use hardware bag SC263-02. e. Adjust the counterknife assembly to its middle way position, then tighten screws. f. Install the counterknife guard 5RKCD725G (E) with four flange screws M8x20 and flange nuts (F) as shown. ZX387518 —UN—06FEB20 d. On the right-hand side of the chopper frame (A), install the counterknife handle 5RKCD666GA (B) using one original flange screw M12x35 with two washers in hole (C), and one original flange screw M12x35 with two washers in the adjusting slot (D). g. Install the right-hand reinforcement plate 5RKCD727GR (G) on the relevant side of the chopper frame (A) with one flange screw M8x20 and nut in the attaching hole (H). • Drill a 12 mm (0.47 in) diameter hole through • chopper side wall using all holes (see arrows) in reinforcement plate (G) as a template excepted in holes (H), (K) and slot (I). Drill a 18 mm (0.71 in) diameter hole through chopper side wall using the hole (K) in reinforcement plate (G) as a template. ZX387519 —UN—06FEB20 IMPORTANT: Counterknife guard (E) must be oriented with sides up as shown. h. Repeat on left-hand side of the chopper frame (A) with the reinforcement plate 5RKCD727GL (J) accordingly. i. Attach the reinforcement plates (G) and (J) with one flange screw M12x25 and flange nut at attaching hole (L)G—Reinforcement Plate—5RKCD727GR H—Attaching Hole I— Slot J— Reinforcement Plate—5RKCD727GL K—Attaching Hole—18 mm (0.71 in) L— Attaching Hole ZX392451 —UN—21FEB20 A—Chopper Frame B—Handle—5RKCD666GA C—Flange Screw M12x35 and Washers—Attaching Hole D—Flange Screw M12x35 and Washers—Adjusting Slot E—Counterknife Guard—5RKCD725G F— Flange Screw M8x20 and Flange Nut (4 used) Continued on next page 5RKSC00201 (12MAY20) 13 OUCC002,0006517 -19-12MAY20-10/12 052020 PN=15 Seed Control Unit ZX392453 —UN—21FEB20 j. Install the chaff door assembly 5RKCD754GA (A) on the chopper frame (B) using one flange screw M12x50 (C) and one bushing 5RKSC320Z (D) on the right-hand side, and one flange screw M12x50 with the threaded bore in head (E) and one bushing 5RKSC320Z (D) on the left-hand side of the chopper frame (B). IMPORTANT: Make sure that bushings (D) are seated in holes and that flange screws (C) and (E) slide through. NOTE: Flange screws (C) and (E) are provided with the chaff door (A). k. Install the proximity sensor tab assembly 5RKCD740GA (F) on head of the flange screw (E) with one M6x16 flange screw (G). A—Chaff Door Assembly—5RKCD754GA B—Chopper Frame C—Flange Screw M12x50 D—Bushing—5RKSC320Z E—Flange Screw M12x50 (with threaded bore in head) NOTE: Magnet (H) requires alignment with the Seed Control Unit sensor once the Seed Control Unit is installed. See Install Redekop™ Seed Control Unit section. NOTE: The flange screws M8x20 are installed under the Step 11-b. l. Remove the two flange screws M8x20 that retain the reinforcement plates, then engage the two spring lock pins (I) into free mating holes. Continued on next page 5RKSC00201 (12MAY20) F— Proximity Sensor Tab Assembly—5RKCD740GA G—Flange Screw M6x16 H—Magnet I— Spring Lock Pin 14 OUCC002,0006517 -19-12MAY20-11/12 052020 PN=16 Seed Control Unit m. Remove the high-speed drive sheave (A) and the low-speed drive sheave (B) from the original speed shifter assembly (C). Keep all attaching screws for further use. n. Install the high-speed drive sheave 5RKRP988 (D) on the shifter hub (E), then the low-speed drive sheave 5RKRP968 (F) using original flange screws M10x35 as shown. Tighten flange screws to 54 N·m (40 lb·ft) in a criss-cross pattern. o. Install the speed shifter assembly (A) back on chopper frame using original flange screw M16x60 and washer (G), then tighten flange screw (G) to 308 N·m (225 lb·ft). E—Speed Shifter Hub F— Low-Speed Drive Sheave—5RKRP968 G—Flange Screw M16x60 and Washer (original) ZX392459 —UN—06FEB20 ZX392458 —UN—06FEB20 ZX392456 —UN—06FEB20 A—High-Speed Drive Sheave (original) B—Low-Speed Drive Sheave (original) C—Speed Shifter Assembly D—High-Speed Drive Sheave—5RKRP988 OUCC002,0006517 -19-12MAY20-12/12 5RKSC00201 (12MAY20) 15 052020 PN=17 Seed Control Unit Install Redekop™ Seed Control Unit 1. On Combine without Premium Beater Option Only - Install the beater extension 5RKSC200G (A) as follows: a. Adjust sieves (B) to closest position. NOTE: To avoid louver damage, protect with a board