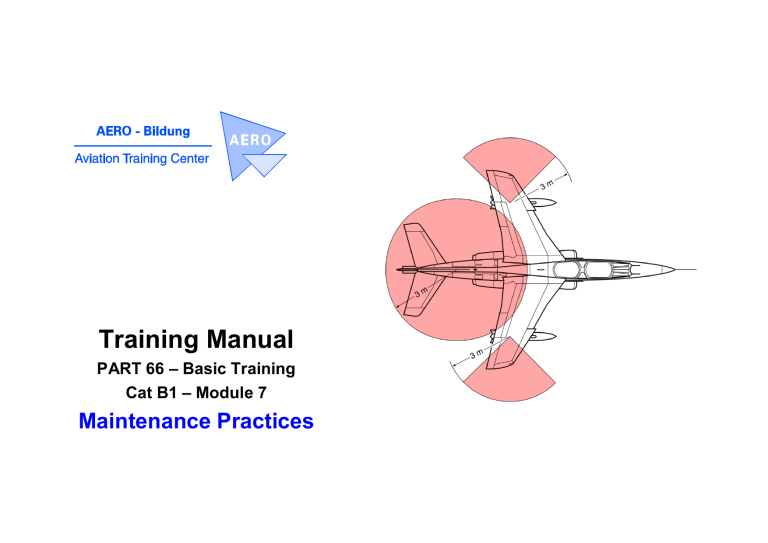

Training Manual PART 66 – Basic Training Cat B1 – Module 7 Maintenance Practices PART 66 – Basic Training Cat B1 – Module 10 Modul 7 Table of Contents 7.3.2.8 7.3.2.9 Table of Contents Safety Precautions – Aircraft an Workshop ..................... 6 7.1 7.1.1 7.1.2 General Safety Precautions......................................................... 6 The Hazards of Electric Current ................................................ 12 Safety Regulations for Experiments .......................................... 17 Rescue of Shock Victim ............................................................ 18 Mouth –to –Mouth or Mouth –to –Nose Resuscitation............... 18 Safety Precautions at the Aircraft ........................................ 20 7.1.2.1 7.1.2.2 7.1.2.3 7.1.2.4 7.1.2.5 General Safety Rules ................................................................ 20 Fire ............................................................................................ 23 Types of Fire Extinguishers ....................................................... 25 Handling of Petrol, Oils, Lubricants and Chemicals ................... 32 First Aid in Case of Accidents at Work ...................................... 33 7.4 7.2.1.1 7.2.1.2 7.2.1.3 7.2.1.4 7.2.1.5 7.3. Tools and Test Equipment......................................................... 35 Equipment, Tools and Material According to EASA Part –145 .. 35 Measuring Systems ................................................................... 36 Fits and Tolerances .................................................................. 41 Calibration of Tools and Equipment .......................................... 45 7.4.3.1 7.3.2 7.3.2.1 7.3.2.2 7.3.2.3 7.3.2.4 7.3.2.5 7.3.2.6 7.3.2.7 General ................................................................................... 116 Scales or Rules ....................................................................... 116 Scribers ................................................................................... 117 Combination Set ...................................................................... 118 Dividers ................................................................................... 119 Thickness Gauges................................................................... 119 Calipers .................................................................................... 120 For Training Purposes Only 7.5.1.1 7.5.1.2 7.5.1.3 7.5.1.4 7.5.1.5 7.5.1.6 7.5.2 7.5.2.1 7.5.2.2 7.5.2.3 7.5.3 7.5.3.1 7.5.4 7.5.4.1 7.5.4.2 7.5.4.3 7.5.5 7.5.5.1 7.5.5.2 7.5.5.3 7.5.6 7.5.6.1 7.5.6.2 7.5.6.3 7.5.7 Issue: August 2014 Flight Line Test Sets ................................................................ 158 Engineering Drawings, Diagrams and Standards .... 165 7.5.1 Measuring Tools ................................................................. 116 Accuracy of Instruments ........................................................... 150 Electronic Avionic Test Equipment ...................................... 158 7.4.4.1 7.5 Tools ....................................................................................... 48 7.3.1 Common Hand and Power Tools ........................................................ 48 7.3.1.1 Marking Tools ............................................................................ 48 7.3.1.2 Punches ................................................................................... 51 7.3.1.3 Cutting Tools ............................................................................ 54 7.3.1.4 Hand Cutting Tools.................................................................... 65 7.3.1.5 Drills ......................................................................................... 74 7.3.1.6 Forming Tools ........................................................................ 101 7.3.1.7 Torque Wrenches .................................................................... 106 7.3.1.8 Lubrication Equipment and Methods ....................................... 113 Multi Meter .......................................................................... 140 Oscilloscop .......................................................................... 147 Pitot Static Test Equipment ................................................ 150 7.4.4 Tools, Dimensions and Calibration ...................................... 35 Digital and Analogue Multimeters............................................. 130 Digital Multimeter ..................................................................... 132 Analogue Multimeter ................................................................. 133 Avionic General Test Equipment................................. 140 7.4.1 7.4.2 7.4.3 Workshop Practices........................................................ 35 7.2.1 Operation, Function and Use of Electrical Test Equipment130 7.3.3.1 7.3.3.2 7.3.3.3 Safety Precautions in the Workshop ..................................... 6 7.1.1.1 7.1.1.2 7.1.1.3 7.1.1.4 7.1.1.5 7.2 7.3.3 Vernier Calipers ....................................................................... 123 Dial Indicators ........................................................................... 129 Technical Drawing .............................................................. 165 Fundamentals .......................................................................... 165 Standards................................................................................. 165 Drawing Instruments ................................................................ 165 Scales ...................................................................................... 169 Sheet Sizes .............................................................................. 170 Title Block and Parts List.......................................................... 172 Lettering .............................................................................. 174 Style and Type of Lettering ...................................................... 174 Dimensions for Lettering According ......................................... 175 Execution of Handwritten Lettering .......................................... 176 Lines in Technical Drawings ............................................... 177 Line Types, Thicknesses, Groups and Applications ................. 177 Dimensioning in Drawings ................................................... 182 Dimensioning Concepts ............................................................ 182 Basic Dimensioning Rules ....................................................... 185 Arrangement of Dimensions ..................................................... 187 Indicating Surface Texture and Tolerances ........................ 193 Surface Finish Marking to DIN 3141 ......................................... 193 Method of Indicating Surface Texture to DIN ISO 1302 ............ 194 Tolerancing in Drawings (DIN 7182) ........................................ 199 Geometrical Tolerancing (According to DIN ISO 1101) ..... 202 Generalities .............................................................................. 202 Tolerances of Form .................................................................. 202 Tolerances of Position.............................................................. 205 Normal and Special Projection ........................................... 208 Page 2 of 926 PART 66 – Basic Training Cat B1 – Module 10 Modul 7 Table of Contents 7.5.7.1 7.5.7.2 7.5.7.3 7.5.7.5 7.5.7.6 7.5.7.7 7.5.7.8 7.5.8 7.5.9 Types of Representation ......................................................... 208 Planes of Projection ................................................................ 209 Special Representations and Marking ..................................... 218 Drawing Procedure for the Construction of Views ................... 220 Division of the Drawing Sheet ................................................. 221 Axonometric Projections (DIN 5) ............................................. 222 Freehand Sketches ................................................................. 226 Prismatic Workpieces ........................................................ 228 Air Engineering Drawings and Standards.......................... 230 7.5.9.1 7.5.9.2 7.5.10 7.5.11 ATA Specification 100 .............................................................. 240 Illustrated Parts CataIogues ................................................. 255 7.5.12 7.5.13 SI Units ..................................................................................... 274 Definitions of Electrical Quantities ............................................ 280 Standards used in Transport Aviation ...................................... 283 Fundamentals of Power Circuits ......................................... 284 7.5.13.1 Representation of Voltages and Currents ................................ 284 7.5.13.2 Circuit Diagram Letter Codes and Symbols ............................. 289 7.5.13.3 Types of Diagrams ................................................................... 299 7.5.13.4 Standard Phase Notations and Terminal Markings for Motors and Generators ................................................................................................. 308 7.5.14 Wiring Diagrams ................................................................. 309 Fits and Clearances ...................................................... 327 7.6.1 7.9 7.6.2 Basics of Tolerances and Fits ................................................. 327 Standards for Fits and Clearances .......................................... 333 Inspection Tools ...................................................................... 345 Rolling Bearing Shaft and Housing Fits ................................... 349 7.6.2.1 7.9.2 Maintenance Practices on Electrical Cables and Connectors .. ............................................................................................ 364 7.9.3 For Training Purposes Only 7.10 General Care and Maintenance of Hoses ................................. 445 General Test and Inspection Procedures for Hose .................. 445 Types of Testing Equipment ..................................................... 449 Springs ......................................................................... 454 7.10.1 7.10.1.1 7.10.1.2 7.10.1.3 Maintenance of Springs ....................................................... 454 Visual Inspections ..................................................................... 454 Spring Testing ........................................................................... 457 Spring Testing Equipment ......................................................... 459 Bearings ........................................................................ 467 7.11.1 7.11.1.1 7.11.1.2 7.11.1.3 Bearing Handling and Maintenance .................................... 467 Rules of Bearing Maintenance .................................................. 467 Bearing Handling....................................................................... 468 Bearing Failures ........................................................................ 471 Transmissions .............................................................. 477 7.12.1 Issue: August 2014 Flexible Hose Installations ........................................................ 442 Testing Equipment ............................................................. 445 7.9.3.1 7.9.3.2 7.9.3.3 7.12 Working Rigid Tubing ............................................................... 422 Joining Rigid Tubing................................................................. 426 Rigid Tubing Installation ........................................................... 434 Repair of Rigid Tubing .............................................................. 437 Hoses ................................................................................. 442 7.9.2.1 Wear Inspection of Engine Parts ............................................. 357 Electrical Wiring Interconnection System .................... 364 Pipes ................................................................................... 422 7.9.1.1 7.9.1.2 7.9.1.3 7.9.1.4 Methods for Checking Aircraft Parts .................................. 357 Riveted Joints .......................................................................... 398 Pipes and Hoses........................................................... 422 7.9.1 7.11 Special Assembly Tools ........................................................... 389 Rivet Guns ............................................................................... 394 Bucking Bars ............................................................................ 397 Rivet Shaver Tool..................................................................... 398 Riveting Techniques ........................................................... 398 7.8.2.1 Tolerances ......................................................................... 327 7.6.1.1 7.6.1.2 7.6.1.3 7.6.1.4 7.7.1 7.8.2 General Units, Standards and Definations ......................... 274 7.5.12.1 7.5.12.2 7.5.12.3 Riveting Tools ..................................................................... 389 7.8.1.1 7.8.1.2 7.8.1.3 7.8.1.4 Aircraft Zoning .................................................................... 264 Wire Installation and Routing .................................................... 364 Lacing and Tying of Wire Bundles ............................................ 371 Wire Termination ....................................................................... 373 Maintenance Practices on Electrical Connectors ...................... 378 Grommets ................................................................................ 384 Heat-Shrink Material, Types, Application Tools and Techniques ... .................................................................................................. 385 Riveting ......................................................................... 389 7.8.1 Introduction.............................................................................. 230 Types of Drawings................................................................... 231 7.5.11.1 Airline Requirements for Aircraft Zoning ................................... 264 7.5.11.2 Airline Requirements for Designation of Engine Areas, Engine Mounted Components/Parts and Access Ports ......................................... 273 7.7 7.8 Standards for Maintenance Documentation ....................... 240 7.5.10.1 7.5.10.2 7.6 7.7.1.1 7.7.1.2 7.7.1.3 7.7.1.4 7.7.1.5 7.7.1.6 7.12.1.1 Inspection of Transmission Components ............................ 477 Gears ........................................................................................ 477 Page 3 of 926 PART 66 – Basic Training Cat B1 – Module 10 Modul 7 Table of Contents 7.12.1.2 7.12.1.3 7.12.1.4 7.13 Belts and Pulleys ...................................................................... 483 Chains and Sprockets .............................................................. 492 Jacks and Lever Devices ......................................................... 500 Control Cables .............................................................. 504 7.13.1 Control Cable Basics ................................................................ 504 Installation of Swaged End Fittings .......................................... 506 Control Cable Installation ......................................................... 509 Cable Inspections ................................................................ 512 Bowden Controls ...................................................................... 516 7.16.2 7.16.2.1 7.16.2.2 7.16.2.3 7.16.2.4 7.16.2.5 7.16.2.6 7.16.2.7 7.16.2.8 Cutting and Forming used in Sheet Metal Work ................. 518 7.14.1.1 7.14.1.2 7.14.2 Cutting ...................................................................................... 519 Forming .................................................................................... 523 Application and Repair of Composite Materials ................. 535 7.14.2.1 7.14.2.2 7.14.2.3 7.14.2.4 Structures 7.15 7.16.1.1 7.16.2.2 7.16.1.3 7.16.1.4 Material Handling .......................................................... 518 7.14.1 Minor Repair with Adhesive ...................................................... 535 Application of ’Wet Lay - Up’ Materials ..................................... 535 Standard Composite Repair by Hot Curing .............................. 536 Repair of Plastic, Fibre and Fibreglass Materials in Sandwich 537 7.17 7.17.1.1 7.17.1.2 7.17.1.3 7.17.1.4 7.17.1.5 7.17.1.6 Soldering ............................................................................. 539 7.15.1.1 7.15.1.2 7.15.1.3 7.15.2 7.17.2 7.17.2.1 7.17.2.2 7.17.2.3 7.17.2.4 Shielded Metal Arc Welding................................................ 550 7.15.2.1 7.15.2.2 7.15.2.3 7.15.2.4 7.15.2.5 7.15.3 Principle of SMAW ................................................................... 550 SMAW Equipment .................................................................... 552 Workshop Safety ...................................................................... 559 General Safety Precautions...................................................... 561 SMAW Procedures and Techniques ........................................ 563 Gas Arc Welding ................................................................. 576 7.15.3.1 7.15.3.2 7.15.3.3 Gas Metal Arc Welding ............................................................. 576 Gas Tungsten Arc Welding....................................................... 588 Practical Exercises ................................................................... 593 7.17.3 7.17.3.1 7.17.3.2 7.17.4 Oxy –Acetylene Welding and Brazing ................................ 596 7.15.4 7.15.4.1 7.15.4.2 7.15.4.3 7.15.5 Principles of Soldering .............................................................. 539 Types of Soldering ................................................................... 545 Fluxing Agents and Solder Materials ........................................ 547 Oxy –Acetylene Welding Equipment ........................................ 597 Oxy –Acetylene Welding Techniques ....................................... 607 Brazing ..................................................................................... 622 Introduction to Weight and Balance .................................... 635 Importance of Weight and Balance ........................................... 635 Purpose of Weight and Balance Control ................................... 640 Principles of Weight and Balance.............................................. 641 Terms Used in Weight and Balance .......................................... 651 Weight and Balance Procedures ......................................... 656 Weighing Procedure.................................................................. 656 Finding the Center of Gravity .................................................... 661 Center –of –Gravity Range ....................................................... 666 Shifting the Center of Gravity .................................................... 668 Weight and Balance Changes after an Alteration ..................... 672 Checklist for Aircraft Weighing .................................................. 673 Weight and Balance of Helicopters ........................................... 677 Loading and Weight Distribution ............................................... 683 Aircraft Handling and Storage ..................................... 691 7.17.1 Welding, Brazing, Soldering and Bonding ................. 539 7.15.1 Bonding of Sheet Metal Parts ................................................... 630 Aircraft, Weight and Balancing ................................ 635 7.16.1 Control Cable Inspections................................................... 504 7.13.1.1 7.13.1.2 7.13.1.3 7.13.1.4 7.13.1.5 7.14 7.15.5.1 7.16 7.17.4.1 7.17.4.2 7.17.4.3 7.17.4.4 7.17.4.5 7.17.4.6 Airfield Safety Regulations .................................................. 691 Characteristics of an Airfield ..................................................... 691 Airfield Traffic ............................................................................ 691 Aircraft Noise ............................................................................ 692 Flight Line Safety ...................................................................... 694 Engine Safety............................................................................ 695 Danger Zones during Aircraft Refuelling ................................... 702 Ground Handling and Storage of Aircraft ............................ 704 Introduction ............................................................................... 704 Movement of Aircraft on the Ground ......................................... 704 Parking and Picketing ............................................................... 712 Jacking ...................................................................................... 714 Aircraft Servicing ................................................................. 716 Ground Servicing Equipment .................................................... 716 Aircraft Fuelling and Defuelling ................................................. 720 Aircraft De-Icing ................................................................... 729 Introduction ............................................................................... 729 Types of De-Icing and Anti-Icing Agents ................................... 730 De-Icing/Anti-Icing Procedures ................................................. 731 Types of De-Icing Vehicles ....................................................... 733 Ice-Control Nozzle..................................................................... 737 Other Aircraft De-Icing Methods ................................................ 740 Bonding ............................................................................... 630 For Training Purposes Only Issue: August 2014 Page 4 of 926 PART 66 – Basic Training Cat B1 – Module 10 Modul 7 Table of Contents 7.19.1.2 7.19.1.3 7.19.1.4 7.18 Disassembly, Inspection, Repair and Assembly Techniques ............................................................................... 744 7.18.1 Inspection Techniques ........................................................ 744 7.18.1.1 7.18.1.2 7.18.1.3 7.18.2 Types of Defects ...................................................................... 744 Visual Inspection ...................................................................... 747 Treatment of Corrosion ............................................................ 751 7.18.3 Introduction............................................................................... 764 Repair of Sheet Metal ............................................................... 770 Repair of Fibre –Reinforced Material........................................ 783 Structural Repair Manual .......................................................... 786 Corrosion Prevention and Control Program ......................... 828 7.19.2.1 Inspection after Excessive Load Factor in Flight due to Turbulence orManoeuvre in Excess of VMO/MMO ........................................ 887 7.19.2.2 Inspections after Hard/Overweight Landings ........................ 889 7.20 7.18.4 Introduction .......................................................................... 830 Liquid Penetrant Inspection.................................................. 831 Magnetic Particle Inspection ................................................ 834 Eddy Current Inspection....................................................... 841 Ultrasonic Inspection ............................................................ 849 Resonance Frequency Inspection ........................................ 859 X–Ray Inspection ................................................................. 861 Disassembly and Re -Assembly Techniques ..................... 863 7.18.4.1 7.18.4.2 7.18.4.3 7.18.4.4 7.18.4.5 7.18.4.6 7.18.4.7 7.18.4.8 7.18.4.9 7.18.4.10 7.18.4.11 7.18.4.12 7.18.5 Maintenance Procedures ............................................ 896 7.20.1 Non - Destructive Testing Methods .................................... 830 7.18.3.1 7.18.3.2 7.18.3.3 7.18.3.4 7.18.3.5 7.18.3.6 7.18.3.7 Complete Airframes ............................................................. 863 Replacement of Major Components/Modules........................... 864 Replacement of Minor Components/Modules........................... 864 Disassembly and Re – assembly of Major Components .......... 865 Disassembly and Re – assembly of Minor Components .......... 865 Basic Disassembly and Re-assembly Techniques ................... 865 Small Part and Component Identification ................................. 866 Discarding of Parts ................................................................... 867 Freeing Seized Components .................................................... 867 Removal of broken studs ..................................................... 867 Use of Correct Tools ............................................................ 867 Murphy’s Law’ ...................................................................... 868 Aircraft Maintenance ........................................................... 896 7.20.1.1 7.20.1.2 7.20.1.3 7.20.1.4 7.20.1.5 7.20.1.6 7.20.1.7 7.20.1.8 7.20.1.9 7.20.1.10 7.20.1.11 7.20.1.12 Preface ................................................................................. 896 Emergence of MSG .............................................................. 897 Development of Scheduled Maintenance Program............... 900 Stores Procedures ................................................................ 906 Certification of Airline and Aircraft......................................... 910 Post Type Certification Activities/Modifications ..................... 911 Additional Maintenance Procedures ..................................... 912 Certification of Airline Personnel ........................................... 917 Maintenance Management ................................................... 920 Quality Assurance................................................................. 921 Additional Maintenance Procedures ..................................... 923 Control of Life Limited Parts.................................................. 925 Troubleshooting Techniques .............................................. 869 7.18.5.1 7.18.5.2 7.19 7.19.2 Inspections after Flight through Turbulence and Heavy Landings ............................................................................................. 887 Repair Methods .................................................................. 764 7.18.2.1 7.18.2.2 7.18.2.3 7.18.2.4 7.18.2.5 Inspection Requirements ...................................................... 881 Inspection Procedures .......................................................... 881 High Intensity Radiated Fields (HIRF) Penetration.................... 883 Introduction .......................................................................... 869 Troubleshooting Methods..................................................... 870 Abnormal Events ....................................................... 878 7.19.1 Inspection following Lightning Strikes and HIRF Penetration... ............................................................................................ 878 7.19.1.1 Introduction .......................................................................... 878 For Training Purposes Only Issue: August 2014 Page 5 of 926 Modul 7 Safety Precautions – Aircraft an Workshop 7.1 Safety Workshop Precautions – Aircraft 7.1.1 Safety Precautions in the Workshop 7.1.1.1 General Safety Precautions an PART 66 – Basic Training Cat B1 – Module 7 Reasons for Accidents Accidents are caused by human failures, like ignorance of the danger, thoughtlessness and negligence, as well as technical failures (breakdowns). Human Failures Introduction Safety regulations are necessary in each workshop to prevent any accidents to the people who use tools and machines for their work. Human failures cannot be excluded despite thorough training and carefulness. The consequences can be limited by installing safety equipment, e.g. by means of barriers. Technical Failures There are accident prevention regulations for every professional branch for safety reasons and accident prevention. Every technician must fully comply with these regulations. Accident prevention can be learnt. Accidents to personnel and damage to equipment are mostly caused by disregard of safety regulations. Everybody who disregards regulations and safety signs endangers himself and his colleagues as well as plant and equipment. Accidents can be avoided by the following preventive safety measures: Dangerous risks have to be eliminated. Dangerous locations have to be protected and marked. Dangerous actions have to be avoided. For Training Purposes Only Technical failures can occur due to material fatigue or unexpected overload. Apart from this, technical failures can also occur if the load pressure of a checking device drops. In this case the machine must be shut down. Avoidance of Possible Dangerous Risks Accidents can be avoided if the safety regulations are followed and any sources of danger are removed. Sources of danger are defects of machines, tools and other working devices (which have to be reported immediately to the responsible personnel) blockages in transportation and escape ways (these areas have to be kept free) sharp, pointed tools (which must not be carried in working dress). Issue: August 2014 Page 6 of 926 Modul 7 Safety Precautions – Aircraft an Workshop Personal Protective Clothing and Devices To avoid accidents in the working place, the correct protective clothing must be worn and all safety rules must be followed. It is the employer’s responsibility to provide protective clothing and equipment. Employees have to wear correct clothing in order to prevent themselves from possible serious injury. Working Clothes Refer to Figure 1. PART 66 – Basic Training Cat B1 – Module 7 Working clothes should be resistant to tear and should fit tightly. Wide sleeves, loose scarfs, trousers with turn –ups (cuffs) are forbidden according to the accident prevention regulations. The following items shall not be worn when working with machines, especially rotating ones: leisure wear finger rings wrist watches bracelets necklaces. Safety Boots Hard –toed safety boots with antiskid, antistatic as well as oil – and acid –resisting soles must be worn where required. Head Protection Only safety helmets which have been tested and have a test mark and a registration number should be worn. A shock –proof helmet must be worn in areas where warning signs prescribes them. Eye Protection Safety glasses are always necessary when any dust, metal swarf etc. might hit the eye. When the cornea of the eye is penetrated by a splinter and the fluid of the eye is lost, no doctor can help. The eyesight is permanently destroyed. Noise Protection Figure 1: Protective Clothing For Training Purposes Only Noise protection for the individual worker is necessary in many work places, although the prescribed noise level of machines is limited. Issue: August 2014 Page 7 of 926 Modul 7 Safety Precautions – Aircraft an Workshop PART 66 – Basic Training Cat B1 – Module 7 Personal noise protection measures are: ear protection measures in the form of a headset ear protection wadding V foam plastic ear plugs. Ear protection wadding and foam plastic ear plugs should be pressed into the ear to form a close fit. Hand Protection An efficient hand protection is necessary when working with acids, solvents and other substances hazardous to the skin. Rubber or synthetic gloves will give protection. Leather gloves are advantageous when working with sharp –edged or rough materials. Refer to Figure 2. Figure 2 shows typical mandatory signs referring to correct safety clothes. For Training Purposes Only Issue: August 2014 Page 8 of 926 Modul 7 Safety Precautions – Aircraft an Workshop PART 66 – Basic Training Cat B1 – Module 7 Figure 2: Mandatory Signs (Safety Signs) For Training Purposes Only Issue: August 2014 Page 9 of 926 Modul 7 Safety Precautions – Aircraft an Workshop PART 66 – Basic Training Cat B1 – Module 7 Warning Signs Refer to Figure 3. Figure 3 shows typical warning signs. Warning signs are employed to mark dangerous areas. Warning signs must not be attached to live parts. Containers with easily inflammable, explosive, corrosive or toxic substances have to be marked and stored safely. Prohibition Signs Refer to Figure 4. Figure 4 shows another type of signs. These are used in workshops for the prohibition of smoking and the use of naked flames, for example. Figure 3: Warning Signs Warning and Prohibition Signs For Training Purposes Only Issue: August 2014 Page 10 of 926 Modul 7 Safety Precautions – Aircraft an Workshop PART 66 – Basic Training Cat B1 – Module 7 Figure 4: Mandatory Signs (Prohibition) For Training Purposes Only Issue: August 2014 Page 11 of 926 Modul 7 Safety Precautions – Aircraft an Workshop 7.1.1.2 PART 66 – Basic Training Cat B1 – Module 7 The Hazards of Electric Current The hazards of electric current mainly depend on the strength and duration of the current passing through the human body. There is a difference between the hazard related to direct current (DC) and that with alternating current (AC). AC is more dangerous than DC. As regards AC, the level of danger varies depending on the frequency. Frequencies of 50 Hz or 60 Hz are dangerous to the human body, whereas frequencies below and above these values are less dangerous. Refer to Figure 5. For Training Purposes Only Issue: August 2014 Page 12 of 926 Modul 7 Safety Precautions – Aircraft an Workshop PART 66 – Basic Training Cat B1 – Module 7 Figure 5: Relation between Current/Time and Human Body For Training Purposes Only Issue: August 2014 Page 13 of 926 Modul 7 Safety Precautions – Aircraft an Workshop The table in Figure 5 shows how a human body can be affected by current, depending on the strength of the current and the time the current is allowed to pass the body(’contact time’). PART 66 – Basic Training Cat B1 – Module 7 Heart attack occurs when the current through the body reaches 100 mA. This causes the loss of the pumping action of the heart. It will usually continue until some force is used to restore the coordination of the heart’s actions. The description of the zones is as follows: zone 1:usually no reaction zone 2:usually no harmful physiological effects zone 3:usually no organic damage to be expected zone 4:probability of heart attack. Severe burns and unconsciousness are also produced by currents of 200 mA or higher! Current as low as 5 mA can be dangerous! If the palm of the hand makes contact with the conductor, a current of approximately 12 mA will tend to cause the hand muscles to contract, freezing the body to the conductor. Such a shock may or may not cause serious damage, depending on the contact time and physical condition, particularly the condition of the heart. A current of only 25 mA has been known to be fatal; a current of 100 mA is likely to be fatal! Due to the physiological and chemical nature of the human body, 5 times more direct current is needed than alternating current to freeze the same body to a conductor. These currents do not usually cause death if the victim is given immediate attention. The victim will usually respond if resuscitation in the form of artificial respiration is given. When a person is rendered unconscious by a current passing through the body, it is impossible to find out how much current has caused the unconsciousness. Artificial respiration must be applied immediately when breathing has stopped! Electrical Safety The following rules apply to personnel in all types of activities. Each individual should strictly observe the following precautions as applicable to his work or duty: The damage from shock is also proportional to the number of vital organs that the current passes through, especially the percentage of current that reaches the heart. Report any unsafe condition or any equipment or material which appears to be unsafe. Warn others if they are endangered by known hazards or by a fault. Report any injury or evidence of impaired health occurring in the course of work or duty. Currents between 100 and 200 mA are lethal! For Training Purposes Only Issue: August 2014 Page 14 of 926 Modul 7 Safety Precautions – Aircraft an Workshop Exercise, in the event of any unforeseen hazardous occurrence, such reasonable caution as is appropriate to the situation. Many pieces of electrical equipment use voltages which are dangerous and can be fatal if contacted. Technical safety devices have been built/included into electrical systems. But when the most basic rules of safety are ignored, the built –in protection devices become useless. The following rules should be followed at all times by all personnel when working with or near high –voltage circuits: Consider the result of each action! There is absolutely no reason for an individual to take chances which will endanger his life or the lives of others. Keep away from live circuits! Do not change parts or make adjustments inside the equipment with high voltages on. Do not work alone! Always work on electrical equipment in the presence of another person capable of giving first aid in an emergency. Do not tamper with interlocks! Do not rely on interlocks or other devices for protection; always shut down the equipment. Never remove, short –circuit or tamper with interlocks except to repair the switch. Do not ground yourself! Make sure that there is no electrical contact between you and earth when adjusting equipment or using measuring equipment. Use only one hand when servicing energised equipment. Keep the other hand at your back. For Training Purposes Only PART 66 – Basic Training Cat B1 – Module 7 Do not energise equipment if there is any evidence of water leakage! Repair the leak and dry up the water before energising. Never touch a conductor that carries 50 V DC/ 30 V AC or more! This may cause a lethal electrical shock. Never touch any parts of electrical equipment directly! Electrical equipment should never be touched directly if you are not sure whether it carries a voltage of less than 50 V DC or 30 V AC. Safety Precautions When Using Electrical Tools As a general precaution, be sure that all tools used conform to applied standards as to quality and type, and use them only for the purposes for which they were intended. All tools in use should be kept in good condition, and all damaged or defective tools should be repaired or replaced. In selecting a screwdriver for electrical work, be sure that it has a non –conducting handle. The screwdriver should not be used as a substitute for a punch or a chisel, and care should be taken that one is selected of the correct size to fit the screw. When using a fuse puller, ensure that it is the correct type and size for the particular fuse to be pulled. The soldering iron is a fire hazard and a potential source of burns. Always assume that a soldering iron is hot; never rest the iron anywhere but on a metal surface or rack provided for that purpose. Keep the iron holder in the open to minimise the danger of fire from accumulated heat. Do not shake the iron to dispose of excess solder; a drop of hot solder may hit someone, or it may strike the equipment Issue: August 2014 Page 15 of 926 Modul 7 Safety Precautions – Aircraft an Workshop and cause a short circuit. Hold small parts to be soldered with pliers or clamps. PART 66 – Basic Training Cat B1 – Module 7 Safety Precautions When Using Cleaning Solvents Dust and dirt can disturb the function of electronic equipment , so that it will When cleaning the iron, place the cleaning rag on a suitable surface and wipe the iron across it; do not hold the rag in the hand. Disconnect the iron when leaving the work, even for a short time; the delay may be longer than intended. Safety Precautions During Maintenance and Repair at Electrical Switchgear The following general safety precautions also apply: Only remove the slide –in units or only take the units out of their housing, when the voltage supply has been disconnected. Place a safety guard next to the mains switch when repair has to be carried out on energised equipment. He shall disconnect the complete system if life is endangered. In the off –state take care as to the mains voltages and synchro reference voltages, which may still be available, and to capacitors in high –voltage circuits which may still be charged. Pay attention to the anti –condensation heating which is often automatically switched on when the relevant unit is switched off. Do not work on any type of electrical apparatus when wearing wet clothing, or if the hands are wet. Do not wear loose or flapping clothing. Do not wear thin –soled shoes and shoes with metal plates or hob nails. Do not wear rings, wrist –watches, bracelets and similar metal items when working on any equipment. Strictly observe all warning signs! Dust and dirt can disturb the function of electronic equipment For Training Purposes Only be necessary to do some cleaning from time to time. For any cleaning on electrical or electronic equipment it is not allowed to use alcohol, gasoline, benzine, ether or other volatile substances. Only non –volatile solvents should be used. Many cleaning solvents are very toxic and capable of damaging the human respiratory (breathing) system in case of prolonged inhalation. When toxic cleaning solvents are used, the operator should leave the room during the cleaning, if possible. If this is not possible, he should carefully observe the following safety precautions: Do not work alone in poorly ventilated compartments. Do not directly breathe the vapour of any cleaning solvent for a long time. Do not apply cleaning solvents to warm or hot equipment since this increases the toxicity hazard. Do not spray solvents on electrical windings or insulation. Do not eat, drink or smoke during the use of solvents. Remove all food or drink from a room where solvents are used. Adequately ventilate the room during and after using solvents. Avoid direct skin contact with the cleaning solvent. Note: If your skin has been in contact with any toxic solvent, immediately wash it with plenty of water. If some cleaning solvent gets into your eyes, wash them out with plenty of water and obtain medical treatment immediately. Issue: August 2014 Page 16 of 926 Modul 7 Safety Precautions – Aircraft an Workshop 7.1.1.3 The power source normally supplies 230 V AC between live and neutral. A supply earth (green/yellow) cable is connected to the metal frame or case of the load appliance. This ensures that the housing is at earth potential, and that a dangerous potential between the case and earth can never be built up. Safety Regulations for Experiments Accident Prevention In order to avoid accidents during experiments: Nobody except the person in charge of the experiment is allowed to switch on the power supply, to operate control boards or to close switches. In the event of danger, immediately push the EMERGENCY OFF switch. When setting up a circuit for an experiment, take all necessary precautions to prevent excessive contact voltages on bare surfaces. All circuits must be correctly set up before switching on the power supply. The power supply must be switched off before any changes are made in the circuit connections. Any defective items of equipment are to be reported immediately to the instructor/supervisor. Make sure that the diameters of all conductors are adequate. Do not use the lead to pull the plugs out of sockets. Do not touch any live parts. In order to carry out an electrical experiment, a closed circuit must be connected from the live (black) power supply lines (also called ’phase wires’) via a protection device (fuse or circuit breaker) a switch a load to the neutral (blue) power supply line. For Training Purposes Only The neutral cable is connected to earth potential by the electricity supply authority. That means that the phase line has a dangerous voltage (230 V) between phase and neutral, phase and earth or phase and body when a person is standing on non –insulated material and has contact with earth. In some circuits there is more than one phase line. There can be either two phase lines (2 –phase system) or three phase lines (3 – phase system). Between any two phases L1, L2 or L3 there is a high voltage of 1.73 times the phase voltage, i.e. in a normal 230 V system, there are 380 V between two phases. There is danger to life if contact is made between the phase lines L1, L2, L3 and earth (or neutral) or between two phase lines. Damp conditions considerably increase the danger to life because the person makes a ’better’ contact to earth. The wearing of rubber shoes reduces the danger. The fuse (or circuit breaker) and switch must always be connected in the phase line. The load is then safe when the circuit is switched off. Safety Requirements PART 66 – Basic Training Cat B1 – Module 7 Therefore: Issue: August 2014 Always make sure that the metal frame of a load is connected to earth. Use the list of components to select the modules required. Place the modules in a neat order. Connect the modules as shown in the relevant circuit diagram. Page 17 of 926 Modul 7 Safety Precautions – Aircraft an Workshop Build up a clear arrangement of the circuit by suitable selection of the colours of the connecting leads, e.g. – PE: green/yellow – N: blue – phase leads: black Check the circuit to ensure that it is connected properly. Take note of the main data of the equipment used. Ask the person in charge to switch the power on. 7.1.1.4 PART 66 – Basic Training Cat B1 – Module 7 Rescue of Shock Victim For immediate first aid for the victim of an electrical shock the following precautions must be observed: Shut off the voltage supply. If the high voltage cannot be turned off without delay, remove the victim from the live conductor as follows: – Protect yourself with dry insulating material. – Use a dry board, your belt, dry clothing or other non – conducting material to move the victim. – If possible push (do not pull) the victim away from the high voltage source. Do not touch the victim with your bare hands until the electricity is shut off or until the victim is no longer in contact with the current. 7.1.1.5 Mouth –to –Mouth or Mouth –to –Nose Resuscitation Refer to Figure 6. Figure 6: Rescue Breathing For Training Purposes Only Issue: August 2014 Page 18 of 926 Modul 7 Safety Precautions – Aircraft an Workshop If the victim needs assistance in breathing, first clear the mouth of any food particles, foreign objects, or loose dentures. When a victim becomes unconscious, the muscles relax and the tongue may slide back into the airway blocking it. To open the airway in this situation, the head or jaw tilt technique is recommended. The head tilt technique is performed with the victim on his back and the rescuer kneeling at his side – head and neck in line with the victim. Place one hand on the victim’s forehead and the other under his neck. Apply pressure on the forehead and at the same time lift the neck. Tilting the head in this manner opens the airway. To check for breathing, look for chest movement or put your ear next to the victim’s nose and mouth to listen and feel for breath. The two most likely results of an electrical shock are bodily injury (from falling down) and cessation of breathing. While doctors and ambulance are being sent for, you must do the following: 1. Place the victim on the back immediately. Do not waste time on moving to a better place (unless dangerous) or loosening clothing. 2. Clear the mouth and throat. With the casualty lying flat on his back, first remove any obvious obstruction from the mouth, including broken or displaced dentures. 3. Tilt the head back and lift the jaw. Open the airway by tilting the head and lifting the chin. 4. Pinch the nose. Close the casualty’s nose by pinching it with the index finger and thumb. For Training Purposes Only PART 66 – Basic Training Cat B1 – Module 7 5. Blow. Take a full breath and place your lips around the casualty’s mouth, making a good seal. Blow into his mouth until you see the chest rise. Take approximately two seconds for full inflation. 