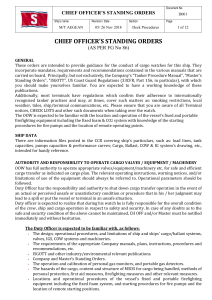

Document No. OIL TRANSFER PROCEDURE Ship’s name “AEGEAN” Revision / Date 2 / 26 Nov 2018 Section Deck Procedures D002 Page 1 of 4 OIL TRANSFER PROCEDURES These procedures apply to all cargo oil transfers either to or from the vessel and internal cargo transfer operations RESPONSIBILITIES The designated person in charge of cargo oil transfer operations is the Chief Officer. Responsible to the Master. He shall immediately inform the Master of any deficiencies, emergencies or breakdown during operations. Personnel assisting with cargo oil transfer operations include Deck Officers, Engineer Officers, Pumpman, Bosun and deck ratings. SAFETY HAZARDS The Chief Officer shall ensure that all the relevant material safety data sheets (MSDS) are prominently displayed in the CCR for all cargo carried on board. A list of cargo carried on board shall be attached to the safety data sheets. Special consideration shall be given to ‘sour’ crude oils, i.e. those which may generate high levels of hydrogen sulphide gas. CARGO SYSTEM / OIL TRANSFER SYSTEM The tank system of this vessel consists of 5 Centre & 10 Wings cargo tanks (5 pairs) having a total capacity of 335323.1 m3 and two slop tanks of total capacity equal to 9509.6 m3. Slop tanks are located at the aft end of the cargo space, one on each side. Cargo discharge is accomplished by 3 centrifugal steam turbine driven cargo pumps. Each pump has capacity of 5000 m3/h at 150 mTH. There are, also, a piston reciprocating stripping pump (400 m3/h at 150 mTH) and 2 (two) cargo educator (each 600 m3/h at 30 mTH, driven by cargo from cargo pumps). Each pair of cargo pumps is connected by 650 mm bore piping to crossover manifold located amidships. There are three 650 mm bore piping loading/discharging each pair of cargo tanks (port and starboard) in a separate segregation. In addition, the slop tanks are connected to the segregation. The cargo tanks are organised in three groups. Group 1 consists of COTs 1, 2 & 4 (C) + COTs 5 (P&S); Group 2: COT 3 (C) + COTs 1 & 4 (P&S) + Slop (P&S); Group 3: COT 5 (C) + COTs 2 & 3 (P&S). The cargo loading and discharging system is arranged so that the independent pipeline from each group of cargo tanks (P&S) is led to crossover manifold, forming a total of 3 segregations. Each segregation is linked to its own manifold, one on each side amidships. The manifold valves are of the butterfly type manually operated. Drainage from all manifolds leads to Marpol line. Last remains of cargo are pumped via the Marpol stripping line to the manifold and it is discharged ashore. Refer to schematic diagram from CCR and to the COW operations and equipment manual. THE BALLAST SYSTEM Ballast system is totally segregated comprising of fore peak, 5 sets of double bottom and double side/wing tanks, and aft peak tank, water ballast tanks capacity (including peak tanks) is 90823.6 m3. This is serviced by two dedicated ballast pumps, vertical centrifugal single stage, (both electrical motor driven) each having capacity of 3000m3/h at 30 mTH plus a 500 m3/h at 25 mTH ballast eductor. There are no permanent connections between cargo and seawater ballast system (spool piece should be used for this connection). Document No. OIL TRANSFER PROCEDURE Ship’s name “AEGEAN” Revision / Date 2 / 26 Nov 2018 Section Deck Procedures D002 Page 2 of 4 PERSONNEL ON DUTY DURING CARGO TRANSFER OPERATIONS Chief Officer, as required. Deck officer on watch CCR Engineer officer on watch ECR. Pumpman, as required Two or three deck ratings on watch at Chief Officer’s discretion. CCR will be at no time left unattended. COMMUNICATIONS Communications from CCR to manifold, deck watch personnel, and ECR are carried out, in English, by portable radio or telephone as appropriate. Means of communications between vessel and terminal or lightering vessel must be established prior to commencing cargo transfer operations, wherever possible primary communications should be by radio. Means of communications should be tested periodically throughout the cargo operation. CARGO TRANSFER SYSTEMS The Chief Officer will ensure that all cargo valves and piping systems are correctly set prior to the commencement of any oil cargo transfer operation. All tank I.G. branch valves are to be checked and confirmed open. This should also be checked and confirmed by the Duty Officer. CARGO TRANSFER Prior to commencing any cargo transfer, the Chief Officer shall ensure that rates are agreed for initial loading, maximum permissible loading rate and maximum rate during topping off, if possible in writing, with the terminal representative or the responsible officer for the lightering vessel. Initial transfer rates should not exceed the rate agreed by pre-transfer consultation. After it has been confirmed by all concerned parties that the initial transfer is satisfactory and that the rate may be increased, the rate may be increased to the agreed maximum transfer rate as agreed by pre transfer consultation. Prior to topping off tanks during cargo transfer the Chief Officer will ensure that contact is maintained with the shore terminal or lightering vessel and that agreed rates required for topping off are strictly adhered to. After completion of cargo transfer operations the Chief Officer shall ensure that all cargo and ballast valves used during the transfer are in a closed position. DUTIES OF PERSONNEL ON WATCH Moorings to be attended regularly and adjusted