overtop the sieves. ZX392461 —UN—08FEB20 Install the Redekop™ Seed Control Unit in the following order. b. Remove the four round head attaching screws M10x25 (C) from the beater plate (D). ZX392462 —UN—08FEB20 c. Install the beater extension 5RKSC200G (A) on the beater plate (D) with four flange screws M10x20 and flange nuts (E) as shown. NOTE: Flange screws and nuts (E) are part of the hardware bag SC263-03. D—Beater Plate E—Flange Screw M10x20 ZX392464 —UN—08FEB20 ZX392463 —UN—08FEB20 A—Beater Extension—5RKSC200G B—Sieves C—Attaching Screws M10x25 (4 used) Continued on next page 5RKSC00201 (12MAY20) 16 OUCC002,0006518 -19-12MAY20-1/23 052020 PN=18 Seed Control Unit C—Round Head Screw M10x25 (original) D—Beater Extension—5RKSC200G ZX392466 —UN—08FEB20 A—Fin—5RKCD733G (2 used) B—Beater Plate ZX392465 —UN—08FEB20 d. Install the two fins 5RKCD733G (A) on top of the beater plate (B) using the original round head screws M10x25 (C) as shown. Continued on next page 5RKSC00201 (12MAY20) 17 OUCC002,0006518 -19-12MAY20-2/23 052020 PN=19 Seed Control Unit a. Remove the sieve actuator cover (B), the two seed loss deflectors (C), the sieve extension (D), and the sensor plates (E) with the wiring harness from the machine. Keep all hardware for further use. IMPORTANT: Note the location of both sensor plates (E) for further installation. NOTE: Disconnect the sensor plates (E) from wiring harness, then keep wiring harness and retaining hardware for further use. ZX392467 —UN—08FEB20 2. Install Sieve Extension - Install the sieve extension assembly 5RKSC340GA (A) as follows: NOTE: Depending on the combine model and the mounting plate, all hardware (F) might not be reused. c. Install both sensor plates (E) to their relevant location on the sieve extension (A), then route and retain original wiring harness (G) on the sieve extension (A) using original hardware (H). E—Sensor Plate F— Attaching Hardware (original) G—Wiring Harness (original) H—Attaching Hardware (original) ZX392471 —UN—08FEB20 ZX392470 —UN—08FEB20 A—Sieve Extension Assembly—5RKSC340GA B—Actuator Cover C—Seed Loss Deflector D—Sieve Extension ZX392468 —UN—08FEB20 b. Install the new sieve extension assembly (A) behind and below combine sieve, to side plates and rear mounting plate using original hardware (F). Continued on next page 5RKSC00201 (12MAY20) 18 OUCC002,0006518 -19-12MAY20-3/23 052020 PN=20 Seed Control Unit e. Install the two seed loss deflectors 5RKSC283G (D) on the seed loss sensor plates using original hardware (E) as shown. Make sure that seed loss deflectors (D) are above the rubber (F). f. On both sides, place and center the grain loss guard 5RKCD691G (G) on top of sensor plate (H), then drill two 6 mm (0.23 in) diameter holes through attaching holes of the grain loss guard (G). Attach the grain loss guard (G) with two flange screws M6x20 and flange nuts (I). ZX392472 —UN—08FEB20 d. Retain wiring harness (A) on sieve extension 5RKSC340GA (B), then connect the sieve actuator (C). NOTE: Flange screws and nuts (I) are part of the hardware bag SC263-04. G—Grain Loss Guard—5RKCD691G H—Seed Loss Sensor Plate I— Flange Screw M6x20 and Flange Nut (4 used) J— Sieve Actuator Cover—5RKSC307G K—Hardware (original) ZX392475 —UN—08FEB20 ZX392474 —UN—08FEB20 A—Wiring Harness (original) B—Sieve Extension —5RKSC340GA C—Sieve Actuator D—Seed Loss Deflector—5RKSC283G E—Hardware (original) F— Rubber ZX392473 —UN—08FEB20 g. Install the sieve actuator 5RKSC307G (J) using original hardware (K) as shown. Continued on next page 5RKSC00201 (12MAY20) 19 OUCC002,0006518 -19-12MAY20-4/23 052020 PN=21 Seed Control Unit 3. Install Cover Plate - Install the cover plate 5RKSC251G (A) as follows: b. Install the fin cover plate (A) on inside of upper rear wall using six round head screws M10x25 and flange nuts (D) as shown. NOTE: Round head screws and flange nuts (D) are part of the hardware bag SC263-05. C—Bracket D—Round Head Screw M10x25 and Flange Nut (6 used) ZX392479 —UN—08FEB20 ZX392478 —UN—08FEB20 ZX392477 —UN—08FEB20 A—Cover Plate—5RKSC251G B—Deflector Fin ZX392476 —UN—08FEB20 a. Remove the three deflector fins (B), then remove the bracket (C) from the upper rear wall. Continued on next page 5RKSC00201 (12MAY20) 20 OUCC002,0006518 -19-12MAY20-5/23 052020 PN=22 Seed Control Unit 4. Install