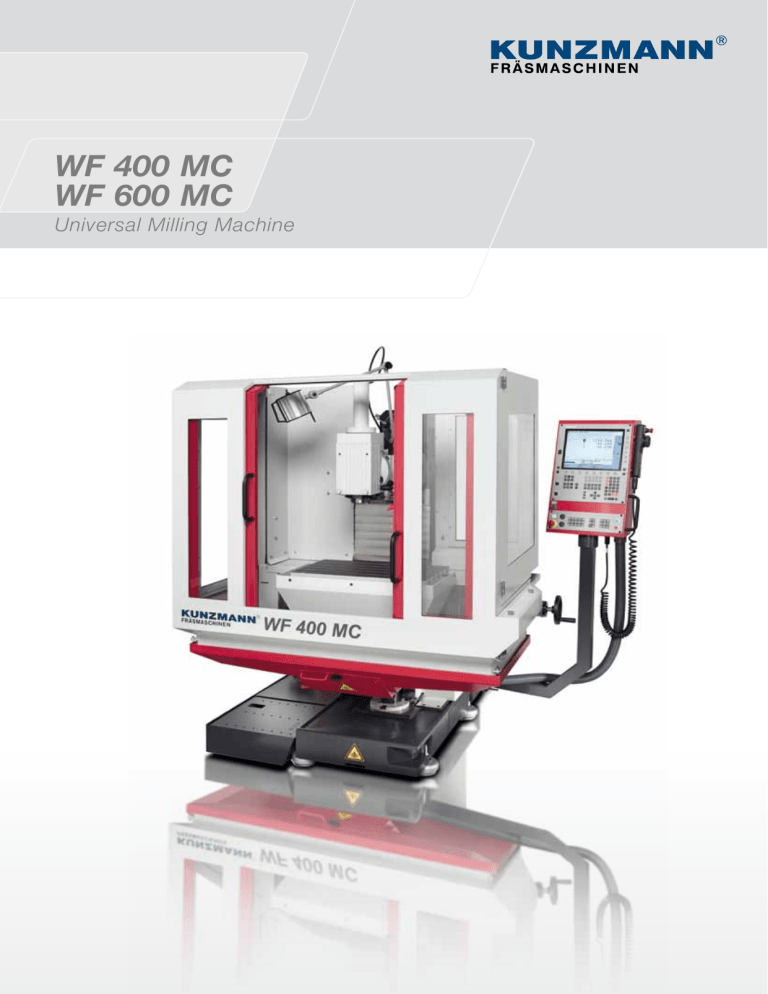

WF 400 MC WF 600 MC Universal Milling Machine WF 400 MC WF 600 MC_ Manual and CNC-operated CNC milling with contouring control Heidenhain TNC 320 Manual and CNC-operated High performance The WF 400 MC and WF 600 MC are primarily used Modern, high-torque drives as well as a solid for training purposes and the manufacture of single machine column with hardened flat guideways also parts and small-batch products. High performance, make it possible to process materials that are maximum precision and ease of use are the difficult to machine. Both the spindle speeds and distinguishing features of these modern conventional the feed rates can be steplessly adjusted using and CNC-operated universal milling machines. a potentiometer. Even the standard versions offer mechanical handwheels and can be operated effortlessly and Maximum precision immediately, thereby dispensing with extensive Thanks to the steplessly adjustable single feed training. drives and backlash-free ballscrews, the WF 400 MC and WF 600 MC permit exact positioning and The vertical milling head has an extending quill effortless up and down milling. and can quickly be swivelled through ± 90°. For horizontal processing, the vertical milling head In addition, the machines have linear measuring can be swivelled to one side on a swivel arm in a systems in all axes. few simple steps, freeing the horizontal milling spindle, and permitting milling with or without an Automatic axis clamping via the feed motor brakes arbor holder and long milling spindle. ensures operational safety and guarantees a consistently high long-term accuracy of the In place of the rigid angular table, the WF 400 MC and WF 600 MC can also be equipped with an universal table including digital readout. machine geometry. Right side door open, operation with mechanical handwheels and 3-axis digital readout Manual and CNC-operated Optimum accessibility and precision-oriented In handwheel operation, the contouring control arrangement oft the control elements make the TNC 320 is automatically reduced to the function WF 400 MC and WF 600 MC flexible, compact of a purely 3-axis digital readout. This means that machines that are easy to use. simple milling tasks can be quickly processed without programming knowledge and also with the A key-operated switch makes it possible to cabin doors opened. change directly between manual handwheel operation and CNC operation. In CNC operating mode, the user then has access to the full functionality of a modern, dialogue-guided A key-operated switch permits 3 different contouring control system with a large monitor and operating modes: extensive programming cycles. 3 Manually: Using mechanical handwheels with opened doors and 3-axis digital readout 3 CNC: With contouring control TNC 320 3 Set-up: Setting-up the machine for CNC operation with opened doors by pressing a confirmation button WF 400 MC WF 600 MC_ Options Arbor holder Electronic handwheel The arbor holder is an additional device for This is a handheld device enabling the operator to horizontal milling. In just a few steps it is mounted get closer to the working range of the machine to the ram of the machine and allows the efficient during set-up or similar procedures. The handwheel use of long cutter spindles with one or more housing incorporates axis keys, keys for feed disk milling cutters up to a diameter of 160 mm. rates and control keys for the machine. Universal table Oriented spindle stop The universal tilting and swivelling table allows the Machine and control system are set-up in a way operator to position the work piece in different that thread cutting is possible without the use of angular positions. The adjustment is done manually a compensation chuck. using a handwheel while the rotation angle of the clamping plate is digitally indicated on the display Touch probe systems of the control system. Together with the probing cycles of the control system, switching 3D touch probe systems simplify CNC dividing unit the set-up, measuring and checking functions Work pieces