as necessary with change of drafts / tides. All moorings to be kept taught with equal strain. Vessel to be kept alongside berth. Fire wires are to be correctly rigged and adjusted as required (if applicable). The gangway is to be tended regularly and gangway net adjusted as required. The cargo pumps and hydraulic room should be checked hourly. Check the water around the vessel for any signs of pollution and report any findings. When made fast to an SBM a continuous watch should be maintained on the buoy. The bow watchman should report the location of the buoy to the CCR as required. A continuous manifold watch is to be maintained during loading or discharging. Manifold pressures are to be monitored and any changes reported to the CCR. The Chief Officer will ensure that the ratings on watch are adequately instructed and that they understand their obligations and duties, the deck officer on duty shall ensure that the ratings on watch carry out their duties. A list of officers, petty officers and ratings with their names and duties will be placed on a notice board in alleyway close to CCR or in CCR itself. Document No. OIL TRANSFER PROCEDURE Ship’s name “AEGEAN” Revision / Date 2 / 26 Nov 2018 Section Deck Procedures D002 Page 3 of 4 CARGO TANK OPENINGS Openings include: tank lids; sounding caps; and Butterworth lids The Chief Officer shall ensure that all openings are closed prior to the commencement of any cargo transfer. This should also be confirmed by the duty officer. The Chief Officer shall confirm the integrity of all opening lids prior to arrival at each port. Where required to be opened for operational reasons, openings shall only be opened under the direction of the Chief Officer, openings shall be closed as soon as possible and openings shall not be left unattended to any space containing cargo oil. Openings shall be closed prior to the commencement of any helicopter operations and shall remain closed for the duration of any such operation. Openings shall be closed during all close operations with tugs, stand by vessels, and other craft, and during mooring and unmooring of lightering vessels. EMERGENCY SHUTDOWN – SEE ALSO CARGO EMERGENCY CONTINGENCIES In the event of an emergency requiring cessation of transfer operations the following steps will be undertaken. Loading: Watch keeping officer or Chief Officer will contact loading master or terminal representative or implement agreed emergency signal to immediately cease loading cargo. Cargo system valves should not be closed against a loading operation until it has been confirmed by the terminal that it is safe to do so. Discharging: Watch keeping officer or Chief Officer will stop cargo pumps by means of emergency trips in CCR, front of Pumproom or at manifold and advice parties concerned as soon as possible i.e. receivers, Engine room staff. Cargo system valves may be closed as soon as pumps are stopped. OIL CONTAINMENT In the event of an oil spillage Emergency Alarms MUST be sounded The manifold containment system on this vessel consists of save all trays permanently constructed under the manifold area. The save all trays are permanently connected to the COTs 4 (P&S) by steel piping and an associated valve system. Oil may be drained to COTs 4 (P&S) should it be required to drain the manifold save all trays. The Chief Officer will ensure that: In the event of oil spillage or potential oil spillage into the deck containment area all cargo operations shall be immediately suspended. Manifold save all trays are empty and ready for use. Prior to transferring cargo he will ensure the valves and pipelines for draining the drip trays into COTs 4 (P&S) are in working order. Scupper plugs on the main deck are in position and effectively sealed. Oil pollution clean-up equipment and materials are readily available in strategic positions. The watch keeping officer and petty officers and deck watch understand the operation of drain valves and pipelines from manifolds drip trays to COTs 4 (P&S) . The vessel is also fitted with salvage pump ready for discharge oil into the Slop tank (Stbd) and in case of a large spill on deck this can be used to pump the oil into the appropriate tank. Also vessel if fitted with dump valves, which can be used for draining spilled oil into Slop (P&S). Document No. OIL TRANSFER PROCEDURE Ship’s name “AEGEAN” Revision / Date 2 / 26 Nov 2018 Section Deck Procedures D002 Page 4 of 4 CLEAR UP OF DECK CONTAINMENT AREA The Master and the Chief Officer will ensure that sufficient crewmen are available on board to deal with any oil spills, within the deck containment area. The Chief Officer shall supervise and control the vessel's response to an oil spill as laid down in the Vessel Response Plan or in the Shipboard Oil Pollution emergency plan manual M008 as appropriate. MARINE OIL POLLUTION OR SUSPECTED MARINE OIL POLLUTION If occur the Chief Officer or OOW will immediately stop all cargo operations and then close all cargo system valves. There after he/she will inform the Master and all parties concerned locally and commence oil spill clean-up operations. The Master will notify all interested parties as required by the Vessel's Response Plan or the Shipboard Oil Pollution Emergency Plan Manual M008 as appropriate. ADDITIONAL REFERENCES ISGOTT NMM Tanker Procedures Manual (M103) COW operations and equipment manual Chief Officer’s Standing Orders Cargo Emergency Contingencies Cargo Material Safety Data Sheets