Vent Covers and Inspection Door - Install the inspection door 5RKSC277GA (A) and the covers HXE73659 (B), and HXE73660 (C) as follows: ZX392480 —UN—08FEB20 a. Remove the existing vent cover (D), the latch (E), the lock (F), and the attaching screws (G). Keep hardware (G) and lock (F) for further use. b. Install the inspection door (A) using original hardware (G) and lock (F) as shown. Make sure that lock (F) rotates smoothly onto the side wall of combine. E—Latch F— Lock G—Attaching Screws ZX392483 —UN—08FEB20 ZX392482 —UN—08FEB20 ZX392481 —UN—08FEB20 A—Door—5RKSC277GA B—Cover—HXE73659 C—Cover—HXE73660 D—Vent Cover (original) Continued on next page 5RKSC00201 (12MAY20) 21 OUCC002,0006518 -19-12MAY20-6/23 052020 PN=23 Seed Control Unit c. Remove the existing left- and right-hand side vents (A) and (B), then keep hardware (C) for further use. D—Cover—HXE73659 E—Cover—HXE73660 ZX392487 —UN—08FEB20 ZX392486 —UN—08FEB20 ZX392485 —UN—08FEB20 A—Vent (left-hand side) B—Vent (right-hand side) C—Attaching Hardware ZX392484 —UN—08FEB20 d. Install the cover HXE73659 (D) on the left-hand side of the combine and the cover HXE73660 (E) on the right-hand side using original hardware (C) as shown. Continued on next page 5RKSC00201 (12MAY20) 22 OUCC002,0006518 -19-12MAY20-7/23 052020 PN=24 ZX392489 —UN—08FEB20 ZX392488 —UN—08FEB20 Seed Control Unit 5. Install Screen Covers - Install the covers 5RKSC302G (A), 5RKSC281G (B), 5RKSC303G (C), and 5RKSC304G (D) as follows: IMPORTANT: To reduce the amount of soil into the cleaning system, the Seed Control Unit, and to avoid premature wear of the Seed Control Unit components, the covers (A), (B), (C), and (D) must be installed over the inlet screens. a. On the right-hand side, install covers (A) and (B) over the inlet screens of the cleaning fan (see arrows) using ten flange screws M10x20 and flange nuts (E) as shown. NOTE: Flange screws and flange nuts (E) are part of the hardware bag SC263-06. D—Cover—5RKSC304G (rear) E—Flange Screws M10x20 and Flange Nuts (10 used) ZX392490 —UN—08FEB20 A—Cover—5RKSC302G B—Cover—5RKSC281G C—Cover—5RKSC303G (front) Continued on next page 5RKSC00201 (12MAY20) 23 OUCC002,0006518 -19-12MAY20-8/23 052020 PN=25 Seed Control Unit b. On the left-hand side, install the front cover 5RKSC303G (A) and rear cover 5RKSC304G (B) over the inlet screens (see arrows) using eight flange screws M10x20 and flange nuts (C) as shown. C—Flange Screw M10x20 and Flange Nut (8 used) ZX392492 —UN—08FEB20 A—Cover—5RKSC303G (front) B—Cover—5RKSC304G (rear) ZX392491 —UN—08FEB20 NOTE: Flange screws and flange nuts (C) are part of the hardware bag SC263-06. Continued on next page 5RKSC00201 (12MAY20) 24 OUCC002,0006518 -19-12MAY20-9/23 052020 PN=26 ZX392494 —UN—11FEB20 ZX392493 —UN—11FEB20 Seed Control Unit 6. Install Baffle - Install the baffle 5RKSC346GA (A) as follows: a. On the left-hand side, punch out the two pre-cut areas (B) and open the door (C). ZX392495 —UN—11FEB20 b. Install one shim 5RKSC258-01G (D) and the baffle mounting plate 5RKSC258GL (E) on inside of the left-hand side wall of the machine, then attach with two round head screws M10x25 and flange nuts (F) as shown. IMPORTANT: Make sure that the shim (D) in placed between mounting plate (E) and side wall. c. Drill a 10 mm (0.39 in) diameter hole (G), then attach the mounting plate (E) with one round head screw M10x25 and flange nuts (F). d. Close and lock the door (C). E—Mounting Plate—5RKSC258GL F— Round Head Screw M10x25 and Flange Nut (3 used) G—Hole—10 mm (0.39 in) ZX392497 —UN—11FEB20 A—Baffle—5RKSC346GA B—Pre-Cut Area C—Door D—Shim—5RKSC258-01G ZX392496 —UN—11FEB20 NOTE: Round head screws and flange nuts (F) are part of the hardware bag SC263-07. Continued on next page 5RKSC00201 (12MAY20) 25 OUCC002,0006518 -19-12MAY20-10/23 052020 PN=27 Seed Control Unit f. Install one shim 5RKSC258-01G (B) and the baffle mounting plate 5RKSC258GR (C) on inside of the right-hand side wall of the machine, then attach with two round head screws M10x25 and flange nuts (D) as shown. IMPORTANT: Make sure that the shim (B) in placed between mounting plate (C) and side wall. NOTE: Round head screws and flange nuts (D) are part of the hardware bag SC263-07. ZX392498 —UN—11FEB20 e. On the right-hand side, punch out the two pre-cut areas (A). D—Round Head Screw M10x25 and Flange Nut (3 used) E—Hole—10 mm (0.39 in) ZX392501 —UN—11FEB20 ZX392500 —UN—11FEB20 A—Pre-Cut Area B—Shim—5RKSC258-01G C—Mounting Plate—5RKSC258GR ZX392499 —UN—11FEB20 g. Drill a 10 mm (0.39 in) diameter hole (E), then attach the mounting plate (C) with one round head screw M10x25 and flange nuts (D). Continued on next page 5RKSC00201 (12MAY20) 26 OUCC002,0006518 -19-12MAY20-11/23 052020 PN=28 Seed Control Unit IMPORTANT: If necessary, remove the shims placed between the mounting plates (C) and the side walls so that the baffle (A) can be installed. D—Spring Locking Pin (4 used) E—Slots ZX401619 —UN—12FEB20 ZX392502 —UN—11FEB20 A—Baffle—5RKSC346GA B—Pin C—Mounting Plate ZX401618 —UN—11FEB20 h. Slide the hooked ends (see arrows) of the baffle 5RKSC346GA (A) over the pin (B) of both mounting plates (C). Ensure that the spring locking pins (D) are engaged into slots (E) of the mounting plates (C). Continued on next page 5RKSC00201 (12MAY20) 27 OUCC002,0006518 -19-12MAY20-12/23 052020 PN=29 Seed Control Unit 7. Install Chopper Assembly - Install the chopper assembly (A) and tailboard (B) on combine as follows: a. Install the shield 5RKCD757GA (C) around the drive sheave (D) with five round head screws M8x16 and flange nuts (E) as shown. NOTE: Round head screws and flange nuts (E) are part of the hardware bag SC263-08. ZX401620 —UN—11FEB20 NOTE: Depending on the fork length of the forklift, the tailboard (B) can be installed separately or attached to the chopper (A). b. Install the slider 5RKCD72901L (F) on the left-hand side lip (G) of the chopper (A) so that cutout in slider fits over the reinforcement plate on side wall (see arrow). F— Slider—5RKCD72901L (left-hand side) G—Lip (left-hand side) H—Slider—5RKCD72901R (right-hand side) I— Lip (right-hand side) ZX392506 —UN—11FEB20 ZX392505 —UN—11MAY20 A—Chopper Assembly B—Tailboard C—Shield—5RKCD757GA D—Drive Sheave E—Round Head Screw M8x16 and Flange Nut (5 used) ZX392504 —UN—11MAY20 c. Install the slider 5RKCD72901R (H) on the right-hand side lip (I) of the chopper (A) so that cutout in slider fits over the reinforcement plate on side wall (see arrow). Continued on next page 5RKSC00201 (12MAY20) 28 OUCC002,0006518 -19-12MAY20-13/23 052020 PN=30 ZX392508 —UN—11FEB20 Seed Control Unit A—Chopper Assembly B—Slide Rail (left-hand side-original) C—Spacer Plate (original) D—Attaching Screws (2 used-original) E—Attaching Screws (2 used-original) F— Attaching Screws (7 used-original) d. Lift the chopper assembly (A) up to the bottom of combine until the sliders are flush with underside of both side walls (see arrows). e. On the left-hand side, install the original left-hand slide rail (B) under the slider CD729-01L with the original spacer plate (C) between slide rail (B) and combine side wall, and the original hardware in the following order: NOTE: Use original hardware. 2. Install the two attaching screws and washers (E) and tighten to specified torque (refer to Section 120-Group 15 of the relevant Technical Manual). 3. Install the seven attaching screws and washers (F) and tighten by hand. 4. Check that the slide rail (B) is flush with the side wall. 5. Tighten screws (D) and (F) to specified torque (refer to Section 120-Group 15 of the relevant Technical Manual). f. Repeat on the right-hand side. 1. Install the two attaching screws and washers (D) and tighten by hand. Continued on next page 5RKSC00201 (12MAY20) 29 OUCC002,0006518 -19-12MAY20-14/23 052020 PN=31 Seed Control Unit h. Connect the original speed sensor connector (F) to the machine wiring harness (E). D—Position Sensor E—Wiring Harness (machine) F— Speed Sensor Connector (original) ZX401630 —UN—12FEB20 ZX401621 —UN—11FEB20 ZX392512 —UN—11FEB20 A—Actuator B—Flange Screw M12x60 (original) C—Spacer 0.5x1.0x0.313 in (original) ZX392509 —UN—11FEB20 g. Attach both actuators (A) on chopper frame using the original flange screw M12x60 (B) and the spacer (C) as shown, then connect the chopper position sensor (D) and the actuator to the machine wiring harness (E). Continued on next page 5RKSC00201 (12MAY20) 30 OUCC002,0006518 -19-12MAY20-15/23 052020 PN=32 Seed Control Unit 8. Install Speed Sensor - Install the speed sensor 5RKRP1124 (A) as follows: b. Remove the two front flange nuts (C), then