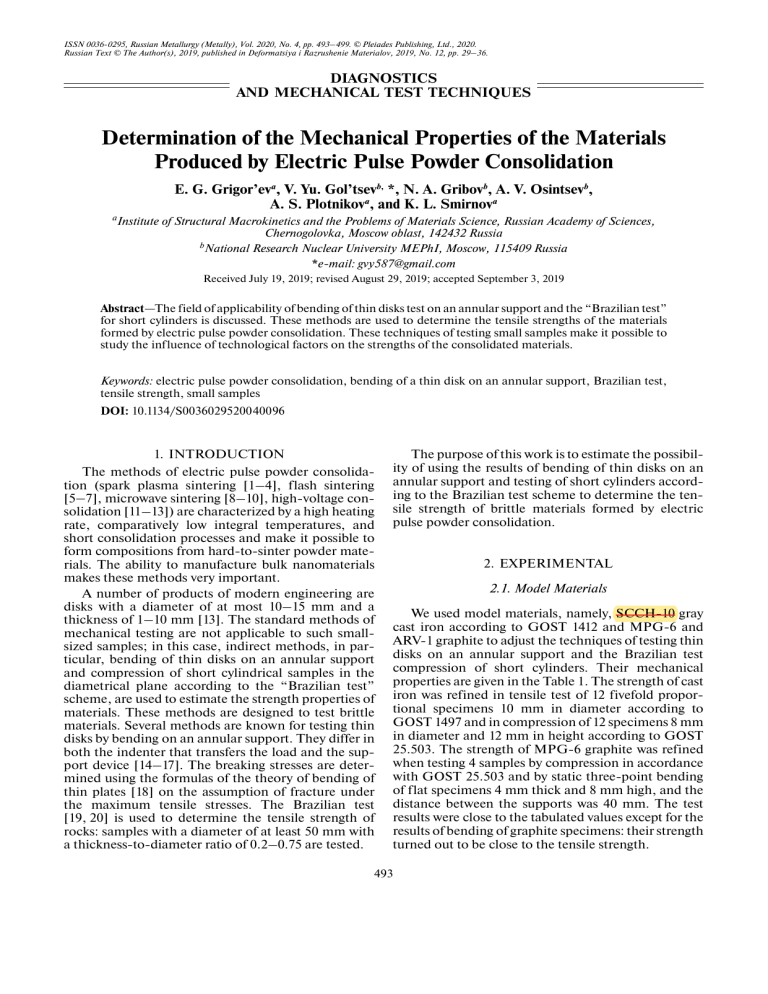

ISSN 0036-0295, Russian Metallurgy (Metally), Vol. 2020, No. 4, pp. 493–499. © Pleiades Publishing, Ltd., 2020. Russian Text © The Author(s), 2019, published in Deformatsiya i Razrushenie Materialov, 2019, No. 12, pp. 29–36. DIAGNOSTICS AND MECHANICAL TEST TECHNIQUES Determination of the Mechanical Properties of the Materials Produced by Electric Pulse Powder Consolidation E. G. Grigor’eva, V. Yu. Gol’tsevb, *, N. A. Gribovb, A. V. Osintsevb, A. S. Plotnikova, and K. L. Smirnova a Institute of Structural Macrokinetics and the Problems of Materials Science, Russian Academy of Sciences, Chernogolovka, Moscow oblast, 142432 Russia b National Research Nuclear University MEPhI, Moscow, 115409 Russia *e-mail: [email protected] Received July 19, 2019; revised August 29, 2019; accepted September 3, 2019 Abstract—The field of applicability of bending of thin disks test on an annular support and the “Brazilian test” for short cylinders is discussed. These methods are used to determine the tensile strengths of the materials formed by electric pulse powder consolidation. These techniques of testing small samples make it possible to study the influence of technological factors on the strengths of the consolidated materials. Keywords: electric pulse powder consolidation, bending of a thin disk on an annular support, Brazilian test, tensile strength, small samples DOI: 10.1134/S0036029520040096 1. INTRODUCTION The methods of electric pulse powder consolidation (spark plasma sintering [1–4], flash sintering [5‒7], microwave sintering [8–10], high-voltage consolidation [11–13]) are characterized by a high heating rate, comparatively low integral temperatures, and short consolidation processes and make it possible to form compositions from hard-to-sinter powder materials. The ability to manufacture bulk nanomaterials makes these methods very important. A number of products of modern engineering are disks with a diameter of at most 10–15 mm and a thickness of 1–10 mm [13]. The standard methods of mechanical testing are not applicable to such smallsized samples; in this case, indirect methods, in particular, bending of thin disks on an annular support and compression of short cylindrical samples in the diametrical plane according to the “Brazilian test” scheme, are used to estimate the strength properties of materials. These methods are designed to test brittle materials. Several methods are known for testing thin disks by bending on an annular support. They differ in both the indenter that transfers the load and the support device [14–17]. The breaking stresses are determined using the formulas of the theory of bending of thin plates [18] on the assumption of fracture under the maximum tensile stresses. The Brazilian test [19, 20] is used to determine the tensile strength of rocks: samples with a diameter of at least 50 mm with a thickness-to-diameter ratio of 0.2–0.75 are tested. The purpose of this work is to estimate the possibility of using the results of bending of thin disks on an annular support and testing of short cylinders according to the Brazilian test scheme to determine the tensile strength of brittle materials formed by electric pulse powder consolidation. 