6. Remove your lips and allow the chest to fall fully. Deliver subsequent breaths in the same manner at a rate of approximately 10 to 12 times per minute. In situations where mouth injuries make a good seal impossible, the mouth –to –nose method of artificial respiration may be chosen. While it is usually easy to blow air into the nose, it is not so easy for the air to escape, because the soft parts of the nose may flop back like a valve. The method is as follows: 1. With the casualty’s mouth closed form a tight seal with your lips around the casualty’s nose and blow. 2. Open the mouth to let the breath out. Continue as stated above. Continue artificial respiration until the victim breathes naturally or a medical person arrives! Issue: August 2014 Page 19 of 926 Modul 7 Safety Precautions – Aircraft an Workshop 7.1.2 Safety Precautions at the Aircraft 7.1.2.1 General Safety Rules check that these switches and push –buttons are either correctly shrouded or in their ’safe’ positions. The following switches and push –buttons are to be checked: Loose Articles It is dangerous to leave tools and other loose articles in an aircraft as they may foul the flight controls. When the aircraft is manoeuvring in the air a loose item may easily change its position, lock the controls and cause the aircraft to crash because of the loss of control. Therefore it is essential that every precaution is taken to prevent such a risk. On completion of any work carried out on an aircraft, a full and thorough ’loose article check’ should be carried out and signed for on the relevant worksheet. A complete tool check of the box and associated tools and equipment is carried out and signed for in the relevant record. This signature certifies that all tools and equipment used have been returned and a loose article check carried out. If for any reason there is a lost tool or piece of equipment the aircraft is to be grounded for further investigation and an ’all trades check’ carried out. Polyurethane paints are dangerous to health when applied by aerosol or other spraying methods. The following precautions must be taken: Never touch the switches or push –buttons in the cockpit unless you know the service affected! Inadvertent operation can be dangerous and may cause damage to the aircraft or the death of personnel. explosive jettison and control severing devices secret equipment destroying mechanisms engine starter buttons gun and missile buttons fire extinguisher switches fuel jettison switches bomb installation panel switches firing buttons for assisted take –off units. Polyurethane Finishes Switches and Push –Buttons Many switches and push –buttons are ’shrouded’ or ’hooded’ against accidental operation. When entering the cockpit each airman should For Training Purposes Only PART 66 – Basic Training Cat B1 – Module 7 Issue: August 2014 All personnel using such paints are to use barrier cream on their hands and protect themselves from skin and hair contamination. All splashes are to be removed immediately with soap and water. Smoking, eating and drinking are prohibited in spray shops or other areas where these paints are used. Air supply respirators are to be worn by all persons spraying these paints. Every effort is to be made to ensure that the air fog is as low a concentration as possible. Face masks are not to be removed until the air is clear again. Warning notices are to be posted to ensure that visitors to the hangar or spray shop do not enter until the air is clear. When a brush or roller is used to apply the paint a respirator must be worn. It can be removed as soon as the painting is finished. Page 20 of 926 Modul 7 Safety Precautions – Aircraft an Workshop PART 66 – Basic Training Cat B1 – Module 7 Compressed Gases Modern aircraft need a convenient, quick method of being supplied with gas of one form or another to aircraft systems or components. High-pressure gas cylinders meet this requirement. Cylinders designed for the storage of gases are made of steel and normally have a manual stop valve and in many instances a pressure regulator and pressure gauge at its neck. The cylinders are painted all over in one colour and the content name is printed in large letters of a contrasting colour. The most common gases required by aircraft are: compressed air compressed nitrogen compressed oxygen carbon dioxide (aircraft systems) (systems, tubes and undercarriage) (crew/passenger survival) (fire extinguishers). Refer to Figure 1. The colour code markings on gas bottles are as distinctive as they are important because if a wrong gas is inadvertently filled into a system or component the result can be disastrous for both aircrew and aircraft. Serious accidents with gas cylinders have often been caused by abuse, mishandling and wrong storage. It is the direct responsibility of each cylinder operator that proper safety measures are in effect and that he knows the safety rules concerning the handling and use of gas cylinders. Note: To exlude any doubts, each cylinder has a plate or stamp with detailed information of its content. Figure 1: Colour Coding of Gas Cylinders (Examples) For Training Purposes Only Issue: August 2014 Page 21 of 926 Modul 7 Safety Precautions – Aircraft an Workshop Compressed Air Precautions must be taken at all times when handling high –pressure air and lubrication equipment. Accidental injection of compressed air or lubricant into the skin can cause serious injury. Therefore highpressure air nozzles or lubricating guns are never to be directed towards the clothing, hands or any other parts of the body. Any accidental injection into the skin must receive immediate medical treatment. PART 66 – Basic Training Cat B1 – Module 7 position, but it should be remembered that maintenance men may have to work in that area. The only safe way to prevent an accident is to guard all the dangerous parts and areas permanently. Further Health Hazards Radiation Never direct a compressed air jet at anybody else. Never use a compressed air jet for cleaning away swarf or other small particles that may inadvertently become lodged in the eye or other body part. Oxygen Pure oxygen in contact with oil or grease can produce a spontaneous explosion and subsequently a fire. Any leakage in an oxygen system is dangerous unless the valves and pipelines are clean and free from these materials. Oxygen pipelines and components can be recognised by the international markings at every joint and care must be taken not to contaminate or lubricate the valves or pipelines. Machine Tools Machines with moving parts are always a source of danger. It is always to be assumed that ’the unexpected will happen’, i.e. a dangerous situation will primarily arise when an operator’s attention is distracted or his concentration is affected by fatigue. Thought should also be given to the hazards likely to arise during cleaning or maintenance operations. For instance, some moving parts such as overhead shafts are thought to be safe because of their For Training Purposes Only Radar equipment is a source of microwave radiation which can be very dangerous to health. Personnel, in their own interest, must keep well outside the danger zone during any ground testing or transmission. When radar equipment of a grounded aircraft is being operated a danger zone with a radius of 15 m is to be roped off and signboards stating the lethal dangers are to be placed. Some of the radio valves used in older aircraft radio sets contain radio- active materials. Such valves are identified by orange coloured bands, or the words ’Radiation Hazard’. If these valves break harmful particles can be released and care must be taken not to inhale dust or vapours. The fragments of a broken radio –active valve must not be touched with the bare hands at all. If a radio –active valve is broken the Maintenance Engineering Officer on duty is to be consulted immediately. An X –ray machine is a source of potential danger to the operator due to the adverse effect of the ionising radiations on the human body. Therefore, X –ray equipment is not to be operated or tested by persons who do not possess a certificate of competency to operate the equipment. Issue: August 2014 Page 22 of 926 Modul 7 Safety Precautions – Aircraft an Workshop Cleaning Materials The materials used to remove dirt and preservative from aircraft components often cause skin irritation unless preventative action is taken. Before working with these materials a ’barrier cream’ is to be applied to the hands. Additionally, rubber gloves should be worn whenever possible, otherwise dermatitis or other inflammation of the skin may be encouraged. After completion of the work the hands are always to be scrubbed and washed with soap and water. Personnel should also take care not to inhale vapours evaporating from cleaning fluids as they may be toxic; this applies especially to trichlorethylene and carbon –tetrachloride. Furthermore, it is dangerous to smoke within 30 min after having used these cleaners because traces of fluid vapour on the lips in contact with the nicotine in the tobacco produces a deadly poisonous gas. The first indications of being affected when working with cleaning fluid in an unventilated place may be drowsiness, headache or painful eyes. Should any of these symptoms occur get to the fresh air immediately! Methyl –Bromide Methyl –bromide, a liquid used in fire extinguishers, forms a toxic gas when in contact with fire or hot material. The resulting gas as well as the liquid causes burns or blisters on the skin. If the liquid is splashed on the hands or other parts of the body, the affected part should be washed immediately with soap and water. Personnel affected by the vapour must not smoke and should obtain immediate medical attention. For Training Purposes Only PART 66 – Basic Training Cat B1 – Module 7 Another chemical agent used in fire extinguishers is carbon – tetrachloride. Its effects and the precautions to be taken are the same as described above. Note: Hot water burns; special fuels, ammonia and other liquids will burn the skin as well! 7.1.2.2 Fire The very nature of aircraft makes them highly susceptible to fire: they carry large amounts of highly flammable fuel as well as oxygen under high pressure. Chemically, a fire is a reaction between a material and oxygen. During this process, the material is reduced to its elements with the release of ma great amount of heat. Example: Paper is an organic material basically composed of hydrogen and carbon. When it is heated up to its kindling temperature, i.e. when reaching the flash point, it will unite with the oxygen in the air. Finally, it will change into carbon dioxide and water. Other elements in the paper and incomplete combustion will result in a residue known as ash or black carbon. From this example it can be seen, that there are three requirements for fire to occur: there must be a combustible material there must be oxygen to combine with the material the temperature of the combustible material must reach the flash point (kindling temperature) of this material. Refer to Figure 2. Issue: August 2014 Page 23 of 926 Modul 7 Safety Precautions – Aircraft an Workshop PART 66 – Basic Training Cat B1 – Module 7 Different materials have different flash points and other characteristics like autoignition temperatures. E.g. the flash point of diesel varies between 52°C and 96°C, that of kerosene between 38°C and 72°C while the autoignition temperature of both is between 210°C and 220°C. Fuel (gasoline) has a flash point of – 40°C and an autoignition temperature of 246°C. Other materials, especially solid ones like wood, have considerably higher flash points than liquids. Finally, the concentration of oxygen also determines the combustibility of a material. For example, oil or grease may ignite at room temperature already when blanketed with pure oxygen. Classification of Fires Note: There are several different fire classification systems known all over the world. In this Chapter, only the systems applied in USA and Europe will be mentioned. European System Fires are generally classified according to the following definitions: Figure 2: Typical Firepoint For Training Purposes Only Issue: August 2014 Class ’A’: The majority of fires fall in class ’A’ which indicates the burning of combustible materials such as wood, paper and cloth. Aircraft cabin fires are usually of this class. This type of fire can most effectively be extinguished by cooling with water. Class ’B’: Class ’B’ indicates fires from flammable liquids such as paraffin, fuel, paint, thinners, varnishes, oil and from greases and fats. These can most effectively be extinguished by smothering with foam or other agents which exclude (’cut off’) the air’s oxygen. Class ’C’: Class ’C’ fires are those in which escaping gases are involved. Page 24 of 926 Modul 7 Safety Precautions – Aircraft an Workshop PART 66 – Basic Training Cat B1 – Module 7 Class ’D’: Class ’D’ indicates fires with burning metals, e.g. magnesium. The use of the wrong type of extinguisher can intensify these fires rather than extinguishing them. Class ’E’: Class ’E’ fires are those in which energised electrical equipment and wiring is involved. The safest method to extinguish these fires is to displace the oxygen by applying a gas or dry powder into the vicinity of the fire after having switched OFF the current. Classification System applied in USA Class ’A’: Class ’A’ fires are those in which combustible materials such as wood, paper or textiles burn. Aircraft cabin fires are usually of this class. Class ’B’: Class ’B’ fires involve combustible liquids such as gasoline, oil, fuel and many paint thinners and solvents. Class ’C’: Class’C’ fires are those in which energised electrical equipment is involved. Class ’D’: Class ’D’ fires are those in which some metal is burning. 7.1.2.3 Types of Fire Extinguishers Refer to Figure 3. Figure 3: Dry Powder Fire Extinguisher For Training Purposes Only Issue: August 2014 Page 25 of 926 Modul 7 Safety Precautions – Aircraft an Workshop PART 66 – Basic Training Cat B1 – Module 7 Portable fire extinguishers are mainly used for small fires. They are also used by the first man who detects a fire for first –aid fire fighting. Dry Powder Fire Extinguishers Dry powder fire extinguishers are designed mainly for immediate fighting of small fires. Larger fires may be fought only by the use of several extinguishers at the same time. The dry powder normally used for fire fighting is sodium hydrogen carbonate powder. This dry powder is used for fighting class B and C fires. Dry powder is very effective in fighting heavily flaming fires. Class A fires must be re-extinguished with water, though, because of the danger of reflash due to glow formation. Refer to Figure 4. Figure 4: Portable CO2 Fire Extinguisher For Training Purposes Only Issue: August 2014 Page 26 of 926 Modul 7 Safety Precautions – Aircraft an Workshop Typical extinguishers are charged with 12 kg (26.5 lbs) or 6 kg (13.2 lbs) of dry powder. A dry powder extinguisher consists of cylindrical casing containing the dry powder lifting handle hose with discharge lever operated nozzle carbon dioxide (CO2) cylinder rotary valve for releasing the carbon dioxide. A pressure relief valve protects the equipment against overpressure in the extinguisher and is set to ’open’ at a pressure of approx. 24 bar (approx. 350 psi). The CO2 is released by fully opening the rotary valve. The propellant flows through the gas tube and check valves into the extinguisher casing. It loosens and stirs up the dry powder and raises the pressure within the fire extinguisher casing to approx. 15 bar (approx. 220 psi). Now, the fire extinguisher is ready for use. When the discharge lever is operated, the dry powder is discharged by the gas pressure through the riser, hose and nozzle. The burst of powder may be interrupted by releasing the discharge lever. Operation and Handling 1. Remove the fire extinguisher from its bracket. 2. Point discharge nozzle away from your body. 3. Fully open the rotary valve. Wait until the compressed gas has built up the required pressure in the fire extinguisher casing (until the hissing sound stops after 4 to 5 s). 4. Before attempting to fight the fire operate the extinguisher by discharging a small burst of powder. This ensures that the extinguisher has been activated. For Training Purposes Only PART 66 – Basic Training Cat B1 – Module 7 5. If possible, keep a safe distance from the scene of fire: 3 to 5 m (9.8 to 16.4 ft), allowing a powder cloud to form, as only a cloud has an extinguishing effect. 6. Start to discharge the dry chemical powder in short bursts. Hold the pressurized hose in the safety grip (the back of your hand up) to prevent it from lashing. 7. Make yourself as small as possible in front of the fire (protection against flame and radiant heat). 8. Direct the powder cloud towards the flame and move the nozzle to cover the whole fire. Do not point the nozzle straight into a liquid fire (class B). 9. When first fighting a fire, do not fully discharge dry chemical extinguishers, but in short bursts, the length of which varies with the size of fire, extending to a continuous stream (20 s to 25 s), or by using 2 or more fire extinguishers at the same time. 10. After use, turn the fire extinguisher upside down and press the discharge lever torelease all pressure from the extinguisher while holding the hose. Do not return the extinguisher to its bracket, but have it refilled immediately. Water Fire Extinguishers Water fire extinguishers are very similar in design to dry powder fire extinguishers. Instead of a chemical agent these extinguishers are filled with water. Water can be used for fighting fires of class A only. The advantage of water is the possibility of extinguishing the glow of solid fires. The operation and handling is very similar to that of dry powder extinguishers. Issue: August 2014 Page 27 of 926 Modul 7 Safety Precautions – Aircraft an Workshop PART 66 – Basic Training Cat B1 – Module 7 Foam Extinguishers Foam extinguishers are ideal where both class A and class B fire risks exist. The extinguishing agent, aqueous film forming foam (AFFF), is particularly suited to fires of liquid materials such as petrol, paint, oils etc. Carbon Dioxide Fire Extinguishers CO2 fire extinguishers are designed for fighting incipient and small fires in electrical systems, galleys, provision and paint stores and for extinguishing small amounts of burning liquids. Carbon dioxide is electrically non –conductive and does not leave any residue. Its use is authorized for class B fires, but it may also be used for fighting small class A and C fires. Carbon dioxide (which is 1.5 times heavier than air) covers the fire and removes part of the atmospheric oxygen. It smothers the fire with an additional slight cooling effect. 6 kg (13.2 lbs) of CO2 will result in approx. 3,000 l (792.5 gal) of carbon dioxide gas. Refer to Figure 5. For Training Purposes Only Issue: August 2014 Page 28 of 926 Modul 7 Safety Precautions – Aircraft an Workshop PART 66 – Basic Training Cat B1 – Module 7 Figure 5: Colour Code of Fluid Lines For Training Purposes Only Issue: August 2014 Page 29 of 926 Modul 7 Safety Precautions – Aircraft an Workshop PART 66 – Basic Training Cat B1 – Module 7 CO2 fire extinguisher consists of Do not hold the snow tube during operation as this will cause severe skin burns. steel cylinder filled with (usually) 6 kg (13.2 lbs) of CO2 handle discharge valve high –pressure hose snow spray head or snow tube. 3. Turn the handwheel counter –clockwise. 4. Attack the fire: a) Move snow spray head/snow tube in circles in order to speed up distribution of CO2 and achieve an improved extinguishing effect. b) Keep as low as possible while attacking the fire, as the discharged stream of CO2 pushes the flames upwards, which might result in burns. c) Do not open the valve too far, since a low –velocity CO2 stream has a better extinguishing effect. d) After use, have the extinguisher refilled immediately. Do not return the extinguisher to its bracket. The fire extinguisher is activated by turning the handwheel. By opening the discharge valve, liquid carbon dioxide flows through the high –pressure hose and expands in the snow tube. The discharge valve is provided with a safety device including a diaphragm for preventing the build –up of pressure in the bottle. When the diaphragm is ruptured, a green or red cover disk is ejected, revealing a red –and –white striped indicating disk. CO2 is released, and the fire extinguisher cannot be used. Fire extinguishers (Type K6) with a charging factor of 1.34 must not be exposed to sustained temperatures of more than 35°C (95°F). When temperatures above 50°C (122°F) are to be expected (operation in tropical areas), the testing and charging facility must reduce the CO2 charge, so as to prevent the pressure from rising to 186.4 bar (2,702 psi), which would result in the escape of CO2 via the safety device. Note: Charging factor = ratio of volume in liters to charging weight in kilograms. Operation and Handling 1. Take the fire extinguisher from its bracket. 2. Pull snow spray or snow tube from the bracket and point it to the fire. For Training Purposes Only After a CO2 extinguisher has been discharged in a confined space the space must be evacuated. CO2 will replace the oxygen without any indication, i.e. smell, etc. and it can create a life hazard. Before re –entering such a space make sure that the space has been ventilated. Halogenated Hydrocarbon Extinguishers The most popular fire extinguishing agent for cabin fires in modern aircraft is HALON 1301. The agent has an immediate effect on the fire by chemically breaking the chain reaction of the combustion process. Due to the high rate of flow, it is distributed very fast. Besides the use inside the cabin, HALON is very effective for extinguishing fires in engine compartments of both piston and turbine powered aircraft. In engine compartment installations, the HALON Issue: August 2014 Page 30 of 926 Modul 7 Safety Precautions – Aircraft an Workshop container is pressurised by compressed nitrogen and is discharged through spray nozzles into the nacelle. – HALON 1301 itself is not dangerous to health, as long as persons are exposed to concentrations of less than seven vol –% for a period not longer than four to five min. only. – Handling Precautions – Fire can cause loss of lives, equipment, materials and buildings. Therefore it is essential that all personnel should have training in the use of extinguishers and precautions to prevent fire. All standing fire orders of the base must be fully observed at all times. The following additional rules and considerations apply: – Smoking and use of fire are prohibited on aprons, in aircraft hangars, in aircraft repair shops marked by relevant warning signs, as well as within a safety distance of 15 m around parked aircraft and refuelling installations. Open fire is only allowed in rooms specially equipped according to the fire protection regulations and released for that purpose by the airport authorities. Vehicles and ground equipment with internal –combustion engines operated on the apron, in hangars and aircraft repair shops must have commercial safety provisions, e.g. exhaust installations comprising silencers, in order to prevent the exit of burning gases. Material, equipment and waste has to be kept in such a way and location that fire and explosion hazard is excluded. – Lubricating oils used in or near aircraft hangars and repair shops have to be stored in tanks equipped with the prescribed discharge device. For Training Purposes Only – PART 66 – Basic Training Cat B1 – Module 7 Empty fuel high –pressure storage containers for dangerous materials are not to be kept in hangars and repair shops. Inflammable waste (lubricating oil remainders, used cleaning material, etc.) has to be collected and stored in specially marked metal containers equipped with tight –closing covers. All flammable fluids should be kept in a secure flameproof store. Oils and greases should be kept separate from paints, resins and toxicants. All spillages should be cleaned up immediately by using speedy dry and rags. All contaminated cleaning materials should be disposed of in the correct bins. The containers have to be emptied as often as necessary to avoid spontaneous ignitions of the waste. Waste oil trays and similar containers have to be emptied and cleaned after use. Issue: August 2014 The storage of dangerous material, especially radio –active materials, is only allowed on special permission and under the condition that the relevant safety precautions are observed. The storage of freight, packing cases, building material, devices, etc., outside the specially assigned places is only allowed on special permission. Contamination of airport installations must be avoided. Containers for waste oil shall be used as far as necessary. Contamination has to be removed immediately by those having produced it. Only normal waste water may be drained into the sewer system. If there is any doubt that the water may be contaminated, either by radio-active material or by fuel, oil, Page 31 of 926 Modul 7 Safety Precautions – Aircraft an Workshop etc., it must be stored in special containers and treated accordingly. The official national safety regulations have to be observed. PART 66 – Basic Training Cat B1 – Module 7 In the case of POL with storage time limitations, the production dates mentioned on the package must be observed. Ground support equipment using or storing any type of POL media have signs at the filling necks stating type and quantity to be filled in. Emergency Fire Responses Handling of Fuels On discovering the outbreak of a fire, do you know V how (from where) to get assistance without delay? the sound of the fire alarm? where the nearest fire point is? how to use the fire –fighting appliances correctly? the nearest emergency exit? If not, find out immediately! 7.1.2.4 Handling of Chemicals Petrol, Oils, Lubricants and Aviation fuels have a flash point of–25°C, i.e. even at this temperature there will be a vapour above the fuel surface which will flash or burn immediately if ignited. Therefore, smoking and working with open fires in the vicinity of aircraft are strictly forbidden. Turbine fuels (JET A/JET A1) are liable to lead to skin irritations because of their high content of sulphur (0.2 to 0.4 %). Refer to Figure 6. In aviation a large number of petrol, oils and lubricants (POL) contain crude oil derivatives, especially fuels for piston and gas turbine engines. Lubricants for piston engines are also crude oil derivatives while turbine oils are exclusively synthetic oils today. Further POL are hydraulic oils, water methanol mixtures, special oils, cleansing fluids, special grease and preservation media. All types of POL have a type designation or specification number and must be used according to the applicable guidelines. Alternative products may only be used according to operating instructions or upon consultation with the appropriate department in charge. For Training Purposes Only The aviation fuels in use today are toxic because of the relatively high content of plumbing tetra ethyl (0.06 to 0.12 %). This lead combination will be combusted to plumbing oxide in the cylinders so that the exhaust gases, the exhaust tubes and even the aero engine oil will be somewhat toxic. Handling of Lubricants For piston engines, mineral oils with special viscosity characteristics are used. For gas turbines, synthetic oils are used which are thin – bodied even at low temperatures. Oils, in particular old oil, may cause ulceration on sensitive skin even after short exposure. Long exposure times to oil are to be avoided because engine oils frequently contain chemical additives. To avoid mistakes, lubricants may only be taken from containers which clearly state the type of lubricant. Issue: August 2014 Page 32 of 926 Modul 7 Safety Precautions – Aircraft an Workshop The following precautions have to be taken in the case of accidents and exposure to larger amounts of operating media such as fuels and lubricants: Immediately change any clothing exposed to fuels and lubricants. Thoroughly wash all parts of your body exposed to fuels or lubricants with water and soap. Rinse thoroughly with water. Apply grease creme to dry skin. Special attention is to be paid to the fact that spilled operating and cleansing media on the hangar floor and the apron are a serious risk as regards accidents of persons and vehicles. To avoid sliding, sawdust, granulate or foam should be used to cover affected areas which should then be thoroughly cleaned. 7.1.2.5 The following rules apply to first aid: Furthermore there are additional factors which have a certain influence on the endangered person. When working in heat or heat radiation the danger potential increases due to a raised blood circulation. A high air humidity makes the skin swell and thus makes it more receptive. Due to the above –mentioned reasons, endangered parts of the body must be protected appropriately to avoid any penetration via contact with the skin when dealing with dangerous chemicals. For Training Purposes Only First Aid in Case of Accidents at Work Everybody is obliged to help in emergencies, in particular in case of accidents at work. However, only a person trained in first aid can really prevent the worse from happening. Handling of Chemicals Sulphuric acid, hydrochloric acid, and nitric acid are extremely dangerous materials due to their corrosive characteristics. Hydrofluoric acid is an extremely dangerous material due to its corrosive and poisonous characteristics. PART 66 – Basic Training Cat B1 – Module 7 Be alert, careful, quiet and efficient. Remember that human life may depend on correct and fast First Aid. The emergency bandage will have a decisive bearing on the healing process of an injury. As a matter of principle, a doctor or the first aid man in charge should be informed of each accident. Only provide first aid if you are trained in first aid and the necessary means (dressing material, first aid kit) are available. Never try to take the place of a doctor. Blinkered zeal will be detrimental for the person injured. As a person trained in first aid, you must know the first aid provisions available at the place of work and be able to handle them correctly. In case of accidents at work, the location of accident is to be safe –guarded and the cause of the accident eliminated so that nobody else will be endangered as well (for example: switch off electricity, cut off the engine, etc.). There are several first - aid installations on the premises. Every person must know how to reach the doctor and the first aid man. The first aid man must know the location and the contents of the first aid kits available. The first - aid material used for an accident must be properly replenished thereafter. Issue: August 2014 Page 33 of 926 Modul 7 Safety Precautions – Aircraft an Workshop PART 66 – Basic Training Cat B1 – Module 7 It is a severe violation of safety rules at work to use first - aid material without justification. ’Instructions for first aid in Case of Accidents’ are posted at conspicuous locations. They describe first - aid measures in plain words and use illustrations for better understanding. They also state the telephone numbers of the accident information station, the doctor and the first aid service. There are several manuals and regulations dealing with accident prevention. They include national regulations and instructions for handling and storage of dangerous chemicals, for dealing with electrical appliances, compressed gases, and inflammable liquids, such as fuels and lubricants. In addition there are corresponding military/Air Force regulations. For Training Purposes Only Issue: August 2014 Page 34 of 926 Modul 7 Workshop Practices 7.2 Workshop Practices 7.2.1 Tools, Dimensions and Calibration 7.2.1.1 Tools and Test Equipment 7.2.1.2 Equipment, Tools and Material According to EASA Part –145 The rules regarding equipment, tools and materials are prescribed in EASA Part –145.A.40: Tools will only be readily available when needed if they are stored properly and according to type. After use, all tools have to be checked for completeness and defects and must be properly stored again. The primary rule to be applied in ground servicing is that, after each activity carried out, a check must be made whether all tools and parts used or put down somewhere during the work have been removed again. Never put tools, parts and cleaning rags at hidden places! Always check your tool set for completeness after work! Special tools and test equipment are to be used according to the applicable instructions for use. Also, the inspection dates have to be observed. Special care has to be taken when working with pneumatic, hydraulic and electrical test equipment. The maximum pressure or voltage values as well as the type of current applicable have to be observed. Master gauges, i.e. calibrated test instruments, have to be handled with special care and properly stored after use. The calibration checks prescribed for master gauges have to be carried out by the workshops in charge at regular intervals. For Training Purposes Only PART 66 – Basic Training Cat B1 – Module 7 a) The organisation shall have available and use the necessary equipment, tools and material to perform the approved scope of work. 1. Where the manufacturer specifies a particular tool or equipment, the organisation shall use that tool or equipment, unless the use of alternative tooling or equipment is agreed by the competent authority via procedures specified in the exposition. 2. Equipment and tools must be permanently available, except in the case of any tool or equipm ent that is so infrequently used that its permanent availability is not necessary. Such cases shall be detailed in an exposition procedure. 3. An organisation approved for base maintenance shall have sufficient aircraft access equipment and inspection platforms/docking such that the aircraft can be properly inspected.” b) The organisation shall ensure that all tools, equipment and particularly test equipment, as appropriate, are controlled and calibrated according to an officially recognised standard at a frequency to ensure serviceability and accuracy. Records of such calibrations and traceability to the standard used shall be kept by the organisation.” Issue: August 2014 Page 35 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Workshop Practices 7.2.1.3 Refer to Figure 1. Measuring Systems In order to arrive at values of distance, weight, speed, volume, temperature, pressure, etc., it is necessary to become familiar with the accepted methods for measuring such values and the units used to express them. Through the ages, human beings have devised many methods for measuring. However, it would be impossible to cover even a small part of the information accumulated for these several thousands of years. Today, the English (Imperial) system and the SI metric system are used extensively throughout the world. English (or: Imperial) System The majority of people in English –speaking countries is familiar with the English unit system. Its basic units of length and weight are inch (’in’) and pound (’lb.’). For example, the complete documentation of BOEING aircraft follows the English unit system. English Length System Originally the units inch, foot, yard and mile were not exact multiples or factors of each other. But for the sake of convenience the foot was made equal to 12 inches, the yard was made 3 feet and the mile was made 5,280 feet or 1,760 yards. It is said that the inch was the width of a finger, the foot was the length of a human foot and the yard was the distance from the tip of the nose to the tip of the thumb when the arm was extended to the side with the thumb pointing forward. The mile was originated by the Romans and represented 1,000 paces, each being two steps (appr. 5 –6 feet). This distance was later changed to 5,280 feet, which is the statute mile used today in the USA. For Training Purposes Only Issue: August 2014 Figure 1: Origin of the Nautical Mile Page 36 of 926 Modul 7 Workshop Practices The nautical mile (’nm’ or ’NM’), internationally used for navigation, is based on one –sixtieth of one degree of the earth’s circumference at the equator. Its length is approx. 6,080 feet or 1,852 m. Many other units of length measurement have been used in various countries; some being the rod, the ell, the fathom and the league. All these units were established to meet particular needs in different areas. Because of the increase in travel, international commerce and scientific exchanges, there is a need for standardisation of measurements. This is taking place through the use of the metric system. Temperature Unit The temperature is the degree of heat or cold measurable in a body. The measurement is accomplished with a thermometer, and the value is expressed in degree Fahrenheit or Celsius. Fahrenheit Unit In the English/American unit system, temperatures are usually given in degrees Fahrenheit. In this scale, the freezing point of water is 32 degrees Fahrenheit (°F) and the boiling point 212 °F, placing the boiling and freezing points of water exactly 180 degrees apart. PART 66 – Basic Training Cat B1 – Module 7 Metric System The International System of Units, which is now called the SI (Système International d’Unités), had its origin when the meter was selected as the unit of length and the kilogram as the unit of mass. These units were created by the National Academy of Science and adopted by the National Assembly of France in 1795. The United States Congress legalised the use of the metric system throughout the USA in 1866. But it was not until December 1975 that the metric bill was signed into law in the USA to convert all measurements into the metric system. One of the great advantages of the metric system is the fact that it is built on decimal units. Each basic unit may be multiplied or divided by ten as many times as it is necessary to get a convenient size. Each of these multiples has a definite prefix, symbol and name. Refer to Figure 2. Note: On the Celsius scale, the freezing and boiling points of water are exactly 100 degrees apart, thus the unit of this scale. A temperature interval of one degree Fahrenheit is an interval of 5/9 of one degree Celsius. The Fahrenheit and Celsius scales coincide at - 40 degrees (i.e. - 40 oF and - 40 oC describe the same temperature). For Training Purposes Only Issue: August 2014 Page 37 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Workshop Practices This length is equal to the distance travelled by light in vacuum during 1/299’792’458 of a second. This means, that the meter is based on a speed –of –light reference that will always be the same. In order to provide an exact reference meter for scientific purposes, a bar of platinum iridium was inscribed with two lines exactly 1 m apart at the freezing point of water, which is at 32 °F or 0 °C. The international meter bar is kept at the ’Bureau of Weights and Measures’ near Paris. Copies of this bar have been made and are kept in depositories in all principal nations. The ’meter’ has derived its name from the Latin ’metrum’ and the Greek ’metron’, which both mean ’measure’. One meter is equal to 39.37 in, which is a little longer than one yard. Thus 1 decimeter (dm) is equal to 3.937 in. In practice, the following units of length are most commonly used: 10 millimeters 10 centimeters 10 decimeters 10 hectometers = = = = 1 centimeter 1 decimeter 1 meter 1 kilometer Units and Conversion Figure 2: Origin of the Meter The basic unit of measurement in the metric system is the meter. The length of a meter is based on the distance equal to one ten –millionth of the distance from the equator to the poles measured along a meridian. The following table shows units with its abbreviations commonly used in aviation business. Note: A meridian is the shortest distance from north pole to south pole along the earth’s surface and at right angles to the equator. For Training Purposes Only Issue: August 2014 Page 38 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Workshop Practices Abbreviation Weight: g kg lbs Volume: l US gal Imp gal liq QT QT Length: in ft mile nm Speed: knots mph Pressure: psi bar Power: hp W Unit Equivalent gram kilogram pound (1/1,000 kg) 1,000 g 453.6 g liter US gallon imperial gallon American quart British quart 3.785 l 4.546 l 0.946 l 1.136 l For exact work, it is an absolute must to know the conversion of meter and inch. Hole sizes, material gages etc. are often given in inch and must be often converted to the metric system. Conversion English – Metric Note: Keep in mind: 1 in = 25.4 mm Example: 1 in = in = in = 0.312 in = 2 1 4 3 inch foot/feet statute mile nautical mile 25.4 mm 0.3048 m 1.609 km 1.852 km nautical miles per hour miles per hour 1.852 km/h 1.609 km/h pounds per square inch 0.0689 bar 14.5038 psi horse power Watt 745.7 W 0.001341 hp 16 25.4 2 25.4 2 25.4 𝑥 3 16 25.4 ô 0.312 = 12.7 mm = 6.35 mm = 4.76 mm = 7.92 mm. Refer to Figure 3. Unit Conversion For Training Purposes Only Issue: August 2014 Page 39 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Workshop Practices Inches 1/64 1/32 3/64 1/16 5/64 3/32 7/64 1/8 9/64 5/32 11/64 3/16 13/64 7/32 15/64 1/4 17/64 9/32 Decimal Equivalent Millimeter Equivalent 0.0156 0.397 0.0313 0.794 0.0469 1.191 0.0625 1.585 0.0781 1.985 0.0938 2.381 0.1094 2.778 0.1250 3.175 0.1406 3.572 0.1563 3.969 0.1719 4.366 0.1875 4.762 0.2031 5.159 0.2188 5.556 0.2344 5.953 0.2500 6.350 0.2656 7.747 0.2813 7.144 11/32 23/64 3/8 25/64 13/32 27/64 7/16 29/64 15/32 31/64 1/2 5/16 21/64 0.2969 7.541 0.3125 7.937 0.3281 8.334 For Training Purposes Only 8.731 0.3594 9.128 0.3750 9.525 0.3906 9.922 0.4063 10.319 0.4219 10.716 0.4375 11.112 0.4531 11.509 0.4688 11.905 0.4844 12.203 0.5000 12.700 Figure 3: Inch/Metric Conversion Table For reasons of convenience and to reduce errors caused by wrong calculation, conversion tables like that shown in Figure 3 have been developed. Convervion Fahrenheit – Celsius To convert one type of temperature to the other the following formulas are used: o 19/64 0.3438 C= 5 9 (oF – 32) o F = 95 (oC 32) Refer to Figure 4. Issue: August 2014 Page 40 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Workshop Practices For reasons of convenience and to reduce errors caused by wrong calculation, conversion tables like that shown in Figure 4 have been developed. 7.2.1.4 Fits and Tolerances Introduction Tolerance in engineering is an allowance, given as a permissible range, in the nominal dimension or value specification of a manufactured object. The purpose of a tolerance is to provide leeway for imperfections or other uncontrollable factors such as temperature or line voltage. For example, an electrical specification might call for a resistor with a nominal value of 100 Ω , but will also state a tolerance such as ’1 %’. This means that any resistor with a value in the range 99 Ω to 101 Ω is acceptable. It would not be reasonable to specify a resistor with a value of exactly 100 Ω, because the resistance will vary with temperature and other factors in any case. The tolerance may be specified as a factor or percentage of the nominal value, a maximum deviation from a nominal value, an explicit range of allowed values, or refer to a published standard where this information is specified. Tolerance can be symmetrical, as in 400.1mm, or asymmetrical, such as 40+0.2/ –0.1mm. Figure 4: Temperature Conversion Table For Training Purposes Only It is good engineering practice to specify the largest possible tolerance while maintaining functionality, since closer or tighter tolerances are more difficult to manufacture and hence cost more to either build or buy. Tolerance is related to, but different from fit, which is a designed in clearance or interference between two parts. For example, if a shaft with a nominal diameter of 10 mm is to have a sliding fit within a hole, Issue: August 2014 Page 41 of 926 Modul 7 Workshop Practices PART 66 – Basic Training Cat B1 – Module 7 the shaft might be specified with a tolerance range from 9.964 to 10 mm and the hole might be specified with a tolerance range from 10.04 to 10.076 mm. This would provide a clearance fit of somewhere between 0.04 mm (largest shaft paired with the smallest hole) and 0.112 mm (smallest shaft paired with the largest hole). In this case the range of tolerance for both the shaft and hole is 0.036 mm. Tolerance is different from safety factor, but an adequate safety factor will take into account relevant component tolerances as well as other possible variations. Deviations and Tolerances The quality of a hole or a shaft depends on the surface texture and on the deviation of the actual diameter from the desired (nominal, basic) diameter. Refer to Figure 5. Figure 5: Deviations and Tolerances For Training Purposes Only Issue: August 2014 Page 42 of 926 Modul 7 Workshop Practices PART 66 – Basic Training Cat B1 – Module 7 Depending on the purpose of the workpiece the quality of the hole or shaft must meet certain requirements. The tolerance gives an allowable range for the actual diameter. The actual diameter of the workpiece must be within the tolerance zone to meet the given conditions. The width of the tolerance zone depends on the required quality and on the size of the basic diameter. Tolerance grades are standardized and give the width of the tolerance zones. Tolerance grades are identified by IT (for ISO tolerance), and are numbered 1 to 18. An excerpt of this standard is given in Figure 1, lower part. Refer to Figure 6. Figure 6: Positions of Tolerance Zones For Training Purposes Only Issue: August 2014 Page 43 of 926 Modul 7 Workshop Practices PART 66 – Basic Training Cat B1 – Module 7 The tolerance grade gives only the width of the tolerance zone but not the position of this zone in relation to the zero line. The positions are indicated by letters: capital letters for holes and small letters for shafts. The number of the tolerance grade is added to the letter. All holes with the tolerance zone letter H have zero lower deviation. Such holes are called ’standard holes’. If shafts shall be fitted in holes tolerance zones and especially their positions must be taken into account. The tolerance grade of a shaft to be fitted in a hole is usually in the same range as the tolerance grade of the hole. The positions of the tolerance zones for the shafts may be totally below the zero line, intersecting or above the zero line. According to these relations the shafts will fit more or less easily in the holes. Fits Refer to Figure 7. Figure 7: Types of Fits For Training Purposes Only Issue: August 2014 Page 44 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Workshop Practices The fit, i.e. the fitting of the shaft in the hole, may be: 7.2.1.5 a clearance fit a transition fit an interference fit. Calibration of Tools and Equipment Calibration Standards In a clearance fit the shaft tolerance zone position is completely below the hole tolerance zone. With (maximum) upper deviation of both shaft and hole there is a maximum clearance between shaft and hole. With (minimum) lower deviation of both shaft and hole there is still a minimum clearance. The examples H9 –e9, H8 –f7 and H7 –g6 of Figure 4, lower part, are clearance fits. In a transition fit there is a maximum clearance if both hole and shaft have the upper deviation, i.e. the hole has the maximum allowable diameter and the shaft has the minimum diameter. If the shaft has maximum diameter and the hole has minimum diameter, i.e. if both have lower deviation, the shaft diameter is slightly wider (by some "m) than the hole. In this case the shaft must be pressed into the hole. There is no clearance and the oversize of the shaft gives an interference. In an interference fit the shaft diameter is always wider by a few "m than the hole; there is always interference. A calibration regulation for tools and equipment which have to be calibrated must always be available on site. Theses documents must contain all information necessary for proper calibration. Calibration refers to determining and documenting the deviation of the reading of a meter or controller from the correct value of the measuring. Calibration is a comparison between measurements – one of known magnitude or correctness made or set with one device and another measurement made in as similar a way as possible with a second device. The device with the known or assigned correctness is called the standard. The second device is the unit under test, test instrument, or any of several other names for the device being calibrated. Basically, equipment and tools have to be calibrated according to the manufacturer manuals. In case such manual does not exist the calibration has to be carried out in accordance with valid national or international regulations and rules or the quality assurance management has to prepare a calibration manual for that particular equipment. In engineering drawings the tolerances are added to the nominal (basic) diameter as an index: for shafts as lower index, e.g. 20f7, for holes as upper index, e.g. 20𝐻7 . For Training Purposes Only Issue: August 2014 Page 45 of 926 Modul 7 Workshop Practices Calibration Interval Basically, calibration has to be done at intervals prescribed by the manufacturer. If this information is not available, the quality assurance management has to determine these intervals with respect to the following criteria: stability of the equipment/tool place of operation frequency of operation. PART 66 – Basic Training Cat B1 – Module 7 Stickers for equipment which will not be calibrated at prescribed intervals. These stickers contain the same information as the previous one, however, under the heading recalibration has to be written: ’On Condition’. This sticker has to be marked with a green crossline. This type of equipment cannot be used for measurements. The third type of sticker is used for equipment which is too small to house a common –type sticker. This sticker shows only the next date for recalibration. Calibration Schedule and List of Equipment to be calibrated If measuring equipment has been damaged it must be presented immediately the calibration section for assessment. The calibration intervals are part of the calibration manual and should be mentioned in the list of equipment/tool to be calibrated. Calibration Sticker Refer to Figure 8. For identification and checking purposes each equipment/tool out of the calibration list has to be provided with a clearly visible calibration sticker. There are three types of calibration stickers: The common type, giving information about – the date of the last calibration – the inspector who carried out the calibration including his authorisation code – year and month of the next calibration For Training Purposes Only The calibration schedule has to be edited once a month and printed out. The list of equipment to be calibrated lists all equipment and tools which are due for calibration. The list contains: name of equipment part/identification number calibration interval and manual. Calibration Procedure on Site Calibration has to be done using a standard. Adjustments as well as common maintenance work for measuring equipment have to be taken from the relevant manufacturer documentation. The adjusting device must be sealed after completion of the adjustment. The seals have to be such that they will be damaged if the adjusting device has been manipulated. Issue: August 2014 Page 46 of 926 Modul 7 Workshop Practices PART 66 – Basic Training Cat B1 – Module 7 The procedure for calibration of equipment/tools on site is as follows: a) b) c) d) Cancel the equipment in the monthly schedule. Calibrate the equipment according to the calibration manual. Prepare the calibration report. Fix the new calibration sticker to the equipment. The equipment will be released to service after the report has been signed by an authorised person. e) After customer acceptance the report has to be saved in the respective file. The equipment must be banned and provided with a ’banned’ sticker. If the calibration has not been successful or the values for adjustment could not be reac. Figure 8: Examples of calibration stickers For Training Purposes Only Issue: August 2014 Page 47 of 926 Modul 7 Tools PART 66 – Basic Training Cat B1 – Module 7 Lead Pencil 7.3. Tools Most of the layout marks made on sheet metal should be made with a chinograph or fine –tipped non –permanent marker. These marks can be more easily seen if the metal is wiped clean with lacquer thinner or toluol and degreased. 7.3.1 Common Hand and Power Tools 7.3.1.1 Marking Tools Scribers Do not use a lead pencil to make any mark on the hot section of a turbine engine or on the exhaust system of a reciprocating engine. The heat can cause the carbon from the pencil mark to infuse the metal and cause it to crack. Refer to Figure 1. Common lead pencils can cause scratching an induce graphite into the material. Felt Marking Pen Figure 1: Steel Scriber In sheet metal work, we deal almost exclusively with soft metal and so we seldom need a carbide tip scriber. The handiest scriber is made of plain steel and has a removable point that can be reversed in the handle so it will not be dulled by contacting other tools in the tool box. Scribers are used in sheet metal work only for marking the cut –off lines of a part. They should never be used for marking bend –tangent or sight lines. Any mark on a piece of sheet aluminium or magnesium scratched with a scriber can cause the part to crack (when it is bent) or set up a weak spot (due to corrosion by a breakdown in surface coating). For Training Purposes Only Felt marking pens are becoming more widely used by sheet metal technicians because the marks they make are more visible than other kinds of marking tools. To obtain sharp clear lines it is best to use a fresh felt marking pen with a new sharp tip for laying out bend lines. The lines made by a felt marking pen can easily be removed by wiping them with a rag soaked in alcohol. Marking with Scriber Marking is the transfer of measurements from drawings or according to other instructions onto the workpiece in question by drawing marking lines. Issue: August 2014 Page 48 of 926 Modul 7 Tools PART 66 – Basic Training Cat B1 – Module 7 It serves to produce workpieces to the correct measurements as a check during the work. Refer to Figure 2. Figure 2: Scriber For Training Purposes Only Issue: August 2014 Page 49 of 926 Modul 7 Tools PART 66 – Basic Training Cat B1 – Module 7 The tool used for marking out is the scriber. There are scribers with steel needle (hardened point) for marking hard material, and scribers with brass needle for marking softer materials and workpieces whose surfaces must not be scratched. Work Safety The point of the scriber must be made safe by inserting it into a cork. Working Techniques Guiding the Scriber The point of the scriber on the workpiece has to be placed against the straight edge. The scriber has to be held inclined away from the straight edge and in the direction in which it is to be drawn. The marking line should be drawn not too deep once only so that it will be visible. Refer to Figure 3. Figure 3: Marking a Workpiece For Training Purposes Only Issue: August 2014 Page 50 of 926 Modul 7 Tools PART 66 – Basic Training Cat B1 – Module 7 Marking with One Reference Plane Using a steel rule and working from the reference plane ’a’, the marking measurements have to be marked twice at two points as far away from one another as possible. The steel straight edge has to be placed on the marks and the marking line must be drawn with the scriber. Marking with Two Reference Planes Using a steel rule and working from reference plane ’a’, mark the marking measurements have to be marked once. The back square with its edge has to be placed on reference plane ’b’. The long blade of the back square should be pushed right up to the markings. The marking line has to be drawn with the scriber. 7.3.1.2 Punches Figure 4: Center Punch Enlarging the prick punch mark with a center punch allows the drill to be centered so that it will start cutting the metal. The center punch has a blunt point, ground to an angle of approx. 