install the bracket 5RKSC282G (D) as shown. Retain with flange nuts (C). C—Flange Nuts D—Bracket—5RKSC282G ZX392516 —UN—11FEB20 ZX392515 —UN—11FEB20 ZX392514 —UN—11FEB20 A—Speed Sensor—5RKRP1124 B—Shield ZX401622 —UN—11FEB20 a. Remove the original sensor shield (B) and keep hardware for further use. Continued on next page 5RKSC00201 (12MAY20) 31 OUCC002,0006518 -19-12MAY20-16/23 052020 PN=33 Seed Control Unit d. Install the speed sensor (D) onto bracket (C) using the two nuts (E), then adjust speed sensor (D) position so that a distance (X) of 1—3 mm (0.04—0.12 in) between tip of sensor (D) and pulse wheel (F) is achieved. e. Tighten flange nuts (G) to 215 N·m (159 lb·ft). f. Install and retain shield (B) back in place with original hardware. ZX392518 —UN—09MAY20 E—Adjusting Nuts F— Pulse Wheel G—Flange Nuts (original) X—Distance 1—3 mm (0.04—0.12 in) ZX392519 —UN—11FEB20 A—Hole—12.5 mm (0.5 in) B—Shield C—Bracket D—Speed Sensor ZX392517 —UN—11FEB20 c. Drill a 12.5 mm (0.5 in) diameter hole (A) on shield (B) in alignment with the speed sensor mount hole in bracket (C), then pass the speed sensor (D) through the hole (A). Continued on next page 5RKSC00201 (12MAY20) 32 OUCC002,0006518 -19-12MAY20-17/23 052020 PN=34 Seed Control Unit a. Ensure that the original drive belts (B), (C), and drive belt 5RKBE2C112K (D) are already placed on their relevant location on jackshaft sheaves (see Upgrade the Combine Straw Choppersection). b. Install the original low speed drive belt (B) onto large drive sheave on chopper. c. Install the drive belt (A) onto middle sheave on chopper. ZX401623 —UN—11FEB20 9. Install Drive Belts - Install the Seed Control Unit drive belt 5RKBE2C103K (A) as follows: d. Install the high speed drive belt (D) onto small sheave on chopper. e. Adjust relevant belt tensioners. C—Beater Drive Belt (original) D—2-Rib Drive Belt—5RKBE2C112K ZX392520 —UN—11FEB20 A—Drive Belt—5RKBE2C103K B—Low Speed Drive Belt (original) Continued on next page 5RKSC00201 (12MAY20) 33 OUCC002,0006518 -19-12MAY20-18/23 052020 PN=35 Seed Control Unit 10. Install Seed Control Unit - Install Seed Control Unit 5RKCD730GA (A) as follows: a. With the straw chopper in its rear most position, lift Seed Control Unit (A) up and align with the mounting holes on front of chopper. On both sides, remove the chopper door attaching screws (C) if necessary. b. Attach the Seed Control Unit (A) with four flange screws M12x25 and flange nuts (D) and reinstall the attaching screws (C). ZX392522 —UN—11FEB20 NOTE: Keep the SCU mounted on shipping frame (B) during installation. NOTE: Flange screws and nuts (D) are part of the hardware bag SC263-09. c. On both sides, remove the attaching screws (E), then remove the shipping frame (B). D—Flange Screw M12x25 and Flange Nuts E—Frame Attaching Screws ZX401624 —UN—11FEB20 ZX392523 —UN—12FEB20 A—Seed Control Unit—5RKCD730GA B—Shipping Frame C—Door Attaching Screw Continued on next page 5RKSC00201 (12MAY20) 34 OUCC002,0006518 -19-12MAY20-19/23 052020 PN=36 Seed Control Unit d. On the left-hand side, with the locking pins (A) of the chaff door (B) latched, adjust the angle (C) position so that the magnet (D) is aligned with the proximity sensor 5RKRP1125 (E). D—Magnet E—Sensor—5RKRP1125 X—Distance 1—3 mm (0.04—0.12 in) ZX401626 —UN—12FEB20 A—Locking Pin (2 used) B—Chaff Door C—Angle ZX401625 —UN—12FEB20 e. Adjust proximity sensor (E) position so that a distance (X) of 1—3 mm (0.04—0.12 in) between tip of sensor (E) and magnet (D) is achieved. Continued on next page 5RKSC00201 (12MAY20) 35 OUCC002,0006518 -19-12MAY20-20/23 052020 PN=37 Seed Control Unit f. Install backside shield 5RKCD758G (A) with three round head screws M8x25 and flange nuts (B) as shown. ZX405190 —UN—11MAY20 g. Install the drive belt (C) on Seed Control Unit drive sheave (D), then adjust tensioner (E). h. Install the original shield (F) on shield (G) using original hardware. i. Install the drive shield 5RKCD732GA (H) with two flange screws M8x16 (I) and two flange nuts M8 (J) as shown. NOTE: Screws (B), (I) and nuts (J) are part of the hardware bag SC263-10. ZX392524 —UN—11MAY20 F— Shield (original) G—Shield H—Shield—5RKCD732GA I— Flange Screw M8x16 (2 used) J— Flange Nut M8 (2 used) ZX392529 —UN—11MAY20 ZX392528 —UN—11MAY20 A—Backside—5RKCD758G