2. EXPERIMENTAL 2.1. Model Materials We used model materials, namely, SCCH-10 gray cast iron according to GOST 1412 and MPG-6 and ARV-1 graphite to adjust the techniques of testing thin disks on an annular support and the Brazilian test compression of short cylinders. Their mechanical properties are given in the Table 1. The strength of cast iron was refined in tensile test of 12 fivefold proportional specimens 10 mm in diameter according to GOST 1497 and in compression of 12 specimens 8 mm in diameter and 12 mm in height according to GOST 25.503. The strength of MPG-6 graphite was refined when testing 4 samples by compression in accordance with GOST 25.503 and by static three-point bending of flat specimens 4 mm thick and 8 mm high, and the distance between the supports was 40 mm. The test results were close to the tabulated values except for the results of bending of graphite specimens: their strength turned out to be close to the tensile strength. 493 494 GRIGOR’EV et al. Table 1. Strengths of the model materials under various loading conditions Material bend σcomp , σtens , τsh u u , σu f , Source MPa MPa MPa MPa SSch-10-40 cast iron 530 100 MPG-6 graphite 73.6 25 ARV-1 graphite 45 12 280 34.3 15 110 — — [21] [22] [23] The letters in subscript indicate the type of loading: comp. stands for compression; tens, for tension; bend., bending; and sh., shear. 2.2. Aluminum Dioxide We used the following two powder fractions formed by oxidation of dispersed aluminum in the air plasma of an electric arc discharge: nanosized and ultradispersed (UD) fractions with an average particle size of 45 and 150 nm, respectively. The particles had a spherical shape. The specific surface area of the nanopowder was 35.8 m2/g and that of the UD powder was 10.1 m2/g. The powders were consolidated by sparkplasma sintering in a SPS Labox 625 (Sinter Land Inc., Japan) setup in graphite equipment in vacuum at a pressure of 50 MPa, a heating rate of 100°C/min, the maximum temperature of 1400°C, and a holding time of 10 min at the maximum temperature. 2.3. Composite Ceramic β-Si5AlON7 (SiC, TiN, BN, Y2O3) The powders of the initial refractory compounds were formed by self-propagating high-temperature synthesis. The sintering of β-Si5AlON7 and h-BN powders was based on filtration combustion in nitro- gen of reaction mixtures containing silicon, aluminum, and boron. The initial nitrogen pressure in the reactor was 8–10 MPa. To ensure the necessary degree of conversion of the combustible components, a diluent (namely, β-Si5AlON7 and h-BN powders) was additionally introduced into the composition of the reaction mixtures. According to X-ray diffraction (XRD) results, the initial β-Si5AlON7, h-BN, and TiN powders did not contain impurity phases, and insignificant traces of residual β-Si3N4 powder were noted in the composition of the β-SiC powder. The preparation of sintering mixtures was combined with grinding of the synthesized powders and was carried out in a high-speed planetary mill. The specific surface area of the mixtures after this treatment increased by a factor of 4–6. The following conditions of sintering of β-Si5AlON7-based powder compositions were used: heating from room temperature to 600°C without loading followed by heating to 1550– 1800°C at a pressure of 50 MPa. The heating rate was 50°C/min and the holding time at the maximum temperature was 5 min. Sintering was carried out in an SPS Labox 625 setup. 