60° that approximates the tip angle of a twist drill. The marks should be deep enough for the drill to start cutting. But the blow used on the punch must not be too hard to distort the metal. Prick Punch When we have made our layout marks with a soft lead pencil and have transferred distances or divided lines with an extremely light mark with a pair of dividers, we can permanently mark locations for rivet holes with a sharp prick punch. It takes only a very light tap with a small hammer to mark these locations which we will later enlarge with a center punch. An automatic center punch is one of the handiest tools a sheet metal technician can have, allowing you to make your punch marks fast and uniform. This punch is spring - loaded so all you need to do is to center it in the prick punch mark and press. When you press hard enough, a spring - loaded plunger inside the handle is released and hits the point with a solid blow. Center Punching Center Punch Refer to Figure 5. Refer to Figure 4. For Training Purposes Only Issue: August 2014 Page 51 of 926 Modul 7 Tools PART 66 – Basic Training Cat B1 – Module 7 Center punching is striking small depressions with a pointed cone – shaped tool, the center punch, on specified lines or points of intersection. Center punching fixes marking lines and their points of intersection and enables a good work check. Center punch marks are a means of checking. During center punching the center punch is hit with a hammer and its hardened point penetrates the material and forms a cone - shaped depression. Work Safety A marking center punch is harder than the material which is being center punched. Working Techniques When center punching, the center punch has to be set up at a slight angle exactly where the marking lines cross. Then the center punch should be moved into an upright position and hit with the hammer. The center punch mark should be checked and corrected, if necessary, by means of an angled center punch blow. The center punching must be checked continually by the instructor. Only in this way can a steady improvement be achieved. The final center punch marks must be perfect. Refer to Figure 6. Figure 5: Center Punching For Training Purposes Only Issue: August 2014 Page 52 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Tools For center punching the workpiece should be placed on a steel support plate. The center punch should be held as shown in detail a). The center punch should be placed in position (detail b)). In doing so one hand should rest on the workpiece. The center punch should be set upright (detail c)). The center punch should be struck (detail d)). The center punch is struck with the hammer. The blow must be delivered in the direction of the center punch axis. While center punching, the eyes should always be fixed on the point of the center punch. The center punch mark has to be checked. The accuracy of the center punch mark depends on: exact marking out the ground point of the center punch the placing of the center punch in position the correct use of the hammer. Transfer Punch Refer to Figure 7. Figure 6: Center – Punching Process For Training Purposes Only Much sheet metal repair work consists of replacing damaged skin with new skins. Since many of these skins are made of straight sheets of metal, you can straighten the old skin and use it as a pattern for the new one. Issue: August 2014 Page 53 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Tools The transfer punch is used to locate the exact center of the rivet holes. This punch has a shank with the same diameter like that of the rivet hole and has a sharp point in its exact center. The point will make a mark similar to a prick punch mark in the center of the rivet hole. Pin Punch 7.3.1.3 Cutting Tools Metal cutting tools can be divided into hand –operated and floor – mounted types. The list of hand tools which are used for sheet metal work is rather long. However, in this text the most commonly used ones will be mentioned. There are not as many floor –mounted tools as there are hand tools, yet there are a sizable number of these tools available, so only those most widely used will be covered. Refer to Figure 8. Metal - Cutting Power Tools Ketts Saw Refer to Figure 9. Figure 8: Pin Punch The pin punch is a valuable tool for removing the rivet shank which remains in the hole after drilling off the manufactured head. Use a pin punch with a diameter equal to the rivet being removed, place the pin punch on the rivet shank in the hole, back up the shank with a bucking bar and tap out the remaining shank. Pin punches are available in sizes which correspond to standard rivet diameters. For Training Purposes Only Figure 9: Ketts Saw The electrically operated portable circular - cutting Ketts saw uses blades of various diameters. The head of this saw can be turned to any desired angle. It is very handy for removing damaged sections on a stringer. Issue: August 2014 Page 54 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Tools Advantages of the Ketts saw are: the ability to cut metal up to five mm thickness no starting hole is required a cut can be started anywhere on a sheet of metal the capability of cutting an inside or outside radius. To prevent grabbing, keep a firm grip on the saw handle at all times. Before installing a blade, it should be checked carefully for cracks. A cracked blade can fly apart and perhaps result in serious injury. Reciprocating Saw Refer to Figure 10. The number of cutting teeth over the length is important when trying to cut through metal. For thick metal (six mm thick) use a coarser cutting blade. If a coarse cutting blade is used on thin metal, the blade will hang up, dull rapidly or break. The reciprocating saw is often misused by sheet metal technicians because they expect it to do things it is not capable of doing. The trick to using a reciprocating saw is to bear down on the surface being cut so as to prevent the saw from jumping around. The saber saw is another tool commonly used for sheet metal repair work. The saber saw is electrically operated. It is often used for cutting holes on a metal wing or control surface. It is also used for rough cutting of the edges of sheet metal parts. An advantage of using the saber saw is its shoe plate which can be tilted, allowing for beveled –edge cuts. This tool can be adapted to cut materials other than metal by changing its cutting blade. Nibbler Refer to Figure 11. Figure 10: Reciprocating Saw A reciprocating saw is an electrically powered tool used to do much of the same work as a saber saw. It is a useful tool for rough cutting – out of damaged sections of a spar or a large stringer which is going to be repaired. The cutting blade must be of good quality steel and made to cut metal. Figure 11: Hand - operated Nibbler For Training Purposes Only Issue: August 2014 Page 55 of 926 Modul 7 Tools The nibbler is a tool used for rough cutting metal by a series of small nibbles or bites. PART 66 – Basic Training Cat B1 – Module 7 Shop Tools Squaring Shear (Guillotine) There are three types of nibblers available: Refer to Figure 12. the hand - operated type which is operated like a pair of hand shear an electrically powered hand tool a pneumatic version known as ’half moon nibbler’ (because of the shape of the metal waste). The main advantage of the hand nibbler is its simplicity of operation. When a piece of metal is fitted into the slot on the blade, the handle is squeezed and the cutter nibbles away small pieces of metal. The action is repeated until the opening is made to the size required. After using the nibbler, the rough edges must be filed to the limit marks of the skin/metal requirements. The electrically operated nibbler is more effective than the hand - held type for making large cutouts. One limitation of the electric nibbler is that, because it is large, it tends to get away from the operator once in a while. An electric nibbler which is fixed into place operates like a jig saw and gives the operator better control of the cutting process. The amount of metal removed during one nibble cut is approx. two mm deep and as wide as the cutter blade. Of all of the shop tools, a squaring shear (or: guillotine) is the one most commonly used for sheet metal work. A handy –size shear will accept a full 1.2 m wide sheet of aluminum alloy. Most shops use foot –operated shears, but where thick metal must be cut, the shears are operated by electric motors. Squaring shears/guillotines have a guide edge which is exactly perpendicular to the blade. They have a clamp to hold the metal tight against the table so you can keep your fingers away from the blade. When the metal is in place and clamped down, stepping on the foot treadle lowers the blade across the sheet with a slicing action. Squaring shears/guillotines, when properly used and maintained, will cut metal smoothly and leave a minimum of burrs on its edges. The hand - operated nibbler can be used for closer - tolerance work where the pneumatic nibbler may cause an error due to its pneumatic action. Where larger or rougher areas of metal require cutting or trimming, the pneumatic nibbler is both faster and accurate enough for the job. For Training Purposes Only Issue: August 2014 Page 56 of 926 Modul 7 Tools PART 66 – Basic Training Cat B1 – Module 7 Of all of the shop tools, a squaring shear (or: guillotine) is the one most commonly used for sheet metal work. A handy –size shear will accept a full 1.2 m wide sheet of aluminum alloy. Most shops use foot –operated shears, but where thick metal must be cut, the shears are operated by electric motors. Squaring shears/guillotines have a guide edge which is exactly perpendicular to the blade. They have a clamp to hold the metal tight against the table so you can keep your fingers away from the blade. When the metal is in place and clamped down, stepping on the foot treadle lowers the blade across the sheet with a slicing action. Squaring shears/guillotines, when properly used and maintained, will cut metal smoothly and leave a minimum of burrs on its edges. Figure 12: Squaring Shear (Guillotine) For Training Purposes Only Issue: August 2014 Page 57 of 926 Modul 7 Tools Throatless Shears PART 66 – Basic Training Cat B1 – Module 7 throatless. A sheet of any length can be cut and the metal can be turned in any direction to allow for cutting irregular shapes. The cutting blade (top blade) is operated by a hand lever. Refer to Figure 13. Rotary Punch Press The rotary punch press is used in the airframe repair shop to punch holes in metal parts. This machine can be used for cutting radii in corners, for making washers and for many other jobs where holes are required. The machine is composed of two cylindrical turrets, one mounted above the other and supported by the frame. Both turrets are synchronised so that they rotate together. Index pins ensure correct alignment at all times. The index pins may be released from their locking positions by rotating a lever on the right side of the machine. This action withdraws the index pins from the tampered holes and allows the operator to run the turrets to any size punch desired. When rotating the turret to change punches, release the index lever when the desired die is within 25 mm of the ram. Continue to rotate the turret slowly until the top of the punch holder slides into the grooved end of the ram. The tapered index locking pins will then seat themselves in the holes provided. At the same time, release the mechanical locking device, which prevents punching until the turrets are aligned. Figure 13: Throatless Shear Throatless shears are best used to cut 10 –gauge mild carbon sheet metal and 12 - gauge stainless steel. The shear gets its name from its construction; it actually has no throat. There are no obstructions during cutting since the frame is For Training Purposes Only To operate the machine, place the metal to be worked between the die and the punch. Pull the lever on the top side of the machine toward you. This will actuate the pinion shaft, gear segment, toggle link and the ram, forcing the punch through the metal. When the lever is returned to its original position, the metal is removed from the punch.The diameter of the punch is stamped on the front of each die holder. Each punch has a point in its center which is placed in the center –punch mark to punch the hole in the correct location. Issue: August 2014 Page 58 of 926 Modul 7 Tools Band Saw PART 66 – Basic Training Cat B1 – Module 7 One of the most versatile band saws found in aircraft sheet metal shops is the ’do - all’ saw. This saw has a variable speed drive that allows to get the correct cutting speed for any metal. The table can be tilted so we can cut bevels and tapers on thick metal. Refer to Figure 14. But one of the most useful features of this saw is a blade cutter - and - welding facility. If we need to cut the inside of a hole, we can drill a starting hole, cut the saw blade and insert it in the hole. Then with a resistance welder that is built into the saw, we can weld the blade back together and with a small grinder, also on the saw, smooth the edges of the weld. In just a few minutes, the saw is ready to cut the inside of the hole. Figure 14: Band Saw When sheet metal must be cut along curved lines, or when the metal is too thick to shear, we often cut it with a band saw. For Training Purposes Only Issue: August 2014 Page 59 of 926 Modul 7 Tools Disc Sander Scroll Shears Refer to Figure 15. Refer to Figure 16. PART 66 – Basic Training Cat B1 – Module 7 Figure 15: Disc Sander Figure 16; Scroll Shear Wood, plastic materials and sheet metal can be cut on the band saw to almost the correct size and then finished very accurately with a heavy –duty disc sander. With this tool, we can cut the material right up to the scribed line. Scroll shears are used for cutting irregular lines on the inside of a sheet without cutting through to the edge. The upper cutting blade is stationary while the lower blade is movable. The machine is operated by a handle connected to the lower blade. For Training Purposes Only Issue: August 2014 Page 60 of 926 Modul 7 Tools PART 66 – Basic Training Cat B1 – Module 7 Basics of Sawing Refer to Figure 17. Figure 17: Hand Hacksaw For Training Purposes Only Issue: August 2014 Page 61 of 926 Modul 7 Tools Sawing mainly serves to separate materials and also to produce slits and grooves. Sawing is the removal of small chips by means of many chisel –type cutting edges (teeth), arranged behind one another along the narrow edge of a saw blade. A large number of these cutting edges are effective at the same time. The teeth of the saw blade must face in the direction of the cut. PART 66 – Basic Training Cat B1 – Module 7 Work Safety The workpiece must be clamped firmly into the vice. When starting the cut, the saw has to be handled carefully. A pilot groove should be filed first. At the end of the cut the sawing should be done carefully, otherwise it may damage the saw blade or cause hand injuries. Clamping the Workpiece The work process is by moving the saw in the direction of the cut (cutting motion) with simultaneous pressure on the saw (cutting pressure); the teeth penetrate into the material and remove chips. Refer to Figure 18. After clamping in, the workpiece must be solid, not springy. Sawing action is only unimpeded if the workpiece is being clamped. The single saw tooth is wedge –shaped, the angles are: Narrow edges should be clamped vertically towards the right of the vice and positioned higher, if necessary. Wide edges should be clamped flat and towards the right of the vice. Marking must be visible and remain so. α = free angle or clearance angle β = wedge or key angle γ = rake or chip angle. The pitch ’t’ is the distance in mm between one tooth and the next. The saw blade is designated according to the number of teeth present in 25 mm of a saw blade. Coarse blades are for soft materials, medium for normal, and fine blades for hard materials. To prevent the saw blade from seizing when penetrating the material, the cut must be broader than the thickness of the saw blade. The saw blade must cut freely. Free cutting action is achieved by: Preparatory Filing A pilot groove enables the saw to cut into the workpiece at the correct point when sawing is started. The pilot groove is filed in with the triangular file. The marking line must remain visible setting of the teeth wave form of the saw blade. For Training Purposes Only Issue: August 2014 Page 62 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Tools Guiding the Saw Refer to Figure 19. When sawing with the hand hacksaw the movement starts from the arms and is assisted by a corresponding movement of the body. Attention should be given to: holding the saw correctly correct body positioning correct positioning of the feet. In order to achieve a perfect cut, the saw has to be placed at an angle of incidence (as shown), and sawing commenced. The forward stroke is with pressure, the return stroke without pressure. The full length of the saw blade should be used. Sawing is done in a straight line along the marking line. The marking line must remain visible. Figure 18: Clamping and Preparatory Filing For Training Purposes Only Issue: August 2014 Page 63 of 926 Modul 7 Tools PART 66 – Basic Training Cat B1 – Module 7 Figure 19: Guiding the Saw For Training Purposes Only Issue: August 2014 Page 64 of 926 Modul 7 Tools 7.3.1.4 PART 66 – Basic Training Cat B1 – Module 7 Hand Cutting Tools Sheet Metal Shears The popular ’tin snips’ are useful in aircraft maintenance work for cutting the metal to its rough shape and size, but for more accurate work we use aviation snips. Aviation Snips These are compound action shears which have a serrated cutting edge to hold the metal that is being cut. Aviation snips come in sets of three pairs. The snips with the yellow handles cut straight, those with green handles cut to the right and the snips with red handles cut to the left. Files Refer to Figure 20. Figure 20: The File For Training Purposes Only Issue: August 2014 Page 65 of 926 Modul 7 Tools PART 66 – Basic Training Cat B1 – Module 7 Despite the most modern machines, work by hand is still necessary. Filing is a manual work process, whereby fine shavings (chips) are removed. The file by itself is a tool used for treating materials with a cutting effect. It has many cutting edges (file teeth) which are like small chisels. These are harder than the treated material. A distinction can be made between cut file blades and milled blades. The difference is in the shape of the teeth. A cut file has a scraping effect, while a milled file has a cutting effect. A sheet metal technician uses a file to finish off the edge of a hole in a skin and on the cover which is fitted over the hole and also for finishing and smoothing edges of cut materials. The file is one of the most mistreated tools in a technician’s tool box. It is often used as a pry bar, a hammer or without a handle on the tang end. The best way to keep a file in good condition is to store it in a plastic bag with an appropriate coating sprayed onto the face of the file. There are two types of files: with single cuts with double cuts. The types of file most commonly used by a sheet metal technician are the half - round and the rat - tail. A bastard and second - cut file can be used for more severe removal of material before finishing with a smooth file. Cut Arrangements Refer to Figure 21. Figure 21: Cut Arrangements For Training Purposes Only Issue: August 2014 Page 66 of 926 Modul 7 Tools PART 66 – Basic Training Cat B1 – Module 7 A cut file usually has two cuts: V under –cut (angle e.g. 54°) V over – cut (angle e.g. 71o). Coarseness ’t’ is the gap between one tooth and the next. Under - cut and over - cut have different coarseness, t1 and t2. It is for this reason that the teeth are offset behind one another. One tooth removes what the other has left behind. Shapes of Files Refer to Figure 22. Files exist in different shapes: as flat, triangular, square, half –round and round files. The choice of a particular file shape is dependent on the size and the shape of the surface to be worked. Different grades of cut are used dependent on the required smoothness of the treated surface. There are: rough files and bastard files for rough treatment, to remove much material per stroke second - cut files for medium requirements V smooth files for finishing of surfaces. Chalk can be used on smooth files for achieving a well finished surface in the last step of treatment. Working Technique Correct clamping of the workpiece in the vice and correct adjustment of the height of the vice are important for a successful working process. Figure 22: Shapes of Files For Training Purposes Only Issue: August 2014 Page 67 of 926 Modul 7 Tools PART 66 – Basic Training Cat B1 – Module 7 The height of the vice shall be adjusted five to eight cm below the worker’s elbow. The workpiece shall be clamped centrally. Its surface shall be parallel to the jaws of the vice and shall project as little as possible. Nevertheless, the markings shall be visible. Protective pads are auxiliary pieces for clamping. They protect the surfaces of workpieces. Protective pads are made of a softer material than the workpiece, for example, copper, aluminium, lead or pressboard. The correct positioning of one’s feet results in a safe stance during filing. Accurate holding and guiding of the file depend on it. Correct positioning of the body allows swift and regular movement. Refer to Figure 23. Figure 23: Correct Positioning to the Workpiece For Training Purposes Only Issue: August 2014 Page 68 of 926 Modul 7 Tools PART 66 – Basic Training Cat B1 – Module 7 To hold large files, the right hand grips the file handle so that the end of the handle is pressed against the ball of the thumb. The left hand presses on the file blade with the ball of the thumb. Tool Handling Refer to Figure 24. The file is guided in its longitudinal axis over the workpiece. The right hand pushes and presses, the left hand only presses the file down to the workpiece. The forward stroke is carried out with pressure, the return stroke without pressure, because the file is only cutting in forward direction. The whole length of the file shall be used, but the handle must never be pushed against the workpiece or the vice. Possible ways of filing a surface are: diagonal filing: the file is applied across the workpiece surface at an angle of 45o. The direction of filing is changed by 90° each time the complete surface has been filed traverse filing: the file is employed at a right angle (90o) to the longer edge of the workpiece longitudinal filing: the file is applied in parallel to the longer edge of the workpiece. Filing errors can be compensated by turning the workpiece 180° several times and using diagonal filing. Figure 24: Correct Tool Handling For Training Purposes Only Issue: August 2014 Page 69 of 926 Modul 7 Tools PART 66 – Basic Training Cat B1 – Module 7 The varying height of the workpiece surface is compensated by reclamping a number of times. From time to time the edges of the workpiece surface must be deburred to reduce the danger of injuries. Flatness and dimensions must be checked as well. Refer to Figure 25. For deburring, the edges of the workpiece are filed with the file at an angle of approx. 45o (detail a)). During flat filing chips must be removed in such a way that the surface worked becomes neither hollow nor crowned (detail b)). Checking: The distance between the surface being worked and the marking lines must be equal on both sides. First the flatness of the surface is checked visually (comparison with marking line), then with the square or the straight edge (detail c)). Figure 25: Deburring and Flat Filing For Training Purposes Only Issue: August 2014 Page 70 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Tools Checking Squareness Surfaces on the workpieces usually meet rectangularly (i.e. at an angle of 90o) or are parallel to each other. Refer to Figure 26. For angle filing one surface must already be flat and finished. This is the reference plane. Normally the largest surface of the workpiece is chosen as the reference plane. Nothing should be done to change the reference plane. The surface to be worked must be flat and at right angles to the reference plane. During parallel filing the surface to be worked must be flat and parallel to the reference plane. Parallelism is the equal distance of two surfaces from one another along their length. It can be checked by measuring with the vernier caliper. Tidiness Tidiness in the working area is very important. It saves working time, helps to avoid injuries and eases correct and accurate working. Only the tools necessary for the work shall be ready on the bench. Measuring tools shall be put into the measuring tray. The bench must be cleaned using the hand brush (never use the hand itself). Cleaning the file is necessary because dirty files produce messy finishes (serrations) or do not bite at all. The file brush should only be used in the direction of the over - cut. Figure 26: Checking Squareness For Training Purposes Only Issue: August 2014 Page 71 of 926 Modul 7 Tools Stubborn chips should be removed with a file cleaner (brass or copper sheet). PART 66 – Basic Training Cat B1 – Module 7 A drill several sizes larger than the hole or a standard countersink cutter held in a file handle are good tools for removing the burrs from the edge of rivet holes. Deburring Tools Note: Remember: when using these cutters you only want to remove the burrs – you do not want to countersink the holes! Refer to Figure 27. A file can be used to remove the burrs from the edges of a sheet. But a tool that makes the job much faster can be made by grinding a sharp V - shaped notch in the end of a small file. To use this tool, just pull it along the edge of the sheet, and the sharp edges of the ’V’ will cut the burrs from both sides of the sheet at the same time. Cutting a Hole in Sheet Metal Use of a Drill If the hole required is of a small enough size, then a drill can be used to cut the hole. If the hole is 20 mm in diameter or larger, it can be finished by using a smooth file and emery paper, if necessary. Use of a Rotary Disc Cutter Refer to Figure 28. Figure 27: Deburring Tools For Training Purposes Only Issue: August 2014 Page 72 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Tools Use of a Trepanning Tool Refer to Figure 29. Figure 28: Rotary Disc Cutter A rotary disc cutter can also be used to cut a hole in sheet metal. This type of cutter has a center drill of nominal size, surrounded by a coarse, medium or fine toothed cutting disc. These discs are of different diameters and can be used to cut the required size hole up to a maximum of approx. 60 mm to 70 mm. For Training Purposes Only Figure 29: Trepanning Tool Larger holes in sheet metal can be cut by using a trepanning tool (or: fly cutter). Issue: August 2014 Page 73 of 926 Modul 7 Tools The center of the hole to be cut is marked and center –punched. The location rod point is placed in the punch mark and the cutter is adjusted along the beam to the required radius of the hole. By turning the cutter through an arc of 360! a line is scribed with the diameter of the hole required. By increasing the pressure on the cutter, an indenting cut is made getting progressively deeper. Once the material is ’cut through’, a disc remains which can be discarded. The hole is left at the size required and may be cleaned up/finished by use of a soft file or emery cloth. PART 66 – Basic Training Cat B1 – Module 7 The most popular air drill motor is the pistol grip model with a 6.4 – mm chuck. The speed of these drills is controlled by the amount of pull on the trigger. But if it is necessary to limit the maximum speed, a regulator may be installed in the air line where it attaches to the drill. For drilling holes where the structure interferes, a right –angle drill can be used. If the chuck and the length of the drill itself prevents getting the drill in where it is needed, we can use a right –angle drill motor equipped to use short –threaded drills. Drill Attachments and Special Drills 7.3.1.5 Drills Drill Motors The vast majority of holes drilled in aircraft sheet metal structure are small and are drilled in relatively soft metal, so there is seldom need for a drill motor larger than one with a 6.4 mm chuck. Electric Drill Motors The convenience of electric outlets in the shop and the relatively low cost of electric drill motors as compared with air drills make them useful tools. A variable speed control makes them even more useful. But an electric drill motor is larger and heavier than an air drill and has the potential of producing an electric shock when working on an aircraft structure. So air drills are more accepted for sheet metal work than electric drills. Pneumatic (Air) Drill Motors The availability of compressed air to operate the rivet guns makes air drill motors a logical choice for aircraft structural repair. These drills are lightweight, have good speed control, do not overheat regardless of the amount they are used and are available in a number of shapes that allow to reach ’hard to get to’ locations. For Training Purposes Only Drill jigs are used to assist in drilling accurate holes in skins and structural subassemblies. Drill jigs are held in place by drilling a hole and using it to line up the jig for the remaining holes. The alignment of the jig makes it possible to obtain holes which are round, straight and free from cracks. This is especially true when the metal is thick and holes drilled free –hand have a tendency to be made crooked. Drill jigs are most commonly used during the assembly process while an aircraft is being built. Drill jigs are very useful while installing anchor nuts or anything which requires a high degree of accuracy. Rivet Removal Tool A drill attachment used very often by sheet metal technicians during the disassembly of a damaged aircraft is the rivet removal tool. A rivet removal tool is available with interchangeable drills which correspond to standard rivet sizes being removed. Drilling out rivets is made easier because the tool can be adjusted to cut only the depth of the manufactured rivet head. The procedure is the same as for the free –hand rivet drill –out technique: simply tap or snap off the drilled manufactured rivet head and tap out the remaining shank. Issue: August 2014 Page 74 of 926 Modul 7 Tools Right – Angle Attachment PART 66 – Basic Training Cat B1 – Module 7 A right - angle drill motor attachment is also used to open holes in close quarters. The attachment is chucked into a straight pistol - type motor. The drill used on a right-angle attachment is held in the angle attachment by a collet which can hold a standard drill. When a drill in the collet becomes too short, a broken straight drill (with a newly sharpened tip) will make a good replacement. The drill is pressed into the collet and held in by pressure exerted by the compressed wall of the collet when it is threaded into the attachments holder. Refer to Figure 30. Snake Attachment Refer to Figure 31. Figure 31: Snake Drill Figure 30: Right – Angle Drill Attachment Angle motors are designed for operation in tight locations where there is limited access to the part which is being drilled. The angle drill motor is available in two standard head angles, 45o and 90o. For Training Purposes Only The flexible snake attachment is also used in limited –access areas where an angle drill motor or attachment cannot be used. The snake attachment basically does the same thing that a right –angle attachment does, except it can be snaked in to drill a hole much Issue: August 2014 Page 75 of 926 Modul 7 Tools further away than a right - angle drill. It is an excellent tool for getting into a location where a regular motor with a handle will not permit a straight entry into the metal being drilled. The snake attachment is useful for back - drilling through holes in original members into new skins. Back - drilling means to open holes in new skins through the holes left in ribs, stringers or spars which were previously made during the original installation of sheet metal parts. PART 66 – Basic Training Cat B1 – Module 7 There are applications in aircraft maintenance where we must reach through a part of the structure to drill a hole that is beyond the reach of an ordinary twist drill. When this type of problem occurs, there are two types of extension chills which can be used. One is a long drill that must have a piece of aluminium tubing slipped over the shank to prevent it whipping when it is used. The other has a heavy shank with a small drill fixed into its end and needs no protective cover, as it is too rigid to whip. Drill Press (Pillar Drill) A variety of drill presses (or: pillar drills) are available. The common type is the upright drill press. When using a drill press, the height of the drill press table is adjusted to accommodate the height of the part to be drilled. When the height of the part is greater than the distance between the drill and the table, the table is lowered. When the height of the part is less than the distance between the drill and the table, the table is raised. Extension Drill Refer to Figure 32. After the table is properly adjusted, the part is placed on the table and the drill is brought down to aid in positioning the metal so that the hole to be drilled is directly beneath the point of the drill. The part is then clamped to the drill press table to prevent it from slipping during the drilling operation. Parts not properly clamped may bind on the drill and start spinning, causing the loss of fingers or hands or serious cuts on the operator’s arms or body. Always make sure the part to be drilled is properly clamped to the drill press table before starting the drilling operation. Figure 32: Extension Drill For Training Purposes Only The degree of accuracy that is possible to attain when using the drill press will depend to a certain extent on the condition of the spindle hole, sleeves and drill shank. Therefore, special care must be Issue: August 2014 Page 76 of 926 Modul 7 Tools PART 66 – Basic Training Cat B1 – Module 7 exercised to keep these parts clean and free from nicks, dents or warpage. Always be sure that the sleeve is securely pressed into the spindle hole. Never insert a broken drill in a sleeve or spindle hole. Be careful never to use the sleeve –clamping vise to remove a drill since this may cause the sleeve to warp. Twist Drills Refer to Figure 33. Figure 33: Twist Drill Drills are used for opening holes in metal, wood and other materials. The tip of a drill has two lips which make up the tip. The lips are sharpened at an angle from the center line of the drill. This angle depends on the material to be cut. It is called the ’point angle’. For general - purpose aircraft aluminium this angle is usually approx. 118o. For Training Purposes Only Issue: August 2014 Page 77 of 926 Modul 7 Tools PART 66 – Basic Training Cat B1 – Module 7 The body of a drill consists of hollow flutes, reamers and webbing. The shank of a drill is chucked into the motor. The flutes of a drill carry the drilling to the surface, provide a method for cooling the tip and provide a path for lubricating the drill tip. Refer to Figure 34. There are four types of drill size identification available: number, letter, fraction (or: decimal) and metric. For sheet metal work, number and letter drills are the types most widely used. The number drill sizes correspond to the size of the fasteners being installed. Drilling Procedure Drilling is a chip –removing material treatment process to produce holes of a required diameter. Drilled holes serve to take screws, rivets, shafts etc. Refer to Figure 35. For Training Purposes Only Issue: August 2014 Page 78 of 926 Modul 7 Tools PART 66 – Basic Training Cat B1 – Module 7 Figure 34: Twist Drill Sizes For Training Purposes Only Issue: August 2014 Page 79 of 926 Modul 7 Tools PART 66 – Basic Training Cat B1 – Module 7 The tool commonly used for drilling into steel and cast iron is the twist drill. The drilling process results from two motions of the tool and the resulting forces. The main motion is the rotary motion, which produces the cutting force at the drill point. The secondary motion is the feeding motion, which produces the feeding force and enables the tool to penetrate into the material. The effect of these forces to the two cutting edges of the twist drill is the same as the effect of hammer blows to a chisel: chips of material are removed from the workpiece. The motions of the drill are continuous. Thus the chip removal is continuous and the removed material escapes as a twisted band, often called ’boring’ or ’drilling’. Refer to Figure 36. The point of a twist drill is conical, usually the angle of point is 118!. The lip angle, clearance angle and angle of rake are existing and their value may be compared with, e.g. a countersink. The heel at the circumference of the twist drill determines the diameter of the hole. The diameter of the center web, which is the body of the drill, is smaller and gives a clearance to reduce friction. For the same reason the clearance surface at the point is inclined by the clearance angle. The core of the twist drill ends in the center line between the two cutting edges. Along this line there is no cutting (chipping) effect. The material is squeezed away in this area range. Figure 35: Drilling Process For Training Purposes Only Issue: August 2014 Page 80 of 926 Modul 7 Tools PART 66 – Basic Training Cat B1 – Module 7 The twist drills are made of high –speed tool steel. Up to 10 mm diameter the shank of a twist drill is cylindrically shaped (straight shank), above 10 mm diameter they have taper shanks. Drilling Machine Small diameter holes can be produced using a hand drill. For greater diameters drilling machines must be used. Drilling machines commonly used in workshops are bench drilling machines (placed onto a workbench) and upright drilling machines (standing on the floor). The workpiece is clamped onto the work table or in a vice, which, in turn, must be clamped to the work table. The electric motor applies the rotary motion to the drill spindle and thus to the twist drill via an adjustable gear mechanism. Refer to Figure 37. Figure 36: Twist Drill Angles and Therms For Training Purposes Only Issue: August 2014 Page 81 of 926 Modul 7 Tools PART 66 – Basic Training Cat B1 – Module 7 Figure 37: Typical Drilling Machine For Training Purposes Only Issue: August 2014 Page 82 of 926 Modul 7 Tools PART 66 – Basic Training Cat B1 – Module 7 The gear mechanism is usually constructed as belt gear drive. Both driving and driven shaft have several pulleys with different diameters. By putting the belt to different pairs of pulleys the spindle speed can be varied at constant motor speed. The feeding force is applied to the drill via a feeding mechanism. A handle is connected to a gear wheel, which is in contact with a toothed sleeve. When the handle is pulled down, the gear wheel is turned and pushes the sleeve down. Via an axial roller bearing this force is transferred to the rotating spindle. Small drills (up to 10 mm straight shank) are usually fixed in a drill chuck for drilling work. This drill chuck is fixed in the drill spindle by a taper shank. Turning the sleeve (not the spindle) presses the jaws against the straight shank of the drill. To loosen the drill shank the sleeve must be turned in the opposite direction. Never touch the drill chuck when the spindle is turning! Work Safety The operating instructions of the drilling machine must be followed strictly. Clothing must be close –fitting during machine tooling. The workpiece or drill press vice must be secured against turning. Chips (borings) must be kept short. Chips must not be removed by hand, a brush shall be used. The feeding force must be reduced at the end of drilling. Drilling Techniques Figure 38: Drilling Techniques (I) Refer to Figure 38. For Training Purposes Only Issue: August 2014 Page 83 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Tools The marking procedures for drilling (detail a)) are as follows: First the center lines for the hole are marked according to the drawing. The intersection of the center lines is the drill center, which must be center punched deeper (and wider) than a normal center punch marking. Using the dividers, two circles are marked around the drill center: Spindle Speed Adjustment Refer to Figure 39. The spindle speed and thus the cutting speed of the twist drill can be adjusted by the gear mechanism as described earlier. The optimum spindle speed depends on: the hole circle with the nominal hole diameter the control circle with a diameter greater by two to three mm. The intersections of the center lines and the hole circle are marked as control marks by center punching. Control circle and control center punch marks offer a working check aid. For small hole diameters they are not necessary. The drill center punch mark serves to guide the twist drill in the first moments of work. After marking, the measurements as well as the accurate positions of the center punch holes must be checked carefully. If marking and center punching have not been carried out carefully, the drilling work will not be good, as well. Rough Drilling When drilling holes with diameters of more than 10 mm the center line of the twist drill will be wider than the drill center punch mark (detail b)). In this case the drill cannot be guided by the center punch mark and the hole will be displaced from its desired position. the diameter of the twist drill the material of which the drill is made the material of which the workpiece is made. The materials of which workpiece and drill cutting edges are made determine the permissible cutting speed to a great extent. Given the cutting speed and drill diameter, the spindle speed can be read from the diagram. The following basic relations can be read from the diagram: V the smaller the diameter, the higher the spindle speed V the larger the diameter, the lower the spindle speed. The average value of the cutting speed, which can be used for practical tasks, is 25 m/min. With this value and a drill diameter of 12 mm the optimum spindle speed of 670 rpm (revolutions per minute) can be read from the diagram. To avoid this error a rough drilling (detail c)) must be done using a small diameter twist drill before the original drill can be used for drilling the hole. For Training Purposes Only Issue: August 2014 Page 84 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Tools Drilling Work Stages Refer to Figure 40. Figure 39: Drilling Techniques (II) Figure 40: Drilling Techniques (III) For Training Purposes Only Issue: August 2014 Page 85 of 926 Modul 7 Tools The work table height must be adjusted so that the twist drill point is a few millimeters above the workpiece surface. Before drilling may be started the workpiece must be fixed to the work table or in a drill press vice, which, in turn, is fixed to the work table. Fixing means either to clamp by clamps and screws or, at least, to hinder the workpiece or vice from turning. PART 66 – Basic Training Cat B1 – Module 7 At the end of the drilling process, just before the twist drill escapes at the lower surface of the workpiece, the feeding force must be reduced. This helps to prevent drill or workpiece from being damaged. To produce holes with diameters of more than 10 mm the complete cycle of work stages must be done twice: first producing a rough drilling hole with small diameter, then drilling to the nominal diameter. Countersinking Fixing must be done so that the drill point (center line) of the twist drill is exactly above the drill center punch mark. After switching on the drilling machine, the feed handle is pulled down to apply sufficient force to the twist drill to produce a spot drill. After releasing the handle, the drilled spot must be checked because the twist drill point might run off the center. This check is done by comparing the spot position and the marked circles. If the drill did run off, the drilling machine must be switched off and the drill center must be repunched. If the spot is in the center the hole can be drilled to the nominal diameter and then drilled through to the desired depth. During the drilling process, chips are cut off and escape from the hole. At the same time heat is produced. To keep the escaping chips (borings) short, the feeding force shall be reduced from time to time. To cool down the twist drill and the workpiece a cooling liquid must be applied to the drilled hole. The cooling liquid may be oil or an emulsion of water and oil. This liquid serves as lubricant and at the same time reduces the required forces. It also washes away small chips of material. For Training Purposes Only Refer to Figure 41. Countersinking is a chip –removing working process to produce conical bores (taper bores). It is done for several purposes: to deburr cylindrical holes, to produce the hole for countersunk cone head screws or rivets, to produce a spot facing for thread holes. In all cases a cylindrical hole must be produced before countersinking can be done. The tool used is the countersink (also called ’rose –bit’). It has one or more cutting edges. The cutting (chipping) actions as well as the angles at the cutting edges are similar to a twist drill. They also have straight or taper shanks. More important than the diameter is the angle of point. It determines the shape of the produced cone. Usual values of point angles of countersinks are 90o and 120o. To produce a smooth surface of the cone and to avoid chatter marks, the cutting speed and thus the spindle speed must be remarkably lower than for a twist drill. As an average value one can say that the spindle speed for a countersink should be only 1/5 (20 %) of the respective twist drill speed. Issue: August 2014 Page 86 of 926 Modul 7 Tools PART 66 – Basic Training Cat B1 – Module 7 Working Process The working process for countersinking is the same as for drilling holes. The workpiece must be adjusted and fixed. The feed force must be reduced at the end of the process. Workpiece and countersink must be cooled during work. Counterboring Refer to Figure 42. Counterboring is a chip –removing working process to produce circular flat surfaces in or at previously drilled holes. These surfaces may serve to bear screw heads, bolt heads, shafts or other machinery parts. The cutting speed during counterboring should not be more than five m/min. The tool is the counterbore. It may have a straight or taper shank. It has its cutting edges at the point rectangular to the center line. A pilot guide at the point serves to enable correct alignment with the previously drilled hole. This hole must have the diameter of the pilot guide. If necessary, this hole must be drilled to the nominal diameter after counterboring. Working Process The working process is again similar to drilling with a twist drill. The prepared workpiece must be aligned and fixed. With the spindle not turning, the pilot guide is inserted into the drilled hole until the cutting edges touch the workpiece surface. The feed scale of the drilling machine is then adjusted to zero. After releasing the feed handle the drilling machine is switched on. With low spindle speed and medium feed force counterboring is done Figure 41: Countersinking For Training Purposes Only Issue: August 2014 Page 87 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Tools to the desired depth. The depth can be read at the feed scale. At the end, the feed force must be reduced. Measuring Depth and Angle Depth Measurement Refer to Figure 43. Figure 43: Depth Measurement Figure 42: Counterboring and Counterbore For Training Purposes Only Issue: August 2014 Page 88 of 926 Modul 7 Tools PART 66 – Basic Training Cat B1 – Module 7 To measure the depth of holes, grooves, keyseats, etc., a universal vernier caliper or a special depth gauge may be used. When using a vernier caliper the rule is placed onto the workpiece surface and the depth gauge tongue is inserted into the hole by adjusting the slide. When using a special depth gauge the head is placed onto the workpiece surface and the rule is inserted into the hole until the depth stop touches the bottom. In both cases the measured depth is read from the rule and the vernier, as usual. The rule must be rectangular to the surface in all directions. For this reason the special depth gauge has a special head design. Holes drilled by a twist drill are deeper in the center than at the circumference. This is an effect of the point angle of a twist drill. The depth of such holes is always measured at the circumference. Angle Measurement Refer to Figure 44. Figure 44: Angle Measurement For Training Purposes Only Issue: August 2014 Page 89 of 926 Modul 7 Tools PART 66 – Basic Training Cat B1 – Module 7 All angles measured so far have been right angles. For this purpose the 90o back square was used. Back squares are also available with 135o and 120o leg angle. They can be used for testing (measuring) angles of 135o or 120o and marking angles of 135o, 45o, 120o and 60o. A bevel protractor can be employed to measure or mark any angle. It has a fixed blade with a semicircular graduation (scale) and a movable blade (angle attachment) with a pointer, fastened in the center of the fixed blade by a fixing screw. The graduation is marked from 0o to 180o. To measure obtuse angles the read value must be subtracted from 180o. To measure an angle the fixing screw is loosened and both fixed blade and angle attachment are placed onto the workpiece. The angle is then read at the pointer. To mark an angle the fixing screw is loosened, the angle is adjusted, the fixing screw is fastened again and the fixed blade is placed onto the workpiece. The line is then marked along the angle attachment by a scriber. Surface Finish (Surface Texture) Refer to Figure 45. Figure 45: Roughness of Surfaces For Training Purposes Only Issue: August 2014 Page 90 of 926 Modul 7 Tools All real surfaces of a workpiece will never be ideally flat and smooth. Irregularities of the surface configuration (texture, finish) are the result of material treatment. Any chip - removing material treatment produces smallest grooves, scores and flakes. This roughness is always present but the degree of roughness depends on the care and attendance during work. The allowable roughness depends on the purpose of the workpiece or its surface. Sliding bearings, for example, require a finer surface finishing than machinery parts which are not in contact with other parts. PART 66 – Basic Training Cat B1 – Module 7 To produce fine - finished surfaces by filing, finest smooth files shall be used in combination with chalk. Chalk is rubbed in between the file teeth. The chalk settles to the base of the file teeth and thus reduces the penetration of the teeth into the material. Small chips, which could otherwise damage the smooth surface of the workpiece, are embedded in the chalk. The file should be cleaned repeatedly and recoated with chalk again. Only relatively small pressure shall be applied to the file during fine finishing. The maximum depth of roughness is the distance between the reference profile and the basic profile of a surface section. The reference profile is a line at the highest points of the surface, the basic profile is a line at the deepest points. The roughness number is the average depth of roughness. This is the average of all distances between the actual profile and the center line of the surface section. To give information about the allowable roughness symbols are entered into engineering drawings. Symbols according to ISO standards give information about the allowable average depth of roughness (roughness number), symbols according to DIN standards give information about the allowable maximum depth of roughness. In many cases the allowable roughness predicts the tool to be chosen for treatment and other treatment conditions. For example, rough or bastard files are used for roughing (Ra< 25 µm, Rd < 160 µm), second cut and smooth files for smoothing (Ra < 6.3 "m, Rd< 40 µm). Fine finished surfaces (Ra < 1.6 µm, Rd < 16 µm) can only be produced by special treatment. For Training Purposes Only Issue: August 2014 Page 91 of 926 Modul 7 Tools PART 66 – Basic Training Cat B1 – Module 7 Round Filing Round Filing of External Surfaces Refer to Figure 46. In order to obtain even, round radii, provisional surfaces are filed, until the approximate shape of the radius is produced. External round filing is done guiding the file in a see - saw motion in the direction of the radius or in a rotary motion at right angles to the radius. The workpiece should be reclamped repeatedly to produce a good circular form. External and internal radii are checked and measured using a radius gauge. A radius gauge has several gauge plates (templates) for different radii, stepped, for example, by 0.5 mm. A radius is checked by placing the respective gauge plate rectangularly onto the radius and looking for gaps between plate and workpiece. The radius is correct if there is no gap visible. Figure 46: Round Filing of External Surfaces For Training Purposes Only Issue: August 2014 Page 92 of 926 Modul 7 Tools PART 66 – Basic Training Cat B1 – Module 7 Round Filing of Internal Surfaces Refer to Figure 47. Round filing of internal surfaces requires the use of rounded files, the radius of which must be smaller than that of the radius of the workpiece to be filed. Filing of internal radii is done guiding the file straight as in flat filing and, at the same time, turning it about its longitudinal axis. To achieve an even radius, an additional sideways feed is necessary. The sideways feed should not be too great; otherwise serrations will be produced. Internal radii are checked and measured using the radius gauge again. Figure 47: Round Filing of Internal Surfaces For Training Purposes Only Issue: August 2014 Page 93 of 926 Modul 7 Tools PART 66 – Basic Training Cat B1 – Module 7 Reaming Reaming Tools and Techniques Refer to Figure 48. Figure 48: Reamers For Training Purposes Only Issue: August 2014 Page 94 of 926 Modul 7 Tools PART 66 – Basic Training Cat B1 – Module 7 Reaming is a chip - removing material treatment process to produce precision holes with fine - finished surfaces and best dimensional quality. Such holes are required for shaft bearings, locking pins, etc. Reamers have a bevel lead, a guide section and a shank. Cutting edges are at the bevel lead and the guide; the effective cutting action, however, takes place only at the bevel lead. At its bevel lead a reamer can cut away only 0.1 to 0.5 mm. The hole to be reamed must therefore be predrilled by means of a twist drill with a diameter little less than the desired final diameter. The cutting edges at the guide section serve to guide the tool in its direction and to improve the surface quality to a fine finish. Reaming is done by turning the reamer slowly with little feed in the predrilled hole. This can be done manually by using a tap wrench, or powered by using a drilling machine. A hand reamer has a long bevel lead and a squared shank end. A machine reamer has a short bevel lead and a straight or taper shank. Most reamers are straight - toothed. Spiral reamers are used for holes that intersect each other, or for holes with grooves where a straight – toothed reamer would bind. Refer to Figure 49. Figure 49: Reaming For Training Purposes Only Issue: August 2014 Page 95 of 926 Modul 7 Tools Reamers have 6 to 18 cutting edges to keep the chips small and to improve the circular alignment. The circular