B—Rounded Head Screw and Flange Nut M8x25 (3 used) C—Drive Belt D—Drive Sheave E—Tensioner Continued on next page 5RKSC00201 (12MAY20) 36 OUCC002,0006518 -19-12MAY20-21/23 052020 PN=38 j. Machine with Advanced PowerCast™ Tailboard Only: Place and center the cover 5RKCD672G (A) on jackshaft shield (B), then drill three 8 mm (0.3 in) diameter holes on shield (B) using cover as a template. Attach cover (A) with three round head screws M8x16 and flange nuts (C). NOTE: Round head screws (C) and nuts are part of the hardware bag SC263-10. A—Cover—5RKCD672G B—Shield C—Round Head Screw M8x16 and Flange Nut (3 used) ZX392526 —UN—11FEB20 Seed Control Unit k. On both side of the machine, attach one axle stop AN233321 (A) on rear steering cylinder rod (B) as shown, then make sure that when the rear wheels are fully steered to the left- and right-hand side, there is a minimal clearance (X) of 50 mm (2 in) between tire (C) and shield (D). NOTE: The axle stop (A) must be ordered separately through regular parts channel. To ensure the minimal clearance (X) of 50 mm (2 in), order as many as necessary stops. D—Shield X—Clearance—Minimal 50 mm (2 in) ZX392531 —UN—11FEB20 A—Axle Stop—AN233321 B—Cylinder Rod C—Tire ZX392530 —UN—11FEB20 OUCC002,0006518 -19-12MAY20-22/23 OUCC002,0006518 -19-12MAY20-23/23 5RKSC00201 (12MAY20) 37 052020 PN=39 Seed Control Unit ZX392534 —UN—12FEB20 ZX401627 —UN—12FEB20 Install Controller and Wiring Harness Install the Redekop™ electrical components in the following order. 1. Install the Redekop™ controller 5RKRP1021 (A) and the bracket 5RKSC297G (B) as follows: b. Attach with one flange screw M8x20 and flange nut (C), and one flange screw M10x20 and flange nut (D). c. Drill a 10 mm (0.39 in) diameter hole through the attaching hole (E), then attach the bracket (B) with one flange screw M10x20 and flange nut (D). d. Install the Redekop™ controller (A) on the bracket (B) using two round head screws M6x16 and flange nuts (F) so that connector receptacles of the controller are facing downward (see arrows). e. To avoid contact between the fuel line (G) and the controller (A), disconnect the clamp (H) and reinstall using the spacer 5RKCS856Z (I), two washers (J), and one flange screw M8x45 and flange nut (K) as shown. G—Fuel Line H—Clamp I— Spacer—5RKCS856Z J— Washer (2 used) K—Flange Screw M8x45 and Flange Nut ZX392538 —UN—12FEB20 A—Controller—5RKRP1021 B—Bracket—5RKSC297G C—Flange Screw M8x20 and Flange Nut D—Flange Screw M10x20 and Flange Nut (2 used) E—Attaching Hole F— Round Head Screw M6x16 and Flange Nut (2 used) Continued on next page 5RKSC00201 (12MAY20) ZX392537 —UN—12FEB20 ZX392536 —UN—12FEB20 a. Place the bracket (B) on the right-hand rear side wall above the chopper as shown. 38 OUCC002,0006519 -19-09MAY20-1/6 052020 PN=40 Seed Control Unit 2. Install the main wiring harness 5RKRP1022 (A), the adapter wiring harness 5RKRP1030 (B), and the chopper wiring harness 5RKRP1123 (C) as follows: C—Wiring Harness—5RKRP1123 (chopper) ZX401628 —UN—12FEB20 A—Wiring Harness—5RKRP1022 (controller power/cab) B—Wiring Harness—5RKRP1030 (adapter) Continued on next page 5RKSC00201 (12MAY20) 39 OUCC002,0006519 -19-09MAY20-2/6 052020 PN=41 ZX392541 —UN—12FEB20 Seed Control Unit A—Wiring Harness—5RKRP1022 F— Connector (wiring harness B—Controller 5RKRP1022) C—Cab Junction Box G—Adapter HarD—Power Line Part ness—5RKRP1030 E—Connector (machine harness) H—Connector (adapter harness 5RKRP1030) a. Route the wiring harness 5RKRP1022 (A) along the right side of the combine from controller (B) to the junction box (C) behind the cab as shown. Secure the wiring harness (A) on existing machine harness or hydraulic lines using tie bands. b. Connect the wiring harness (A) to the free mating receptacle on controller (B). c. At “T” location of the wiring harness (see arrow), route the “power line” part (D) underneath the combine up to the battery box on the left-hand side of the machine. Do not yet connect the part (D) to battery at this stage. I— Connector (wiring harness 5RKRP1022) J— Connector (adapter harness 5RKRP1030) K—Connector (adapter harness 5RKRP1030) e. Connect the connector (E) to free mating connector (F) of the adapter harness 5RKRP1030 (G). f. Connect the connector (H) of the adapter harness 5RKRP1030 (G) to free receptacle of