2.4. VNZh-90 Alloy The samples of a heavy tungsten alloy were prepared by high-voltage consolidation from an industrial powder of the following composition (wt %): 6.93 Ni, 3.12 Fe, W for balance. The powder was formed by mechanical mixing of the components. The theoretical density of the powder was 17.13 g/cm3 at an average particle size of 6.03 μm. The shape of the particles was close to spherical and partial agglomeration took place (Fig. 1). XRD analysis revealed the presence of FeNi3. We studied various consolidation conditions and varied the applied voltage from 4.5 to 5.8 kV and the pressure from 100 to 250 MPa. 2.5. Tests of Thin Disks on an Annular Support We used the technique of loading a disk on an annular support described in [14]. The loading scheme is shown in Fig. 2. The tests were carried out using an Instron machine. The calculation of the breaking stress was carried out according to the formula () 50 µm Fig. 1. VNZh alloy powder (scanning electron microscopy). 2 ⎡ ⎤ (1) σ = 3P 2 ⎢4 − (1 − μ ) d + 4 (1 + μ ) ln D ⎥ , D d⎦ 8πh ⎣ where P is the maximum load during the fracture of the sample, D is the inside diameter of the support ring, d is the diameter of the flat indenter; h is the sample thickness, and μ is Poisson’s ratio. The formula was obtained under the assumption that the contact pressure is uniformly distributed over the contact spot of the indenter with the disk and the disk is hinged against the inner edge of the ring support. In addition, the diameter of the disk was assumed RUSSIAN METALLURGY (METALLY) Vol. 2020 No. 4 DETERMINATION OF THE MECHANICAL PROPERTIES OF THE MATERIALS 495 Y P Z X 1 2 h 3 d 4 Fig. 3. Calculation model for testing short cylinders according to the Brazilian test scheme. D Fig. 2. Scheme of testing a disk on an annular support in loading by a flat-tip indenter: (1) indenter, (2) holder, (3) sample, and (4) support ring. to be slightly larger than the inner diameter of the annular support. An analysis of the state of stress of the model sample, which was performed using the verified ANSYS Mechanical calculation complex of version 16.2 [24, 25], showed the presence of a triaxial state of stress in the indenter–disk contact interaction region. On the reverse side of the disk (as would be expected), a plane stress state arises with the maximum circumferential tensile stresses, which are the cause of brittle fracture of the sample [26]. Fracture nucleation is possible under the maximum tangential stresses in the near-contact zone of loading. 2.6. Brazilian Test The ultimate tensile strengths of the materials under study were determined during compressive tests according to the Brazilian test technique. Short cylindrical samples were loaded by uniformly distributed forces along diametrical generatrices with (Fig. 3). The strength of the material was determined by the formula [20] σt = 2P , πtD RUSSIAN METALLURGY (METALLY) (2) Vol. 2020 No. 4 where P is the maximal load to be withstood by the sample and t and D are the sample thickness and diameter, respectively. The possibility of applying this method to materials of a nongeological origin was substantiated in [27]. A calculation analysis with the study of the effect of the thickness-to-diameter ratio of the cylinder on the maximum tensile stresses showed that parameter σt is a good estimate of the first principal stress averaged in the YZ plane of the cylinder (see Fig. 3). As a result of simulation, we found that the local maximum principal stresses can exceed the average σt stresses by a factor of 2.5. This finding can affect the applicability of Eq. (2) to brittle materials sensitive to stress concentration. 