pitch of these cutting edges is irregular to avoid tool marks (chatter marks). The angles at the cutting edges are defined in the same way as for other chip – removing tools. PART 66 – Basic Training Cat B1 – Module 7 Fits and Tolerances As mentioned in the last chapter reaming is a working technique to produce high quality holes. The quality of a hole or a shaft depends on the surface texture and on the deviation of the actual diameter from the desired (nominal, basic) diameter. Work Safety For manual reaming a double –armed tap wrench must be used. The reamer must always be directed straight, otherwise the reamer might break. The reamer must always be turned clockwise, even when withdrawing it. When a drilling machine is used for powered reaming, it must be set to slow speed. Working Technique For manual reaming the hand reamer is fitted in a tap wrench. The reamer is then inserted into the predrilled hole at right angles to the workpiece. During reaming the reamer must be turned slowly and evenly and with equal pressure, with both hands on the tap wrench. The reamer must always be turned clockwise, even when withdrawing it, otherwise the cutting edges would break out. For machine reaming the machine reamer is fixed in the drill chuck or taper hole. The gear must be shifted to slow speed. After aligning the predrilled hole of the workpiece the drill press vice must be fixed. The feeding motion during machine reaming must also be slow. Lubricating and cooling is necessary for manual reaming as well as for machine reaming. For Training Purposes Only Issue: August 2014 Page 96 of 926 Modul 7 Tools PART 66 – Basic Training Cat B1 – Module 7 Deviations and Tolerances Refer to Figure 50. Figure 50: Deviations and Tolerances For Training Purposes Only Issue: August 2014 Page 97 of 926 Modul 7 Tools PART 66 – Basic Training Cat B1 – Module 7 Depending on the purpose of the workpiece the quality of the hole or shaft must meet certain requirements. The tolerance gives an allowable range for the actual diameter. The actual diameter of the workpiece must be within the tolerance zone to meet the given conditions. The width of the tolerance zone depends on the required quality and on the size of the basic diameter. Tolerance grades are standardized and give the width of the tolerance zones. Tolerance grades are identified by IT (for ISO tolerance), and are numbered ’1’ to ’18’. An excerpt of this standard is given in Figure 50, detail c). Refer to Figure 51. The tolerance grade gives only the width of the tolerance zone but not the position of this zone in relation to the zero line. The positions are indicated by letters: capital letters for holes and small letters for shafts. The number of the tolerance grade is added to the letter. All holes with the tolerance zone letter H have zero lower deviation. Such holes are called ’standard holes’. If shafts shall be fitted in holes tolerance zones and especially their positions must be taken into account. The tolerance grade of a shaft to be fitted in a hole is usually in the same range as the tolerance grade of the hole. The positions of the tolerance zones for the shafts may be totally below the zero line, intersecting or above the zero line. According to these relations the shafts will fit more or less easily in the holes. Figure 51: Positions of Tolerance Zones For Training Purposes Only Issue: August 2014 Page 98 of 926 Modul 7 Tools PART 66 – Basic Training Cat B1 – Module 7 Fits Refer to Figure 52. The fit, i.e. the fitting of the shaft in the hole, may be: a clearance fit a transition fit an interference fit. In a clearance fit the shaft tolerance zone position is completely below the hole tolerance zone. With (maximum) upper deviation of both shaft and hole there is a maximum clearance between shaft and hole. With (minimum) lower deviation of both shaft and hole there is still a minimum clearance. In a transition fit there is a maximum clearance if both hole and shaft have the upper deviation, i.e. the hole has the maximum allowable diameter and the shaft has the minimum diameter. If the shaft has maximum diameter and the hole has minimum diameter, i.e. if both have lower deviation, the shaft diameter is slightly wider (by some "m) than the hole. In this case the shaft must be pressed into the hole. There is no clearance and the oversize of the shaft gives an interference. In an interference fit the shaft diameter is always wider by a few "m than the hole; there is always interference. In engineering drawings the tolerances are added to the nominal (basic) diameter as an index: for shafts as lower index, e.g. 20f7, for holes as upper index, e.g. 20H7. Figure 52: Types of Fits For Training Purposes Only Issue: August 2014 Page 99 of 926 Modul 7 Tools PART 66 – Basic Training Cat B1 – Module 7 Blind Holes Refer to Figure 53. Blind holes are holes which are drilled into the workpiece only to a certain depth. As mentioned earlier the depth of a blind hole is measured at the circumference and does not include the cone produced by the twist drill point. The height of the twist drill point is 0.3 times the drill diameter. Thus the depth to be drilled is more than the nominal hole depth. The dimensions and their relations can be seen in Figure 53, detail a). During the drilling process the depth cannot be measured directly. For this reason most drilling machines are equipped with a scale and an adjustable mark to indicate the feed motion. The work process to drill blind holes is as follows: After adjustment and fixing of workpiece and drill press vice the feed lever is turned until the twist drill point just touches the workpiece surface at the center –punch mark. Then the scale pointer is adjusted to zero. Now the drilling machine is switched on and the hole is drilled to the desired depth, including the drill point height. At the end, before the complete drill depth is reached, the feeding force is reduced. Example: In the example given in Figure 53, detail b), a blind hole of 8 mm diameter and 20 mm depth shall be drilled. The point height of an 8 mm twist drill is 0.3 ¡ 8 mm = 2.4 mm. The depth to be drilled is 20 mm + 2.4 mm = 22.4 mm. Figure 53: Blind Holes For Training Purposes Only Issue: August 2014 Page 100 of 926 Modul 7 Tools 7.3.1.6 Forming Tools Tools which Produce Straight Bends Press Brake (Fly Press) Refer to Figure 54. PART 66 – Basic Training Cat B1 – Module 7 The secret of economical mass production of aircraft lies in the ability of the designer to specify fabrication methods that require skilled workers only to set up machines and allow the parts to be produced by workers having far less skill. The press brake (or: fly press) needs only to have the dies installed and adjusted and the stops properly set by a skilled worker. Then any number of pieces can be formed with unskilled labour. The female die is fixed and the male die is driven by energy stored in a heavy flywheel by a small electric motor. The material is moved over the female die until it rests against the stop and the male die is lowered into it. The number and types of dies available for press brakes allow them to be used to make almost any kind of bend in sheet metal. Dies are available that bead the edges so wire can be installed. They can also be used to form lock –seams in thin sheet steel or to form channels or boxes. Cornice Brake (Leaf Brake) Refer to Figure 55. Figure 54: Press Brake For Training Purposes Only Issue: August 2014 Page 101 of 926 Modul 7 Tools PART 66 – Basic Training Cat B1 – Module 7 When the correct radius block is in place, the metal to be bent is slipped in the brake and adjusted so the sight line is exactly below the edge of the radius block and the top leaf is clamped tight against the metal. The counterweighted bending leaf is lifted until the metal is folded back over the radius block slightly more than 90° so the metal will spring back to an exact right angle. The bending capacity of a cornice brake is determined by the manufacturer. Standard capacities of this machine are from 12 gauge to 22 - gauge sheet metal, and bending lengths are from 100 mm to 400 mm. The bending capacity of the brake is determined by the bending edge thickness of the various bending leaf bars. Most metals have a tendency to return to their normal shape, a characteristic known as springback. If the cornice brake is set for a 90° –bend, the metal bent will probably form an angle of approx. 87° to 88°. Therefore, if a bend of 90° is desired, the cornice brake must be set to bend an angle of approx. 93° to allow for springback. Bar Folding Machine This brake is the most commonly used bending machine in aircraft maintenance shops. Refer to Figure 56. Figure 55: Cornice (Leaf) Brake The cornice brake (or: leaf brake) is the most generally used brake in maintenance shops, as it covers a wide range of metal thickness and will make bends having flats of any length. These brakes normally have a rather sharp top - nose bar, around which radius bars of any desired radius may be placed. The top leaf may be moved back away from the edge of the bending leaf to accurately adjust the set - back. For Training Purposes Only Issue: August 2014 Page 102 of 926 Modul 7 Tools PART 66 – Basic Training Cat B1 – Module 7 Hold the folding blade in this position and adjust the setscrews so that the metal is clamped securely and evenly the full length of the folding blade. After the folder has been adjusted, test each end of the machine separately with a small piece of metal by actually folding it. To make the fold, adjust the machine correctly and then insert the metal. The metal goes between the folding blade and the jaw. Hold the metal firmly against the gauge and pull the operating handle toward the body. As the handle is brought forward, the jaw automatically raises and holds the metal until the desired fold is made. When the handle is returned to its original position, the jaw and blade will return to their original positions and release the metal. Box (Pan, Finger) Brake Refer to Figure 57. Figure 56: Bar Folding Machine The bar folder is designed for use in making bends or folds along edges of sheets. This machine is best suited for folding small hems, flanges, seams and edges to be wired. Most bar folders have a capacity for metal up to 22 - gauge in thickness and more than 1,000 mm (1 m) in length. Before using the bar folder, several adjustments must be made for thickness of material, width of fold, sharpness of fold and angle of fold. This extremely handy brake is very similar to the cornice brake except that its top leaf is fitted with a number of fingers of varying widths that may be selected to the width of the inside of the box you are forming. two opposite sides of a box may be formed on a leaf brake, but in order to form the last two sides, you must use a box brake. The fingers are selected to fit just between the two sides that have been formed, and when the box is clamped in place and the leaf raised, the sides of the box will slip between the fingers and allow you to form the last two sides of the box. The adjustment for the thickness of material is made by adjusting the screws at each end of the folder. As this adjustment is made, place a piece of metal of the desired thickness in the folder and raise the operating handle until the small roller rests on the cam. For Training Purposes Only Issue: August 2014 Page 103 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Tools the clamp roller adjusts up and down to provide a good tight clamping action on the metal we are rolling the radius roller is adjustable in and out to determine the radius of the roll we are forming. To use the slip roll former, put the metal between the drive and clamp rollers and turn the crank to pull the metal through them and pass it over the radius roller. On the first pass, the radius roller should just touch the metal and form a very slight curve. Each time the metal is passed through, move the radius roller up a bit so it will decrease the radius of the curve in the metal. Pass the metal through the former several times and adjust the radius roller each time until you get exactly the radius you need. Figure 57: Box (Finger) Brake Slip Roll Former Refer to Figure 58. All of the machines mentioned to this point are used to make rather sharp bends in sheet metal. But sometimes we need to make a nice gentle curve in a part to form a metal tube, or form a skin for a fuselage. To do this, the slip roll former is used. This simple machine consists of three hard steel rollers in a framework: the drive roller is turned with a hand crank For Training Purposes Only . Figure 58: Slip Roll Former Tools which Produce Compound Curves Issue: August 2014 Page 104 of 926 Modul 7 Tools PART 66 – Basic Training Cat B1 – Module 7 Stretch Press In a modern aircraft factory, large compound curved skins are produced on stretch presses where the sheet of metal is grasped in two large sets of jaws and the sheet is pulled across a male die until it stretches to the desired shape. It is then trimmed to the proper size. When the operation is completed, the finished part is left in a cold – worked condition. Variations of stretch presses can be rented for use in small repair shops or by aircraft home builders. Drop Hammer A process that has been used longer than the stretch press is drop – hammer forming, where large matching metal male and female dies are used. The sheet metal is laid over the female die and the male die is dropped into it. Hydropress Smaller components such as fuselage formers and wing ribs and all types of compound curved brackets are formed in a hydropress. A blank for the part is punched out of sheet metal on a punch press. This blank is placed over a metal male die and held in place with tooling pins sticking through tooling holes in the blank. Refer to Figure 59. The die is placed on the bed of a hydropress, and the ram which carries a thick rubber blanket is lowered over the die. A pressure of several thousand tons is used to press the rubber down over the metal and force it to form to the shape of the die. Die and a compound–curved part formed over the die. Figure 59: Die Used on Hydropresses For Training Purposes Only Issue: August 2014 Page 105 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Tools Shrinkers and Stretchers 7.3.1.7 These tools are similar in that they both consist of two pairs of heavy jaws that are operated by a hand lever or foot pedal. General Characteristics In the shrinker, the jaws are opened and the edge of the material is put between them and the lever moved back. The first part of the action clamps the jaws tightly onto the metal. Then the two pairs of jaws move together, squeezing the metal. The jaws do not move enough to buckle the metal, but just enough to compress it somewhat. The material is worked back and forth across the full width of the curve, shrinking it just a little with each movement of the jaws. The action of the stretcher is just the same as that of the shrinker except that the two pairs of jaws move apart rather than coming together. This stretches the edge of the material a little bit each time the lever is moved. Sandbag When only one part of a type is to be formed, a heavy canvas bag filled with a good grade of washed sand can serve as a mold. An impression is made in the sand that approximates the shape you want, and the metal is carefully formed into the depression with a round –face plastic or wooden tinman’s mallet. This is strictly a trial – and –error method of forming. Its results depend upon the skill of the worker and the care that is taken. Riveting Tools Because of the highly specialised nature of the riveting equipment used for aircraft construction and repair, this equipment will be discussed in a later Lesson considering the use of these tools in the installation of rivets. For Training Purposes Only Torque Wrenches The holding power of a threaded fastener is greatly increased when it is placed under an initial tensile load that is greater than the loads the fastener is subjected to under operation. This is accomplished by tightening a bolt or nut to a predetermined torque (’pre - load’) with a torque wrench. A torque wrench is a measuring tool which measures the amount of force applied to a threaded fastener. Torque wrenches are precision tools which are applied to all ranges of technique. They are used for the tightening of screws, nuts, pins and similar fastening elements with exactly defined fields of attraction. To maintain the functioning of a torque wrench it is necessary to handle these tools with care and periodically apply a special calibration method. Field of Attraction Torque wrenches must be used only if the exact field of attraction for screws, nuts, pins and similar fastening elements is determined. Range of Operation The prescribed field of attraction must be within the range of operation determined for the particular torque wrench. The range of operation is indicated on the housing or the scale attached to the handle of the torque wrench. Application beyond the prescribed range is not allowed because it would cause damage to the tool. Issue: August 2014 Page 106 of 926 Modul 7 Tools PART 66 – Basic Training Cat B1 – Module 7 Plug –In and Additional Tools Additional tools may be applied only if delivered by the manufacturer. Care must be taken that no changes in the lever arm of a force will take place while applying additional tools. Plug - in tools delivered by the manufacturer normally do not lead to changes in lever arms. Additional tools which have to be attached to the plug - in tools mostly influence the lever arm. Types of Torque Wrenches There are three basic types of torque wrenches typically found in aviation maintenance shops: the deflecting - beam type the torsion - bar type the toggle type. Deflecting –Beam Torque Wrench Refer to Figure 60. The deflecting –- eam torque wrench is of a quite simple design. On one end of an accurately ground beam there is the square drive. A handle is mounted on a pivot at the other end of the beam. The pivot ensures that the force is always applied at a specific point. A pointer is attached to the end of the beam holding the drive square, and a scale is mounted near the handle end. When force is applied to the handle, the beams bends and the pointer moves across the dial showing the amount of the bend. This amount is directly proportional to the amount of torque applied. For Training Purposes Only Issue: August 2014 Figure 60: Deflecting – Beam Torque Wrench Page 107 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Tools Torsion –Bar Torque Wrench Toggle –Type Torque Wrench Refer to Figure 61. Refer to Figure 62. When a torsional force is applied, a bar accurately deflects this torsion as well as bending. Torsion - bar torque wrenches apply this principle. The drive square of such a wrench is accurately ground and has a rack gear on one end. When the bar is twisted, the rack moves across a pinion gear in the dial indicator which shows the amount of bar deflection. The indicator can be calibrated in inch - pounds, footpounds, meter - kilograms or cm - kg. A toggle - type torque wrench is preset to the desired torque before it is put on a fastener. When this preset torque is reached a sound (’click’) is heard and the handle releases a few degrees. The sound and the release both indicate that the desired torque is reached. Now, the handle should no longer Figure 62: Toggle –Type Torque Wrench Refer to Figures 63 and 64. The various types of fastening elements in respect of material, length, diameter and fastening need more or less sensitive adjustment of torque wrenches and also very small or very high fields of attraction. The smaller a fastening element, the lower the field of attraction to avoid damaging. Figure 61: Torsion – Bar Torque Wrench For Training Purposes Only Issue: August 2014 Page 108 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Tools Torque wrenches which are electronically adjustable or with scale measuring mostly have the lowest fields of attraction combined with the smallest square drives. Torque wrenches equipped with automatic release or indicator scale have higher fields of attraction combined with bigger square drives. Figure 63: Types of Torque Wrenches (Details a) to c)) For Training Purposes Only Figure 64: Types of Torque Wrenches (Details d) to f)) Application of Torque Wrenches Issue: August 2014 Page 109 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Tools The torque wrench has to be adjusted to the correct moment of torsion. Prior to applying the torque wrench for the first time, the user has to be informed about the functioning and be instructed in the operation of this tool. In most cases the torque wrench value given by the AMM (Chapter 20 Standard Practices) will account for this increase in length, but it may have to be calculated. The scale reading to which the torque wrench should be set, to take account of this increase in effective length can be found mathematically by using the formula: Ti A torque wrench with automatic release which has not been applied for a long time, has to be released several times (minimum 4 times) with the value which has to be adjusted, before using. This will ensure a proper lubrication of the inner mechanics and by this way avoid malfunction. For torque wrenches which are used steadily, this procedure has to be applied daily before starting work. Prior to application, the torque wrench has to be inspected for outer damage and pollution. If consequences of malpractices in handling are perceptible, it has to be readjusted with a comparison measurement. Ta L L A Torque Wrench Effective Length (L) Adapter Length (A) Torque Wrench Extensions Torque Wrench Refer Figure 65 und 66 During some maintenance procedures an adapter must be attached to the end of the torque wrench, this will change the overall effective length of the lever mechanism. As the distance part of the equation will have increased there will be a resultant decrease in the torque wrench value required irrespective of the type of torque wrench used. Extension socket/spanner Figure 65: Torque Wrench Extension (I) For Training Purposes Only Issue: August 2014 Page 110 of 926 Modul 7 Tools PART 66 – Basic Training Cat B1 – Module 7 Torque Wrench Pre Use Check Before a torque wrench can be used, it should be examined by the operator, to ensure it is satisfactory for the task. The calibration label should be examined to check the date for next calibration has not expired. The operator should also check the torque wrench for general condition and accuracy by completing a test on a Master Checking Rig. This test ensures that the wrench indicates the selected torque value before the tightening procedure is done. Using a Torque Wrench Refer Figure 67 Figure 66: Torque Wrench Extension (II) Ti = indicated Torque Ta = actual (desired) Torque L = Torque Wrench Effective Length A = Adapter Length For Training Purposes Only If a fastener is under torqued, there is danger of the joint being subjected to unnecessary loads resulting in premature failure. On the other hand, when a fastener is over torqued, the threads are over stressed and can fail. Therefore, it is very important that fasteners be torqued to their specified value. Furthermore, it is important to realize that, unless otherwise specified, all torque values given are for clean dry threads. When a self-locking nut is torqued, the nut should be run down on the threads until it nearly contacts the washer. The amount of torque required to run the nut down should be measured and this value added to the amount of torque needed for the fastener. The torque needed to turn the nut down is called friction drag torque. The accuracy of a torque measurement is assured only when torque is applied with a smooth and even motion. Remember that impacttype wrenches should never be used on any fastener whose torque is critical. Issue: August 2014 Page 111 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Tools If a nut is accidentally over torqued, it should be loosened and then retorqued to the proper value. Never back off a nut or a bolt and leave it untorqued. When installing a castle nut, start alignment with the cotter pin hole at minimum recommended torque, plus friction drag. If the hole and nut castellation do not align, change washers and try again. Exceeding the maximum recommended torque is not recommended. Example of various units of torque: Imperial Metric SI pound force foot (lbf.ft) kilogram force metre (kgf.m) Newton metre (Nm) pound force inch (lbf.in) kilogram force centimetre (kgf.cm) centi-Newton metre (cNm) Figure 67: Various Units of Torque For Training Purposes Only Issue: August 2014 Page 112 of 926 Modul 7 Tools 7.3.1.8 PART 66 – Basic Training Cat B1 – Module 7 Lubrication Diagram Lubrication Equipment and Methods Introduction A lubricant is a substance (usually a liquid) introduced between two moving surfaces to reduce the friction and wear between them. Worldwide, more than 50 million tonnes of lubricants are consumed annually. Many lubricants are oils or greases. Typically lubricants contain 90 % base oil (most often petroleum fractions, called mineral oils) and less than 10 % additives. Vegetable oils or synthetic liquids such as hydrogenated polyolefins, esters, silicone, fluorocarbons and many others are sometimes used as base oils. Additives deliver reduced friction and wear, increased viscosity, resistance to corrosion and oxidation, aging or contamination, etc. Lubrication is carried out in accordance with a schedule approved for the particular aircraft. The intervals are normally related to flying hours. Note: Certain positions may require additional lubrication after ground de –icing operations and after cleaning the aircraft. Refer to Figure 68. Non –liquid lubricants include grease, powders (dry graphite, PTFE, Molybdenum disulfide, etc.), teflon tape used in plumbing, air cushion and others. Alternative way to reduce friction and wear is to use bearings such as ball bearings, roller bearings or air bearings or to use sound, in the case of acoustic lubrication. Depending on the type of lubrication the following equipment can be used: grease gun (powered by air or hand) oil can brush clean lint –free cloth aerosol spray. Information about the correct tool and application has to be taken from the manuals of the specific equipment. For Training Purposes Only Issue: August 2014 Page 113 of 926 Modul 7 Tools PART 66 – Basic Training Cat B1 – Module 7 Figure 68: Lubrication Diagram (Example) For Training Purposes Only Issue: August 2014 Page 114 of 926 Modul 7 Tools PART 66 – Basic Training Cat B1 – Module 7 The types of lubricant and the position of the lubrication points are shown in so - called lubrication diagrams in the aircraft maintenance manual. Minor lubrication points have a drilled hole into which oil is fed using an oil can. Nipples are provided where it is necessary to force grease or oil into bearings etc. Some bearings are self –lubricating, other bearings are packed on assembly with sufficient grease for their life. Such bearings will not require any further lubrication during service. Procedure Use only clean lubricants and tools for lubrication purposes. Before starting any lubrication operation, carefully clean the grease nipples and lubrication holes. Check that the grease nipples are fitted with ball and spring. Ensure that the old grease exudes through the pressure relief valves on each side of the spherical bearings (unless the quantity of grease to be used is indicated). After lubrication, remove all surplus grease. Wipe the grease nipple with a clean lint –free cloth. Check that the ball and its spring are in position. Before lubrication, the wheel bearings should be cleaned. The bearings should be lubricated and installed immediately. For Training Purposes Only Issue: August 2014 Page 115 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Tools 7.3.2 Measuring Tools Refer to Figure 1. 7.3.2.1 Because the end of a metal scale is not precisely cut, the cut, or factory end should not be used as a measuring guide. Instead, measuring should always begin somewhere after the first few markings on a scale to ensure a correct measurement. The one inch mark is typically used as the starting point because it is easily subtracted from the final measurement. General In maintenance and repair there are many jobs that require precise measuring for close tolerance fits. Therefore, one has to be familiar with several measuring devices. Some of the common measuring tools include protractors, calipers and telescoping gauges. 7.3.2.2 Scales or Rules Steel scales or rules are essential to have, in both six inch and 12 inch lengths, or in 150 mm and 300 mm, respectively. This type of measuring device is typically used for sheet metal layout, and for taking measurements where extreme precision is not required. Scales are made of either a tempered carbon steel or a satin – finished stainless steel and are available in both flexible and rigid form. The flexible scale typically has a thickness of approx. 0.4 mm, while a rigid scale is approx. 1 mm thick. Scales are graduated in exact portions of either a metric measurement, or a fractional measurement. Scales with fractional graduations are typically divided into increments of 1/32 inch on one side and 1/64 inch on the other side. A decimal scale is usually divided in tenths or fiftieths of an inch on one side while the other side is divided in increments of 1/100 inch. Do not use the end of the scale to make a measurement. Figure 1: Use of Steel Scale Measuring with Steel Rule Metric graduations are measured in centimeters and millimeters, and are often included on the same scale. Since it is sometimes necessary to convert from metric to fractional or decimal form and vice versa, it is recommended to keep a conversion chart with the layout tools. For Training Purposes Only Measuring is ascertaining a dimensional value by comparing a given size with a statutory unit of measurement. Refer to Figure 2. Issue: August 2014 Page 116 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Tools Steel Rule During measuring the rule must be placed either directly onto the length to be measured or at right angles to the reference plane a contact face should be used, if possible, and the measurements be read off by looking at the point from directly above. Note: The reference plane is the surface of the workpiece, from which measurements are made. Measurement is always carried out from the reference plane. Accurate measurement within the given conditions, accurate marking and center punching are unconditional prerequisites for correct and perfect treatment of a workpiece. Training in accuracy begins with the following practical exercise. 7.3.2.3 Scribers Refer to Figure 3. Figure 2: Steel Rule For Training Purposes Only Figure 3: Typical Scriber Issue: August 2014 Page 117 of 926 Modul 7 Tools Dimension layout on metal parts, regardless of the accuracy, is typically accomplished by using layout dye and a marking tool called a scriber. Scribers have needle - sharp points and are usually made of hard steel or are carbide tipped. To use a scriber, a layout dye is typically applied to the metal first and the scriber is used to scratch through the dye. However, this procedure will cause stress concentrations on the surface of a bend and, therefore, it is not acceptable to use this method to indicate bend lines. Instead, bend lines should be marked with a soft tipped marker. 7.3.2.4 Combination Set Refer to Figure 4. An elaboration of the steel scale is the combination set. This measuring device consists of a 12 inch or 300 mm steel scale and three heads that move up and down along the scale. The heads of a combination set are removable to allow the use of any combination of the individual components. PART 66 – Basic Training Cat B1 – Module 7 Stock Head The stock head of a combination set is normally used as a square. One side of the head is exactly perpendicular to the scale, while the other side meets the scale at a 45 degree angle. To determine if something is level, the stock head can be removed from the scale and the built –in bubble level used. Protector Head A bubble level and a 360 degree protractor are built into the protractor head of a combination set. This head has a lock that releases the protractor and allows it to rotate within its frame. This feature makes the head particularly useful for measuring control surface travel. For example, the surface of a protractor head is locked in a streamline, or neutral position, and its head is placed on a control surface that is in its neutral position. Next, the protractor is turned until its bubble level is centered. Now, when the control surface is fully deflected the degree of travel is represented by the angular difference between the level and the scale. To determine the total amount of control surface movement, both extreme measurements must be taken. To accomplish this, the control surface is moved to its other extreme of travel and the bubble level is centered. The sum of the two extreme readings is the amount of control surface movement. Center Head Figure 4: Combination Set For Training Purposes Only The center head of a combination set is used for finding the center of circular objects such as a piece of round bar stock. To use a center head, put the two flat blades of the center head over the end of a Issue: August 2014 Page 118 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Tools piece of circular material that is held perpendicular to the scale. Since the scale bisects the center head angle into two equal parts, the scale also bisects the circular material. Next, scribe a line along the edge of the scale that passes through the center of the circular material. Now rotate the center head 90 degrees and scribe another mark along the edge of the scale blade. The point where the two scribe marks intersect is the center of the circular material. 7.3.2.5 To begin laying out dimensions, first cover the metal with a layout dye and mark a base line with a very sharp scriber. Next, make a very light punch mark on the base line to use as a reference for all measurements. After this is complete, the divider is set to the desired distance with a steel machinist scale. Then one divider leg is placed on the punch mark and a scratch is made with the other divider leg through the transfer dye. This procedure is far more accurate than measuring a dimension directly with a steel scale. Dividers 7.3.2.6 Thickness Gauges Refer to Figure 5. Refer to Figure 6. Thickness gauges are used to measure clearances between two surfaces, such as a piston ring’s fit in a ring groove or its end cap clearance. In addition, they can be used with a surface plate and arbor to check a part for twist or warp. A typical thickness gauge consists of a stack of steel or brass blades of varying thickness. Each blade is ground to a precise dimension, accurate to ten thousandth of an inch. Figure 5: Typical Divider Dividers are layout tools that are used to accurately lay out circles and arcs and for transferring dimensions on metal. A divider has two legs with needle –sharp points that are joined in the center with a pivot. Since a divider does not have a built –in scale, it does not provide a measurement when used as a measuring device. For Training Purposes Only To measure a clearance between two surfaces, select a blade approximately the size of the clearance to be measured and insert it between the two surfaces. If the blade is too loose, try the next larger size. When a blade slides between the two surfaces with a slight amount of friction, the size designation printed on the blade indicates the clearance. Issue: August 2014 Page 119 of 926 Modul 7 Tools PART 66 – Basic Training Cat B1 – Module 7 Calipers are very similar to dividers in that they have two legs with some type of pivot. Figure 6: Thickness Gauge 7.3.2.7 Calipers Refer to Figure 7. Calipers are a type of measuring device typically used to measure diameters and distances or for comparing sizes. There are three types of calipers. These are inside caliper outside caliper hermaphrodite caliper. For Training Purposes Only Figure 7: Different Types of Calipers Inside Calipers Issue: August 2014 Page 120 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Tools Inside calipers are used to measure the inside diameter of a hole, and have legs that point outward. Furthermore, when used in conjunction with other devices, micrometers can measure the fit of many engine parts. The basic parts of a micrometer caliper include Outside Calipers Outside calipers, on the other hand, are used to measure the outside diameter of an object and have legs that point inward. When using either type of calipers, adjust the caliper until it fits snugly across the widest part of an object, and then measure the distance between the caliper leg points with a steel scale. frame, which resembles a C –clamp anvil spindle sleeve thimble. Hermaphrodite Calipers Hermaphrodite calipers are used to scribe marks that represent a specific distance from a radius edge. These calipers have one sharp –pointed leg and one leg that curves to the inside. To use hermaphrodite calipers, the material being worked on is first covered with a lay –out dye and the distance required is adjusted between the two caliper legs. The caliper point is then moved along the radius edge as the sharp point is drawn across the surface. Micrometer Calipers Refer to Figure 8. The precision measuring tool most universally used is the micrometer caliper. These instruments are used to measure the thickness of sheet metal the out – of- roundness of cylindrical objects such as piston pins V the degree of stretch of valve stems. Figure 8: Micrometer Caliper Vernier Scales For Training Purposes Only Issue: August 2014 Page 121 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Tools At times it is necessary to make measurements that are smaller than one - thousandth of an inch. In these situations one must use a micrometer with a vernier scale. A vernier scale is a secondary scale found on some precision measuring tools that further divides the primary scale into even smaller increments. Vernier Micrometer The vernier micrometer is like the standard micrometer except that it has eleven extra lines on the sleeve. These lines are marked longitudinally, just above the longitudinal reference line. To read a vernier micrometer, begin by reading the sleeve and thimble just like a standard micrometer. Then look at the vernier scale and identify the horizontal line that lines up with an increment on the thimble. The number associated with the horizontal line is then added to the measurement. Inside Micrometers Figure 9: Inside Micrometer Refer to Figure 9. An inside micrometer uses a single micrometer head consisting of a basic micrometer mechanism and various extensions to cover a wide range of measurements. An inside micrometer caliper is read in exact the same manner as an outside micrometer. To use an inside micrometer place it inside the opening being measured and adjust the micrometer until it is the same size as the opening. Once this is done, the micrometer is removed from the opening and read. Micrometer Depth Gauge Refer to Figure 10. For Training Purposes Only Issue: August 2014 Page 122 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Tools of the groove. The reading on the micrometer head indicates the depth of the groove. 7.3.2.8 Vernier Calipers Refer to Figure 11. The vernier caliper is a versatile precision instrument used to measure both inside and outside dimensions. In many situations, a vernier caliper is faster to use than a micrometer. Furthermore, calipers typically have a useful range of up to six inches. Figure 10: Micrometer Depth Gauge The depth of grooves or recesses in a part are accurately measured with a micrometer depth gauge. This device has a standard micrometer head mounted onto a precise ground bar. When the spindle of the micrometer is flush with the face of the bar, the depth gauge reads zero. To measure the depth of a groove or recess, the bar is placed across a groove and the spindle is screwed down until it contacts the bottom For Training Purposes Only Issue: August 2014 Figure 11: Vernier Caliper Page 123 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Tools Refer to Figure 12. The English Caliper To use a vernier caliper, loosen the lock screws on the movable jaw and clamp. Next, move the jaw to the approximate position and lock the clamp in place. Then, using the adjustment screw on the clasp, move the jaw into its correct position and lock it. Read the distance between the jaws on the vernier scale for the correct inside or outside dimension as indicated. The English vernier caliper has 25 spaces on the vernier scale that occupy exactly the same distance as 24 spaces on the bar scale. Each graduation on the bar represents 25 –thousandths of an inch (0.025). The line on the vernier scale that is aligned with one of the bar scale marks indicates the number of thousandths of an inch to add to the measurement indicated on the bar before the zero on the vernier scale. To read a vernier caliper, begin by identifying the approximate dimension opposite the zero mark on the sliding scale. Once this is done, identify the number on the sliding scale that is aligned with an increment on the fixed bar scale and add this to the first dimension The Metric Vernier Caliper The metric vernier caliper is read in the same way as an English caliper in that the scale on the movable jaw aligns with a line on the bar. The difference is that each number on the metric bar scale represents one centimeter, or 10 millimeters, with each graduation representing one –half millimeter. The graduations on a metric vernier scale represent divisions of 1/50 millimeter. Application of Vernier Calipers Refer to Figure 13. Vernier calipers are the most important measuring instruments in the workshop. Vernier calipers are used for measuring lengths with a measuring accuracy of 1/10 mm. These lengths can be: external dimensions internal dimensions depths. Figure 12: Vernier Caliper Scales For Training Purposes Only Issue: August 2014 Page 124 of 926 Modul 7 Tools PART 66 – Basic Training Cat B1 – Module 7 A vernier caliper comprises: main (fixed) body with rule slide with vernier (nonius) jaws on main body and slide depth gauge (not necessarily). The slide is adjusted so that the jaws touch the workpiece to be measured. Figure 13: Sliding Caliper Jaws Refer to Figure 14. Figure 14: Vernier Design For Training Purposes Only Issue: August 2014 Page 125 of 926 Modul 7 Tools PART 66 – Basic Training Cat B1 – Module 7 The vernier enables linear dimensions to be read off with an accuracy of 1/10 mm. It is a sliding graduated rule of, for instance, 19 mm in length. The 19 mm are divided into 10 equally graduated divisions. Thus 1 graduated division is 1.9 mm wide. Every graduated division of the vernier is 0.1 mm smaller than 2 mm. Spacing on the Vernier From 0 to the1st mark = 1.9 mm From 0 to the 2nd mark 2 ⋅ 1.9 = 3.8 mm From 0 to the 3rd mark 3 ⋅ 1.9 = 5.7 mm From 0 to the 4th mark 4 ⋅ 1.9 = 7.6 mm From 0 to the 5th mark 5 ⋅ 1.9 = 9.5 mm From 0 to the 6th mark 6 ⋅ 1.9 = 11.4 mm From 0 to the 7th mark 7 ⋅ 1.9 = 13.3 mm From 0 to the 8th mark 8 ⋅ 1.9 = 15.2 mm From 0 to the 9th mark 9 ⋅ 1.9 = 17.1 mm From 0 to the 10th mark 10 ⋅ 1.9 Reading off the Dimensional Values = 19.0 mm. Refer to Figure 15. Whole millimeters are read off with the zero mark (0) on the vernier (Figure 15, details a) and b)). Tenths of millimeters are read when the zero mark (0) on the vernier is between two mm marks (e.g. 19 and 20 mm; detail c)). Figure 15: Reading Verniers (I) For Training Purposes Only Issue: August 2014 Page 126 of 926 Modul 7 Tools PART 66 – Basic Training Cat B1 – Module 7 The mark on the vernier that coincides with any mark on the main rule gives the tenth of a millimeter. The mark on the main rule just below the vernier zero mark gives the whole millimeters. Refer to Figure 16. In Figure 16, detail a), the vernier zero mark is between 0 mm and 1 mm. This means that the measured value is greater than zero and less than 1 mm. Only one mark of the vernier coincides with a mm mark on the main rule. In this example it is the 6th vernier mark. The measured value is 6/10 or 0.6 mm more than the lower whole millimeter, i.e. 0.0 mm + 0.6 mm = 0.6 mm. In detail b), the vernier zero mark is between 21 mm and 22 mm. The 4th vernier mark coincides with one of the millimeter marks on the main rule. The measured value is 21 mm + 0.4 mm = 21.4 mm. The reading in detail c) is 15.7 mm using the same method. Figure 16: Reading Verniers (II) For Training Purposes Only Issue: August 2014 Page 127 of 926 Modul 7 Tools PART 66 – Basic Training Cat B1 – Module 7 Working Technique Refer to Figure 17. External Length Measurement (Detail a)) The vernier caliper should be set to oversize. The fixed caliper jaw should be held against the workpiece. The sliding jaw has to be pushed up against the workpiece. Measuring Parallelism (Detail b)) The measuring process should be repeated at several points. Figure 17: Measuring with Vernier Caliper For Training Purposes Only Issue: August 2014 Page 128 of 926 Modul 7 Tools PART 66 – Basic Training Cat B1 – Module 7 7.3.2.9 Dial Indicators Refer to Figure 18. Dial indicators are precision measuring instruments used to determine the amount of movement existing between certain engine and airframe parts. These indicators are also used to determine an out – of - round condition on a shaft as well as the plane of rotation of a disk. Engine crankshaft run - out is checked with a dial indicator by mounting the dial indicator to its furnished arm and then clamping the assembly to its stand. The dial indicator is then put in contact with a smooth part of the crankshaft. A pre - load is then applied to the dial indicator by pressing it against the shaft until the pointer deflects a few thousandth of an inch. Next, the indicator is zeroed by rotating the dial or turning the bezel on the outside of the instrument case until the needle is opposite the zero mark. When the crankshaft is turned, the needle indicates the maximum deviation in both directions. Figure 18: Dial Indicators For Training Purposes Only Issue: August 2014 Page 129 of 926 Modul 7 Tools 7.3.3 Operation, Function and Use of Electrical Test Equipment 7.3.3.1 Digital and Analogue Multimeters Digital and analogue multimeters are the measurement devices mostly used in the field of electrical and electronic engineering. A multimeter consists of a voltmeter, an ammeter and ohmmeter combined in a single unit. PART 66 – Basic Training Cat B1 – Module 7 An instrument with high resistance would affect the current through the load to a high extent and would generate unacceptable measurement errors. When current is measured the multimeter must always be connected in series with the load. The electrical quantities usually measured are current (DC and AC), voltage (DC and AC) and resistance. The minimum number of functions available on a common multimeter are: several DC ampere ranges several AC ampere ranges several DC voltage ranges several AC voltage ranges V several ohm ranges. Measurement of Current (DC – AC) Refer to Figure 1. A multimeter used as an ammeter (amperemeter) is in series connected to the circuit, so that the current passing through it is the total current through the load. In order to carry out an accurate measurement, the multimeter, when in use as an ammeter, must have a very low input resistance compared with that of the load. Figure 1: Current Measurement with Multimeter For Training Purposes Only Issue: August 2014 Page 130 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Tools Refer to Figure 2. Measurement of Resistance A voltage exists between two points. Therefore, a voltmeter must be connected across the two points where the voltage is to be measured. Refer to Figure 3. The multimeter when used as a voltmeter must have a very high input resistance compared to that of the load. Otherwise a great measurement error would occur. Current flow in circuits is limited by resistance. In order to measure resistances the multimeter is used as an ohmmeter. For ohmic measurements the multimeter must have a very high input resistance. Otherwise a great measurement error would occur. When voltage is measured the multimeter must always be connected in parallel with the load. Figure 3: Resistance Measurement with Multimeter Figure 2: Voltage Measurement with Multimeter For Training Purposes Only Issue: August 2014 Page 131 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Tools 7.3.3.2 Digital Multimeter Refer to Figure 4. The advantage of digital multimeters is the digital readout. In addition to the obvious benefit of the clear and definite numerical display, the digital multimeters offer a variety of flexible versions with improved accuracy of the readings. For example, in comparison with a conventional pointer type of panel meter for DC volts with a + 1 % tolerance, a digital panel meter provides a basic accuracy of + 0.1 % + 1 digit, thus improving the tolerance figure by at least 10 times, without incurring any possible additional inaccuracies due to human error in making the reading. The digital multimeters extend this improvement in accuracy by the increased number of digits in the readout. Many advanced models of digital multimeters are available with 4 or 5 digits, providing an accuracy of + 0.01 % or better. In order to obtain a clear and proper reading the instrument is provided with seven segment displays. Range and function switching is effected manually by means of push –buttons and a rotary button. Measurements with a Digital Multimeter A typical digital multimeter can be used to perform the following measurements: DC voltages up to maximum 1,000 V AC voltages up to maximum 750 V DC currents up to maximum 10 A (fuse –protected) AC currents up to maximum 10 A (fuse –protected) resistance up to maximum 40 MΩ continuity testing and diode testing Figure 4: Digital Multimeter For Training Purposes Only Issue: August 2014 Page 132 of 926 Modul 7 Tools 7.3.3.3 Analogue Multimeter Refer to Figure 5. PART 66 – Basic Training Cat B1 – Module 7 A moving –coil meter forms the heart of an analogue multimeter. The heart of the moving –coil meter is the measuring element. The most popular type of measuring element is the permanent magnet. A horseshoe magnet (permanent magnet) produces the stationary magnetic field. To concentrate the magnetic field in the area of the moving coil, pole pieces are added to the magnet. The lines of flux tend to concentrate in this area, as shown. Also, a stationary soft –iron core is placed between the pole pieces. A moving coil is fitted around the soft –iron core. The coil consists of many turns of extremely fine wire on an aluminium frame. The two ends of the coil are connected to the leads of the meter. The pointer is attached to the moving coil so that it moves when the coil does. Counterweights are often attached to the pointer so that a perfect balance is achieved. Retaining pins on either side limit the distance that the pointer and other rotating parts can move. Two spiral springs at opposite ends of the moving coil force the pointer back to the zero position when no current is flowing through the coil. In most cases, the spiral springs are also used to apply current to the moving coil. The moving coil, pointer, and counterweights rotate around a pivot point. A conductor is deflected at a right angle to a stationary magnetic field if current flows through the conductor. The left –hand motor rule describes this action. Current is forced to flow through the coil so that current flows ’out of the page’ on the left. When applying the left – hand rule to the coil at this point, the coil is forced up on the left and down on the right. This forces the pointer to move up the scale in clockwise direction. Figure 5: Moving – Coil Meter For Training Purposes Only Issue: August 2014 Page 133 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Tools The amount of torque produced by this tiny ’motor’ is proportional to the magnitude of the current which flows through the moving coil. Measuring elements are rated by the amount of current required to produce full –scale deflection. For example, a 50 "A element deflects full –scale when only 50 "A of current flow through it. The 50 "A element is one of the most commonly used types. Figure 6 shows a view of an analogue multimeter. This instrument can be used to perform the following measurements: DC voltages of 300 mV to 1,000 V AC voltages of 300 mV to 1,000 V DC currents of 10 mA to 6 A AC currents of 10 mA to 6 A V resistance of 1 # to 5 MΩ. Refer to Figure 6. Classes of Accuracy and Errors No measurement can be absolute. It is only possible to reduce the errors. In order to do this it is necessary to know what types of error can occur and how these errors can be reduced. The number of possible errors can be divided into two groups. The first group contains the errors made during manufacture of the instrument. The manufacturer knows the accuracy of his instruments and inscribes the class of accuracy to which the instrument belongs on the scale. The second group contains the errors made by the operator. Accuracy of Instruments Figure 7 shows seven classes of accuracy and the conditions for each class. Three classes, the classes 0.1, 0.2 and 0.5 are reserved for precision measurement instruments. The others are for industrial measurement instruments. ’Measurement error’ is the difference between the indicated value and the true value. Should the indicated value be less than the true value the error is negative and vice versa. Figure 6: Analogue Multimeter For Training Purposes Only Issue: August 2014 Page 134 of 926 Modul 7 Tools PART 66 – Basic Training Cat B1 – Module 7 Figure 7: Classes of Accuracy For Training Purposes Only Issue: August 2014 Page 135 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Tools Operator Errors The other group of errors concerns errors made by the operator. It begins with the wrong choice of instrument and may end with a false scale reading. Refer to Figure 8. The wrong choice of instrument may take place if the operator does not understand the term ’internal power consumption’. Detail a), shows typical internal power consumptions due to meter movements and the allocated ranges. Any measurement consumes a certain amount of energy to drive the meter movement. The source of this energy is the circuit which is to be measured. Two types of errors can occur dependent on the measuring method. If the meter movement is in series with the circuit to be measured the internal resistance of the meter movement increases the total resistance so that the current through the complete circuit decreases. The reverse happens if the resistance of the movement is switched in parallel with the circuit which is to be measured. However, any measurement changes the situation in the circuit to be measured. If current is to be measured the internal resistance of the movement cannot be small enough. If voltage is to be measured the internal resistance cannot be high enough, and, if the power consumption of the movement is high, the power generated in the circuit must be very high. The relationship between the power consumption of the meter movement and its auxiliary components and the power generated in the circuit decides how accurate the measured result will be. A very low value may be the factor 10, better factors are 1,000 and more. Figure 8: Power Consumption and Characteristic Resistance For Training Purposes Only Issue: August 2014 Page 136 of 926 Modul 7 Tools PART 66 – Basic Training Cat B1 – Module 7 On many instruments the information ’resistance per volt’ (characteristic resistance) is given. Detail b) shows a table with typical values. The lower values of W/V are normally used in high –power circuits and the higher values are better suited to low –power circuits, such as electronic circuits. Apart from the incorrectly chosen instrument other common errors can happen. Refer to Figure 9 The class of accuracy of the instrument is only given for a full scale deflection (f.s.d.). Detail a) shows an indication on the meter requiring a full scale deflection of the pointer. Because the accuracy of the instrument states 1.5 % to f.s.d. the true voltage may be 100 V á1.5 %. Therefore the true value can be between 100 V plus 1.5 V or 100 V minus 1.5 V (between 98.5 V and 101.5 V). This means that the measured result has a range of uncertainty of 3 V. Detail b) shows an indication of 50 V on the same instrument. The range of uncertainty is still the same: 50 V á1.5 V. That means the voltage is between 51.5 V and 48.5 V. But the accuracy is only half as much as before: 100 % times 1.5 V divided by 50 V is á 3 %. Detail c) shows an indication of 10 V on the same instrument. The range of uncertainty is still the same: 10 V á1.5 V. That means the voltage is between 8.5 V and 11.5 V. But the error is now (100 % times 1.5 V divided by 10 V) = á15 %. Figure 9: Indication and Error For Training Purposes Only Issue: August 2014 Page 137 of 926 Modul 7 Tools PART 66 – Basic Training Cat B1 – Module 7 The meter accuracy becomes progressively worse the nearer the pointer approaches the zero calibrated position. For this reason measurements are more accurate when a measurement range on the instrument is selected that will cause a nearly full –scale deflection of the meter pointer. Not all meters can be used with equal success in both horizontal and vertical positions. The mechanical construction of many meters is such that their accuracy considerably varies with the angle at which they are held. Panel mounting type meters, for instance, are normally adjusted for use only in a vertical position, while meters used in test sets generally work better when they are held or laid flat. Refer to Figure 10. A screw on the front of the meter is used to set the meter needle on the scale to zero when no current flows. This adjustment is carried out with a small screwdriver and should be checked when using a meter, particularly if the vertical or horizontal position of the meter is changed. Figure 10: Meter Zeroing Refer to Figure 11. Meters should always be read from a position directly in front of the meter face (i.e. at right angles) because the space between the individual positions is relatively small and the pointer is raised a little above the scale in order to be able to move freely round it. Reading the position of the pointer from the side would therefore result in an inaccurate reading, often amounting to one division on the scale. An error caused by reading a meter from the wrong angle is named a ’parallax error’. Figure 11, detail a), shows a correct meter reading in contrast to detail b), where an incorrect meter reading is illustrated. For Training Purposes Only Issue: August 2014 Page 138 of 926 Modul 7 Tools PART 66 – Basic Training Cat B1 – Module 7 Figure 11: Parallax Error For Training Purposes Only Issue: August 2014 Page 139 of 926 Modul 7 Avionic General Test Equipment 7.4 Avionic General Test Equipment A multimeter has three parts: 7.4.1 Multi Meter Refer Figure 1. PART 66 – Basic Training Cat B1 – Module 7 Display Selection Knob Ports The following description is based on the Multimeter in the picture (figure1). The display usually has four digits and the ability to display a negative sign. A few multimeters have illuminated displays for better viewing in low light situations. The selection knob allows the user to set the multimeter to read different things such as milliamps (mA) of current, voltage (V) and resistance (Ω ohm). Two probes are plugged into two of the ports on the front of the unit. COM stands for common and is almost always connected to Ground or ‘-’ of a circuit. The COM probe is conventionally black but there is no difference between the red probe and black probe other than color. 