the connector (E) on the junction box. g. Connect the connector (I) of the wiring harness 5RKRP1022 (A) to the free mating connector (J) of the adapter harness 5RKRP1030 (G). h. Connect the connector (K) of the adapter harness 5RKRP1030 (G) to the spare power plug with "Blue" label in back of pillar. d. Disconnect the machine harness connector (E) from the junction box (C). Continued on next page 5RKSC00201 (12MAY20) 40 OUCC002,0006519 -19-09MAY20-3/6 052020 PN=42 Seed Control Unit i. When the connector (A) of the adapter harness 5RKRP1030 (B) is in the correct power plug (C), then both indicator lights (D) on controller (E) light up. D—Indicator Lights (CAN and power ON) E—Controller ZX392544 —UN—12FEB20 A—Connector (adapter harness 5RKRP1030) B—Adapter Harness—5RKRP1030 C—Power Plug (machine harness) ZX401629 —UN—12FEB20 IMPORTANT: If indicators lights (D) do not light up, then try connecting connector (A) to an alternate power plug in back of pillar. OUCC002,0006519 -19-09MAY20-4/6 j. Connect the red cable (A) of the wiring harness 5RKRP1022 (B) to the (+) terminal (C), and the black cable (D) of the wiring harness 5RKRP1022 (B) to the (-) terminal (E) on the battery box (F) as shown. Secure the cables (A) and (D) to the machine wiring harness using tie bands. D—Cable—Black (-) E—Terminal (-) F— Battery Box ZX392545 —UN—12FEB20 A—Cable—Red (+) B—Wiring Harness—5RKRP1022 C—Terminal (+) Continued on next page 5RKSC00201 (12MAY20) 41 OUCC002,0006519 -19-09MAY20-5/6 052020 PN=43 Seed Control Unit k. Route and secure the chopper wiring harness 5RKRP1123 (A) in such a way that it is not damaged when actuator (B) is fully extended. l. Connect the connector (C) of the wiring harness 5RKRP1123 (A) to the free mating receptacle of the controller. m. Connect the connector (D) of the wiring harness 5RKRP1123 (A) to the Seed Control Unit wiring harness (E). n. Connect the connector (F) of the wiring harness 5RKRP1123 (A) to the speed sensor (G). E—Wiring Harness (SCU) F— Connector (to speed sensor) G—Speed Sensor ZX401631 —UN—12FEB20 A—Wiring Harness—5RKRP1123 (chopper) B—Actuator C—Connector (to controller) D—Connector (to SCU) OUCC002,0006519 -19-09MAY20-6/6 5RKSC00201 (12MAY20) 42 052020 PN=44 Seed Control Unit Activate the Redekop™ Seed Control Unit and Configure Tailboard Activate the Redekop™ Seed Control Unit ZX405195 —UN—12MAY20 To activate the Redekop™ Seed Control Unit, a Run page must be created. To setup a Run Page, access the Setup Page, and enter the required software activation codes. Refer to the “Seed Control Unit Monitoring” section in the Redekop™ Seed Control Unit Operator’s Manual. From the Setup Screen, press the blue area of SC Unit1 (A) option that is connected to the system. NOTE: “Uninstalled” is displayed until appropriate software code of the option is installed. To install the option that is connected to the system, proceed as follows: ZX405196 —UN—12MAY20 1. Press the "Uninstalled" blue area beside the option (A) that must be installed 2. Screen displays “00000”. To enter a new code, select numbers on sidebar. Input SCU Code: 53235 3. Confirm code with checkmark (B). Option now states "Installed" A—SC Unit Configure Tailboard To setup the tailboard configuration, it is necessary to reach the CAB 112 or CAB 118 addresses on Cab Controller (CAB 001). B—Checkmark 3. Select Diagnostic Center. 4. Select Controller Diagnostics. NOTE: Also refer to the combine Operator’s Manual. 5. Select Cab Controller (CAB 001). Proceed as follows: 6. Scroll and select line #118 or #112. Record the value displayed. 1. Select Menu icon. 2. Select System. Refer to chart for the value description. Continued on next page 5RKSC00201 (12MAY20) 43 OUCC002,000651B -19-14MAY20-1/2 052020 PN=45 Seed Control Unit Control Unit Address Display Access Level Description CAB 112 XXXXnXXX INPUT Chopper option CAB 118 XXXXXXnX INPUT Spreader control configuration 7. Select Value to input new number. • For line #118, change the 2nd last number to “0” or Details 0 = Disabled 1 = Enabled 0 = No electrical control 1 = Premium spreader control. 2 = Straw spreaders. Left and right chaff spreader speed adjusted together. No wind compensation. 3 = North American PowerCast and chaff spreaders. Left and right spreader speed adjusted separately for wind compensation. 