3. RESULTS AND DISCUSSION 3.1. Analysis of the Field of Application of the Technique of Bending Thin Disks on an Annular Support We tested disks 10–15 mm in diameter and 1– 1.5 mm in thickness made of SCh-10 cast iron and disks 15 mm in diameter and 1.7–1.8 mm in thickness made of MPG-6 graphite. The test results indicate no brittle fracture of the cast iron samples and brittle fracture of the graphite samples (Figs. 4, 5). The presence of a smooth decrease in the load after the maximum in the bending diagram of the cast iron disks (see Fig. 4a) is associated with slow controlled growth and opening of cracks under tensile stresses. In the process of deformation, a cast-iron disk bends, which is unacceptable in determining the strength of a brittle material, and the disk material is indented in the indenter contact area. In this case, circumferential 496 GRIGOR’EV et al. 2.0 0.10 (a) 0.08 Load, kN 1.5 Load, kN (b) 1.0 0.06 0.04 0.5 0.02 0 0.1 0.2 0.3 Displacement, mm 0.4 0 0.05 0.10 0.15 Displacement, mm 0.20 Fig. 4. Characteristic load–displacement diagrams obtained upon bending disks 10 mm in diameter and 1.5 mm in thickness made of (a) SCh-10 cast iron and (b) MPG-6 graphite. (a) cracks form on the back of the disk and cause radial cracks to develop under the action of tensile stresses (see Fig. 5a). The test results showed that the breaking stress of cast iron determined by Eq. (1) does not coincide with its tensile strength and is numerically closer to its compressive strength. Therefore, Eq. (1) cannot be used to determine the ultimate tensile strength of the material that manifests itself as a plastic material in bending. When testing the MPG-6 graphite disks, a completely different picture was observed. For example, brittle dynamic fracture of graphite into several parts occurs (see Fig. 5b) in an almost linear machine bending diagram up to fracture (see Fig. 4b). The level of breaking stresses calculated by Eq. (1) is approximately 20% higher than the level of tensile strength of the material. 3.2. Analysis of the Field of Application of the Brazilian Test (b) Fig. 5. Character of fracture of disks 10 mm in diameter made of (a) SCh-10 cast iron and (b) MPG-6 graphite. According to the Brazilian test scheme, short cylindrical samples made of SCh-10 cast iron and ARV-1 graphite were studied [27]. The cast iron cylinders had D × t sizes of 10 × 4 and 15 × 4 mm. Figure 6a shows the compression diagram of a 10 × 4 cast iron cylinder, which was recorded according to the Brazilian test scheme. Initial cracks in the cast iron sample formed in the contact area, where the maximum tangential stresses are operative. The smooth decrease in the load after the maximum is due to slow crack propagation and the separation of one half of the sample from the other. No explosive failure, which is characteristic of brittle fracture induced by normal stresses, was observed. The breaking stress and the ultimate tensile strength of cast iron are comparable, σt ≈ σfu . Therefore, the test RUSSIAN METALLURGY (METALLY) Vol. 2020 No. 4 DETERMINATION OF THE MECHANICAL PROPERTIES OF THE MATERIALS 7 0.8 (a) 497 (b) 6 0.6 Load, kN Load, kN 5 4 3 2 0.4 0.2 1 0 0.2 0.4 0.6 Displacement, mm 0.8 0 0.1 0.2 Displacement, mm 0.3 Fig. 6. Machine Brazilian test compressive diagrams of cylinders made of cast iron 10 × 4 mm in size and (b) ARV-1 graphite 8 × 8 mm in size. results of the small cast iron cylinders according to the Brazilian test scheme confirmed the possibility of application of Eq. (2) to determine the tensile strength of the material. Graphite cylinders were of the following three D × t sizes: 8 × 4, 8 × 8, and 8 × 12 mm. The characteristic compression diagram of a 8 × 8 mm graphite cylinder in the diametral plane is shown in Fig. 6b. Graphite turned out to be a more brittle material. The graphite cylinder failed dynamically in the linear section of the diagram at the maximum load with the separation of the sample into fragments. Initial cracks in the contact region, which caused the fracture of the sample, were revealed. The ratio of the tensile strength to the breaking stress of graphite determined by Eq. (2) was σt ≈ For β-Si5AlON7, we studied the effect of various additives and the disk thickness on the bending strength. Disks with a diameter of 10 mm (D = 7.5 mm, d = 3.75 mm; see Fig. 2) and 15 mm (D = 11.5 mm, d = 3.75 mm) were tested. The samples failed dynamically at the maximum load in the linear section of the diagram without crack jumps (Fig. 7). The fracture of all β-Si5AlON7 samples was brittle, with separation into many small fragments. A decrease in the strength of the material with an increase in the sample thickness from 1 to 2 mm was revealed (Fig. 8). A weak depen0.6 0.7σfu ; that is, the fracture strength estimated by Eq. (2) is 1.5 times lower than the true rupture strength of the material. 0.4 Load, kN Therefore, Eq. (2), which is used to determine the tensile strength of brittle materials having a linear compression diagram up to failure, should be corrected by increasing the calculation result by 1.5 times. 0.5 0.3 0.2 3.3. Deformation and Fracture of Thin Ceramic Disks 0.1 A comparative study of the compacts of aluminum dioxide made of nano- and UD powders showed a higher strength of the UD powder compacts. For example, the fracture resistance in bending the disks 10 mm in diameter and 1–1.3 mm in thickness made of UD and nanopowders was 174 and 141 MPa, respectively. RUSSIAN METALLURGY (METALLY) Vol. 2020 No. 4 0 0.02 0.04 Displacement, mm 0.06 Fig. 7. Machine bending diagram of a β-Si5AlON7 disk 15 mm in diameter and 1.5 mm in thickness. 498 GRIGOR’EV et al. 800 300 700 250 Stress, MPa Stress, MPa 600 200 150 100 0 1.0 300 1.5 Thickness, mm 2.0 200 200 Stress, MPa 250 150 2 4 6 Y2 O 3 , % 8 4.5 5.0 5.5 Sintering voltage, kV 6.0 Fig. 10. Fracture strength of VNZh-90 alloy vs. the capacitor bank voltage during high-voltage electric pulse sintering at a pressure of (individual point) 150, (1) 200, and (2) 250 MPa. 250 0 2 100 0 4.0 Fig. 8. Breaking stress vs. the sample thickness (disk 10 mm in diameter) for β-Si5AlON7 + 30% BN + 8% Y2O3 ceramic. 100 1 400 200 50 Stress, MPa 500 10 150 100 50 Fig. 9. Breaking stress vs. the Y2O3 content in β-Si5AlON7-based ceramic. 0 1 dence of the strength of β-Si5AlON7 on the Y2O3 content in the range under study was noted (Fig. 9). These results indicate that the technique of testing thin disks on an annular support can be used to estimate the influence of technological factors on the strength of the compacts formed by electric pulse powder consolidation. 