10A is the special port used when measuring large currents (greater than 200mA). mAVΩ is the port that the red probe is conventionally Figure 1: Multi Meter For Training Purposes Only plugged in to. This port allows the measurement of current (200mA), voltage (V), and resistance (ohm). The probes have a banana type connector on the end that plugs into the multimeter. Any probe with a banana plug will work with this meter. Issue: August 2014 Page 140 of 926 Modul 7 Avionic General Test Equipment Measuring Voltage Refer Figure 2 and 3. Plug the black probe into COM and the red probe into mAVΩ. Set the multimeter to correct voltage range. Connect the black probe to the ground or ‘-’ and the red probe to power or ‘+’. The measured voltagevalue is shown on the display! If you’re measuring DC voltage (such as a battery) you want to set the knob where the V has a straight line. Figure 2: Use the V with a straight line to measure DC Voltage For Training Purposes Only PART 66 – Basic Training Cat B1 – Module 7 AC voltage (like what comes out of the wall) can be dangerous so we rarely need to use the AC voltage setting (V with a wavy line next to it). If you’re messing with AC, we recommend you get a non-contact tester rather than use a digital multimeter. Figure 3: Use the V with a wavy line to measure AC Voltage Issue: August 2014 Page 141 of 926 Modul 7 Avionic General Test Equipment Figure 4: Measure the voltage of a battery Figure 5: OL Readout What happens if you switch the red and black probes? The reading on the multimeter is simply negative. Nothing bad happens! The multimeter measures voltage in relation to the common probe. How much voltage is there on the ‘+’ of the battery compared to common or the negative pin? 1.5V. If we switch the probes, we define ‘+’ as the common or zero point. How much voltage is there on the ‘-’ of the battery compared to our new zero? -1.5V! For Training Purposes Only PART 66 – Basic Training Cat B1 – Module 7 This is the meter trying to tell you that it is overloaded or out-of-range. Whatever you’re trying to read is too much for that particular setting. Try changing the multimeter knob to a different range. Issue: August 2014 Page 142 of 926 Modul 7 Avionic General Test Equipment PART 66 – Basic Training Cat B1 – Module 7 Why does the meter knob read 20V and not 10V? If you’re looking to measure a voltage less than 20V, you turn to the 20V setting. This will allow you to read from 2.00 to 19.99. Selection Knob Refer Figure 6. The first digit on many multimeters is only able to display a ‘1’ so the ranges are limited to 19.99 instead of 99.99. Hence the 20V max range instead of 99V max range. Figure 6: Selection knob For Training Purposes Only Issue: August 2014 Page 143 of 926 Modul 7 Avionic General Test Equipment PART 66 – Basic Training Cat B1 – Module 7 Measuring Resistance Refer Figure 7. Remember: In general, turn OFF the system before measuring Resistance. Hold the probes against the resistor legs with the same amount of pressure you when pressing a key on a keyboard. The meter will read one of three things, 0.00, OL, or the actual resistor value. If the meter reads .329, well then you’ve got a 329 Ohm (Ω) resistor (remember you are in the 2kΩ or 2,000 Ohm mode so you need to move the decimal three places to the right). If the multimeter reads 1 or displays OL, it’s overloaded. You will need to try a higher mode. There is no harm if this happen, it simply means the range knob needs to be adjusted. If the multimeter reads 0.00 or nearly zero, then you need to lower the mode. Remember that measuring resistance is not perfect. Temperature can affect the reading a lot. Also, measuring resistance of a device while it is physically installed in a circuit can be very tricky. The surrounding components on a circuit board can greatly affect the reading. Figure 7: measuring resistance If you want to measure a resistor in a circuit, open the circuit! For Training Purposes Only Issue: August 2014 Page 144 of 926 Modul 7 Avionic General Test Equipment PART 66 – Basic Training Cat B1 – Module 7 Measuring Current Refer Figure 8 and 9. Reading current is one of the trickiest and most insightful readings in our world of embedded electronics. It’s tricky because you have to measure current in series. Where voltage is measure by poking at VCC and GND (in parallel), to measure current you have to physically interrupt the flow of current and put the meter in line. Figure 9: DMM connected in series Measuring current works the same as voltage and resistance - you have to get the correct range. We then insert the multimeter inline so that it can measure the current as it “flows” through to the multimeter into the circuit. Figure 8: interupt the circuit Similarly, when measuring current the color of the probes does not matter. What happens if we switch probes? Nothing bad happens! It simply causes the current reading to become negative: Now you can connect the multimeter in series to the circuit. Current is still flowing through the system, you’ve just changed your per spective and now the meter reads negative. For Training Purposes Only Issue: August 2014 Page 145 of 926 Modul 7 Avionic General Test Equipment PART 66 – Basic Training Cat B1 – Module 7 Remember: When you’re done using the meter, always return the meter to read voltage (return the probes to the voltage port, set the meter to read the DC voltage range if necessary). So before you put the meter down for the night, remember to leave your meter in a friendly state (highest DC-Voltage range!!!). Continuity Refer Figure 10. Continuity testing is the act of testing the resistance between two points. If there is very low resistance (less than a few ohms), the two points are connected electrically and a tone is emitted. If there is more than a few ohms of resistance, than the circuit is open and no tone is emitted. This test helps insure that connections are made correctly between two points. This test also helps us detect if two points are connected that should not be. This feature allows us to test for conductivity of materials and to trace where electrical connections have been made. Set the multimeter to ‘Continuity’ mode. It may vary among DMMs, but look for a diode symbol with propagation waves around it (like sound coming from a speaker). Figure 10: Multimeter is set to continuity mode Now touch the probes together. The multimeter should emit a tone. This shows that a very small amount of current is allowed to flow without resistance (or at least a very very small resistance) between probes. Remember: In general, turn OFF the system before checking for continuity. For Training Purposes Only Issue: August 2014 Page 146 of 926 Modul 7 Avionic General Test Equipment PART 66 – Basic Training Cat B1 – Module 7 The function of an oscilloscope is extremely simple: it draws a V/t graph, a graph of voltage against time, voltage on the vertical or Yaxis, and time on the horizontal or X-axis. As you can see, the screen of this oscilloscope has 8 squares or divisions on the vertical axis, and 10 squares or divsions on the horizontal axis. Usually, these squares are 1cm in each direction: 7.4.2 Oscilloscop What does an oscilloscope do? Refer Figure 11 and 12 An oscilloscope is easily the most useful instrument available for testing circuits because it allows you to see the signals at different points in the circuit. The best way of investigating an electronic system is to monitor signals at the input and output of each system block, checking that each block is operating as expected and is correctly linked to the next. With a little practice, you will be able to find and correct faults quickly and accurately. An oscilloscope is an impressive piece of kit: Figure 12: Screen of an oscilloscope Many of the controls of the oscilloscope allow you to change the vertical or horizontal scales of the V/t graph, so that you can display a clear picture of the signal you want to investigate. 'Dual trace' oscilloscopes display two V/t graphs at the same time, so that simultaneous signals from different parts of an electronic system can be compared. Figure 11: Oscilloscope For Training Purposes Only Issue: August 2014 Page 147 of 926 Modul 7 Avionic General Test Equipment PART 66 – Basic Training Cat B1 – Module 7 DC voltage measurement The voltage at the input directs the beam upwards and downwards. An oscilloscope can therefore be used as a voltmeter Figure 14: Volt/Div Now you can connect the test leads to the test object. Over the RFprobe must be a ground connection to the tested circuit established. Figure 13: Null-Linie The VOLT/DIV selector knob is used to set the desired measuring range. The setting shown is 1 volt per division, so the measurement range is up to 8 V. The input selector switch must be in position DC. AC stands for alternating current and feeds the signal through a capacitor. In position GD (ground) the inputsignal is connectet to a internally ground to adjust the zero point For Training Purposes Only Issue: August 2014 Figure 15: DC-Voltage The voltage in the figure is 5 volts Page 148 of 926 Modul 7 Avionic General Test Equipment PART 66 – Basic Training Cat B1 – Module 7 AC voltage measurement If you want to measure an AC signal, the time base is important. The time base is changed at the TIME/DIV knob. Figure 16: Time/Div Figure 17: AC-Voltage In the example, a time base of 0.1 ms per division was chosen. In the X direction, the screen has 10 divisions, so now shows an area of exactly one millisecond. For Training Purposes Only Issue: August 2014 Page 149 of 926 Modul 7 Avionic General Test Equipment 7.4.3 Pitot Static Test Equipment 7.4.3.1 Accuracy of Instruments PART 66 – Basic Training Cat B1 – Module 7 Type of Error Modern aircraft instruments are the means of providing required information to the pilot at any given moment, whether in flight, before take-off or after landing, accurately and with a minimum of delay. Accuracy in an instrument implies truth and an instrument is said to be accurate if it agrees with a true measure. All aircraft instruments are subject to errors and therefore are only accurate to within a defined limit or tolerance. Error Instrument error can be defined as the difference between the observed reading and the true reading when comparing an instrument with a known standard. Capsule operated instruments used for measuring pressures are designed to operate within a permissible percentage error depending upon the application of the instrument. This total error is known as the instrument error, or lag, and is the sum of other errors, these being hysteresis friction error creep error Parallaxis error. Hysteresis Hysteresis is caused by the elastic properties of the capsule material. This causes a material deformed by a stress (pressure) to not immediately return to its former shape or position when the stress is removed. With a hysteresis error there will be a lag in instrument readings at increasing and decreasing pressure input. Tolerance The tolerance of an instrument is the amount by which it is permitted to depart from the true reading and still perform its function. Tolerance is permissible or allowable error. It is usually quoted in one of three ways: as a percentage of scale range as a percentage of observed reading as a given amount on either side of a scale reading which may vary as the scale progresses. Friction Error Friction error is caused by the lever and gear mechanism which converts the linear capsule movement to rotary pointer movement. There will be ’lost motion’ in the mechanism, which will cause the pointer to move erratically. Many instruments use built –in vibrator units to prevent the stiction (or friction) taking place. Creep Error Creep error is caused by the nature of the material used in the capsule manufacture. The stressing of the capsule when pressure is applied will cause the material to undergo ’shear stress’ and when the pressure is reduced the capsule will continue to move until it has readjusted itself. For Training Purposes Only Issue: August 2014 Page 150 of 926 Modul 7 Avionic General Test Equipment Parallaxis Error When observing an instrument at an angle errors due to parallax are probable, the magnitude of the error being governed by the angle at which the relevant part of the scale is observed and also by the clearance distance between the pointer and dial plate. One method used to reduce this type of error on circular display instruments is to raise the scale marks on a circular platform which is secured to the main dial plate, so that it is raised to the same level as the tip of the pointer. PART 66 – Basic Training Cat B1 – Module 7 Attention! Pull the CB's of the Pitot tube heaters that the heating system can not be switched on during the test! Pitot Static Test: When a pitot or static connection in a pitot static system is damaged or broken, or when the pitot or static connection to an instrument is disturbed, all the instruments connected to the system must be checked. This is to ensure that all instruments still read correctly. After replacement of the damaged part of the pipeline the system must also be checked to ensure that it is leak-proof. The method applied to carry out the above checks must be in accordance with the relevant deriving schedules. A functional test of the Pitot-Static system with a Pitot-Static tester (Flight Line Level) should l be performed according the AMM. Particularly in the case of such a function check the safety conditions are considered, which relate to both the aircraft and on the test set (Safety Precautions). In addition to the leak test (primarily), it is possible with the Pitot-Static tester to check the built-in devices such as aircraft altimeter, airspeed indicator, and vertical speed. It should be noted that the barometric altimeter is adjusted to a value of 1013.25 mbar or 29.92 "Mercury, since the test equipment is calibrated to this value and all measurements are based on this value. Figure 18: Pitiot Static Test For Training Purposes Only Issue: August 2014 Page 151 of 926 Modul 7 Avionic General Test Equipment Pitot-Static-Testequipment The pitot-static test equipment consists of the Pitot-Static-static tester, hose assamblies and the Adaption for the relevant aircraft type Pitot Static Testsets PART 66 – Basic Training Cat B1 – Module 7 In the shown tester, the corresponding value for an Airspeed (Ptot) or for an Altitude (Pstatic) is generated with a hand pump. Tester which are able to performe a total test, have a built-in pump system in which the different pressures are generated by 2 pumps. There are Pitot-static tester only for leak testing (leak test) of the system, which are called Flightline Tester Figure 20: System Testset Figure 19: Flightline Testset For Training Purposes Only Issue: August 2014 Page 152 of 926 Modul 7 Avionic General Test Equipment PART 66 – Basic Training Cat B1 – Module 7 The tester shown in the next picture is able to perform an automatic test by using a computer with the appropriate software. So different airspeed and altitude values can be programmed and also an automatic leaktest is possible. Also can be stored a profile therefore total flight can be simulated. This tester is used not only for a Pitot Static Test, it is also possible to test other avionic-systems like TCAS etc. Figure 21: Testset conected to a Laptop For Training Purposes Only Figure 22: Startpage of testset Issue: August 2014 Page 153 of 926 Modul 7 Avionic General Test Equipment PART 66 – Basic Training Cat B1 – Module 7 Hose assamblies Figure 23: Controlpage The data can be entered and saved here and stored in a test protocol. Figure 24: Hose assamblies The hose line system is to be avoided confusion, made in two different colores to mark the Ptotal and the Pstatic connection. For Training Purposes Only Issue: August 2014 Page 154 of 926 Modul 7 Avionic General Test Equipment PART 66 – Basic Training Cat B1 – Module 7 Adaption The adaptation consists of an adapter for the pitot tube and an adapter for the Static connection Figure 25: Pitot Adapter Figure 26: Static Adapter This adapter is slid over the pitot tube and screwed down. Is used to connect the aircraft system to the testset. This adapter is placed over the static ports of the aircraft and then connected to the testset to simulate the aircraft height in relationship to the static pressure For Training Purposes Only Issue: August 2014 Page 155 of 926 Modul 7 Avionic General Test Equipment PART 66 – Basic Training Cat B1 – Module 7 Figure 27: Adapter for Ptot and Static In some aircraft / helicopters only a Pitot tube with holes for static pressure exists, this pitot tube is then known as Pitot / Static Tube. To test aircrafts with such a system, the adapter, shown in the picture, is used. The adapter has both a port, for the ambient pressure (Pstatic) as well as a port for the total pressure (P tot). Figure 28: Complet Adapterset For Training Purposes Only Issue: August 2014 Page 156 of 926 Modul 7 Avionic General Test Equipment PART 66 – Basic Training Cat B1 – Module 7 Example to perform a Pitot-Static-Test Make a visual inspection of the Pitot probes and Static ports Make sure thet the Pitot Heat System is switched off Best Way: Pull the circuit breakers out Set the Baro Selection to 1013.25 mbar or 29,92 "Mercury Connect the Pitot and Static adapters to the Pitot Static System Perform a Selftest of your Pitot Static Test Set Connect the Pitot Static Test Set to the adapters Route the hoses in this way, that nobody can step on or trip over the hoses Set the limits on the Testset (according the AMM) Ventilate the System Make sure that all valves on the testequipment are closed Perform a leak test according the AMM Perform the Pitot Static Test according the AMM After the test, reach ambient preasure in the pitot- and the static system Fill out the testrecord during the test Remove the testset and the adapters from the probes Make oncemore a visual inspection Put the plugs on the probes For Training Purposes Only Issue: August 2014 Page 157 of 926 Modul 7 Avionic General Test Equipment IFR NAV 402 AP: 7.4.4 Electronic Avionic Test Equipment 7.4.4.1 PART 66 – Basic Training Cat B1 – Module 7 Flight Line Test Sets In order to test and maintain electronic avionic systems, simulated ground based stations’ signals are generated in flight line test equipment. Additionally to this function the flight line test equipment provides measuring facilities especially suited for the avionics equipment. The flight line test equipment described in this Lesson are: radio navigation test set – IFR NAV 402AP New radio navigation and communication test set – IFR NAV/COM 4000 transponder and DME test set – IFR ATC 600/A New transponder, DME and TCAS test set – IFR ATC 6000 Figure 29: Radio Navigation Test Set IFR NAV 402AP The radio navigation test set IFR NAV 402AP is used for the generation of simulation signals and parameter measurements of glide slope operation (GS) localiser operation (LOC) VHF communications (VHF COMM) marker beacon operation (MKR) VHF omnidirectional range sets (VOR). General Description The IFR NAV 402AP is an FCC type accepted bench and ramp test set designed to meet the electronic functional test requirements of the systems listed above. For Training Purposes Only Issue: August 2014 Page 158 of 926 Modul 7 Avionic General Test Equipment The IFR NAV 402AP includes a signal generator with a variable attenuator which can be connected to the ’equipment under test’ by a coaxial line or Testantenna. It can be operated under either crystal frequency control or in variable frequency mode of each band. The generator can be modulated internally by a 1020 Hz ident. tone, marker, VOR, LOC or G/S signals, or by an external signal. The IFR NAV 402AP includes a six-digit counter which indicates the RF frequency of the signal generator on any band, the frequency of a COMM transmitter under test, any external signal input from 1 MHz to at least 300 MHz, or the VOR bearing selected by bearing select switches. An RF power meter is built in for measuring COMM transmitter power from 0 -10 W or 0 -100 W either peak or average power by selecting a switch position located on the front panel. A COMM transmitter demodulation output permits viewing or listening to COMM modulation. A built-in modulation meter measures signal generator percent of modulation on any frequency band from 0 -30 % or 0 -100 %. Front panel controls permit quick setting of modulation percentages. A 90° bearing check monitor allows quick verification of basic VOR bearing from the VOR demodulation signal. PART 66 – Basic Training Cat B1 – Module 7 IFR 4000 Test Set: The IFR 4000 tested set is used to test the following aircraft communication and navigation systems: AM-modulated VHF-Com and UHF-Com FM-modulated VHF-Com and UHF-Com VOR Localizer Glideslope Marker Beacon ELT 121,5 MHz; 406MHz Selcall SWR-Measurement The IFR 4000 Testset replace the IFR 402AP Testset and has additional functions to test ELT Transmitters, Selcall and it is able to measure the SWR values. A nickel-cadmium battery and built-in charging system permits completely portable operation for up to 2 hours continuous duty with the counter off, one hour continuous duty with the counter on time. Figure 30: IFR 4000 Test-set For Training Purposes Only Issue: August 2014 Page 159 of 926 Modul 7 Avionic General Test Equipment PART 66 – Basic Training Cat B1 – Module 7 IFR 4000 Control Panel Figure 31: IFR 4000 Control Panel For Training Purposes Only Issue: August 2014 Page 160 of 926 Modul 7 Avionic General Test Equipment Tested Parameters: VHF- Com o Receive Sensitivity o Squelch function threshold o Transmit power o Transmit frequency accuracy o Modulation depth VHF - NAV o VOR sensitivity o VOR bearing accuracy o TO/FROM accuracy o Flag control o VOR – Audio PART 66 – Basic Training Cat B1 – Module 7 IFR ATC 600/A: Figure 32: Transponder and DME Test Set IFR ATC 600/A ILS (Glideslope/Localizer) o ILS bearing accuracy o Backcourse indication o Flag control o Localizer – Audio The transponder and DME test set IFR ATC 600/A is to carry out flight line tests and is used to perform functional tests of Marker Beacon o Ilumination (“O”;”M”;”A”) o Audiofrequencies (“O”;”M”;”A General Description For Training Purposes Only aircraft transponder (XPDR) operation distance measuring equipment (DME) systems. The IFR ATC 600/A is a test set designed to carry out flight line tests and workshop maintenance. It is used to perform functional tests of aircraft transponder and distance measuring equipment systems. It contains built –in signal generators for XPDR and selected DME channels. The RF output of the IFR ATC 600/A is connected to a transponder or DME system via the antenna sockets using a coaxial cable and a 34dB pad. If the testset antenna is used, the 34-dB pad is not necessary. Issue: August 2014 Page 161 of 926 Modul 7 Avionic General Test Equipment PART 66 – Basic Training Cat B1 – Module 7 IFR 6000 Test Set: The IFR 6000 tested set is used to test the following aircraft puls systems: TCAS ATC Transponder DME The IFR 6000 Testset replace the IFR 600A Testset and has additional functions to test Mode S Transponders and the TCAS/ACAS equipment of the aircraft aivionic. Figur 32: IFR 6000 Test Set For Training Purposes Only Issue: August 2014 Page 162 of 926 Modul 7 Avionic General Test Equipment PART 66 – Basic Training Cat B1 – Module 7 Figur 33: IFR 6000 Control Panel For Training Purposes Only Issue: August 2014 Page 163 of 926 Modul 7 Avionic General Test Equipment PART 66 – Basic Training Cat B1 – Module 7 Tested Parameters: ATC Transponter tested parameters o MTL – Sensivitiy o Decoding Tolerances o SLS o Mode “S” – Decoding Tolerances o Mode “S” – SLS o Transmit power o Transmit frequency o Transmit pulswidth and shape o Coding Mode ”A”, Mode “C” and Mode “S” DME o o o o o Receive Sensivity Transmit power Pulswidth and shape Distance accurancy PRF search and track TCAS/ACAS o Simulation of an intruder scenario For Training Purposes Only Issue: August 2014 Page 164 of 926 Modul 7 Engineering Drawings, Diagrams and Standards 7.5 Engineering Drawings, Diagrams and Standards 7.5.1 Technical Drawing 7.5.1.1 Fundamentals The drawing is the most important means of information and communication used in engineering. Every technician concerned with the engineering matters of design, construction, manufacture and processing must be able to fully understand and properly produce technical drawings. Considering that a well made drawing is to reveal every detail of the engineer’s ideas and concepts in a clear and unequivocal way mainly to those, who are charged with the manufacture, the informative function of a technical drawing can be regarded as the language of engineering. In fact, a drawing is a means of communication even more objective than a language, as it leaves no room for misunderstandings and is understood all over the world. A technical drawing must contain everything that is required to understand the workpiece with all the associated data and details of what it looks like and how it is made, processed and finished. The basic requirements for a technical drawing can be summarised in three statements as follows: The drawing must reveal the ideas, concepts and intentions of the design engineer to the detail without leaving any doubt. For Training Purposes Only PART 66 – Basic Training Cat B1 – Module 7 All representations must be well arranged and the form of the workpiece be easily recognised from the chosen views and sections. The drawing must contain all data, instructions, marks, symbols and notes regarding dimensions, geometry and surface texture that are relevant in the workshop. 7.5.1.2 Standards In order to ensure a clear and unequivocal representation of a workpiece in a technical drawing, a set of rules and regulations must be respected. The basic requirements are specified in drawing standards. The competent and responsible authority for drawing standards is the Drawing Standards Committee publishing the applicable standards in Standard Sheets. The standard sheets are identified by the inscription DIN and an indenture number. Rules and regulations in German standards taken over from international standards are marked DIN ISO. Note: ISO stands for International Organization for Standardization and DIN (Deutsche Industrienormen) stands for German Engineering Standards, issued by the German Institute for Standardization (Deutsches Institut für Normung). 7.5.1.3 Drawing Instruments Beside the necessary knowledge of the fundamentals of geometry, good drawing practice requires high accuracy and care. A prerequisite for proper work are appropriate drawing instruments and materials. Refer to Figures 1 to 3. Issue: August 2014 Page 165 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 Figure 1: Drawing Instruments (I) Figure 2: Drawing Instruments (II) For Training Purposes Only Issue: August 2014 Page 166 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 The necessary equipment for engineering drawing comprises the following: a) Drawing board for size A4 or A3 (detail a)) b) Two set squares for triangles 45o – 90o – 45o and 30o – 60o – 90o respectively, with edges for ink drawing 150 mm to 250 mm (detail b)) c) Pencils, preferably clamp or clutch designs with leads of various hardnesses. As a rule, – a soft lead (3B) is used for sketches, – a medium type (2B, B, HB) is used for lettering and drawing, and – a hard type (H, 2H, 3H, 4H) for drawing on transparent paper (detail c)). Drawing on transparent (natural tracing) paper requires harder pencils than drawing on normal drawing paper d) Encased (box –type) or open sharpeners (detail d)) e) Compasses (dividers, (detail e)) f) Erasers and erase paper for compass points (detail f)) g) 300 –mm ruler (detail g)) h) Soft brush for the removal of erase waste (detail h)) i) Drawing templates for round and curved shapes and symbols (detail i)) j) A set of ink pen instruments with setting bow combination for line groups 0.5 mm, 0.35 mm and 0.25 mm (detail j)). In modern drafting offices, various designs of drawing machines and plotters are used instead of drawing boards. Refer to Figure 4. Figure 3: Drawing Instruments (III) For Training Purposes Only Issue: August 2014 Page 167 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 The drawing machine shown in detail a) is an older model still found in many offices, while detail b) shows a more recent design. Essential on both models is the perfect orientation of the two rules at 90° between them such, that true angularity in drawing is ensured. The rectangularity of the two rules should be verified from time to time and, in case, be restored by corrective action. Refer to Figure 5. Figure 5: Adjustment of Measuring Rules The adjustment procedure is as follows: 1. Place the rules in the fixing points of the drawing head, with the long scale mounted in the horizontal fixing device and the short rule in the upward (vertical) device, and unscrew the arresting screws! Figure 4: Drawing Machines For Training Purposes Only Issue: August 2014 Page 168 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 2. Align the long rule parallel with the bottom edge of the drawing board and screw the locking screws of that rule home tight. 3. Draw a thin line approximately in the middle of the board along the aligned rule. 4. Turn the drawing head in clockwise direction, until it snaps on the 90° mark latch. 5. Align the short rule, which now lies horizontal, with the thin line and drive the locking screws of that rule home. 7.5.1.4 Scales Refer to Figure 6. Figure 6: Scales For Training Purposes Only Issue: August 2014 Page 169 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Engineering Drawings, Diagrams and Standards The scale is the ratio between the size drawn and the size of the workpiece. The scale must be chosen such, that the depiction of the workpiece is neither too large nor too small. The scale has to be indicated on the drawing. For enlargements (magnifications) and reductions the scales should be applied as laid down in DIN ISO 5455 (detail a)). The scale used for the drawing must be entered in the title block. Where more than one scale is required for a drawing, the main scale is entered in the title block, while the others are indicated near the respective figures. The drawing scale is a linear measurement only referring to the workpiece edges. This means that angles are not influenced by the respective chosen scale. The size of surfaces is a function of the square of the chosen scale. So, a component scaled up to 2 : 1 is drawn four times larger than the 1 : 1 representation. 7.5.1.5 Sheet Sizes Refer to Figures 7 and 8. According to DIN the basic size of drawing sheets is a rectangle with a surface area of 1 m2. Full –Scale In a 1 : 1 full –scale representation the dimensions of the drawing and the workpiece are the same: 1 mm on the drawing corresponds to 1 mm of the workpiece (detail b)). The component is drawn to scale. Reduction Scale In a reduction –scale representation the workpiece is depicted scaled down. A reduced scale of 1 : 5, for example, means that 1 mm on the drawing corresponds to 5 mm on the real component (detail c)). The side ratio of this rectangle is 1 : √2= 1 : 1.414. A drawing sheet with the side lengths of 841 mm ¡ 1,189 mm has a surface area of 1 m2 and constitutes the standard sheet size A0. When this basic size is consecutively halved down, a number of further reduced sizes are derived (detail a)). Enlargement Scale The common standards A0 . . . A6 can be sized up to 2A0 (1,189 mm x 1,682 mm) and 4A0 (1,682 mm x 2,378 mm) and sized down to A10 (26 mm x 37 mm) (detail b)). The workpiece is represented enlarged (scaled up). A scale of 2 : 1, for example, means that 2 mm on the drawing correspond to 1 mm on the component (detail d)). For subordinate (dependent) sizes such as file covers or envelopes as complementary derived series there are B, C and E. Regardless of the chosen scale, in dimensioning always the real sizes of the finished product must be entered. For Training Purposes Only Issue: August 2014 Series B Series C Series E ≜ ≜ ≜ 1.19 1.09 1.33 ∙ ∙ ∙ series A series A series A Page 170 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 The drawing area is smaller than the finished size of the drawing; the untrimmed size is larger (details b) and c)). On an A3 size, an additional 20 mm wide filing edge is considered, while for a DIN A4 sheet only 15 mm are deducted as filing edge. Figure 7: Sheet Sizes (I) For Training Purposes Only Figure 8: Sheet Sizes (II) Issue: August 2014 Page 171 of 926 Modul 7 Engineering Drawings, Diagrams and Standards 7.5.1.6 PART 66 – Basic Training Cat B1 – Module 7 The title block on Boeing production drawings contains the following information: Title Block and Parts List Written information is entered in the title block and the parts list (detail d)). DRAWING NUMBER: The 1/2−inch−high characters. TITLE: The title of a drawing is in 1/4−inch−high characters. SCALE: The scale of which the majority of views and sections are drawn is entered as a ratio. When various parts are drawn to different scales, or if there is no picture on Sheet One, the word”NOTED” is entered. DIMENSIONAL TOLERANCE NOTES: Preprinted here are the general tolerances to be used with the various drawing dimensions if a tolerance is not otherwise shown on the drawing. SH of: The total number of sheets is shown with the consecutive sheet number such as SH 1 of 1, SH 1 of 4. On drawings with an automated parts list (APL), this entry does not include the total number of picture sheets. The application block of the separate parts list lists all applicable sheets for each item. The title block is always arranged at the right bottom of the respective broadside. SIGNATURES: The”signature” block is a list of approval signatures for the drawing. The title block consists of a drawing number and certain other data conceming the drawing and the object it represents. When a print is correctly folded, the title block is on the outside for easy reference. SECT NO: The section number of the aircraft in which the item is installed. when an installation extends through several sections”MS” Is used for multisections. USED ON: The basic model number. The standard title block and its division are laid down in DIN 6771. It contains written information regarding the drawing and serves the purpose of communication between the supplier and the customer. Where necessary, the standard title block may be completed by supplementary blocks and fields. For drawing sizes larger than DIN A1 the choice of larger blocks is optional. The division of the block is proportioned by a grid that is based on the distances between characters and the line spacing of high –speed printer and typewriters. Apart from the standardised field divisions and assignments, a number of various printed forms has been developed, which are adapted to the specific requirements of a particular application of service. All DIN sizes can be used upright or broadside. A4 is prevailingly used upright, as this facilitates the reading of drawings as they are filed. For Training Purposes Only Issue: August 2014 drawing number Page 172 of 926 is in Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 In the parts list all individual parts of an assembly drawing are listed. Where the parts list information is entered in the fields of a printed – form type drawing, the individual columns are designated at the lower end of the list. The parts are entered consecutively from bottom to top by the order of the assigned item numbers. Regardless of the quantity of parts required, the part designation is always a singular. Where the parts list is written by a machine, the list must be executed on a sheet separate from the drawing and be arranged in a top - to bottom order. The columns of the parts list are filled with the following data: item number (same as on drawing) description (for standard parts: designation and DIN No.) material; identification (drawing no.) no. of ....; in – house information and internal check notes. For Training Purposes Only Issue: August 2014 Page 173 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 Figure 1: Sloping Style Standard Lettering 7.5.2 Lettering Proper lettering is a prerequisite for clear representation and good readability of a drawing giving complete and correct technical information and instructions. The lettering of a drawing must meet the requirements of readability conformity. In engineering drawing practice lettering to ISO Standards is applied worldwide. 7.5.2.1 Style and Type of Lettering Refer to Figures 1 and 2. Figure 2: Vertical Standard Style Lettering The standard lettering according to ISO Standards can be executed in characters and figures either sloping to the right at 15° from the vertical or be arranged vertical to the line. While the vertical style is mainly used for lettering with templates, sloping characters are preferred for lettering without guides. The types used are lettering ’A’ (line thickness 1/4 ¡ nominal size h, which denotes the minimum height of the letters) and lettering ’B’ (line thickness 1/10 ¡ nominal size h). The standard lettering ’A’ according to ISO Standards is also called close - spaced lettering. For Training Purposes Only Issue: August 2014 Page 174 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 Lettering ’A’ should be applied only if required by restricted availability of space. Where capital and small letters are used at the same time, the height of the capital letters must at least be 3.5 mm. Lettering ’B’ is preferred on drawings, as it is more distinct and easier to survey. Indices, exponents, deviations etc. are written one size smaller than the chosen lettering, but must not be smaller than 2.5 mm. The following description exclusively refers to the more common ’B’ characters. Sloping Standard Style on Drafting Grid Refer to Figure 1 again. The lattice size of the drafting grid corresponds to the line thickness of the letters and figures. The form and size of letters and figures as well as the distances between the individual characters can so be checked up easily. Vertical Standard Style on Drafting Grid Refer to Figure 2 again. The statements made for the sloping style apply to the vertical style accordingly. 7.5.2.2 Dimensions for Lettering According Refer to Figure 3. Lettering on a drawing according to ISO Standards requires a minimum type height of capital letters of 2.5 mm or small letters of 1.8 mm, respectively. For Training Purposes Only Issue: August 2014 Page 175 of 926 Modul 7 Engineering Drawings, Diagrams and Standards 7.5.2.3 PART 66 – Basic Training Cat B1 – Module 7 Execution of Handwritten Lettering Refer to Figure 4. Figure 4: Execution of Handwritten Lettering In order to ensure adherence to the standardised sequence of letters and figures, the characters are recommended to be composed of individual parts. Clues on how to perform are given by the arrows beside the characters. The numbers indicate the sequence of execution. Figure 3: Dimensions for Standard Lettering For Training Purposes Only Issue: August 2014 Page 176 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Engineering Drawings, Diagrams and Standards 7.5.3 Lines in Technical Drawings 7.5.3.1 Line Types, Applications Thicknesses, Groups and For a well prepared, tidy and clear drawing it is necessary that the thickness of the lines fit in well with the size of the drawing and that the thicknesses of the various line types have a determined proportion with respect to one another. line type J line type K – – thick chain line thin double dashed chain line. Note: Contrary to ISO, according to DIN standards the line type J is preferred to H, and F is preferred to type E. In drawing practice, the most commonly used line types are A, B, F and G. They can be found in nearly every drawing. The various line thicknesses and types of continuous and discontinuous lines are informative features of the drawing. In order to specify such information, a number of line types and thicknesses have been laid down in DIN 15. Harmonisation of DIN 15 with ISO ensures that drawings prepared with such standardised lines are understood and interpreted in the same way all over the world. Line Types Refer to Figure 1. The following line types are specified in DIN 15: line type A – line type B – line type C – line type D – line type E – line type F – line type G – line type H – changes of direction thick continuous line thin continuous line thin freehand continuous line thin straight continuous line with zigzags thick dashed line thin dashed line thin chain line chain line, thin; thick at ends and For Training Purposes Only Issue: August 2014 Page 177 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 Figure 1: Line Types For Training Purposes Only Issue: August 2014 Page 178 of 926 Modul 7 Engineering Drawings, Diagrams and Standards Line Thicknesses and Line Groups PART 66 – Basic Training Cat B1 – Module 7 The grading of the three thicknesses of lines is by 2 increments (1 : 1.414). Refer to Figure 2. The thicknesses of line occurring in one drawing form a line group. Every group comprises three thicknesses. The individual groups are designated and defined by the thickest line of the group. Refer to Figure 3. In drawing practice, the preferred groups are 0.5 (detail a)) and 0.7 (detail b)). For all views of a workpiece the same line group must be applied. Figure 2: Line Thicknesses The applicable line thickness is ruled by the type and size of the drawing. For the purpose of a clearer layout, a life - sized workpiece will have to be drawn with thicker lines than if scaled 1 : 10. As a rule, two line thicknesses are used for drawings which have a ratio of 2 : 1. When lettering according to ISO (DIN 6776) with ’B’ characters, a third line thickness ranging between the main line widths is required for dimensioning, wording and symbolising. For Training Purposes Only Issue: August 2014 Page 179 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 Applications of Line Types Refer to Figures 4 and 5. Details a) to e) show a number of practical examples of how the line types according to ISO (DIN 15) are applied. The letter given in brackets behind the designation indicates the line type. Figure 3: Line Groups For Training Purposes Only Issue: August 2014 Page 180 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 Figure 4: Applications of Line Types (I) For Training Purposes Only Issue: August 2014 Page 181 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 7.5.4 Dimensioning in Drawings 7.5.4.1 Dimensioning Concepts Refer to Figure 1. Figure 1: Dimensions of a Workpiece Figure 5 Applications of Line Types (II) For Training Purposes Only Issue: August 2014 Page 182 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 The dimensions of a workpiece are inscribed in the drawing. A non – dimensioned drawing would show only the shape of a workpiece without indicating its size. When a drawing is the basis to produce a workpiece, the drawing must contain the shape of the workpiece and all dimensional details. Figure 1 shows an example each of a non – dimensioned (detail a)) and a dimensioned (detail b)) drawing. Dimension Lines and Auxiliary Extension Lines Refer to Figure 2. Figure 2: Dimension Lines and Auxiliary Extension Lines For Training Purposes Only Issue: August 2014 Page 183 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 Dimension lines are executed as thin solid lines. They may be continuous or broken. Where the dimension line is drawn through, the dimension figure is inscribed above the line, while in case of a broken line the dimension figure is entered in the gap between the solid line parts. Auxiliary extension lines are used to draw out the dimension figure. They protrude from the dimension line by 1 mm to 2 mm. Dimension Line Limitations Refer to Figure 3. Figure 3: Dimension Line Limitations For Training Purposes Only Issue: August 2014 Page 184 of 926 Modul 7 Engineering Drawings, Diagrams and Standards Dimension lines are delimited by arrow heads, strokes (oblique, slant or slash) or by dots. The arrow head may be solid, void or open. Note: ’d’ is the line width of the thick solid line (line type A). The stroke is always drawn from the left bottom to the right top, relative to the respective dimension line. The dot may be executed solid or hollow. It is often applied, where the space available is not sufficient for an arrow head. PART 66 – Basic Training Cat B1 – Module 7 The dimensions must be entered in standard lettering according to DIN 6776. The type height approximates five times the width of a solid line marking workpiece edges. In production drawings the height should not be less than 3.5 mm. Within one drawing, the sizes should possibly be uniform. The unit (mm) is omitted; deviating units must be entered. 7.5.4.2 Basic Dimensioning Rules Strokes and dots are predominantly used by architects and engineers in position plans and construction drawings. As a rule, arrow heads for the dimensioning of engineering drawings are executed solid. Dimension Figures Refer to Figure 4. Figure 5: Basic Rules for Dimensioning (I) Figure 4: Dimensioning Figures For Training Purposes Only Issue: August 2014 Page 185 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 Refer to Figures 5 and 6. Dimension lines are arranged parallel to the indicated dimensions (detail a)). The dimension figures are inscribed longitudinally with the dimension lines. The figures must be readable from the bottom or the right with the drawing held in the reading direction. Extension lines are arranged parallel to each other and at an angle of 90! to the dimension lines (detail a), dimension 25). Dimension lines should have a uniform distance of at least 10 mm from the workpiece edges and at least 7 mm from each other (detail b)). Dimension lines with arrow heads may also be arranged between the solid edges or the auxiliary lines (detail c)). Where there is too little space available for arrow heads and dimension figures, the dimension lines may be drawn from the outside to the workpiece edges (details d) and e)) or to the extension lines (details f) and g)). Center lines and solid edges must not be used as dimension lines. Center lines may, however, be used as auxiliary lines. Outside the contours of the symmetrical part they are drawn out as thin continuous lines (detail h)). Center lines and auxiliary lines must not be drawn through between two views. Where the circle of bore holes is visible, dimensioning is carried out according to detail h). Figure 6: Basic Rules for Dimensioning (II) For Training Purposes Only If there is only one view, the thickness of flat workpieces is designated by a ’t’ (details h) to j)). The dimensions entered on the drawing are the dimensions of the finished component (detail i)). This Issue: August 2014 Page 186 of 926 Modul 7 Engineering Drawings, Diagrams and Standards rule also applies to drawings scaled up or down (detail j)). All dimensions necessary for manufacture, application and testing of a component must be read from the drawing without any need for conversion. 