may be machined multi-sided through when machining work pieces. the integration of a CNC dividing unit; the programming is done via the 4th axis of the control Automatic tool measurement system. The dividing unit can be installed The tool is a vital element in ensuring consistent vertically or even horizontally on the angular table. manufacturing quality. Various control system cycles are used to automatically register tool parameters such as the exact tool length, the tool radius and even the tool wear. WF 400 MC WF 600 MC_ Performance Charts TORQUE CHARACTERISTIC WF 400 MC The universal milling machines KUNZMANN WF 400 MC and WF 600 MC are equipped with a two-stage gearbox which is shifted automatically. Additionally, the spindle speed in each gear stage is infinitely variable through a potentiometer. performance 5,5 kW (100% duty cycle) 7,0 kW (40% duty cycle) torque 294 Nm (100% duty cycle) 454 Nm (40% duty cycle) TORQUE CHARACTERISTIC WF 600 MC performance 5,5 kW (100% duty cycle) 7,0 kW (40% duty cycle) torque 294 Nm (100% duty cycle) 454 Nm (40% duty cycle) WF 400 MC WF 600 MC_ Machine Dimensions 6 5 4 3 Tischhöhe max. 1273 1764 Tischhöhe max. 1273 D 5 1764 6 4 min. 1815 min. 1815 max./ max. 2220 2220 WF 400 MC / WF 600 MC (identical dimensions) 1984 C 1926 WF 400 MC R 1 49 77 R7 1914 2382 77 R7 50 R13 3300 350 1913 3300 B 1 49 2383 R R 91 425 650 917 1524 50 R13 5 802 Allgemeintoleranze nach ISO 2768 - m Oberflächen nach DIN ISO 1302 R1 013 A 2399 FRÄSMASCHIN 800 918 2427 1815 6 5 642 4 3 Dieses Dokument 6 5 4 3 min. 1815 1764 Tischhöhe max. 1273 max. 2220 D C 1984 WF 600 MC R 77 R7 1913 2382 B 1 49 425 3300 50 R13 R1 013 800 918 Allgemeintoleran nach ISO 2768 - 642 1815 Oberflächen nach DIN ISO 1302 A 2457 FRÄSMASCH 2744 6 5 4 3 Dieses Dokume WF 400 MC WF 600 MC_ Technical Data Technical data Working range longitudinal cross vertical X-axis Y-axis Z-axis Main spindle drive A.C. motor Spindle speed range horizontal- and vertical spindle Infinitely variable 1 mechanical gear stage Feed drives WF 400 MC WF 600 MC 400 mm 350 mm 400 mm 600 mm 400 mm 400 mm 5,5 kW 5,5 kW 1 – 4500 rpm 1 – 4500 rpm Standard equipment: 3 Vertical milling head with extending quill 3 Horizontal spindle 3 Stable cast iron column with flat guideways in all axes (hardened) 3 Ballscrews 3 Automatic axis clamping 3 Hydraulic tool clamping 3 Automatically shifted gear stage 3 Anti-collision coupling in Z-axis AC single drives AC single drives 0 – 2000 mm/min 0 – 2000 mm / min 5000 mm/min 4000 mm/min 5000 mm/min 4000 mm/min +/- 90° +/- 90° stroke 60 mm stroke 60 mm ISO 40 DIN 69871 / 2080 / 7388 ISO 40 DIN 69871 / 2080 / 7388 3 Distance-coded linear measuring systems 3 Mechanical handwheels Feed rate Infinitely variable Rapid traverse X- and Y-axis Z-axis 3 Automatic central lubrication 3 Splash guard cabin Swivelling range vertical milling head Extending quill, vertical Technical subject to change – updated 05/2011, Design: Formsprache Tool taper 3 Coolant fluid tank, free-standing, 70 litres 3 Machine light 3 Leveling elements 3 Contouring control Heidenhain TNC 320 Options: 3 Angular table: Linear measuring systems direct, distance-coded resolution 0,001 mm resolution 0,001 mm WF 400 MC: 650 x 350 mm WF 600 MC: 800 x 425 mm 3 Universal table Pmax as per VDI/DGQ 3441 0,01 mm 0,01 mm Operating voltage 400 Volt, 50 Hz 400 Volt, 50 Hz Power consumption approx. 15 kVA approx. 15 kVA approx. 1.800 kg appox. 2.000 kg Machine accuracy 650 x 395 mm (rotating angle with digital readaout) 3 Arbor holder 3 Electronic handwheel HR 410 3 Touch probe systems 3 Oriented spindle stop Weight 3 Minimum-quantity lubrication system 3 Dividing units – 4th axis KUNZMANN Maschinenbau GmbH Performance range Tullastraße 29-31 3 Manufacturer of universal milling machines 75196 Remchingen, Germany and vertical machining centres. Telefon: +49 (0) 7232 / 36 74-0 3 Competent technological advice Telefax: +49 (0) 7232 / 36 74-74 3 Customer-specific application technology E-Mail: [email protected] 3 Individual programming training courses Internet: www.kunzmann-fraesmaschinen.de