3.4. Deformation and Fracture of Short Cylinders Made of VNZh Alloy and Al2O3 The tests of short cylindrical samples made it possible to determine the consolidation parameters that provide the optimal strength properties of the VNZh90 alloy. Figure 10 shows the dependence of the strength of the alloy on the sintering stress; samples were formed at various pressures. In all cases, the fracture strength of the material was calculated by Eq. (2). The strength of the samples sintered at a pressure of 200 MPa increased when the stress increased to 5.4 kV, then decreased, and stabilized at a high level. The increase and decrease in the strength occurred against the development of plastic deformation, which pre- 3 5 7 9 11 Thickness, mm Fig. 11. Fracture strength of aluminum oxide made of a nanopowder measured according to the Brazilian test scheme. The left point is the result of testing a disk 10 mm in diameter and 1.3 mm in thickness. ceded the brittle fracture of the samples. The samples sintered at 250 MPa failed in a brittle manner without noticeable traces of plastic deformation. The sample sintered at 150 MPa (point in Fig. 10) has the highest strength (at the same voltage of 5.5 kV). Significant plasticity preceded the fracture of the samples. The tensile strength of the cylindrical samples 10 mm in diameter made of aluminum dioxide nanopowder decreased almost linearly with increasing thickness (Fig. 11), demonstrating the effect of the scale factor during brittle fracture. Note that the results of testing short cylinders according to the Brazilian test scheme are in good agreement with the results of bending of thin aluminum oxide disks with 10 mm in diameter and of 1.5 mm in thickness on an annular support. RUSSIAN METALLURGY (METALLY) Vol. 2020 No. 4 DETERMINATION OF THE MECHANICAL PROPERTIES OF THE MATERIALS 4. CONCLUSIONS The bending of small disks on an annular support and the compression of short cylinders according to the Brazilian test scheme make it possible to determine the ultimate tensile strength of the brittle materials formed by spark plasma sintering and high-voltage powder consolidation. These techniques were used to study the influence of a number of technological factors on the strength of the consolidated materials, namely, the effect of various additives to a β-Si5AlON7 alloy, the pressure in sintering of VNZh alloy samples, and the effect of the particle size and the aluminum dioxide sample thickness. REFERENCES 1. M. Tokita, “Industrial applications of advanced spark plasma sintering,” Am. Ceram. Soc. Bull. 85 (2), 32– 34 (2006). 2. Z. A. Munir, U. Anselmi-Tamburini, and M. Ohyanagi, “The effect of electric field and pressure on the synthesis and consolidation of materials: a review of the spark plasma sintering method,” J. Mater. Sci. 41, 763– 777 (2006). https://doi.org/10.1007/s10853-006-6555-2 3. V. N. Chuvil’deev, A. V. Moskvicheva, Yu. G. Lopatin, Yu. V. Blagoveshchenskii, N. V. Isaeva, and Yu. I. Mel’nik, “Sintering of WC and WC–Co nanopowders with various inhibiting additions by spark plasma sintering,” Dokl. Akad. Nauk 436 (5), 623–626 (2011). 4. R. Marder, C. Estournes, G. Chevallier, and R. Chaim, “Plasma in spark plasma sintering of ceramic particle compacts,” Scripta Mater. 82, 57–60. https://doi.org/10.1016/j.scriptamat.2014.03.023 5. R. Raj, “Joule heating during flash-sintering,” J. Eur. Ceram. Soc. 32 (10), 2293–2301 (2012). 6. M. Yu, S. Grasso, R. McKinnon, T. Saunders, and M. J. Reece, “Review of flash sintering: materials, mechanisms and modeling,” Adv. Appl. Ceram. 116 (1), 24–60 (2017). 7. R. Chaim and Y. Amouyal, “Liquid-film assisted mechanism of reactive flash sintering in oxide systems,” Materials (Basel) 12 (9), 1494 (2019). https://doi.org/10.3390/ma12091494 8. R. R. Menezes, P. M. Sout, and R. H. G. A. Kiminami, “Microwave sintering of ceramics. Part I: Fundamental aspects,” Ceramica 53 (325), 1–10 (2007). 