7.5.4.3 Arrangement of Dimensions Refer to Figure 7. PART 66 – Basic Training Cat B1 – Module 7 The dimensions are divided into dimensions of size, form and location. Dimensions of size are the basic dimensions defining the length, width and height of a given geometrical body (detail a), dimensions 63, 45 and 18). Dimensions of form indicate the form of shoulders, grooves, breakthroughs, openings and the like (detail a), dimensions 20, 6 and 10). Location dimensions define the position of bore holes, grooves and the like (detail a), dimensions 14, 16 and 48). Each dimension is entered only once. Double indication of a dimension should be avoided. Symmetrical parts with identical finish on either side are drawn with a center line. A dimension identifying the location of the center line is not indicated. Dimensions which result in the production process automatically, are not entered (detail a), length of the slant). In the case of several views the dimensions are entered, where the form of the part is best recognised (detail a)). Dimension lines and extension lines should not be drawn from hidden edges. Solid edges must not be used as dimension lines. Dimension line limitations must not be drawn on workpiece corners. Dimension lines may, however, be executed starting from workpiece edges (detail a), dimension 36). Figure 7: Arrangement of Dimensions (I) For Training Purposes Only Issue: August 2014 Page 187 of 926 Modul 7 Engineering Drawings, Diagrams and Standards Dimension lines and extension lines should possibly not intersect each other or cut other lines (detail a)). Not in any case, however, can such intersections be avoided (detail a), dimensions 13 and 7.5). In the case of dimension lines lying closely above one another the dimension figures should be inscribed in a staggered arrangement (detail a), dimensions 16 to 63). Where oversize of the dimension is inevitable for reasons of manufacture, the auxiliary dimensions are put in brackets (detail a), dimension 30°). The auxiliary dimension needs no check in testing. PART 66 – Basic Training Cat B1 – Module 7 Closed dimension chains must be avoided. Where this is not possible, the auxiliary dimensions must be bracketed (detail b), dimension 320). In order to avoid chaining, the dimensions are entered from reference edges (detail a), left and bottom edge of the workpiece). So the permissible deviations of the individual dimensions cannot accumulate. As far as details cannot be depicted and dimensioned on the chosen scale, they are drawn out magnified (detail c)). Refer to Figures 9 and 10. Refer to Figure 8. Figure 8: Arrangement of Dimensions (II) For Training Purposes Only Issue: August 2014 Page 188 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 Figure 10: Arrangement of Dimensions (IV) Figure 9: Arrangement of Dimensions (III) Dimension figures must not be divided or crossed by lines (details d) and h)). Dots may be used, where the available space is not sufficient for arrow heads (detail e)). The applicable figures may be entered at different heights above the dimension line. A reference line makes the connection of the superior figures with the respective dimension line. Dimensions should possibly not be inscribed in the screened areas (30! to the axes). Where this is inevitable, the figures must not stand upside down. They must be readable from the left bottom side (detail For Training Purposes Only Issue: August 2014 Page 189 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 f)). Dimension figures such as 6, 9, 66, 86 have a point behind them to prevent misinterpretation by the positional arrangement of the figures. Angular dimensions are provided with a circular arc as dimension line, with the arc mid –point being the vertex of the angle. Above the center line the dimension figures point in the direction of the mid – point with their foot, while below the center line their head points to the mid –point (detail g)). Radii are identified in any case by the capital letter ’R’ as prefix to the dimension figure (details h) to k)). Dimension lines for radii are delimited only at the inside or outside of the circular arc. Generally, the central point is marked by the axes crossing (detail h)). Where the mid - point of a radius is not marked, the dimension line indicates the real mid - point position (detail i)). In cases, where the space available is not sufficient to dimension the central point position, the dimension line can be bent at a right angle (detail j)), with the arrowhead part of the dimension line pointing to the mid –point position. Several curvatures with the same radius such as 3 mm, for example, need not be dimensioned individually. The radius is, instead, indicated by the note ’non - dimensioned curvatures R3’ (detail k)). Chamfers of 45° and 90° countersinks can be dimensioned in a simplified way with the respective width and bevel angle (details l) to n)). Refer to Figure 11. Figure 11: Arrangement of Dimensions (V) For Training Purposes Only Issue: August 2014 Page 190 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 Only by way of exception and if it makes the representation clearer may auxiliary extension lines be arranged at an angle of 60! to the dimension line (detail o)). A chord dimension is executed by straight dimension lines and with parallel auxiliary lines arranged normally to the dimension line (detail p)). For radian measures the dimension line is part of a circle. The dimension figure is provided with the arc mark. For central angles up to 90° the auxiliary lines must be drawn parallel (detail q)). For center angles in excess of 90°, the auxiliary lines point to the mid –point of the arc. The dimensioned arc is marked by a reference line (detail r)). Dimension figures for dimensions not to scale must be underlined (detail s), dimension 40). This rule does not apply to discontinuous representations of parts (detail s), dimension 90). Refer to Figure 12. Figure 12: Arrangement of Dimensions (VI) For Training Purposes Only Issue: August 2014 Page 191 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 Datum lines should be drawn as exceptions to the rule only in cases of restricted space or to prevent confusion. Datum lines are completed with an arrow head, if they end on an edge (detail t)), and with a dot, if they end on a surface (detail u)). No arrow head or dot is made for datum lines which end on another line (detail v)). If the same dimension occurs several times, auxiliary extension lines can be drawn as continuous lines within one view. In such a case, the applicable dimension is entered only once (detail w)). The distances of holes with various pitches may be drawn from a zero point in a simplified representation (detail x)). Equal bore diameters are entered only once. For Training Purposes Only Issue: August 2014 Page 192 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 7.5.5 Indicating Surface Texture and Tolerances In former times, surface finishes were marked according to DIN 3141. This standard, however, must no more be applied, as it has been replaced by the international standard DIN ISO 1302. Nevertheless, DIN 3141 is introduced here to allow for a clear understanding of already existing drawings made to it. 7.5.5.1 Surface Finish Marking to DIN 3141 Refer to Figure 1. Figure 1: Surface Symbols and Example of Application For Training Purposes Only Issue: August 2014 Page 193 of 926 Modul 7 Engineering Drawings, Diagrams and Standards When a surface is machined, more or less coarse or fine scores will result from the chipping process according to the type of cutting tools used. The depth of such scores or marks is the ’surface roughness’, which is the peak - to-valley height. The permissible surface roughness can be read from tables (detail a)). In a drawing containing the respective symbol indicating the surface finish, an explanatory annotation must be made (detail b)). The not bracketed symbol in detail b) means that the gauge shown may have a surface roughness of 100 "m on all sides according to the table (detail a)), whereas the permissible maximum for the surfaces marked by the bracketed symbol is 6.3 𝜇m. Note: 1 𝜇m = 0.001 mm. 7.5.5.2 PART 66 – Basic Training Cat B1 – Module 7 Roughness Parameters Every surface has a determined characteristic roughness profile. From this profile, the values of the roughness parameters are determined by means of special measuring equipment. The three mostly used roughness parameters are: roughness average Ra average peak –to –valley height Rz maximum peak –to –valley height Rmax. Note: The roughness average Ra is used worldwide, whereas the average peak –to-valley height Rz is predominantly used in European countries. Symbols Indicating Surface Texture Refer to Figure 2. Method of Indicating Surface Texture to DIN ISO 1302 Surface Condition The various surfaces of a workpiece require various qualities of finish according to their functions. The bore for a set pin, for example, requires a better surface quality than a through hole for a bolt. The desired surface condition is indicated in a drawing by characterising symbols according to DIN ISO 1302. Such surface finish marks are not necessary, where the required quality results naturally from the applied common manufacturing process. For Training Purposes Only Issue: August 2014 Page 194 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 There are three symbols characterising surface texture according to DIN ISO 1302 (detail a)). The basic symbol alone does not give any clue. For specific information it is modified and its longer leg completed with a transverse line for information on the type of the manufacturing method, surface finish, reference section and roughness parameters other than Ra. The length of the transverse line depends on the length of the entry to be made. Detail b) shows the additional information and its location at the symbol. Roughness Values Refer to Figure 3. Figure 2: Symbols Indicating Surface Texture (I) For Training Purposes Only Issue: August 2014 Page 195 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Engineering Drawings, Diagrams and Standards Where the symbol is provided with only one roughness value, the stated value is the maximum permissible value which must not be exceeded (detail a)). If upper and lower roughness limits are specified, the maximum value is written above the minimum value (details b) and c)). Detail d) shows some exemplary applications. Indication of Groove Direction The direction of grooves is specified, where the surface function is influenced by the direction of grooves as, for example, in the case of sliding and sealing surfaces. The direction of the grooves is indicated by the following 6 symbols: = ⊥ X = = = C R = = parallel to plane of projection perpendicular to the plane of projection crossing directions, diagonal to the plane of projection M = various directions approximately circular approximately radial to the central point. Refer to Figure 4. Figure 3: Symbols Indicating Surface Texture (II) For Training Purposes Only Issue: August 2014 Page 196 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 The dimensions and line thickness of the symbols depend on the type of lettering applied to the drawing. For lettering by B characters according to DIN 6776 the symbol sizes may be seen from detail a). For a type height of h = 3.5 mm, for example, the symbol size is as shown in detail b); for h = 5 mm symbolising is as shown in detail c). Arrangement of Symbols in Drawings Refer to Figure 5. Figure 4: Sizes for Roughnesses and Groove Direction Symbols For Training Purposes Only Issue: August 2014 Figure 5: Arrangement of Symbols (I) Page 197 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 The symbols and the associated inscriptions must be made such that they can be read from the bottom or the right of the drawing. The symbols should point to the edge of the object or a dimension line from the outside. If required, an arrowhead reference line may be drawn. Neighbouring surfaces with the same characterisation may be provided with a common reference line. Viewing from the point of the symbol, its longer leg must always be on the right side (detail a)). If several views of a workpiece are drawn, the surface specification is entered in that view, which shows the respective dimensioned surface (detail b)). On parts having uniform surface textures, one entry near the part is sufficient (details c) and d)). The surfaces of the workpiece depicted in detail c) may be produced in a chipping or chipless process. The max. roughness average measurement Ra must not exceed the value of 6.3 𝜇m. For the workpiece illustrated in detail d) all surfaces must be machined. Their roughness is not a functional feature and is, therefore, not specified. Refer to Figure 6. Figure 6: Arrangement of Symbols (II) For Training Purposes Only Issue: August 2014 Page 198 of 926 Modul 7 Engineering Drawings, Diagrams and Standards A simplified method of indicating surface conditions is by entering the basic symbol and a capital letter. The explanatory wording is entered near the part or above the title block. PART 66 – Basic Training Cat B1 – Module 7 limit deviations ISO tolerance symbols. General Tolerances 7.5.5.3 Tolerancing in Drawings (DIN 7182) Refer to Figure 8. Refer to Figure 7. Figure 7: Tolerancing in Drawings As in a production process the nominal size can never be realised perfectly, every dimension must be considered with a certain tolerance included. All allowances refer to the zero line. The maximum measurement is the zero line plus the over –allowance, and the minimum measurement is the zero line minus the under –allowance. Tolerances may be indicated on drawings as: general tolerances of form and position For Training Purposes Only Figure 8: General Tolerancing Issue: August 2014 Page 199 of 926 Modul 7 Engineering Drawings, Diagrams and Standards General tolerances according to DIN 7168 are only applied to dimensions without further tolerancing. The permissible off –sizes (upper and lower limit deviations from the nominal size = over – allowance and under –allowance) are taken from a table. Example: For a medium degree of accuracy (m) of a nominal dimension of 30 mm the upper limit deviation is 0.2 mm and the lower limit deviation is –0.2 mm. Where general tolerances are applied, the drawing must contain a reference such as ’DIN 7168 – medium’ or ’DIN 7168 – m’, for example. PART 66 – Basic Training Cat B1 – Module 7 Tolerancing by stating limit deviations is made as shown in Figure 9. The numbers for the limit deviations must be graded down in the amount of one increment with respect to the size of the dimension figures. Irrespective of the applicable prefix, the upper limit deviation is typed high and the lower value is typed low. A zero (0) limit deviation may be omitted. ISO Tolerance Codes (Symbols) Refer to Figure 10. Limit Deviations Refer to Figure 9. Figure 9: Tolerancing by Limit Deviations For Training Purposes Only Issue: August 2014 Page 200 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 The ISO codes consist of letters and figures. Holes are faying surfaces at internal form –fitting parts (circular or angular types), which serve as seats to other parts. Such internal dimensions are written in capital letters. Shafts are faying surfaces at external form –fitting parts (circular or angular), which are enclosed by other parts. Such external dimensions are written in small letters. ISO tolerance symbols are written behind the dimension number. The capital letters and numbers for holes are stepped up, and the small letter and number for a shaft is stepped down (detail a)). The type size to be chosen is by one increment lower than that of the dimension figures, but not smaller than 2.5 mm. The limit deviation values pertinent to the symbols are seen from tables. Note: According to DIN 406 limit deviations and ISO tolerance symbols may be executed with the same type size and at the same level as the nominal size. Tolerance Identification Table A tolerance explanation table with a division of fit dimensions and limit deviations (detail b)) is to allow for immediate recognition of the limit deviations of fit dimensions on the drawing in the production process. The limit deviations to be entered in the identification table can be compiled from general tables (DIN 7154/DIN 7155). If required, the limit deviations of the general tolerances (for example: Ø 33) can be derived from DIN 7168. Figure 10: ISO Tolerance Codes For Training Purposes Only ISO tolerance symbols must not be used for the spacing of holes and for centering. Issue: August 2014 Page 201 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 7.5.6 Geometrical Tolerancing (According to DIN ISO 1101) any specific geometrical tolerancing, the limits of geometrical deviations are included in the dimensional tolerancing. 7.5.6.1 Generalities 7.5.6.2 Tolerances of Form Tolerances of form are to limit the permissible deviations of a geometrical element from its ideal form. They define the tolerance zones, within which the element must be contained and may have any form. Refer to Figure 1. Symbols of Tolerances of Form Refer to Figure 2. Figure 1: Geometrical Elements of a Workpiece Workpieces can be composed of individual geometrical elements. As it is not possible to produce geometrically ideal workpieces, the geometrical deviations must be kept within determined limits. Such geometrical tolerance limitations, however, are only necessary, where a certain limit must not be exceeded for reasons of function. Without For Training Purposes Only Issue: August 2014 Figure 2: Symbols of Tolerances of Form Page 202 of 926 Modul 7 Engineering Drawings, Diagrams and Standards According to DIN 8184, 6 types of tolerances of form can be distinguished: tolerance for the straightness of a line tolerance for the flatness of a surface tolerance for the circularity of a circular lin tolerance for cylindricity V profile tolerance of any line profile tolerance of any surface. PART 66 – Basic Training Cat B1 – Module 7 The example of a straightness tolerance (–) shown in detail a) for a median line shows a cylinder with the diameter ’t’ as tolerance zone. In the presented case, the center of the workpiece must be contained within the diameter t = 0.03 mm of the given cylinder. Detail b) shows the tolerance zone for a surface. The tolerance zone is contained between two imaginary planes arranged parallel at a mutual distance of 0.05 mm. All points of the workpiece surface must lie between the two planes. Tolerance Zones Analogously, the descriptions of the tolerance zones of details a) and b) can also be applied to the other types of tolerances of form. Further exemplary applications may be seen from DIN 7184 as well as from table books. Refer to Figure 3. Tolerance Blocks Refer to Figure 4. Figure 3: Tolerance Zones for Tolerances of Form A tolerance zone is understood to be the range, within which all points of a geometrical element (for example, a line or a surface) must be contained. For Training Purposes Only Issue: August 2014 Page 203 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 Tolerances of form are entered in a block consisting of two fields (detail a)). Field 1 shows the symbol of the tolerance feature. Field 2 shows the tolerance value, which determines the size of the tolerance zone. If the tolerance zone concerned is a cylinder, the symbol Ø designating the diameter is prefixed to the tolerance value (detail a)). The height of the tolerance block is twice the type height ’h’. The length of the fields depends on the space needed for the entries. The length of field 1 is twice the type height h, while the length of the second field depends on the length of the inscription. The frame line thickness is 1/10 h. In professional drawing practice both the tolerance block frames and the symbols are applied by means of templates. The tolerance block is connected to the element, to which the tolerances apply, by a vertical, arrowhead datum line (detail a)). Datum Arrows The datum arrows must be drawn as shown in detail b)). In the left figure the marking refers only to the axis of the small cylinder, while the figure in the middle refers to the axis of the total workpiece. Where reference is to be made only to the generating line, there must be a minimum distance of 4 mm from the dimension line (right part of detail b)). This rule is applied to round and plane surfaces. Framing of Theoretically Precise Dimensions Figure 4: Application of Tolerance Blocks For Training Purposes Only Theoretically precise dimensions (theoretically precise = geometrically ideal position of the tolerance zone) are marked by rectangular framing of the entry (detail c)). Issue: August 2014 Page 204 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 The quantity of the elements concerned must be clearly evident from the drawing. The quantity is indicated above the frame by the addition ’4 bores’ or the simplified statement ’4x ’ (detail c)). 7.5.6.3 Tolerances of Position Tolerances of position are intended to limit the permissible deviations from the geometrically ideal mutual position of two or more elements. Out of these elements one is mostly used as tolerance feature. This feature is the one that is the datum element on which tolerancing of position is based. Tolerance Blocks Refer to Figure 5. Figure 5: Arrangement of Tolerance Blocks (I) For Training Purposes Only Issue: August 2014 Page 205 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 Just as for tolerances of form, tolerances of position are entered in a tolerance block, which is connected with the tolerance element by means of a reference arrow. For the location and arrangement of reference arrows the rules for tolerances of form are applied analogously to the tolerances of position. The reference elements are marked by a solid black datum triangle. This datum triangle may be either connected directly to the tolerance block (detail a)) or be provided with a framed datum letter (detail b)). If a datum letter is used, this letter must at the same time be entered in a third field of the tolerance block. The block for tolerances of position may consist of two or three fields. The first field contains the symbol of the tolerance feature and the second field contains the tolerance value. The third field serves for the entry of one or more datum letters, depending on how many reference elements are used and accordingly are entered in the three –section block (detail b)). As for the datum arrow, the datum triangle may be drawn directly to the reference element or be arranged on the pertinent extension. Refer to Figure 6. Figure 6: Arrangement of Tolerance Blocks (II) The position of the reference arrow indicates, whether the tolerance element is a plane, a line, an axis or a center line. According to the same rules, the arrangement of the datum triangle indicates the type of the reference element, with the following distinction to be made: For Training Purposes Only Issue: August 2014 Page 206 of 926 Modul 7 Engineering Drawings, Diagrams and Standards Case 1 If the reference element is a line or a surface, the datum triangle is placed beside the arrow head of the associated dimension (detail c)). Case 2 If the reference element is the axis or center plane of a geometrical element, the datum triangle is put to the arrow head of the associated dimension (detail d)). Symbols of Tolerances of Position Refer to Figure 7. PART 66 – Basic Training Cat B1 – Module 7 For tolerances of position, 7 symbols can be distinguished for different types of tolerances, which are put up in three main groups (detail a)) as follows: tolerances of orientation, concerning: – parallelism – perpendicularity – angularity tolerances of location, concerning: – position – coaxiality and concentricity – symmetry runout tolerances, concerning: – true running – runout. Tolerance Zones Refer to Figure 8. Figure 7: Symbols of Tolerances of Position For Training Purposes Only Figure 8: Tolerance Zones for Tolerances of Position Issue: August 2014 Page 207 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 Detail a) shows an example of parallelism. The tolerance axis of the bore hole must be contained between two planes parallel to the reference surface having a distance of 0.02 mm. Detail b) is an example of rectangularity. The tolerance surface must be contained between two parallel planes normal to the reference surface A; distance 0.02 mm. The tolerance zones described in details a) and b) are applicable analogously also to the other types of tolerances of position. Further exemplary applications may be seen from DIN 7184 as well as from table books. 7.5.7 Normal and Special Projection 7.5.7.1 Types of Representation Refer to Figure 1. Figure 1: Types of Representation For Training Purposes Only Issue: August 2014 Page 208 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 In brochures, catalogues and the like, objects are often shown in a three-dimensional representation. Such spacial figurations are used for providing a good impression of the geometrical form of a body. Their disadvantage, however, is that the object cannot be seen from all its sides (detail a)). In many cases a three - dimensional representation of a workpiece is not sufficient. A technical representation is chosen, which shows the details of a workpiece and all its sides. Detail b) shows a spacial representation on the left, and a technical representation of the same workpiece on the right - hand side. 7.5.7.2 Planes of Projection Refer to Figure 2. Figure 2: Planes of Projection For Training Purposes Only Issue: August 2014 Page 209 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 A prerequisite for a technical representation is a space formed by 6 drawing planes arranged perpendicularly to one another, which are the planes of projection (detail a)). A workpiece contained within these 6 planes of projection can be depicted in 6 planes. The representations thus resulting are called ’views’. If three of these planes are removed, the representation becomes easier to survey (detail b)). Views Refer to Figure 3. Figure 3: Views For Training Purposes Only Issue: August 2014 Page 210 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 From the corner points of a workpiece to be represented, whose principal planes or axes of symmetry are arranged in parallel to the planes of projection, perpendiculars are drawn to the respective planes of projection (detail a), plane A). These perpendiculars arranged in parallel are termed projection beams. Where they meet the plane of projection, they form points (detail a), plane C). Joining these points by lines provides a view (detail a), plane of projection B). According to the above, a view consists of the edges or outlines of the workpiece. For the purposes of technical representation the different planes must be drawn all on one paper surface so that the resulting views must be turned into one common plane (detail b)). Designation of Views Refer to Figure 4. Figure 4: Designation of Views For Training Purposes Only Issue: August 2014 Page 211 of 926 Modul 7 Engineering Drawings, Diagrams and Standards The views of a workpiece are designated as follows: Standard Term Common Designation View from the front Front view View from above Top view Plan view View from the left Side view End view View from the right Side view End view View from below Bottom view Base view View from the rear Rear view Back view PART 66 – Basic Training Cat B1 – Module 7 The selection of additional views must be such that the number of hidden outlines and edges contained is limited to a minimum. Hidden outlines and edges must be drawn only, if this makes the drawing clearer or allows further views to be omitted. Equivalent Projection Methods The projection methods applied to the representation of workpieces in engineering drawing are Front and side views are also called elevations. Note: In further descriptions the shortest clear designations are used. In engineering drawing practice the execution of three views has proved to be sufficient. As a rule, these are the front view, the view from the left and the top view. the first angle projection the third angle projection the arrowing method. They differ in their positions with respect to the front view. Note: In the present course the views are arranged by the first angle projection method. Indication of the Projection Method Refer to Figure 5. Number of Drawn Views Workpieces are prevailingly represented in component drawings in operating position. As the front view mostly the view is chosen, which offers the optimum content of information. In cases, where for a clear distinction or for complete dimensioning additional views are required, the following rules must be respected: The number of views must be limited to the real requirements. For Training Purposes Only Issue: August 2014 Page 212 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 Figure 5: Projection Methods The use of the first angle projection and the third angle projection method in a drawing is indicated by symbols (detail b)). The applicable symbol is entered in the drawing title block. If no particular method symbolising field is provided, the symbol is placed near the title block. There is no symbol to indicate arrow system arrangements. First Angle Projection Method Refer to Figure 6. Figure 6: First Angle Projection The first angle projection is the most commonly used method in European countries. Its systematic arrangement of views is as follows: For Training Purposes Only Issue: August 2014 The top view is arranged below the front view. The bottom view is arranged on top of the front view. The view from the left is arranged at the right side of the front view. V The view from the right is arranged at the left side of the front view. The rear view is arranged either beside the side view from the left or that from the right. Page 213 of 926 Modul 7 Engineering Drawings, Diagrams and Standards Folding the views into the drafting plane results automatically in the following: The side views from the left and the right as well as the rear view are arranged at the same level as the front view. The top view and the bottom view lie vertically below and above the front view, respectively. PART 66 – Basic Training Cat B1 – Module 7 In the third angle projection (which is primarily used in non –European countries) the views are set up by the following arrangement: Third Angle Projection Method Refer to Figure 7. The top view is arranged on top of the front view. The bottom view is arranged below the front view. The side view from the left is placed at the left side of the front view The side view from the right is arranged at the right side of the front view. The rear view may be arranged either beside the view from the left or the view from the right. Arrowing Method Refer to Figure 8. Figure 7: Third Angle Projection For Training Purposes Only Figure 8: Arrowing Method Issue: August 2014 Page 214 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 In cases where it appears not advantageous to project the workpieces in question neither by the first angle method nor by the third angle method, the views may be freely arranged using reference arrows. With the exception of the front view, all viewing directions for the necessary views are identified by arrows. The location of the views arranged by an arrow system is completely independent of the position of the front view. The only identification requirement is that the views are provided with the same capital letters that indicate the viewing directions on the front view. The capital letters are arranged right on top of or at the right side of the arrow line and in close vicinity to the associated views. Independent of the viewing direction, the letter is always entered perpendicular to the direction of the title block. As compared with the size of the dimension figures, the capital letters must have a type height, which is by at least one increment superior to that of the figures. The arrows should include an angle of at least 15° and have a length of at least 1.5 times the length of the dimensioning arrows. Special Views Refer to Figure 9. Figure 9: Special Views For Training Purposes Only Issue: August 2014 Page 215 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 If a view cannot be arranged according to the first or third angle projection method (detail a)), or where unfavourable (foreshortened) projections are to be avoided, arrowing is applied for such views (details b) and c)). If that view, which lies in the direction of the arrow, is not arranged in the correct position of projection, the letter defining the view must be provided with a symbol that indicates the rotation in the respective direction. The angle value may additionally be indicated (detail c)). Also in such cases the capital letters indicating the viewing directions are principally arranged vertical regardless of the viewing direction (detail b)). Partial Views Refer to Figure 10. Figure 10: Partial Views For Training Purposes Only Issue: August 2014 Page 216 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 Views of workpieces may be represented broken or interrupted, if this does not affect its clear and complete definition. In order to save time and space, half views or quarter views may be drawn of symmetrical objects (details a) and b)). Such partial views are delineated by their symmetry lines. Either end of the symmetry lines is marked by two thin parallel lines. If the lines representing the workpiece slightly exceed the axis of symmetry, the short parallel lines are omitted (detail c)). Where several views of a workpiece are drawn, the internal halves of the views may be omitted (detail d)). Representation of Breaks Refer to Figure 11. Figure 11: Representation of Breaks For Training Purposes Only Issue: August 2014 Page 217 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 In order to save space on the drawing sheet, it is permissible to ’resect’ parts out of a workpiece, if the workpiece has a uniform or uniformly changing cross –section. In such a case the remaining workpiece parts are provided with breaks in the form of a continuous freehand line (type C) or a continuous straight line with zigzags (type D). The remaining parts are drawn put together with only a small area of break between them (details a) to d)). Annotation on detail c): The represented ends of conical workpieces must show the real conicity. To this end, first the basic shape of the entire cone is drafted, and then the cone generating line is transferred by parallel shift. 7.5.7.3 Special Representations and Marking Refer to Figure 12. Figure 12: Special Representations and Marking For Training Purposes Only Issue: August 2014 Page 218 of 926 Modul 7 Engineering Drawings, Diagrams and Standards Details Original Form Partial areas of a workpiece, which cannot be clearly depicted, dimensioned, marked or identified in an overall drawing, are drawn separately mostly magnified. Refer to Figure 13. PART 66 – Basic Training Cat B1 – Module 7 The detail drawing may contain pictorial elements (for example: contours), or information and instructions, which in the overall representation are only indicated or not contained at all. In this case the full form of the detail may be omitted in the workpiece drawing (detail a)). The area drafted as detail is marked in the main drawing by a thin continuous line (type B) forming a circular, elliptic or rectangular frame (details a) and b)). The framed area and the details are identified by the same capital letter. Detailing capital letters must be executed with a type size at least one increment superior to that of the dimension figures. For detailing purposes, the last 3 letters of the alphabet X, Y and Z are recommended to be used. The drawing - out detail, which should be arranged as close to the framed area as possible, is delineated by a break line (details a) and b)). For details drawn on a scale larger than that of the main drawing, the enlargement scale must be indicated behind the capital letter (details a) and b)). In a simplified representation drawn - out details may be depicted without break lines, sections may be drawn without hatchings and contours may be omitted (detail c)). For Training Purposes Only Figure 13: Special Representation of Original Form Where this is necessary, the original form of a workpiece may be marked by means of a thin double –dashed chain line (details a) and b)). 7.5.7.4 Simplified Representation Refer to Figure 14. Issue: August 2014 Page 219 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 Holes on pitch circles, whose central points do not lie on one symmetry line (side views of details a) and b)), are usually depicted on that view, which does not show the circular shape (front views of details a) and b)) with their max. mutual distance on the pitch circle. Regularly recurring shapes must only be repeated often enough to ensure a clear object definition from the drawing. The number of recurring form elements must be stated in all cases, where their quantity is not evident from the representation or other drawing information (details b) to e)). The centers of the recurring form elements as, for example, holes must be marked by their center line intersections (details b) and c)). Hole circle pitches may be presented as patterns not to scale. For other form elements the remaining section concerned by the elements is indicated by a thin continuous line (details d) and e)). 7.5.7.5 Drawing Procedure for the Construction of Views Refer to Figure 15. Figure 14: Simplified Representations For Training Purposes Only Figure 15: Drawing Procedure for the Construction of Views (I) Issue: August 2014 Page 220 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 In engineering drawing practice in general the front view of a workpiece is drawn first. For the subsequent top view, all dimensions of length can be transferred from the front view (detail a)) so, that only the measures of width still have to be executed with the ruler. On cylindrical workpieces the auxiliary projection line runs through point ’S’, which is the intersection of the extended axes. The auxiliary projection line can be used also in this case for the transfer of workpiece edges between top and side views (detail c)). Thus, all dimensions are given for the side view from the left. The height dimensions are derived into the side view from the front view, and the widths are transferred into the side view from the top view by means of a projection auxiliary line drawn at an angle of 45° (detail b)). Detail d) shows another possibility of transfer of workpiece edges between views using dividers. 7.5.7.6 Division of the Drawing Sheet Refer to Figure 17. The auxiliary line of projection runs through the intersection ’P’ of the extended top view edge and the extension of the left side view edge (detail b)). Where after the front view the side view is drawn first, followed by the top view, the construction of views is developed in inverse direction. Refer to Figure 16. Figure 16: Drawing Procedure for the Construction of Views (II) For Training Purposes Only Issue: August 2014 Figure 17: Division of the Drawing Sheet Page 221 of 926 Modul 7 Engineering Drawings, Diagrams and Standards Clear and quick ’legibility’ of a drawing will only be ensured by a useful division of the drawing space available and a well apportioned arrangement of workpiece views. PART 66 – Basic Training Cat B1 – Module 7 Isometric Projection Refer to Figure 18. The first consideration for the division of the drawing sheet is how many views are required to represent the particular workpiece. The minimum mutual distance between the views is 15 mm. Apart from this requirement, the distances are ruled by the size of the views and the number of dimensions to be entered between them. This means that the distances resulting between front view and side view or between front view and top view may be different. Furthermore, a distinct systematic layout requires equal distances of horizontal and vertical view arrangements from the sheet limiting lines as well as the title block and the filing edge, respectively (x – measures for horizontally and y –measures for vertically arranged views). In some cases it may be necessary to disregard the principle of equidistances as, for example, to meet high space –consuming dimensioning requirements. 7.5.7.7 Axonometric Projections (DIN 5) A vivid method of representing an object in a clear survey is drawing it by way of axonometric projections. Among the foremost types there are the isometric projection the dimetric projection the cabinet projection. Figure 18: Isometric Projection For Training Purposes Only Issue: August 2014 Page 222 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 In an isometric projection all dimensions of the object are drawn on the same scale. It is applied, where the essentials of the object are to be presented in three views. The directions X and Y are arranged at 30° each up from the horizontal, while the direction Z is vertical. All dimensions are drawn on natural scale. The ratio of the axes x: y: z is 1 : 1 : 1. The directions X and Y may be arranged mirror –inverted. Dimetric Projection Refer to Figure 19. Figure 19: Dimetric Projection For Training Purposes Only Issue: August 2014 Page 223 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 In a dimetric projection two different scales are used. It is chosen, where the essentials of a workpiece are to be represented in one view. In this projection the views are depicted with the directions at the following angles: X: Y: Z: 42o up from the horizontal 7o down from the horizontal vertical. The directions Y and Z are drawn true to scale, while the direction X is drawn foreshortened to half the dimension value. The picture ratio x : y : z is 0.5 : 1 : 1. The directions X and Y may be arranged mirror –inverted. Cabinet Projection Refer to Figure 20. Figure 20: Cabinet Projection For Training Purposes Only Issue: August 2014 Page 224 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 In a cabinet projection two different scales are used, too. In this projection, direction X is angled 45o up from the horizontal direction Y lies horizontal direction Z is vertical. Directions Y and Z are realised true to scale, while direction X is foreshortened by 50 %. The directions X and Y may be arranged mirror - inverted. Basic Solids Refer to Figure 21. Figure 21: Basic Solids For Training Purposes Only Issue: August 2014 Page 225 of 926 Modul 7 Engineering Drawings, Diagrams and Standards In axonometric projections drawing begins with the basic solid, from which the workpiece is made. Next, the sequence of changes of shape is entered as processed on the workpiece. The basic solids may have the following shapes: Prism The areas of base and top are commensurate and arranged parallel. The side faces are rectangular, arranged at right angles to the base. Cylinder The circular base and top surfaces are commensurate and parallel. The generated surfaces are normal to top and base. Pyramid The triangular side surfaces raised from a plane area of base converge in the top point. Truncated Pyramid A truncated pyramid results when the point of the pyramid is cut away. Cone A cone ends in a top point lying vertically above the center of the circular base. Truncated Cone A truncated cone results, when the point of the cone is cut away. Note: In a few cases the above solids may have an axis which is oblique to the area of base (oblique prism etc.). Sphere 7.5.7.8 PART 66 – Basic Training Cat B1 – Module 7 Freehand Sketches A freehand sketch is generally understood to be a drawing executed mostly freehand, which does not primarily aim at perfect drafting, but rather a clear presentation of engineering concepts, ideas and intentions. A freehand sketch is drawn without the usual auxiliaries such as protractors, scales and compasses. A freehand sketch is indispensable, where an engineering drawing of an existing machine or machine part must be made. Such subsequent drawings must be made, for example, if there is neither a replacement part nor a drawing for a broken or failing part and thus a replacement must be produced. In such a case a freehand sketch is drawn as a preliminary stage to the drawing required for manufacture. Another very important feature of the freehand sketch is its descriptive character for communication on the layout and function of components and systems or technical concepts and ideas etc.. More extensive and comprehensive information is gained from a plain sketch than from a long description by words. The sketch must reflect all necessary views and sections as well as the applicable dimensions. The dimensions in a freehand sketch are realised by way of assessment. In drawing practice graph paper has proved to be a help with the grading facilitating the assessment. Even though sketches need not to be true to scale, any approximate scale should possibly be applied uniformly all over the sketch such as to show realistic dimensional proportions. The sphere has a uniformly convex surface. All points on the surface area are equidistant from the central point. For Training Purposes Only Issue: August 2014 Page 226 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 Drafting a sketch always begins with the center lines. Subsequently the shapes are developed, proceeding in inside and outside direction for hollow bodies with thin lines. The lines are re - drafted and dimensioned in a next step. For dimensioning the real measures are taken from the existing workpiece and the dimension figures are entered in the sketch. Finally, possibly required tolerances and surface instructions are entered. The freehand sketch thus completed serves as draft for a complete and correct engineering drawing or as workshop drawing, to which the workpiece is made. Refer to Figures 22 and 23. Figure 23: Freehand Sketch of a Bearing Bracket Figure 22: Freehand Sketch of a Bolt For Training Purposes Only Issue: August 2014 Page 227 of 926 Modul 7 Engineering Drawings, Diagrams and Standards 7.5.8 Prismatic Workpieces PART 66 – Basic Training Cat B1 – Module 7 In principle, as many views have to be drawn as are necessary for the clear definition and complete dimensioning of a workpiece. Refer to Figure 1. For the representation of sheets normally one view is sufficient. The workpiece thickness is indicated by ’t’ instead of drawing a second view (detail a)). For simple workpieces of basically prismatic form often just two views will suffice for a clear representation. Whether in addition to the front view a side view or a top view has to be drawn, will depend on the shape of the workpiece. The workpiece shown by isometric representation in detail b) is clearly defined with the front and the side views. If instead of the side view the top view were chosen, the form of the milled sections would not be evident. In the isometric representation of detail c) the front and the top view are shown. From a side view (drawn instead of the top view) the profile of the workpiece could not be recognised. Refer to Figure 2. Complicated prismatic shapes require three or even more views. Apart from the front view, this normally includes a side and a top view. For the workpiece isometrically depicted in detail a) neither front and side view nor front and top view would provide a clear definition. This is achieved only by a combination of front, side and top views (detail b)). Figure 1: Prismatic Workpieces (I) For Training Purposes Only Issue: August 2014 Page 228 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 Figure 2: Prismatic Workpieces (II) For Training Purposes Only Issue: August 2014 Page 229 of 926 Modul 7 Engineering Drawings, Diagrams and Standards 7.5.9 Air Engineering Drawings and Standards 7.5.9.1 Introduction The purpose of an engineering drawing is to record and convey the designer’s requirements. The drawing must therefore include sufficient information to enable production planning, manufacture, assembly, testing and inspection of the particular component or assembly. To avoid misinterpretation of drawings it is essential that both the person preparing the drawing and the person using the drawing know the terms, symbols, abbreviations and methods of presentation. Purpose and Function of Drawings When an aircraft is conceived in the minds of the engineers and designers, it is nothing but an idea until it has been laid down on paper so that others can add their expertise and ideas. These ideas and considerations can then be ’translated’ into aluminium and steel. Written descriptions are often difficult to follow. This fact was recognised in ancient times when some wise Chinese men said that ’one picture would replace thousands of words’. PART 66 – Basic Training Cat B1 – Module 7 aircraft factory. Every aircraft drawing is numbered and carefully recorded. If any changes are required the respective information is passed on to the people affected so that they will be able to incorporate all changes into the parts during the manufacturing process. In the past (and still up to today), the actual drawings have been made on translucent vellum or mylar by the draftsman. After they have been checked for accuracy, they are released for copying in the reproduction department. The prints will then be recorded and distributed throughout the factory as they are needed. Nowadays, most technical drawings are created by using highly sophisticated computer systems and special programs called ’CAD’ which stands for ’computer aided (or assisted) design’. After having been checked for accuracy the drawings are printed and distributed. All aircraft factories have a drawing room manual that details all the lines, symbols and conventions used in the drawings of that company whether they have been created ’by hand’ or ’by computer’. Drawings exist in many forms. Sometimes they are used to illustrate principles; others are used to lay down impressions and moods. But the aviation maintenance industry is only concerned with drawings which provide information on the construction of an aircraft and details of the proper way to maintain them. When an aircraft is designed, drawings will be made of every individual part. These drawings are called ’detail drawings’. Where single parts must be assembled so –called ’assembly drawings’ are made to provide all information necessary for the workers in the For Training Purposes Only Issue: August 2014 Page 230 of 926 Modul 7 Engineering Drawings, Diagrams and Standards 7.5.9.2 Types of Drawings Detail Drawings PART 66 – Basic Training Cat B1 – Module 7 When a part is designed, the draftsman must make such a detailed drawing that the part can be manufactured at the workbench. All dimensions must be included and the material and finish of the part specified. Refer to Figure 1. Each drawing gets a drawing number which usually becomes the part number that this particular part carries throughout the manufacturing process and further on to its assembly and installation in the finished unit. This number will be laid down in the service parts inventory. In a detail drawing the part is carefully and accurately drawn to scale and dimensioned. But when this drawing is printed the paper can shrink or stretch, thus showing the part seldom in the exact size as that on the original drawing. For that reason the dimensions of a part should never be measured in a print. The dimensions indicated in the drawing are always to be used. Figure 1: Detail Drawing (Example) For Training Purposes Only Issue: August 2014 Page 231 of 926 Modul 7 Engineering Drawings, Diagrams and Standards Assembly Drawings Refer to Figure 2. PART 66 – Basic Training Cat B1 – Module 7 After all individual parts have been manufactured, they are assembled in various subassemblies according to the information laid down in the assembly drawings. The individual parts are listed by their part numbers in these drawings. Moreover the type and number of fasteners to be used to join them are listed. Only dimensions needed for the assembly of the parts are included. Since detail drawings already exist for every part no material will be specified on the assembly drawing. Figure 2: Assembly Drawing (Example) For Training Purposes Only Issue: August 2014 Page 232 of 926 Modul 7 Engineering Drawings, Diagrams and Standards Installation Drawings Refer to Figure 3. PART 66 – Basic Training Cat B1 – Module 7 All subassemblies are brought together in an installation drawing. The bill of materials on these drawings lists every required fastener. Notes on the face of the drawing furnish all information necessary for the installation. Dimensions are given for any adjustments which must be made for the part to function properly. Often, portions of the aircraft not actually involved in the installation process are shown to ease finding the location of the part being installed. Such portions are drawn with so –called ’phantom lines’ (very thin lines). These portions are identified by their names and, sometimes, labelled with the word ’Ref.’ to indicate that they are only shown for reference purposes. Figure 3: Installation Drawing (Example) For Training Purposes Only Issue: August 2014 Page 233 of 926 Modul 7 Engineering Drawings, Diagrams and Standards Exploded –View Drawings Refer to Figure 4. PART 66 – Basic Training Cat B1 – Module 7 lllustrated parts lists often make use of exploded –view drawings to show every part that belongs to a certain assembly. All parts are shown in their relative positions, but are expanded outwards, so that each part can be identified both by its physical appearance and its name or reference number. Figure 4: Exploded – View Drawing (Example) For Training Purposes Only Issue: August 2014 Page 234 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 Block Diagrams Refer to Figure 5. With electrical and electronic systems and components having become more and more complex, methods and procedures had to be developed to aid the technician in locating troubles. Since much of the maintenance carried out on these systems consists of identification and replacement of a malfunctioning subassembly, block diagrams are used. Each block shown in such a diagram represents many components usually mounted on a printed - circuit board or some other types of replaceable modules. Using a block diagram for troubleshooting in a system, the technician identifies the area of the problem, i.e. the module that receives the correct input, but does not produce the required output (represented by one block in the diagram) and then replaces it. For Training Purposes Only Issue: August 2014 Page 235 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 Figure 5: Block Diagram (Example) For Training Purposes Only Issue: August 2014 Page 236 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 Logic Flow Charts Refer to Figure 6. As a further aid in troubleshooting, the logic flow chart has been developed. When such a flow chart is used for troubleshooting of a system, the technician starts at the oblong symbol ’Start’ and follows the arrows. Rectangular boxes state what is to be done, the diamonds are decision points. Each diamond has one input which is the actual result of the actions taken according to the preceding instruction and only 2 outputs (results): yes no. By using this ’yes/no’ logic the chart can be followed to any of the oblong symbols ’End of test’. This type of chart identifies the probable fault (or faulty area) in a system and specifies how to fix it. Such a chart minimises the time required for troubleshooting because unnecessary testing and checks can be avoided. Figure 6: Logic Flow Chart (Example) For Training Purposes Only Issue: August 2014 Page 237 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 Schematic Diagrams Refer to Figure 7. A schematic diagram is used to explain the principle of operation instead of showing the parts as they actually appear, or as they actually function. Figure 7 shows the operation of a constant - speed propeller without displaying any details of its construction or installation. Figure 7: Schematic Diagrams (Example) For Training Purposes Only Issue: August 2014 Page 238 of 926 Modul 7 Engineering Drawings, Diagrams and Standards Pictorial Diagrams Refer to Figure 8. PART 66 – Basic Training Cat B1 – Module 7 Pilot’s handbooks and some training manuals often use pictorial diagrams of electrical and hydraulic systems. Line drawings represent the components, rather than the more conventional symbols used in schematic diagrams. Diagrams of the kind shown in Figure 8 help visualise the operation of parts of the electrical power system on board an aircraft or of the whole system Figure 8 Pictorial Diagram of an Electrical System (Example) For Training Purposes Only Issue: August 2014 Page 239 of 926 Modul 7 Engineering Drawings, Diagrams and Standards 7.5.10 Standards for Maintenance Documentation 7.5.10.1 ATA Specification 100 When following this structure a manual may have had as many sections as required in order to cover the entire aircraft. An alphabetical index was included in the manual for reference purposes. Structural Sections (Old Format) Structure of ATA Specification 100 The older type of maintenance manuals was structured as follows: Standardisation The first part included information on inspections, weight and balance computations and general servicing. Each of the additional sections covered the maintenance of a certain area/ sub –system such as – – – – engine fuel system electrical system several airframe sections (as required). Each section was further broken down into – – – – – – – – – description and operation troubleshooting maintenance practices servicing removal/installation adjustment/test inspection/check cleaning/painting approved repairs. For Training Purposes Only PART 66 – Basic Training Cat B1 – Module 7 The need for standardisation of both civil and military aircraft by aircraft manufacturers was stated many years ago and appropriate regulations were laid down by the Air Transport Association of America (ATA) or national governments in the ’ATA Specification 100’ and in so - called ’Military Standards’. The ATA Specification 100 (commonly referred to as ’ATA - 100’) provides a standardised breakdown of civil aircraft manuals and documentation. It also forms the basis of a standardised breakdown of military aircraft documents with additional chapters added to cover the roles established by the more specialised needs of the military (e.g. for armament and specific sensors). Note: Since the year 2000, the ATA - 100 is integral part of the ATA iSpec 2200 ’Information Standards for Aviation Maintenance’. Note: The following is an extract from the ATA - 100, chapter ’Introduction’: ’The ATA Specification 100 establishes a standard for the presentation of certain data produced by aircraft, engine and component manufacturers, required for support of their respective products. These standards are intended to minimise the cost and effort expended by the airlines and other customers to make the Issue: August 2014 Page 240 of 926 Modul 7 Engineering Drawings, Diagrams and Standards manufacturer’s data compatible with the needs of the mechanic and other airline personnel. – – – – – – – – – – Airframe manufacturers’ manuals shall include all data covering the complete aircraft, its units and components (e.g. generators, instruments, radio equipment) where such equipment is installed on the aircraft at the time of delivery to the operator except for components and parts installed (or supplied) by the vendor. The airframe manufacturer’s manuals shall also cover powerplant and propeller installation data pertinent to that airframe. Additionally, they shall make provision for inclusion of engine and propeller manufacturers’ data. Material supplied by the accessory or component manufacturer shall cover all his equipment in accordance with the pertinent sections of this specification.’ PART 66 – Basic Training Cat B1 – Module 7 aircraft recovery manual (ARM) component maintenance manual (CMM) consumable products manual (CMM) engine (shop/maintenance) manual (EM) engine cleaning, inspection and repair manual (CIR) fault reporting manual (FRM) fault isolation manual (FIM) non –destructive –testing manual (NDT) powerplant build –up manual (PPBM) service bulletins (SB) for configuration control and product definition: – – – (aircraft) illustrated parts catalogue ((A)IPC) engine illustrated parts catalogue (EIPC) tool and equipment manual (TEM) Types of Manuals wiring (diagram) manual (WM) V for flight operations: The set of documentation that accompanies an aircraft on first delivery is very large. It is normally divided into a series of publications similar to standard books of reference but reflects the customer’s aircraft configuration as well. The set of publications normally comprises: for maintenance requirements: – maintenance planning document (MPD) for maintenance procedures: – – – aircraft maintenance manual (AMM) structural repair manual (SRM) weight and balance manual (WBM) For Training Purposes Only – – – – – – flight crew operation manual (FCOM) master minimum equipment list (MMEL) V for other applications: component manual index (CMI) publications index (PI) service bulletin index (SBI) service letter (SL). Note: Not all the documents listed above are necessarily individual books. Some may be printed together with others or contained in the same file/book. Issue: August 2014 Page 241 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 Note: For detailed usage, refer to the ’Introduction’ section at the beginning of each manual. Maintenance Planning Document A maintenance planning document (MPD) provides the data to assist an operator in developing and revising an approved scheduled maintenance program. It shall include, as a minimum, all scheduled on –aircraft maintenance tasks mandated by the manufacturer’s governing regulatory authority as well as other tasks recommended bay the airframe manufacturer. Note: ’Scheduled maintenance’ is the maintenance performed at defined intervals to retain an item in a serviceable condition by systematic inspection, detection, replacement of worn –out items, adjustment, calibration, cleaning etc. Aircraft Maintenance Manual Refer to Figure 1. The aircraft maintenance manual (AMM) contains all information necessary to enable the mechanics to service, functionally check and repair all systems and equipment installed in the aircraft. This includes information necessary for the mechanic to perform maintenance or carry out minor repairs to any unit in the aircraft normally requiring such action on the flight line or in the hangar. It covers the configuration of the aircraft as delivered to the customer. The AMM does not contain information about any work normally done on units or assemblies after deinstallation. For Training Purposes Only Issue: August 2014 Page 242 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 Figure 1: Example of AMM Pages For Training Purposes Only Issue: August 2014 Page 243 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 Note: In the latter case, sometimes the section is called ’list of consumable materials (LCM)’. Structural Repair Manual A structural repair manual (SRM) shall contain descriptive information for identification and repair of the aircraft’s primary and secondary structure. The manual shall inform operators about repair procedures developed by the manufacturer or by operators. Weight –and –Balance Manual The weight –and –balance manual (WBM) shall be the manufacturer’s means of handing over weight and balance data to an airline. This manual usually contains data in sufficient detail so that the airline weight engineer or other personnel concerned may analyse and establish weight and balance procedures for airline operation. Engine Manual The engine manual (EM) with CIR manual provides technical data required to maintain the engine and the maximum potential number of parts that could remain with the engine when it is removed from the aircraft. Additionally, the data file shall cover such interrelated parts which remain with the aircraft when the QEC unit is dropped, but which can be deinstalled as long as the engine is removed. Note: ’QEC unit’ means ’quick engine change unit’. Engine manuals and CIR manuals are available for auxiliary power units (APU) as well. Aircraft Recovery Manual The aircraft recovery manual (ARM) contains the description of aircraft recovery operations in terms of equipment and tooling requirements as well as procedures necessary to lift, shoe and recover the aircraft from any abnormal condition to which it may be subjected. Engine Cleaning, Inspection and Repair Manual The purpose of the engine cleaning, inspection and repair (CIR) manual is to provide the technical data required to maintain the engine and associated parts and subsystems when it is removed from the aircraft. Component Maintenance Manual Procedures contained in a component maintenance manual are intended to be applied to the applicable components in the workshop. The manual shall contain sufficient detail for the return of the component to a serviceable condition. Note: The CIR manual is an optional manual. It may be offered as an alternative to the single –document engine manual. Fault Reporting and Fault Isolation Manuals The fault reporting/fault isolation manuals (FRM/FIM) enable Consumable Products Manual This is a complete shopping guide of consumable materials provided by the aircraft and the engine manufacturer. It is distributed either as a separate manual/file or as a section of a maintenance or a repair manual. For Training Purposes Only Issue: August 2014 effective use of electronic fault indicating features in the flight compartment effective use of electronic fault isolation features and maintenance data retrieval features in the aircraft. Page 244 of 926 Modul 7 Engineering Drawings, Diagrams and Standards The FRM provides technical data for flight crews to easily identify and communicate details of aircraft faults to ground based maintenance personnel. Furthermore, the manual contains listings of faults as recognised earlier by flight, cabin, servicing and maintenance personnel. The FIM provides technical data for maintenance crews to assist them in isolating the cause of a certain fault and in determining the necessary corrective action. A FIM shall be, to the highest possible degree, compatible with the airline’s/operator’s maintenance concepts, maintenance training and maintenance manual procedures. Non –Destructive Testing Manual powerplant’ includes the engine, nacelle and certain accessory components. Service Bulletin Service bulletins (SB) shall be issued to publish any changes which fall into one of the following categories: The non –destructive testing (NDT) manual is intended to provide procedures and guidelines in the various methods of non –destructive testing. The NDT manual shall contain the standard practices and explanations of each testing procedure. These procedures shall be defined including the relevant details of/for Powerplant Build –Up Manual The powerplant build –up manual (PPBM) shall contain all information necessary to assemble the powerplant from the basic engine to the desired configuration. For this manual, the term ’demountable For Training Purposes Only effectivity tooling/equipment preparation equipment calibration inspection procedures evaluation and acceptance rejection standards. PART 66 – Basic Training Cat B1 – Module 7 Issue: August 2014 modifications of the aircraft, engine or accessory including embedded software modifications which affect performance, improve reliability, increase safety of operation, provide improved economy or facilitate maintenance or operation substitution of a part by another replacement part only when it is not completely interchangeable both functionally and physically, or when the change is considered to be sufficiently urgent or critical so that special scheduling or record of accomplishment will be required special inspections/checks required to maintain the aircraft, engine or accessories in ’safe –operation’ condition one –time inspections/checks to detect a flaw or manufacturing error special inspections/checks required to be performed until a corrective action can be taken (e.g. an inspection to detect cracks in a given radius until this radius can be ground out) special functional checks of an urgent nature required to detect a beginning failure, such as pressure checks, functional checks, etc. reduction of existing life limits or establishment of first time life limits for components conversions from one engine model to another changes affecting the interchangeability or intermixability of parts. Page 245 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 (Aircraft) Illustrated Parts Catalogue Refer to Figure 2. Figure 2: Extract from an Illustrated Parts Catalogue For Training Purposes Only Issue: August 2014 Page 246 of 926 Modul 7 Engineering Drawings, Diagrams and Standards An illustrated parts catalogue (IPC) is used for identification and ordering of replaceable aircraft parts and units. The IPC is a companion document to the AMM and shall contain information about all parts for which maintenance activities have been laid down in the AMM. Note: Further details on the content and the handling of IPCs are laid down in Chapter 7.5.10.2. Engine Illustrated Parts Catalogue An engine illustrated parts catalogue (EIPC) is used for identification and ordering of replaceable engine parts and units. The EIPC is a companion document to the engine manual. Tool and Equipment Manual The tool and equipment manual (TEM) contains all special tools and equipment (including testing equipment) prescribed or recommended by the airframe and other manufacturers for servicing, fault isolation and repair of the airframe, engine, components and accessories. Note: The term ’STATE’ means ’standard tools and test equipment’. It is another word for the list or manual of tools and equipment recommended or prescribed by the manufacturer. Wiring (Diagram) Manual PART 66 – Basic Training Cat B1 – Module 7 The flight crew operating manual (FCOM) includes information required by the flight crew for aircraft operation. The manual contains all normal, supplementary and emergency operations and procedures and the required technical data, e.g. speeds, settings, tables etc. Furthermore, descriptions of all aircraft systems and related controls and indicators as well as performance data under normal and abnormal conditions are provided. Note: The FCOM is sometimes called pilot operating handbook (POH). Master Minimum Equipment List A master minimum equipment list (MMEL) contains a listing of the allowable minimum serviceable equipment and systems which are necessary for the safe operation of a certain aircraft. This document is governed by the applicable aviation authority (e.g. EASA, FAA). Component Manual Index The manufacturer’s component manual index (CMI) identifies all documentation required to support a certain component or (sub) system. It includes component manuals issued by the manufacturers and their vendors (where applicable). Publications Index The publication index (PI) provides a status list of all technical support documentation, i.e. manuals, catalogues, revisions (permanent or temporary), information letters etc. Refer to Figures 3 and 4. The wiring (or: wiring diagram) manual (WM) illustrates all aircraft, engine and component electrical/electronic circuits. The wiring and schematic diagrams, lists and location charts shall sufficiently describe the circuits to enable fault isolation and servicing of the electrical systems during maintenance. Service Bulletin Index Periodically, the manufacturer shall issue an index of service bulletins (SBI). This index is a complete listing of all service bulletins for a certain aircraft. Flight Crew Operations Manual For Training Purposes Only Issue: August 2014 Page 247 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 Service Letter A service letter (SL) is used to notify airlines and other operators of the types of information not issued in form of an SB or not listed in the SBI. Figure 3: Example of WM Schematics Page For Training Purposes Only Issue: August 2014 Page 248 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 Figure 4: Example of WM Diagram Page For Training Purposes Only Issue: August 2014 Page 249 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 Structure of Manuals According to ATA Specification 100 Refer to Figure 5. Figure 5: ATA – 100 Standard Chapter Breakdown For Training Purposes Only Issue: August 2014 Page 250 of 926 Modul 7 Engineering Drawings, Diagrams and Standards lrrespective of the size, all aircraft documentation produced in accordance with the ATA - 100 (except of the wiring diagram manual) is to be arranged in: groups chapters (referring to the aircraft’s systems) sections (referring to the sub - systems) V subjects (referring to units). Groups This is the primary division of the manual, which separates the manual contents into the following broad groups: Aircraft: ’Aircraft’ deals with all factors concerning the aircraft as a complete, operational machine. Example: Fuselage, stabilisers, wings. Propellers: ’Propellers’ deals with the complete propeller system, with the exception of the propeller anti - icing system which is dealt For Training Purposes Only Example: Engine, air intake, cowling. Chapters Chapters are the secondary divisions of the manuals, and break down the subject matter of the groups into separate subsystems. Each chapter is allotted an identification number between 1 and 99. The allotted number is used in the standard 3 - element numbering system as the first element (e.g. 12 - xx - xx). These chapter numbers are fixed. They represent the aircraft’s systems as required. Sections Air - conditioning, communications, electric power. Structure: This group embraces the aircraft structure except the systems covered in the ’Airframe Systems’ group. Example: with in the chapter ’Ice and Rain Protection’ (in ’Airframe Systems’ group). Powerplant: The group ’Powerplant’ contains the overall power package. Example: The chapter that refers to aircraft towing and taxiing is chapter 09. The chapter that refers to landing gear is 32 etc. Parking, towing, lifting, servicing. Airframe Systems: ’Airframe Systems’ includes all airframe systems except the powerplant. Example: PART 66 – Basic Training Cat B1 – Module 7 The chapters are further broken down into sections, which refer to the sub - systems of the system dealt with in a chapter. Again, each section is allotted an identification number between 1 and 99, and again, the allotted number is used in the standard 3 - element numbering system, this time as the 2nd element (e.g. xx - 12 - xx). Example: Issue: August 2014 79 –01 –Oil (General) 79 –11 – Mechanical Parts 79 –21 –Distribution System 79 –31 –Pressure Indication. Page 251 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 Example: The fuel cells are covered in chapter 28 ’Fuel System’, section 28 - 10 ’Storage System’, subject 28 - 10 - 01 ’Fuel Cells’: Subjects These are the final divisions used in the manuals, breaking the sections down into individual subjects. The subjects are allotted the 3rd element (xx - xx - 00) in the standard 3 –element numbering system. Refer to Figure 6. Figure 6: Arrangement of ATA Specification 100 For Training Purposes Only Issue: August 2014 Page 252 of 926 Modul 7 Engineering Drawings, Diagrams and Standards Standard Page Number Blocks By the structure of the ATA - 100, all subjects can be covered under 3 main topics: description and operation troubleshooting/fault isolation maintenance practices. PART 66 – Basic Training Cat B1 – Module 7 When covering general maintenance instructions which do not definitely fall within one of the sub –topic categories as listed above, the topic maintenance practices topic (201 through 300 page block) will also be used for general instructions. The applicable sub - topic page blocks are used for the other maintenance procedures required for the sub - topic. Topic Contents A standard system of page block numbering is used in the maintenance manuals which breaks down each subject (xx - xx - 00) into Topics: Description and operation Troubleshooting Maintenance Practices Servicing The purpose of this topic is to explain the location, configuration, function, operation and control of the system Fault Isolation pages pages pages pages 001 101 201 301 to to to to 099 199 299 399 When it is considered to be of value to the operator, troubleshooting tables are given in some chapters of the maintenance manual(s). The object of these tables is to transfer to the operator the experience gained by the manufacturer in isolating faults in a system. Note: If not dealt with separately, the topics described below form the topic ’Maintenance Practices’. Sub –topics: Removal/Installation Adjustment/Test Inspection/Check Cleaning/Painting Approved Repairs Description and Operation pages pages pages pages pages 401 501 601 701 801 to to to to to 499 599 699 799 899. Servicing This topic refers to servicing that must be carried out owing to the accomplishment of any other maintenance practice, for example the replenishing of an oil tank after removal/installation of an oil system component. Removal/Installation This topic covers the sequence of steps required to remove and reinstall a component or unit. For Training Purposes Only Issue: August 2014 Page 253 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 Adjustment/Test Standard Figure Numbering Instructions are given for carrying out a test or check to ensure the integrity of a component or unit. The numbering of figures follows the page numbering system, thus: There are 3 categories of tests: operational test: a simple test using no special equipment to ensure only that a system or unit is operable functional test: more complex test that may require special equipment to ensure that a system or unit is operating within the specified performance rang system test: a major procedure containing all adjustment specifications and tolerances required to maintain the system/unit performance at maximum efficiency; normally used during major maintenance periods. Inspection/Check This topic provides information and procedures necessary to gain access to a unit or component and details of the inspection/check to be carried out. Cleaning/Painting Description and Operation (page 1 to 100) Figure 1, 2, 3, etc. Fault Isolation (page 101 to 200) Fig. 101, 102, 103, etc. Maintenance Practices (page 201 to 300) Fig. 201, 202, 203, etc. and so on. The vast majority of both civil and military aircraft documentation follows this standardised breakdown. However, customised systems sometimes found in military environments may be different. Manufacturer’s System Code The ATA –100 breakdown covers all systems and units which may be fitted in an aircraft, whether fixed –wing or rotary –wing. When publishing the manual of a certain type of aircraft the manufacturer will list only those systems and items fitted in the specified aircraft. The code numbers follow strictly the ATA –100 numbering system but certain chapters and sections which are not applicable for a fixed – wing aircraft (e.g. Chapter 62 ’Rotor(s)’) will be omitted. Such a breakdown of a specified type of aircraft is called ’system code (SYCO)’. This topic specifies material and procedures used for cleaning/painting an area and the safety precautions to be observed for the protection of personnel and material. Approved Repairs This topic includes the processes and techniques necessary for carrying out a repair and specifies the tools, equipment and materials required. Excluded are repairs contained in the structural repair manual (SRM). For Training Purposes Only Issue: August 2014 Page 254 of 926 Modul 7 Engineering Drawings, Diagrams and Standards Terms and Symbols in the Field of Aircraft Maintenance 7.5.10.2 In former times, each manufacturer used his ’own’ terms and symbols to describe maintenance procedures and to indicate intervals, materials etc. Nowadays, many manufacturers have agreed on using standardised definitions and signs. These standard terms and definitions are laid down in the World Airlines Technical Operations Glossary (WATOG). Purpose Refer to Figure 7. PART 66 – Basic Training Cat B1 – Module 7 Illustrated Parts CataIogues A parts catalogue is published by manufacturers to assist the aircraft operator in the procurement of spares and other materials required for servicing, maintenance, repair or overhaul of the entire aircraft or any of its systems. The majority of modern catalogues are illustrated with extensive information to assist the user in identifying parts and to eliminate expensive errors and costly delays. These catalogues are normally known as either illustrated parts catalogues (IPC) or illustrated parts listings (IPL). Structure lllustrated parts catalogues are normally published in one or more volumes depending on the size and complexity of the aircraft. An average volume may contain approx. 20,000 entries plus the appropriate illustrations. The introduction to each volume usually contains comprehensive details on how to use the lPC. Explanations of special features, e.g. the codes used and their meanings or a cross –reference to other explanations are stated as well. The last volume in an lPC of 3 or more volumes usually contains a complete index of the entire set. This index will be in numerical order or in alpha –numerical order. Figure 7: Inspection Symbols (Examples) Symbols and signs may still vary but a certain ’standard’ has already been reached to ease the work of maintenance personnel. For Training Purposes Only Issue: August 2014 Page 255 of 926 Modul 7 Engineering Drawings, Diagrams and Standards Breakdown PART 66 – Basic Training Cat B1 – Module 7 comprehend the meaning of these codes and when any doubt exists must seek advice from suitably qualified personnel. Refer to Figure 2 again. The breakdown of the IPC follows the breakdown of the MM, with the contents divided into the same chapters, sections and subjects. However, the 3 –element number is expanded to a 4 –element number (e.g. 77 –00 –00 –01). The reason for this is as follows: The IPC is laid out with illustrations and the corresponding detailed parts lists on facing pages, continuing if necessary on succeeding pages. This layout permits easy cross –reference from illustration to detailed parts list. The first left –hand page in any section or subject is numbered page 0, with the facing page (i.e. the parts list) numbered page 1. If there is more than one illustration in a subject, each of the illustrations (figure 01, figure 02, etc.) and the related detailed parts lists in that subject will be numbered page 0, page 1, etc., resulting in more than one page 0, page 1, etc., in that subject, depending on the number of illustrations. It is therefore necessary to extend the normal 3 –element identification number ’Chapter – Section – Subject’ to a 4 – element number, with the figure number of the illustration used as the 4th element ’Chapter – Section – Subject – Figure’. Examples of codes which could be found are: code AX: install at any level of maintenance code BX: install at second line (hangar) maintenance only code CX: not procured; replace higher assembly code DX: not procured (an identification error may clarify this code or it may be a structural fitting). Other codes indicate expendable and non –expendable materials, aircraft maintenance levels, such as first line, second line, depot and contract maintenance, cost indicators etc. These codes may vary depending on the manufacturers of aircraft and equipment. Nowadays, the IPCs of most aircraft indicate chapters and sections according to the ATA –100 system. This means that the same numbering system is used in both, the IPC and the appropriate maintenance manual, i.e. sub –systems, parts etc. can be found in both documents under the same chapter/section designation. Typical Illustrated Parts Catalogue Note: The following details are extracted from the ’DORNIER 328 lllustrated Parts Catalogue’. They serve as an example only. General Information Codes The codes shown in an lPC are of particular interest to maintenance personnel and should be studied carefully. They contain information about ordering of replacements, disposal of unserviceable parts, repair potential of certain parts, etc. Maintenance personnel must fully For Training Purposes Only This illustrated parts catalogue has been prepared in accordance with ATA Specification 100 established by the Air Transport Association of America and is intended as a companion document, not a substitute for the associated maintenance and engine manuals which shall be considered the authority on assembly procedures. Issue: August 2014 Page 256 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 The purpose of this lPC is to list and illustrate replaceable assemblies and detail parts of the DORNIER 328 aircraft. Arrangement of Detailed Parts List The detailed parts list presents the aircraft divided into sections which match the breakdown used in the associated maintenance and engine manuals. These sections are further broken down into their assemblies and detail parts, intended to show item relationship back to the next highest assembly. Refer to Figure 8. Figure 8: IPC Detailed Parts List (Example) For Training Purposes Only Issue: August 2014 Page 257 of 926 Modul 7 Engineering Drawings, Diagrams and Standards Figure/Item Numbers Each item listed in the catalogue is allocated a ’fig/item’ number which serves as a cross - reference for illustrations and numerical indexing purposes. The numbers are arranged in numerical sequence but gaps are left to allow for the insertion of additional items. The addition of a suffix letter to either a figure or item number denotes a variant. Part Numbers Part numbers identify assemblies and parts which are related to a set of documents (drawing, list of materials etc.). The part number comprises the basic part and the necessary suffixes for the designation of assembly/detail part number and manufacturer. A 15 character code is used, e.g. ’001A112A5001200’. National standard part numbers are identifiable by the following prefixes: A or SP British Standards Institute (B.S.l.) AGS or AS Society of British Aerospace Companies (S.B.A.C.) Standards AN, MS or NAS American Standards DIN Deutsche Industrienorm (German Industrial Standard). PART 66 – Basic Training Cat B1 – Module 7 recurrence of that item in other positions. To assess whether or not a part recurs, reference should be made to the numerical parts list index. Arrangements or items shown for reference purposes but which are normally listed with all necessary information in another figure of the IPC carry the letters ’REF’ (meaning: ’reference’) in the units - per assembly column. Items where the required quantity can only be determined during assembly, e.g. shims, carry the abbreviation ’AR’ (meaning: ’as required’). The letters ’NP’ indicate that the item is not procurable. Illustrations Refer to Figure 9. Each assembly, sub - assembly or unit is illustrated, mostly with an exploded view to show detail parts. The parts are shown in the order of assembly/installation. Refer to Figure 10. Nomenclature The column ’NOMENCLATURE’ states the name of the part. Parts having the same name, e.g. ’bolt’, ’placard’, need to be clearly identified from the appropriate illustration. Units per Assembly The number of units per assembly (’UNITS PER ASSY’) indicates the quantity required in the position shown and does not preclude the For Training Purposes Only Issue: August 2014 Page 258 of 926 Modul 7 Engineering Drawings, Diagrams and Standards Figure 9: IPC Illustration of Locations (Example) For Training Purposes Only PART 66 – Basic Training Cat B1 – Module 7 Figure 10: IPC Illustrations of Parts and Items (Example) Issue: August 2014 Page 259 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 When it is impracticable to completely explode an assembly on one sheet, the illustration may be divided into separate breakdowns showing the exploded view of sub –assemblies on the second and possibly on subsequent sheets. This applies as well if the scale of the drawing does not provide clear identification of the individual part(s). Numerical Parts Index Refer to Figure 11. To enable identification of parts by using only their specific part numbers a numerical parts index (or: ’cross –reference part number/chapter –section number (CSN) (from ATA 100)’) is attached. This index is broken down into conveniently sized parts to enable selective update. Parts follow in alpha –numerical sequential order. The arrangement of part numbers begins in the left –hand position and continues from left to right, one column at a time until the part number sequence has been accomplished. How to Use the Catalogue Refer to Figure 12. Figure 11: IPC Numerical Index (Example) For Training Purposes Only Issue: August 2014 Page 260 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 Figure 12: Use of IPC with Part Number Known For Training Purposes Only Issue: August 2014 Page 261 of 926 Modul 7 Engineering Drawings, Diagrams and Standards To identify an item when only the part number is known: 1. Find the part number in the numerical index and note the chapter/section/ subject, figure and item number. 2. Turn to this figure/item number in the detailed parts list. 3. For the description of the desired part, refer to the text. 4. Locate the item in the appropriate illustration. Refer to Figure 13. To identify an item when the part number is not known: 1. Turn to the system’s table of contents in which the major assembly appears and find the section figure number. 2. Turn to the figure where this major assembly is illustrated. 3. Note the item number. 4. Locate the figure and item number in the detailed parts list which shows the part number and the description. Abbreviations In inch LH left –hand LP low –pressure LT low tension mm millimeter Mod. modification o/s oversize REF reference RH right –hand SB service bulletin TR repair scheme. PART 66 – Basic Training Cat B1 – Module 7 Note: The abbreviations listed above can be found in other IPCs as well. Abbreviations used in this illustrated parts catalogues are as follows: AR as required assy assembly dia. diameter ft feet fwd forward HE high energy HFC hydromechanical fuel control HP high –pressure HT high tension For Training Purposes Only Issue: August 2014 Page 262 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 Figure 13: Use of IPC with Part Number Unknown For Training Purposes Only Issue: August 2014 Page 263 of 926 Modul 7 Engineering Drawings, Diagrams and Standards 7.5.11 Aircraft Zoning 7.5.11.1 Airline Requirements for Aircraft Zoning Requirements To enable maintenance planning, preparation of job instructions, location of work areas and components, and a common basis for various maintenance tasks, the following zoning requirements shall be fulfilled: The zoning shall be simple and logical in arrangement. The zoning shall be usable by all airlines as a framework for accomplishing maintenance tasks and yet adaptable to data processing techniques. The zoning should be adaptable to current and future aircraft. The zoning shall permit individual airlines the flexibility to tailor the system, if necessary, to their own use. The zone shall be identified by a three –digit number as the ’standard’. Additional digits may be used for additional, more detailed breakdown. One digit of the zone number shall indicate, where applicable, left or right zones by the use of an odd digit for left side, even digit for the right side. Zones straddling the centerline may be assigned an odd or even zone number. The sequence of zone numbers shall run preferentially from inboard to outboard, front to back in the wing; front to back and away from the floor line in the fuselage and from root to tip in the vertical stabiliser. Major structural components including entrance doors, cabin service doors, cargo doors, landing gears, landing gear doors, rudders, elevators, flaps, ailerons, slots, slats and leading edge devices shall have individual zone numbers For Training Purposes Only PART 66 – Basic Training Cat B1 – Module 7 Wing leading edges, trailing edges, wheel wells, fuel tanks, accessory compartments, flight compartment and other high manpower work areas shall be suitably zoned to define the work area. The zones, wherever possible, shall be defined by actual physical boundaries such as wing spars, major bulkheads, cabin floor, major partitions, control surface boundaries, skin, etc. Internal boundaries in the wing and fuselage normally are of a greater value in establishing zone boundaries than external boundaries such as skin joints, The area enclosed by the wing - to - fuselage fillets shall have individual fuselage zone numbers. The center wing area within the fuselage and area between the wing and the fuselage floor shall have fuselage zone numbers Zone numbers shall be compatible with both passenger and cargo versions of the aircraft. However, for significant differences such as a nose loading door or a large cabin cargo entry door separate new zone numbers shall be assigned. Zone charts or diagrams shall clearly designate zone boundaries and their station numbers. A physical description of the zone boundaries shall be included. In zoning the fuselage, zone boundaries shall not split galleys, toilets or major equipment centers. Zone boundaries shall enclose related structure such as door jambs. That is, a jamb for a specific door shall not be split by a zone boundary. A zone shall be identified by one of the following three manners: Refer to Figure 1. Issue: August 2014 Page 264 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Engineering Drawings, Diagrams and Standards Major Zone Number 100 200 Standard 300 Series Numbers 400 Figure 1: Major Zones of an Airliner – large areas shall be identified by a three digit 100 series number as follows: For Training Purposes Only Special Series Issue: August 2014 Area Lower half of fuselage to rear pressure bulkhead; ’lower half’ means the area below the main cabin deck Upper half of fuselage to rear pressure bulkhead;’upper half’ means the area above the main cabin deck Empennage Powerplants and struts 500 Left wing 600 Right wing 700 Landing gear and landing gear doors 800 Load –carrying, latchable doors 900 Reserved for uncommon differences between aircraft types not covered by standard series numbers pressure –barrier Page 265 of 926 and Modul 7 Engineering Drawings, Diagrams and Standards – division of the 100 series zones is accomplished by subzoning on the basis of the second digit in the zone number. As an example, major zone 300 may be subzoned as follows: Major Subzone Number Area 310 Fuselage aft of pressure bulkhead 320 Vertical stabiliser and rudder 330 Left horizontal stabiliser and elevator 340 Right horizontal stabiliser and elevator – divisions of sub –zones are accomplished by use of the third digit in the zone numbers. As an example, zone 320 may be divided as follows: Zone Number Area 321 Vertical stabiliser leading edge 322 Vertical stabiliser auxiliary spar to front spar 323 Front spar to rear spar 324 Rear spar to trailing edge 325 Lower rudder 326 Upper rudder 327 Vertical stabiliser tip – The application of the zoning arrangement shall permit to define a work task or inspection area by any one of the three manners of zone identification. For example, an external inspection of the exterior of the empennage may be specified as follows depending upon the area desired to be inspected: For Training Purposes Only PART 66 – Basic Training Cat B1 – Module 7 Issue: August 2014 Zone 300 ... inspect external structure (entire major zone) Zone 320 ... inspect external structure (vertical stabiliser and rudder) Zone 321 ... inspect external structure (vertical stabiliser leading edge) Page 266 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 Numbering of Major Zones and Subzones Note: ’STA’ means ’station’, ’WS’ means ’wing station’; ’WBL’ means ’wing buttock line’. Major Zone 100 Refer to Figure 2. Figure 2: Major Zone 100 (Typical) For Training Purposes Only Issue: August 2014 Page 267 of 926 Modul 7 Engineering Drawings, Diagrams and Standards Major zone 100 Sub –major zone 110 sub –major zone 120 sub –major zone 130 sub –major zone 140 sub –major zone 150 sub –major zone 190 PART 66 – Basic Training Cat B1 – Module 7 lower half of fuselage station 90 to station 460 station 460 to station 1000 station 1000 to station 1480 station 1480 to station 2160 station 2160 to station 2360 fairings station 760 to station 1700. Major Zone 500 Refer to Figure 3. Major zone 500 Sub –major zone 510 sub –major zone 520 sub –major zone 530 sub –major zone 540 sub –major zone 550 sub –major zone 560 sub –major zone 570 sub –major zone 580 sub –major zone 590 left wing leading edge to front spar from WBL 128.4575 to WBL 470 leading edge to front spar from WBL 470 to WBL 834 leading edge to front spar from WBL 834 to WBL 1169 front spar to rear spar from WBL 128.4575 to WBL 470 front spar to rear spar from WBL 470 to WBL 834 front spar to rear spar from WBL 834 to WBL 1169 rear spar to trailing edge from WBL 128.4574 to WBL 515 rear spar to trailing edge from WBL 515 to WBL 849 rear spar to trailing edge from WBL 849 to WBL 1169. For Training Purposes Only Issue: August 2014 Page 268 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 Figure 3: Major Zone 500 (Typical) For Training Purposes Only Issue: August 2014 Page 269 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 Major Zone 800 Refer to Figure 4. Figure 4: Major Zone 800 (Typical) For Training Purposes Only Issue: August 2014 Page 270 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Engineering Drawings, Diagrams and Standards Major zone 800 Sub –major zone 810 sub –major zone 820 sub –major zone 830 sub –major zone 840 doors, load carrying –, pressure barrier, latchable –, (passenger, crew, cargo, equipment access) lower half of fuselage, left side, from station 90 to station 2360 lower half of fuselage, right side, from station 90 to station 2360 upper half of fuselage, left side, from station 134.75 to station 2360 upper half of fuselage, right side, from station 134.75 to station 2360. Airline Requirements for Access Door and Panel Identification T B L R Z Scope This portion of the specification defines the requirements for access door and panel identification. The requirements presented here shall be coordinated with the actual markings on access doors and panels to ensure a system which best suits the maintenance needs of the airlines. Requirements Aircraft maintenance manuals, illustrated parts catalogues, wiring manuals and structural repair manuals shall contain appropriate access identification diagrams which clearly show the position of access doors, service doors, fillets, fairings, removable radio rack access panels, removable floor panels, removable cargo pit panels and removable ceiling panels. All maintenance access doors, service doors, fillets, fairings, removable radio rack access panels, removable floor panels, removable cargo pit panels and removable ceiling panels shall be identified as follows: For Training Purposes Only The identification shall be prefixed by the three –digit zone number that designates the smallest zone in which the door is located. Normally, a two letter suffix shall be utilised consisting of a primary identifier and a locator. A third suffix may be used to further identify floor, wall and ceiling panels. The first letter is the primary letter identifying the door in a logical sequence, i.e. inboard to outboard or front to rear, starting with ’A’ within each zone. The second letter (or: locator) fixes the door in its relation to the aircraft, if required, e.g. top bottom left hand right hand internal. The third suffix, consisting of six letters, may be added to further identify floor, wall and ceiling panels as follows: F - G *) W - X *) C - D *) floor wall (side) panels ceiling panels Note: *) = Letters G, X, and D will only be used after F, W and C have been used up. Example: The code used for a left - hand floor panel in zone 251, using three suffix letters,is: Issue: August 2014 Page 271 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 A door located on a zone boundary shall be numbered according to the zone from which it is removed (whenever possible, zone boundaries shall not divide a door). Further examples of access panel identification using two suffix letters are: – 521 AT Top of wing – 521 CB Bottom of wing – 321 AL Vertical stabiliser, left side – 321 AZ Internal vertical stabiliser. Cabin entrance doors, cargo doors and main landing gear doors shall be identified by the zone number only since each is a zone in itself The letters I and O shall not be used Blow –out doors and tank vents need not be assigned access door identifications. Doors in the fuselage centerline shall be assigned a left –zone number. Doors in the vertical stabiliser and rudder shall be identified from bottom to top Corresponding doors on opposite sides of the aircraft shall have the same letter designator even though zone numbers will differ. When one door is located on a larger door the large door shall be lettered first. If a door lies in more than one zone the lowest zone number involved shall be used. For Training Purposes Only Issue: August 2014 Page 272 of 926 Modul 7 Engineering Drawings, Diagrams and Standards 7.5.11.2 Airline Requirements for Designation of Engine Areas, Engine - Mounted Components/Parts and Access Ports PART 66 – Basic Training Cat B1 – Module 7 Location of engine –mounted parts/components and engine interior access ports (chambers/borescope) shall be identified by their location and clock position (e.g. diffuser case, 3 o’clock This portion of the specification defines the requirements for method(s) of designation of engine areas, engine –mounted components and access ports to engine interior. These methods should be consistently adhered to throughout the publication/ manual. Requirements Maintenance and other supplemental engine manuals shall contain specific statements indicating the methods used to easily identify engine –related areas, parts/components and access ports. The statements on methods of identification should be contained in the description and operation part of the manual. In cases of ambiguity, an illustration or a table providing exact identification shall be included. Application Main engine areas shall be identified by their function (e.g. diffuser, turbine, etc.). Main bearings shall be referred to as to their location by using numbers. In the interest of brevity and clarity, main bearings and their companion seals will be referred to by number. Directional references as to right and left, clockwise and counterclockwise, upper and lower, apply to the engine as viewed from the rear (exhaust end) with the engine being in the normally installed flight position. For Training Purposes Only Issue: August 2014 Page 273 of 926 Modul 7 Engineering Drawings, Diagrams and Standards 7.5.12 General Units, Standards and Definations 7.5.12.1 SI Units The units of quantities most commonly used in electrical engineering, such as volts, amperes, watts, ohms, etc., are those of the metric system. They are embodied in the International System of Units (Système International d‘Unités, abbreviated SI). The SI units are used throughout the courses, in accordance with the established practice of electrical engineering publications throughout the world. The SI electrical units are based on the ’mksa’ (meter –kilogram – second –ampere) system. They have been adopted by standardisation bodies throughout the world, including the: International Electrotechnical Commission (IEC) American National Standard Institute (ANSI) Standard Board of the Institute of Electrical and Electronic Engineers (IEEE). CGPM Basic Quantities Seven quantities have been adopted by the General Conference on Weights and Measures (CGPM) as basic quantities, that is, quantities that are not derived from other quantities. The units of the basic quantities have been defined by the CGPM as follows: Meter The length equal to 1,650,763.73 wavelengths in vacuum of the radiation corresponding to the transition between the levels 2p10 and 5d5 of the krypton –86 atom (CGPM, 1960) Kilogram The unit of mass; it is equal to the mass of the international prototype of the kilogram (CGPM, 1901). Note: The kilogram is approximately equal to the mass of 1,000 cubic centimeters of water at maximum density temperature. The prototype is a platinum –iridium cylinder maintained at the International Bureau of Weights and Measures near Paris. Length Mass Tim electric current For Training Purposes Only thermodynamic temperature amount of substance luminous intensity. The table shown in Figure 1, detail a), lists these quantities, gives the SI unit for each, and the standard letter symbol by which each is designated in the International System. Refer to Figure 1. These basic quantities are PART 66 – Basic Training Cat B1 – Module 7 Issue: August 2014 Second The duration of 9,192,631,770 periods of the radiation corresponding to the transition between the two hyperfine levels of the ground state of the caesium –133 atom (CGPM, 1967). Ampere The constant current that, if it were maintained in two straight, parallel conductors of infinite lengths, of negligible circular cross-sections, and placed 1 meter apart in vacuum, would produce a force equal to 2 ∙ 10 –7 newton per meter of length between these conductors (CGPM, 1948). Page 274 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 Kelvin The unit of thermodynamic temperature is the fraction 1/273.16 of the thermodynamic temperature at the triple point of water (CGPM, 1967). Note: Zero on the Celsius scale (the freezing point of water) is defined as 0.01 K below the triple point, that is 273.15 K. Mole That amount of substance of a system that contains as many elementary entities as there are atoms in 0.012 kilogram of carbon –12 (CGPM, 1971). Note: When mole is used, the elementary entities must be specified. They may be atoms, molecules, ions, electrons, other particles, or specified groups of such particles. Candela The luminous intensity, in a given direction, of a source that emits monochromate radiation of a frequency of 540 ∙ 1012 Hz and that has a radiant