4 = Dual Advanced PowerCast control 5 = Single Advanced PowerCast control. 6 = Maxi spreader Rekord independent left/right control 7 = Chaff spreader with speed sensor installed 8 = Both maxi spreader and chaff spreader with speed sensor installed 8. Accept and store new numbers, then return to Home page. for line #112, change the the 4th last number to a “1”. 1 SC=Seed Control OUCC002,000651B -19-14MAY20-2/2 Reinstall Necessary Parts and Check Function Reinstall necessary parts. IMPORTANT: Once all the component assemblies have been installed, do an operational check. Connect battery. Check new function. AK53658,0000D16 -19-18OCT19-1/1 Access and Delete any Diagnostic Trouble Codes Diagnostic trouble codes may be generated while programming is in progress. Access the diagnostic trouble codes (if any) and delete. If, after programming, diagnostic trouble codes appear that indicate that a function has not been calibrated, the relevant calibration must be performed. For instructions on calibration, see relevant Diagnostic Technical Manual, Section 245. AK53658,0000C4D -19-18OCT19-1/1 5RKSC00201 (12MAY20) 44 052020 PN=46 Seed Control Unit ZX401523 —UN—08FEB20 Parts List for Redekop™ Seed Control Unit Attachment Parts List for Redekop™ Seed Control Unit Attachment—Part 1 Item Part no. Designation Quantity 1 5RKH38 Swivel Fitting 1 2 5RKH122 Hydraulic Hose Continued on next page 5RKSC00201 (12MAY20) 45 1 OUCC002,0006516 -19-12MAY20-1/4 052020 PN=47 Seed Control Unit Item Part no. Designation Quantity 3 4 5RKH123 Hydraulic Hose 1 H227595 Drive Sheave (4-groove) 1 5 H240899 V-Belt (4-rib) 1 6 5RKBE2C112K V-Belt (2-rib) 1 7 5RKCD754GA Chaff Door assembly 1 8 5RKCD723G Chopper Knife Floor 1 9 5RKCD725G Knife Bar Guard 1 10 5RKCD72901R Slider (right-hand side) 1 11 5RKCD72901L Slider (left-hand side) 1 12 5RKCD724GAK Counterknife Assembly 1 13 5RKCD740GA Tab Proximity Sensor Assembly 1 14 5RKCD666GA Counterknife Handle 1 15 5RKCD727GL Reinforcement Plate (left-hand side) 1 16 5RKCD727GR Reinforcement Plate (right-hand side) 1 17 SC263-02 Hardware Bag (for pos. 8, 9, 12, 13, 14, 15, and 16) 1 18 5RKRP988 Drive Sheave—High Speed 1 19 5RKRP968 Drive Sheave 1 20 5RKSC200G Beater Extension 1 21 5RKCD733G Beater Fin 2 22 SC263-03 Hardware Bag (for pos. 19 and 20) 1 23 5RKCD691G Grain Loss Guard 2 24 5RKSC283G Seed Loss Deflector 2 25 5RKSC307G Sieve Cover 1 26 5RKSC340GA Sieve Extension Assembly 1 27 SC263-04 Hardware Bag (for pos. 23) Continued on next page 5RKSC00201 (12MAY20) 46 1 OUCC002,0006516 -19-12MAY20-2/4 052020 PN=48 ZX401617 —UN—12MAY20 Seed Control Unit Parts List for Redekop™ Seed Control Unit Attachment—Part 2 Item Part no. Designation 1 5RKSC251G Cover Plate 1 2 SC263-05 Hardware Bag (for pos. 1) 1 3 5RKSC277GA Inspection Door Continued on next page 5RKSC00201 (12MAY20) 47 Quantity 1 OUCC002,0006516 -19-12MAY20-3/4 052020 PN=49 Seed Control Unit Item Part no. Designation Quantity 4 5 HXE73659 Vent Cover 8left-hand side) 1 HXE73660 Vent Cover (right-hand side) 1 6 5RKSC302G Cover 1 7 5RKSC281G Cover (left-hand side) 1 8 5RKSC303G Cover (front right-hand side) 1 9 5RKSC304G Cover (rear right-hand side) 1 10 SC263-06 Hardware Bag (for pos. 6, 7, 8, and 9) 1 11 5RKSC258-01G Shim 2 12 5RKSC258GL Internal Baffle Mounting Plate (left-hand side) 1 13 5RKSC258GR Internal Baffle Mounting Plate (right-hand side) 1 14 5RKSC346GA Internal Baffle 1 15 SC263-07 Hardware Bag (for pos. 11, 12, 13, and 14) 1 16 5RKCD757GA Shield 1 17 SC263-08 Hardware Bag (for pos. 16) 1 18 5RKSC282G Speed Sensor Bracket 1 19 5RKRP1124 Speed Sensor Assembly (with adjusting nuts) 1 20 5RKCD730GA Seed Control Unit Assembly 1 21 SC263-09 Hardware Bag (for pos. 20) 1 22 5RKCD732GA Shield 1 23 5RKCD672G Cover 1 24 SC263-10 Hardware Bag (for pos. 22 and 23) 1 25 5RKSC297G Controller Bracket 1 26 5RKRP1021 SCU Controller 1 27 5RKCS856Z Spacer 1 28 5RKRP1022 Wiring Harness (controller power/cab) 1 29 5RKRP1030 Wiring Harness Adapter 1 30 5RKRP1123 Wiring Harness (chopper) 1 31 5RKSC320Z Bushing 2 32 5RKCD758G Backside Drive Shield 1 5RKSC00201 Installation Instructions 1 OUCC002,0006516 -19-12MAY20-4/4 5RKSC00201 (12MAY20) 48 052020 PN=50 Seed Control Unit 5RKSC00201 (12MAY20) 49 052020 PN=51 Seed Control Unit 5RKSC00201 (12MAY20) 50 052020 PN=52