9. A. B. Tovstonog, E. E. Sych, and N. N. Skorokhod, “Microwave sintering of bioceramics based on nanostructured biogenic hydroxyapatite,” Nanosist., Nanomater., Nanotekhn. 11 (4), 791–796 (2013). 10. Yu. V. Bykov, S. V. Egorov, A. G. Eremeev, I. V. Plotnikov, K. I. Rybakov, A. A. Sorokin, and V. V. Kholoptsev, “Ultrafast sintering of ceramic oxide materials during microwave heating,” Zh. Tekh. Fiz. 88 (3), 402– 408 (2018). https://doi.org/10.21883/JTF.2018.03.45598.2398 11. T. Alp, M. Can, and S. T. S. Al-Hassani, “The Electroimpact compaction of powders: mechanics, structure and properties,” Mater. Manuf. Proc. 8 (3), 285–298 (1993). https://doi.org/10.1080/10426919308934834 RUSSIAN METALLURGY (METALLY) SPELL: 1. ok Vol. 2020 No. 4 499 12. S. Heuera, T. Lieniga, A. Mohrb, Th. Webera, G. Pintsuka, J. W. Coenena, F. Gormanna, W. Theisenb, and Ch. Linsmeier, “Ultra-fast sintered functionally graded Fe/W composites for the first wall of future fusion reactors,” Composites, Part B 164, 205–214. https://doi.org/10.1016/j.compositesb.2018.11.078 13. S. S. Bashlykov, V. D. Demenyuk, E. G. Grigor’ev, E. A. Olevskii, and M. S. Yurlova, “Electropulse consolidation of UN powder,” Inorg. Mater.: Appl. Res. 5, 278–283 (2014). https://doi.org/10.1134/S2075113314030034 14. Methods of Testing, Control and Research of MachineBuilding Materials: A Handbook. Vol. II. Methods for Studying the Mechanical Properties of Metals, ed. by A. T. Tumanov (Mashinostroenie, Moscow, 1974). 15. ASTM C1499. Standard Test Method for Monotonic Equibiaxial Flexural Strength of Advanced Ceramics at Ambient Temperature (PA: ASTM Intern., West Conshohocken, 2019). URL: www.astm.org. 16. E. Khaleghi, Yen-Shan Lin, M. A. Meyers, and E. A. Olevsky, “Spark plasma sintering of tantalum carbide,” Scr. Mater. 63, 577–580 (2010). https://doi.org/10.1016/j.scriptamat.2010.06.006 17. ISO 6872. Dentistry—Ceramic Materials (Int. Organization for Standardization, Geneva, 2006). 18. S. Timoshenko, Theory of Plates and Shells (McGrawHill, New York 1940). 19. Q. Z. Wang, X. M. Jiaa, S. Q. Koub, Z. X. Zhangh, and P. A. Lindgvistg, “The flattened Brazilion disc specimen used for testing elastic modulus, tensile strength and fracture toughness of brittle rocks analytical and numerical results,” Int. J. Rock Mech. Mining Sci. 41 (2), 245–253 (2004). 20. ASTMD3967–95a. Standard Test Method for Splitting Tensile Strength of Intact Rock Core Specimens (PA: ASTM Int. West Conshohocken, 1995). URL: www.astm.org 21. V. I. Anur’ev, Handbook of Designer–Mechanical Engineer, 9th ed. (Mashinostroenie, Moscow, 2006). 22. Graphite for the Manufacture of Shaped Products and Blanks. www.graphitel.ru/index.php?id=363. Cited September 3, 2019. 23. Yu. S. Virgil’ev, “Radiation change in the strength properties of structural graphite,” Atomn. Energ. 36 (6), 479–490 (1974). 24. NAFEMS Search Engineering Analysis and Simulation: FEA, Finite Element Analysis, CFD, Computational Fluid Dynamics, and Simulation (NAFEMS Ltd., Hamilton, 2016). 25. Release 16.2 Documentation for ANSYS (ANSYS Inc.). 26. V. Y. Goltsev and N. A. Gribov, “The use of thin disc samples for the determination of the tear resistance of brittle materials,” KnE Mater. Sci., 148–154 (2018). https://doi.org/10.18502/kms.v4i1.2139 27. A. V. Osintsev, V. Yu. Gol’tsev, and A. S. Plotnikov, “The use of a disk sample loaded according to the “Brazilian test” scheme for assessing the brittle strength of nongeological materials," Pis’ma Mater. 7 (1), 21–25 (2017). https://doi.org/10.22226/2410-3535-2017-1-21-25 Translated by K. Shakhlevich