intensity in that direction of 1/683 watt per steradian (CGPM, 1979). Supplementary SI Units Two supplementary SI units, numerics which are considered dimensionless units, are the radian and the steradian for the quantities plane angle and solid angle, respectively. Refer to Figure 1 again. Figure 1: SI Units and SI Supplementary Units For Training Purposes Only Issue: August 2014 Page 275 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 Figure 1, detail b), lists these quantities, their units and symbols. The supplementary units are defined as: Radian The plane angle between two radii of a circle which cut off an arc equal in length to the radius on the circumference (CGPM, 1960). Steradian The solid angle which, having its vertex in the center of a sphere, cuts off an area of the surface of the sphere equal to that of a sphere with sides equal to the radius of the sphere (CGPM, 1960). Derived SI Units Most of the quantities and units used in electrical engineering fall in the category of SI derived units, that is, units which can be completely defined in terms of the basic and supplementary quantities described before. Refer to Figure 2. Figure 2: Derived SI Units, Their Designation Symbols and Definitions For Training Purposes Only Issue: August 2014 Page 276 of 926 Modul 7 Engineering Drawings, Diagrams and Standards The table shown in Figure 2 lists the principal electrical quantities in the SI system, and shows their definitions in terms of other units. The definitions of these quantities, as they appear in the ’IEEE Standard Dictionary of Electrical and Electronic Terms’ are: Hertz The unit of frequency, 1 cycle per second Newton The force that will impart an acceleration of 1 meter per second to a mass of 1 kg Pascal The pressure exerted by a force of 1 newton uniformly distributed on a surface of 1 square meter Joule The work done by a force of 1 newton acting through a distance of 1 meter Watt The power required to do work at the rate of 1 joule per second Coulomb The quantity of electric charge that passes any cross –section of a conductor in 1 second when the current is maintained constant at 1 ampere Volt The potential difference between two points of a conducting wire carrying a constant current of 1 ampere, when the power dissipated between these points is 1 watt Farad The capacitance of a capacitor in which a charge of 1 coulomb produces 1 volt potential difference between its terminals Ohm The resistance of a conductor related to a constant current of 1 ampere in it which produces a voltage of 1 volt between the conductor’s ends Siemens The conductance of a conductor related to a constant voltage of 1 volt between the conductor’s ends which produces a current of 1 ampere in it Weber The magnetic flux whose decrease to zero provided it is linked with a single turn induces a voltage whose time integral is 1 volt/second in the turn Tesla The magnetic induction equal to 1 weber per square meter For Training Purposes Only PART 66 – Basic Training Cat B1 – Module 7 Henry The inductance for which the induced voltage in volts is numerically equal to the rate of change of current in amperes per second Lumen The flux through a solid state angle (steradian) from a uniform point source of 1 candela; the flux on a unit surface whose entire points are at unit distance from a uniform point source of 1 candela Lux The illumination on a surface of 1 square meter on which a flux of 1 lumen is uniformly distributed; the illumination produced on a surface whose entire points are at a distance of 1 meter from a uniform point source of 1 candela. Refer to Figure 3. The table shown in Figure 3 lists further derived quantities which are not designated by individual names but are used in engineering applications. SI Decimal Prefixes All SI units may have standard prefixes affixed to them, which multiply the indicated quantity by a power of 10. Issue: August 2014 Page 277 of 926 Modul 7 Engineering Drawings, Diagrams and Standards Figure 3: Common Derived SI Units and Formulas (without Individual Designations or Symbols) For Training Purposes Only PART 66 – Basic Training Cat B1 – Module 7 Figure 4: SI Prefixes and Time/Angle Units Issue: August 2014 Page 278 of 926 Modul 7 Engineering Drawings, Diagrams and Standards The table shown in Figure 4, detail a) lists standard prefixes and their symbols. A substantial part of the extensive range covered by these prefixes is in common use in electrical engineering, e.g. PART 66 – Basic Training Cat B1 – Module 7 The letter symbols serve the function of abbreviations; they are used without periods. Compounding gigawatt gigahertz nanosecond picofarad, etc. Compounding a prefix, e.g. micromicrofarad, is no longer used. The correct term is picofarad. Usage of SI Units, Symbols and Prefixes Spelling Care must be exercised in using SI symbols and prefixes to follow exactly capital –letter and lower –case –letter usage prescribed. Example: pA (picoampere) is the SI symbol for 10 –12 of the SI unit for electrical current, while Pa, the pascal, is the SI symbol for pressure. The spelled –out names of the SI units, e.g. volt, ampere, watt, are not capitalised. The SI letter symbols are capitalised only when the name of the unit stands for, or is directly derived from, the name of a person. Examples are: V for volt, after the Italian physicist Alessandro Volta (1745 to 1827) A for ampere, after the French physicist André Ampère (1775 to 1836) W for watt, after the Scottish engineer James Watt (1736 to 1819). For Training Purposes Only With the exception of ampere, all the SI electrical quantities are derived from the SI base and supplementary units, or from the SI derived units. Thus, many of the short names of SI units may be expressed in compound form embracing the SI units from which they are derived. Examples: volt per ampere for ohm joule per second for watt ampere –second for coloumb watt –second for joule. Such compound usage is permissible, but in engineering publications the short names are customarily used. The use of SI prefixes with non –SI units is not recommended; the only exception is the microinch. Non –SI units which are related to the metric system but are not decimal multiples of the SI units, such as calorie, torr, and kilogram –force, should be avoided. Units of Time Refer to Figure 4 again. A particular problem arises with the universally used units of time, such as minute, hour, day, year, that are non –decimal multiples of the second. The table shown in Figure 4, detail b), lists these and their equivalents in seconds, as well as their standard symbols. Issue: August 2014 Page 279 of 926 Modul 7 Engineering Drawings, Diagrams and Standards The watthour (Wh) is such a case; it is equal to 3,600 joules. The kilowatthour (kWh) is equal to 3,600,000 joules or 3.6 megajoules (MJ). In the late 1980’s the use of the kilowatthour persisted widely, although eventually it was expected to be replaced by the megajoule, with the conversion factor 3.6 megajoules per kilowatthour. PART 66 – Basic Training Cat B1 – Module 7 Note: The definitions shown in Figures 5 to 9 are based on the principal meanings listed in the ’IEEE Standard Dictionary’ which should be consulted for extended meanings, compounded terms and related definitions. Some Special Cases Frequency The CGPM has adopted the designation ’hertz’ as the unit of frequency. Magnetic flux density The CGPM has adopted the designation ’tesla’ as the SI unit of magnetic flux density. The name ’gamma’ shall not be used for the unit ’nanotesla’. Temperature scale The CGPM abandoned ’centigrade’ as the name of the temperature scale. The corresponding scale is now properly named ’Celsius scale’. Luminous intensity The SI unit of luminous intensity has been given the name ’candela’. The term ’candle –power’, either as designation or quantity or as the name of a unit, is no longer used. Luminous flux density The common British –American unit of luminous flux density is ’lumen per square foot’. Micrometer and micron The designations ’micron’ for micrometer and ’millimicron’ for nanometer are no longer used. Gigaelectronvolt (GeV) Because billion means a thousand million in the United States, but used to be a million million in most other countries, its use should be avoided in technical writing. The term ’billion electronvolts’ is no longer used; ’giga electronvolts’ should be used instead. 7.5.12.2 Definitions of Electrical Quantities Refer to Figures 5 to 9. For Training Purposes Only Figure 5: Standard Symbols of Quantities (Space and Time) Issue: August 2014 Page 280 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 Figure 7: Standard Symbols of Quantities (Radiation and Light) Figure 6: Standard Symbols of Quantities (Mechanics and Heat) For Training Purposes Only Issue: August 2014 Page 281 of 926 Modul 7 Engineering Drawings, Diagrams and Standards Figure 8: Standard Symbols of Quantities (Fields and Circuits, Part 1) For Training Purposes Only PART 66 – Basic Training Cat B1 – Module 7 Figure 9: Standard Symbols of Quantities (Fields and Circuits, Part 2) Issue: August 2014 Page 282 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 Airdcraft Manufacturing Regulations: 7.5.12.3 Standards used in Transport Aviation Standards are documentented aggrements containing technical specifications or other precise criteria to be used consistendly as rules, guidelines or definations of characteristics. This is to ensure that material, products, processes and services are fit for ther purpose. The following list show the most used Standards for transport aviation: JAR FAR Joint Aviation Regulations Federal Aviation Regulations Aircraft Manuals: ATA Air Transport Association of America Materials: AAA AISI AMS SAE American Aluminum Association American Iron and Steel Institute Aerospace Material Specification Society of Automotive Engineers Hardware: AN MS HMS MILSPEC NAS AS UNC UNF BPS ISO Airforce Navy Standard Military Standard Harrison Military Aviation Standard Military Specification National Aerospace Standard Aeronautical Standard Unified National, Coarse Unified National Fine Boeing Process Standard International Standard Organisation For Training Purposes Only Issue: August 2014 Page 283 of 926 Modul 7 Engineering Drawings, Diagrams and Standards 7.5.13 Fundamentals of Power Circuits 7.5.13.1 Representation of Voltages and Currents PART 66 – Basic Training Cat B1 – Module 7 According to IEEE standard 268 –1992 the symbols ’U’ and ’u’ are used to designate electric voltage. The letter ’E’ is more commonly used instead of UEMF to designate the electromagnetic force (EMF) of a voltage source. Occasionally the letter ’V’ might also be used to define voltage. But since this letter is also used to designate the unit ’volt’ (’V’) for volt(s) (for example V = 3 V), the letter ’U’ is preferred to designate voltage (U = 3 V), thus avoiding ambiguity. The capital letter ’U’ is used for voltages which do not vary with respect to time, i.e. for DC voltages. If changes in voltage occur with respect to time, the lower –case letter ’u’ is used. If several voltages have to be represented in a circuit, they are marked by subscripts, such as UR, US or UG. Electric currents are represented by ’I’ and ’i’, whereby capital letter ’I’ and lower-case –letter ’i’ have the same significance as ’U’ and ’u’ in the case of voltages. Figure 1: Representation of Voltages and Currents Figure 1 gives an example how currents and voltages are represented in a circuit diagram. There are different ways to represent current flow and direction of voltage in circuit diagrams. In principle, two different ways can be distinguished: Refer to Figure 1. The current flows from the positive pole to the negative pole of the source (e.g. battery). In the case of DC, the voltage arrow points to the same direction (from the positive to the negative pole). The current flows from the negative to the positive pole of the battery (DC). The voltage arrow points to the same direction (from the negative to the positive pole of the battery). Note: On the basis of the IEEE standards (and if not otherwise indicated) the agreement for all circuit diagrams is as follows: For Training Purposes Only Issue: August 2014 Page 284 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 Current always flows from the positive to the negative pole of the source. The DC voltage arrow points to the same direction, i.e. from the positive to the negative pole of the source. In the DC circuit depicted in Figure 1, detail a), the direction of the arrow indicates the conventional flow of current, i.e. from the positive pole to the negative pole of the source. Accordingly, the voltage arrow points from the positive to the negative pole of the voltage source, as well. In an AC circuit, as shown in Figure 1, detail b), however, magnitude and direction of voltage vary as a function of time. Therefore the arrows can correctly indicate an instantaneous value only. Thus, arrows generally provide little information. Arrows are nevertheless used for alternating and mixed quantities, because there, their application can be of advantage in the measurement of electrical quantities, for example. Measurement of Voltages and Currents Refer to Figure 2. Figure 2: Measurement of Voltages and Currents The magnitude and direction of voltages and currents can be determined using electrical measurement instruments. Figure 2 shows voltmeters and an amperemeter (ammeter) connected in a DC circuit. Voltmeters are always connected in parallel with the voltage source, i.e. at points between which the voltage occurs. DC voltmeter operation is direction –dependent; DC voltmeters therefore have a positive and negative terminal. A DC voltmeter can consequently also determine the direction of voltage. In AC voltmeters, which are used to measure AC voltages, the needle deflection is always in one direction, regardless of the polarity. Ammeters are basically connected in the current flow, i.e. in series with the load. In practice, multimeters are frequently used. By appropriate switching, these can be used to measure DC and AC voltages and currents in For Training Purposes Only Issue: August 2014 Page 285 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 different measuring ranges. With modern electronic digital multimeters, it is often not necessary to take care of polarity when connecting them, because the polarity of the measured value is shown by an indicator. Arrow System It is often necessary to measure or calculate voltages and currents of circuits. In doing so, both the value and the direction of electrical quantities have to be determined. Voltages and currents can be represented in circuit diagrams by arrows. These arrows are primarily used to indicate type and direction, but not the magnitude of the voltage. Reference Point It proves expedient, or even essential, to establish an unambiguous reference point, in addition to the arrows for voltage and currents. This reference point is usually referred to as ’ground’, ’earth’, ’chassis’ or ’frame’. Figure 3: Representing the Reference Point by a Frame/Chassis Symbol In DC circuits, the negative pole of the DC voltage source is generally chosen as the reference point. Figure 3 shows two examples serving for the representation of circuits. The frame/chassis is used as reference point. Refer to Figure 3. In Figure 3, detail a), the reference point is specified by indicating the chassis at the negative pole of the battery. Figure 3, detail b), shows another form of representation common in electronics. In this case, both the negative pole of the battery and the negative pole of the load are separately grounded. This means that there is an electrical connection between these two points, even if it is not shown in the circuit diagram. It is, however, by no means obligatory to make the negative pole of a voltage source the reference point, e.g. frame or chassis. When special measurements in electronic circuits are made, in particular, it For Training Purposes Only Issue: August 2014 Page 286 of 926 Modul 7 Engineering Drawings, Diagrams and Standards is often expedient to select another point in the circuit as reference point. PART 66 – Basic Training Cat B1 – Module 7 common reference point for all voltages present, the reference point of the voltage will usually not be given in the subscript. Such a representation is shown in Figure 4, detail b). Subscripts Voltage arrows drawn in extensive electronic circuit diagrams make such diagrams difficult to read. No voltage arrows are therefore shown in large circuit diagrams, and the subscripts are also omitted, provided ground is the reference point. Such a simplified representation is shown in Figure 4, detail c). Refer to Figure 4. Magnitude of Voltages Refer to Figure 5. Figure 4: Representation of Voltages by Arrows and Subscripts An electric voltage is the potential difference between two points. A voltage is consequently not only represented by an arrow but by the symbol U with subscripts. These subscripts indicate the points between which the voltage occurs. Several examples of such designations are represented in Figure 4. In Figure 4, detail a), the voltage is represented by the directions of the arrows. The voltage direction is, however, also apparent from the order of letters given as subscripts for voltage U. The reference point is conventionally always given as the second letter. If an unambiguous ground is specified in a circuit and if this is a For Training Purposes Only Figure 5: Indication of Voltage Values Representations of voltages by arrows and symbols with subscripts indicate the directions of the voltages, but not their magnitudes. The magnitude is consequently indicated by additional numerical values, which may have a positive or negative sign. A few examples are given in Figure 5. In detail a), point A is more positive than point B. The arrow correctly indicates the voltage direction from the more –positive point to the more –negative point. The associated voltage value is positive, i.e. Issue: August 2014 Page 287 of 926 Modul 7 Engineering Drawings, Diagrams and Standards UAB = +12 V. This is the conventional way of denoting voltage. All other possible designations of voltage can be related to it. Although detail b) shows the same state of affairs as detail a), this voltage value requires a negative sign. The negative sign indicates that the direction of the arrow does not agree with the conventional arrow direction from the positive to the negative pole. Mathematically, the following relationships can be stated: PART 66 – Basic Training Cat B1 – Module 7 Point ’G’ is positive in relation to point ’F’. Refer to Figure 6. UAB = +12 V UBA = –12 V –UBA = +12 V. Since the two voltages UAB and UBA are equal to +12 V: UAB = –UBA. Details c) and d) show further examples of voltage designations, in which none of the points between which the voltage is measured is at zero or at ground potential. In details e) and f), representations with an unambiguous reference point are shown. Example: In a circuit, a voltage of - 6 V with respect to point ’G’ is measured at point ’F’ with a voltmeter. How can this relationship be represented by arrows and which point is positive in relation to the other? Figure 6: Representation of Voltages across Voltage Sources and Loads Electric voltages occur both across sources (Figure 6, detail a)) and across loads (detail b)), and can then be measured at their terminals. These two consequently need to be represented. This is done by the above mentioned method, but with a few more details to be considered, as shown in Figure 6. Provided the points between which the voltage is determined are specified, the voltage can be indicated using subscripts, e.g. UAB or UCD. On condition that there is no risk of confusion, this precise designation is usually neglected, and the voltage is represented by an For Training Purposes Only Issue: August 2014 Page 288 of 926 Modul 7 Engineering Drawings, Diagrams and Standards arrow parallel to the component and by symbol ’U’ or ’u’, with only the one significant subscript appended, e.g. UR, UL, and so on. Representation of Currents Refer to Figure 7. PART 66 – Basic Training Cat B1 – Module 7 In detail b), the direction of the current has been reversed. The current is therefore indicated with a negative sign. Detail c) shows the same situation, but the negative sign is not added to the physical quantity, but to its value. Additional designations of currents with subscripts, such as IR, ITOT, iL, and so on, are customary. However, no terminal points are indicated in this instance, since currents, unlike voltages, do not differ between two points. 7.5.13.2 Circuit Diagram Letter Codes and Symbols To read and understand schematic diagrams, a knowledge of electric symbols is necessary. Electrical diagrams are part of system manuals or equipment manuals so the electrician must be able to interpret these diagrams, including the symbols. Refer to Figures 8 to 10. Figure 7: Representing Currents by Arrows Currents are easier to represent than voltages. If current direction and the direction selected for the arrow coincide, the current will be indicated by a positive value. If, on the other hand, the directions of current and arrow are opposite to each other, the current will be indicated by a negative sign. The various possibilities for designating currents are shown in Figure 7. In detail a), the direction of the arrow corresponds to the conventional current direction, i.e. the current flows from the positive to the negative pole of the battery and the DC voltage arrow points to the same direction (from the positive to the negative pole). For Training Purposes Only Issue: August 2014 Page 289 of 926 Modul 7 Engineering Drawings, Diagrams and Standards Figure 8: Letter Code for Electrical System Components (A – B) For Training Purposes Only PART 66 – Basic Training Cat B1 – Module 7 Figure 9: Letter Code for Electrical System Components (K – U) Issue: August 2014 Page 290 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 Figure 10: Letter Code for Electrical System Components (V – Z) According to various standards the kind of equipment may be identified by a single letter. This can be allotted to an individual item of equipment and also to a combination of various items, e.g. a starter with limit switch. For the identification of a particular item the letter code may be completed with a consecutive number. Figures 8 to 10 give the letter code of the German DIN 40719 as an example. Refer to Figure 11. For Training Purposes Only Issue: August 2014 Page 291 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 Figure 11: Circuit Breaker Connection Diagram For Training Purposes Only Issue: August 2014 Page 292 of 926 Modul 7 Engineering Drawings, Diagrams and Standards Figure 11 shows the use of this letter code in the internal connection diagram of a generator circuit breaker. It is apparent that all auxiliary switches are marked by the letter ’S’ regardless of whether they are manually operated (push –buttons) or interlocked with the circuit breaker. They are marked by an additional number and can thus be identified easily. S14, for example, is the designation of the switch which is attached to over –current and short –circuit release showing the respective state. PART 66 – Basic Training Cat B1 – Module 7 Note: In the following not the complete variety of symbols is shown, but some are given as examples of symbols commonly used in electrical and electronic engineering. Refer to Figures 12 to 18. These Figures show various graphic symbols of electrotechnical devices according to the IEC standard 617. In most countries the IEC standard publications are used as reference for drawing circuit diagrams. The protective devices in this circuit are the fuses F10 to F13 and the releases F4 and F6. The electrically operated mechanical release of the energy store is identified by Y1. H1 identifies the lamp showing the circuit breaker state. The terminals connecting the circuit breaker module to the peripheral devices are arranged as terminal strips and marked X5 to X8. The individual terminals are numbered separately. In most countries the IEC standard publications are used as reference for drawing circuit diagrams. Therefore this example will be described in more detail. The most important standards in use are the American standard the British standard the German standard. The German standard DIN 40 900, which defines the symbols to be used in circuit drawings, is derived from the international standard IEC 617. Therefore all symbols in DIN 40 900 are identical to those specified in the international standard IEC 617. For Training Purposes Only Issue: August 2014 Page 293 of 926 Modul 7 Engineering Drawings, Diagrams and Standards Figure 12: Examples of IEC Symbols (Earth and Connections) For Training Purposes Only PART 66 – Basic Training Cat B1 – Module 7 Figure 13: Example of IEC Symbols (R, C and L) Issue: August 2014 Page 294 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Engineering Drawings, Diagrams and Standards Figure 14: Examples of IEC Symbols (Transformers and Semiconductors) For Training Purposes Only Figure 15: IEC Mechanisms Issue: August 2014 Symbols of Switches, Switchgear Page 295 of 926 and Modul 7 Engineering Drawings, Diagrams and Standards Figure 16: IEC Symbols (Operating Devices, Releases and Electric Motors) For Training Purposes Only PART 66 – Basic Training Cat B1 – Module 7 Figure 17: IEC Symbols (Measuring Devices, Signalling Devices, Couplings, Brakes) Issue: August 2014 Page 296 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 In order to trace a particular symbol, the complete set has been divided into the following categories: Denomination Figure Earth and connection symbols R, L and C symbols 12 13 Note: The ’preferred form’ is commonly used in German publications whereas the ’other form’ is commonly favoured in American and British publications. Transformers and semiconductor symbols 14 Symbols of switches, switchgear and mechanisms 15 Symbols of operating devices, releases and electrical motors 16 Symbols of measuring devices, signalling devices, couplings and brakes Symbols of conductors and junctions 17 18. This collection of symbols will serve as a reference guide during the following subjects, as well. Refer to Figures 19 to 21. Figure 18: IEC Symbols (Conductors and Junctions) For Training Purposes Only Issue: August 2014 Page 297 of 926 Modul 7 Engineering Drawings, Diagrams and Standards Figure 19: Comparison of Standards (Basic Symbols) For Training Purposes Only PART 66 – Basic Training Cat B1 – Module 7 Figure 20: Comparison of Standards (Machines and Relays) Issue: August 2014 Page 298 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 Equally important symbols used in the field of electrical engineering are British Standard (BS) symbols and symbols defined by the American National Standard Institute (ANSI). Figures 19 to 21 show examples of circuit symbols used in the most important standards IEC, BS and ANSI. 7.5.13.3 Types of Diagrams The graphic representation of a circuit system in electrical engineering is contained in circuit diagrams. They include information on various functional features and modes of operation, switchgears and devices, and sometimes enormous quantities of wiring, terminals and designations. The circuit diagram must give clear information on all concerns of planning, assembly, maintenance and trouble –shooting. For this reason, common symbols, codes, designations and types of diagram are laid down in standards. The most important types of diagram are: block diagram one –line diagram circuit diagram schematic diagram. Refer to Figure 22. Figure 21: Comparison of Standards (Connections, Fuses and Switches) For Training Purposes Only Issue: August 2014 Page 299 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 A clear and precise diagram make –up and arrangement needs the following general rules to be observed: The diagram must be structured in a top –to –bottom and left – to –right reading direction. The line circuit or power line must be drawn lying in the upper part and the load in the lower part of the diagram. All circuit lines must be drawn in vertical or horizontal arrangement (no diagonal or oblique routing is allowed). The electrical symbols should, if possible, be arranged uniformly in vertical current paths, so that they can be located quickly by the current path numbers later on. All contact mechanisms are shown in their normal (off) positions. So, for instance, a normally –open (NO) contact is shown in the open position and a normally –closed (NC) contact is shown in the closed position. Any deviation from this principle requires a special note in the drawing. Each electrical device, switchgear or contact mechanism is coded by an identifier. For the distinction of identical units, a number is added to the identifying letter. One –Line Diagrams Refer to Figure 23. Figure 22: Circuit Diagram Rules For Training Purposes Only Issue: August 2014 Page 300 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Engineering Drawings, Diagrams and Standards The one –line diagram is an extremely simplified representation of a circuit system without auxiliary lines and auxiliary equipment. Figure 23 shows that the overall diagram contains only the effective parts of the main circuit and the circuit codes. In order to avoid confusion in a circuit with more than one identical component, they are coded vertically and horizontally. Components in the same current path advance by one number, i.e. F1, F2, F3 etc. Current codes in other current paths are prefixed by the current path number, i.e. 10F1, 11F1, 12F1 etc. Meaning of codes in this example: Q 10F1, 11F1 10K1, 11K1, 12K1 10F2, 11F2, 12F1 10M1, 11M1, 12M1 Main switch (tripolar) Line protection panels Main contactors Motor protection relays Three –phase asynchronous motors. From this diagram, the order and type or size of the main switchgear and the number of main circuits can be seen. Functional relations and sequences of circuit control cannot be shown in an overall diagram. For this purpose a schematic diagram is used. Figure 23: One – Line Diagram For Training Purposes Only Issue: August 2014 Page 301 of 926 Modul 7 Engineering Drawings, Diagrams and Standards Block Diagrams PART 66 – Basic Training Cat B1 – Module 7 A special type of diagram is the block diagram, where the electrical relationships between component groups (assemblies) are illustrated. Figure 24 shows an alarm system, in which a horn will be operated via a relay, as soon as the bridge circuit is triggered by the alarm signal. Power is supplied by a mains rectifier circuit and a battery. Meaning of codes in this example: Refer to Figure 24. A1 A2 B1, B2 G1 G2 H1 S1 Bridge circuit Relay circuit Burglar alarm signal transmitter Power supply unit Battery Horn Push–to–test button. Wiring Diagram A wiring diagram shows all the main and auxiliary lines of a circuit. It must give a clear representation of the electrical connections between the devices involved in a system. The switching and the driving elements are drawn on the same working line so that the operating function of the switchgears can be seen. Circuit functions cannot be easily understood from such a diagram. This is particularly true in very complex circuits which have many lines crossing each other. Refer to Figure 25. Figure 24: Block Diagram For Training Purposes Only Issue: August 2014 Page 302 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Engineering Drawings, Diagrams and Standards From this circuit diagram, the arrangement of components, the line connections, the location of terminals and the number of conductors of the connecting lines can be seen. Larger (more extensive) circuits are better drawn as schematic diagrams to ensure clarity. Meaning of codes in this example: F0 F1 F2 S1 S01 H1, H2 H01 K1, a M Control circuit fuse Main circuit fuses Thermal overload protection Start push –button Stop push –button Switch –on indicator lamps Cut –out control lamp Main contactor Main motor. Schematic Circuit Diagram The schematic circuit diagram is the functional representation of a circuit. All the branched electrical lines with their crossings are split up and put together in an ordered logical scheme, i.e. the current paths. To get a diagram without crossing lines, the contact mechanisms and drives of a switchgear can be arranged in different places on the schematic diagram. Refer to Figure 26. Figure 25: Wiring Diagram For Training Purposes Only Issue: August 2014 Page 303 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 Figure 26 shows the circuit diagram with and without identifying letter codes. As shown in detail a), with missing or incomplete identification, the functional circuitry features remain unclear. From detail b), one can clearly see that the signal lamps H1 and H2 are operated by relay K. All control circuits are based on the procedure of signal generation and its routing and conversion. Apart from the simple on – and off –functions, a circuit structure may be made up with additional and combined circuits involving NC and NO contacts, change –over contacts, etc. Circuit diagrams in standard form are the most widely used ones. This is why they are often simply called ’circuit diagrams’. Principles of Representation Refer to Figure 27. Figure 26: Component Identification in Circuit Diagrams For Training Purposes Only Issue: August 2014 Page 304 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 The components of a functional unit, such as a solenoid, the main contacts and the NC and the NO contacts must in any case be given identical designations. Distinction between several identical contact mechanisms of an electrical device may be made by stating the respective terminals (for example main contacts of K1 in detail a) and coil and auxiliary contacts of K1 in detail b)). All vertical current paths containing contact mechanisms shall be labelled with the respective current path numbers in a consecutive left –to –right order. The numbers are stated at the bottom of the circuit diagram of the control circuit, and on top of the circuit diagram of the main circuit. Beneath large schematic diagrams the path numbers of each branch must be shown (detail c)). When comparing the diagrams shown in Figure 25 and Figure 27, the differences are obvious. In the wiring diagram the components are drawn in their local and mechanical relationships. In the schematic diagram the components are drawn in their logical relationship. This makes it much easier to understand the function of a circuit. Figure 27: Schematic Circuit Diagram Note: The main circuit and the control circuit together, as drawn in this circuit diagram, represent the same circuit as shown in Figure 25. The following measures are required for the clear organization of a schematic circuit diagram: The power supply system must be arranged in a horizontal order, with vertical, not crossing current paths. Diagonal or otherwise slanted (oblique) arrangements of electrical lines should be avoided. This system allows the equipment units to be arranged vertically, one succeeding the other in the direction of current flow. For Training Purposes Only Mechanical links between switchgear components are often left out because all mechanically connected components are identified by the same name. Example: has Issue: August 2014 The contactor in the circuit shown in Figures 25 and 27 three main contacts two NO auxiliary contacts and one NC auxiliary contact. Page 305 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 In Figure 25 all the contacts and the contactor coil are connected by a broken line representing the mechanical link. In Figure 27, detail a), only the main contacts and the coil are drawn and connected. the coil designation written next to the symbol of the contact. In order to identify different contacts of one relay or contactor, the terminal numbers may be added. In the control circuit diagram (Figure 27, detail b)) the coil and the auxiliary contacts are drawn but not connected. In this case the designation ’K1’, common to coil and contacts, represents the mechanical link and simultaneous operation. It is quite easy to read the main circuit diagram (Figure 27, detail a)). From the mains supply lines (L1, L2, L3) branch lines lead to the fuses F1 and to the main contacts of contactor K1. If all the fuses are okay and the contactor is energised (i.e. the main contacts are closed) current will flow through the heating elements of overload protection F2 to the motor. The motor will run. In the main circuit diagram only the heating elements of overload protection F2 are drawn. The NC contact of this protection is drawn in the control circuit diagram, to which it belongs logically. Reading a Circuit Diagram Refer to Figure 27 again. To read a schematic diagram, one must start from the left –hand side of the top line and proceed to the right and downwards. If a contact is open, the current will not go through; if it is closed, the current will go through. In order to energise the coil or another device in the circuit, every contact and switch must be closed to form a complete path. In other words, if there is an open contact, the coil will be dead; if not, it will be energised. It must be remembered that contacts and switches are normally shown in their off position. The symbols used in schematic diagrams must have some means of indicating what operates them and on what component they will be found. Since they have been put in their electrical position instead of their physical one in the circuit, the different contacts of a relay might be scattered from one end of the diagram to the other. In order to identify the relay coil and its various contacts, a unique designation (letter code) must be chosen and written next to the coil symbol. Each of the contacts that are operated by this coil will have For Training Purposes Only The requirements for contactor K1 to close or open can be read from the control circuit diagram (Figure 27, detail b)). A branch line from mains line L1 supplies the control circuit via fuse F0. This protects the complete control circuit. The next steps are the NC contacts of F2 and S01. Under normal conditions both contacts are closed and allow current to flow to the terminals of S1 and of the auxiliary contacts of K1. The NC contact of K1 in current path 3 (terminals 12 –11) allows current to flow through the indicating lamp H01. Under normal conditions, this lamp is on, as long as the supply voltage is present. If switch S1 is closed current will flow to the coil of K1 and energise the contactor. Now all the contacts of K1 change their state, i.e. all NO contacts close, the motor runs and the NC contact opens. After the NC contact in current path 3 is open, the lamp H01 will be off. The NO contacts in current paths 2 and 4 will close and switch on the indicating lamps H1 and H2. If the NO contact of S1 is open again, the contact of K1 in current path 2 will still supply the coil of K1. The control circuit will remain in this state until either S01 or F2 interrupts the supply. Issue: August 2014 Page 306 of 926 Modul 7 Engineering Drawings, Diagrams and Standards Other Standards Refer to Figure 28. PART 66 – Basic Training Cat B1 – Module 7 When introducing the symbols of electrical engineering, it was stated that the German symbols are used for the representation of electrical circuits. In manufacturers’ manuals, on the other hand, circuits may be drawn according to other standards. The circuit diagrams in Figure 28 show the differences between two standards: the US standard ’NEMA’ the German standard ’DIN’. Note: In both diagrams the same electrical circuit is illustrated. The circuit diagram (detail b)) shows that this motor control circuit consists of seven components: One motor (M) One main contactor (K1) with three main contacts and one NO auxiliary contact Three overload protection devices (F1, F2, F3) with one NC contact each One ’start’ push –button (S1, NO) One ’stop’ push –button (S01, NC). All these components can be found in the NEMA standard diagram as well (detail a)). The motor and the ’start’ and ’stop’ push –buttons can easily be identified. They have descriptive labels. The contactor coil is represented by a circle. The letter ’M’ in the circle indicates that this is the coil of a main contactor. The main contacts of the contactor are marked as ’line contacts’. The overload protection elements are designated as ’OL’ and identified by T1, T2 and T3. Their NC contacts are drawn next to the respective heating elements. Figure 28: Circuit Diagrams according to Different Standards For Training Purposes Only Issue: August 2014 Page 307 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 The lines of the control circuit are marked by an additional number at both ends. Line No. 1 leads from the mains line L1 to the ’stop’ push – button. Line No. 2 leads from the ’stop’ push –button to the ’start’ push – button and to the auxiliary contact of the main contactor. Line No. 3 connects the auxiliary contact to the ’start’ push –button and to the contactor coil. Line No. 4 connects the coil to the first overload protection device. Lines No. 5 and No. 6 connect the OL devices. Line No. 7, at least, leads to the mains line L2. Note: These line designations must not be misunderstood as terminal numbers. 7.5.13.4 Standard Phase Notations and Markings for Motors and Generators Terminal Many different standards are used to designate and identify the phases of motors and generators. Refer to Figure 29. Figure 29 gives an overview about the German DIN standard phase notations (detail a)), alternative phase notations (detail b)) and terminal markings for motors and generators (detail c)). Additionally, the colours of the terminal connections are stated. Figure 29: Terminal Markings on Three—phase Motors and Generators For Training Purposes Only Issue: August 2014 Page 308 of 926 Modul 7 Engineering Drawings, Diagrams and Standards 7.5.14 PART 66 – Basic Training Cat B1 – Module 7 Wiring Diagrams Standardised logic symbols are used to understand and read aircraft wiring diagrams. They can be found in most diagrams regardless of the manufacturer. The most frequently used symbols are listed in the following Table For Training Purposes Only Issue: August 2014 Page 309 of 926 Modul 7 Engineering Drawings, Diagrams and Standards For Training Purposes Only Issue: August 2014 PART 66 – Basic Training Cat B1 – Module 7 Page 310 of 926 Modul 7 Engineering Drawings, Diagrams and Standards For Training Purposes Only Issue: August 2014 PART 66 – Basic Training Cat B1 – Module 7 Page 311 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Engineering Drawings, Diagrams and Standards In addition to the symbols, there are also abbreviations used for identifying individual components. The examples listed below are taken from a typical aircraft wiring diagram: AN aeronautical norm ANT antenna ANTI COLL anti –collision A ampere ANTI –ICE anti –icing equipment/system A/D analogue to digital AOA angle of attack A/E airfoil/engine intake AOAS angle of attack sensor AC alternating current AP autopilot ACARS aircraft communication and reporting system APU auxiliary power unit ACCU accumulator ASCB avionic standard communications bus ACL anti –collision light ASI airspeed indicator ACTR actuator ASP audio selector panel ACU audio control unit ATC air traffic control ADC air data computer ATCRBS air traffic control radar beacon system ADF automatic direction finding AUX auxiliary ADI attitude deviation indicator AV avionic ADS air data system B blue ADU air data unit BARC barometric altitude computer AFC automatic frequency control BAT battery (electrical) AFCS automatic flight control system BC bus control (controller) AHRS attitude and heading reference system BCN beacon AHRU attitude and heading reference unit BPCU bus protection and control unit AI attitude indicator BRKR breaker AMP amplifier BT bus tie For Training Purposes Only Issue: August 2014 Page 312 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Engineering Drawings, Diagrams and Standards BTC bus tie contactor CNTOR contactor BTR bus tie relay COM communication BU battery unit COMP compass CAA Civil Aviation Authority (UK) CONTR control CAB PRESS CPLR coupler CAP capacitor CPU central processing unit CAS calibrated airspeed CSDB common source data base C/B circuit breaker CT current transformer CCW counter –clockwise CTC cabin temperature control CD control display CTL control/display unit CD –ROM compact disc – read –only memory CTR center CDI course deviation indicator CU control unit CDL configuration deviation list CVR cockpit voice recorder CDU control display unit CW clockwise CFG constant frequency generator CWS control wheel steering CG center of gravity D/A digital to analogue CHAN channel DAB digital audio bus CHIP DET chip detector DADC digital air data computer CKPT cockpit DADS digital air data system CL center –line DAU data acquisition unit CLB climb DB decibel CMPTR computer DC direct current CNCTR connector DC/DC direct current to direct current converter For Training Purposes Only cabin pressurisation Issue: August 2014 Page 313 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Engineering Drawings, Diagrams and Standards DCDR decoder EEC electronic engine control DE –ICE de –icing equipment/system EFCC electronic flight control computer DECR decrease EFCV ejector flow control valve DEG degree EFIS electronic flight instrument system DF direction finder EGT exhaust gas temperature DFDR digital flight data recorder EHSI electronic horizontal situation indicator DG directional gyro EICAS electronic DIA diameter DIM dimming EIS electronic instrument system DISC disconnect EL equipment list DISTR distribution ELEC electric/electrical DM data module ELEV elevator DME distance measuring equipment ELT emergency locator transmitter DMU data management unit EMC electromagnetic compatibility DN down EMERG emergency DON DORNIER norm ENG engine DU display unit EPC external power contactor DWG drawing EPU emergency power unit ECB electronic control box ESS essential ECS environmental control system EV electrovalve ECU engine control unit EVM engine vibration monitoring system EDP electronic data processing EWS electronic warning system EDS electronic display system EXT external For Training Purposes Only indication caution and system Issue: August 2014 Page 314 of 926 advisory PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Engineering Drawings, Diagrams and Standards EXTING extinguishing GALY galley FAA Federal Aviation Administration (USA) GB gearbox FD flight director GCU generator control unit FDR flight data recorder GDCP guidance and display control panel FDS flight director system GEN generator FF fuel flow GLC generator line contactor FIG figure GLR generator line relay FLT flight GMT Greenwich Mean Time FM flight manual GND ground FMC flight management computer GPC ground power connector FMS flight management system GPCU ground power control unit FQ fuel quantity GPPU ground power protection unit FR frame GPS global positioning system FREQ frequency GPU ground power unit FSB fasten seat belt GPWC ground proximity warning computer FT/MN feet per minute GPWS ground proximity warning system FUS fuselage GS ground speed FV flux valve GSE ground support equipment FWC flight warning computer GYRO gyroscope FWD forward H (or: h) hour FWS flight warning system HDG heading GA go –around HECS Hall effect current sensor GAL gallon HF high frequency For Training Purposes Only Issue: August 2014 Page 315 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Engineering Drawings, Diagrams and Standards HG horizontal gyro ILLUM illumination HGS HUD guidance system ILS instrument landing system HISL high intensity strobe light IMC instrument meteorological condition HLD hold IN HG inches of mercury HMU hydro –mechanical unit (fuel) INCR increase HOR STAB horizontal stabiliser IND indicator HP high pressure INS inertial navigation system HPA hectopascal INST instrument HRS hours INU inertial navigation unit HSI horizontal situation indicator INV inverter HYD hydraulic IPC Illustrated Parts Catalogue HZ hertz IRS inertial reference system IAC integrated avionic computer IAS indicated airspeed ISG instrument symbol generator ICAO International Civil Aviation Organisation ISS inner section stabiliser ICU integrated communication unit ISW inner section wing IDG integrated drive generator ITEM Illustrated Tool and Equipment Manual IDP integrated data processing ITT interturbine temperature IEDS integrated electronic display system JB junction box IF intermediate frequency JIC Job Instruction Card IFMS integrated flight management system KG kilogram KHZ kilohertz IFR instrument flight rules KIAS knots indicated airspeed IGN ignition KT knot(s) For Training Purposes Only IRU inertial reference unit Issue: August 2014 Page 316 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Engineering Drawings, Diagrams and Standards KV kilovolt MIL military LCM list of consumable materials min minute LCV load control valve MIN. minimum LDG landing MIN. ALT LED light –emitting diode MIN. FUEL minimum fuel LEP list of effective pages MIN. TIME minimum time LG landing gear MLG main landing gear LH left hand (side) MLS microwave landing system LIRS laser inertial reference system MM maintenance manual LOC localiser MOD modification LOX liquid oxygen MSL mean sea level LWR lower MSW microswitch M Mach MSW middle section wing MAG magnetic MWC master warning computer MAN manual MWP master warning panel MAX. maximum MWS master warning system MB millibar N north MECH mechanic/mechanical NAV navigation MEL minimum equipment list NCU navigation computer unit MEM memory NDB non direction beacon MFD multifunction display NEG negative MFR manufacturer NH high pressure rotor speed MHZ megahertz NLG nose landing gear For Training Purposes Only Issue: August 2014 minimum altitude Page 317 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Engineering Drawings, Diagrams and Standards NM nautical mile PNL panel NO number PNS position navigation system NORM normal POH pilot’s operating handbook NP propeller speed POS position NSM no smoking PPH pounds per hour NTS negative torque system PREAMP preamplifier NUM numerical PRESS pressurisation NWS nose wheel steering PRIM primary OAT outside air temperature PROP propeller OBS omnibearing selector PROX proximity ONS omega navigation system PSEU proximity switch electronic unit OSC oscillator PSI pound per square inch OSS outer section stabiliser PSU passenger service unit OSW outer section wing PUB publication OVHD overhead PUBLICS publication –, information – and control system OVHT overheat PWR power OVV overvoltage QTY quantity OXY oxygen QTZ quartz PAX passenger R radial PCU power control unit R red PFD primary flight display R/T radio transmission PLT pilot RA radio altimeter PN part number RADAR radio detection and ranging For Training Purposes Only Issue: August 2014 Page 318 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Engineering Drawings, Diagrams and Standards RAM random access memory SAF safety RAS radio altimeter system SAR search and rescue RB radio beacon SB service bulletin RBI relative bearing indicator (ADF) SCN specification change notice RCPT receptacle SEC secondary RCVR receiver SECT section REL release SEL select REPL BY replaced by SGU symbol generator unit RETR retract SHLD shield REV revision SHP shaft horse power RF radio frequency SIG signal RFC request for change SMK smoke RH right hand (side) SOL solenoid RLY relay SOV shut –off valve RMI radio magnetic indicator SP splice RMS radio management system SPBK speed brake RMU radio management unit SPEC specification RPM revolution per minute SPKR speaker RST reset STA station RTN return STAB stabiliser RUD rudder STAT static S (or: s) second STBY stand –by S south STD standard For Training Purposes Only Issue: August 2014 Page 319 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Engineering Drawings, Diagrams and Standards STDY steady UHF ultra high frequency STL WARN stall warning UNS universal navigation system STOL short take-off and landing US GAL US gallons SW switch V volt SYM symmetry V/UHF very/ultra high frequency SYS system VENT ventilation TACAN tactical air navigation VERT vertical TACAS (or TCAS) traffic alert and collision avoidance system VFR visual flight rules TACH tachometer VG vertical gyro TAS true airspeed VHF very high frequency TAT total air temperature VIB vibration TB terminal block VLF very low frequency TDU time display unit VMTR voltmeter TEL telephone VOL volume TEMP temperature VOR VHF omnidirectional radio range TGT turbine gas temperature VSI vertical speed indicator TMR timer WDI wind direction indicator TOC table of contents WDW window TQ torque WM wiring manual TSC torque signal conditioner WOW weight on wheels TURB turbine WRS weather radar system TYP typical WSHLD windshield UFDR universal flight data recorder WXR weather radar For Training Purposes Only Issue: August 2014 Page 320 of 926 Modul 7 Engineering Drawings, Diagrams and Standards X trans – XCVR transceiver XDCR transducer XFEED crossfeed XFMR transformer XFR transfer XMTR transmitter XPDR transponder Y yellow. PART 66 – Basic Training Cat B1 – Module 7 These symbols and abbreviations are only used for identifying individual components in the appropriate systems. Refer to Figure 1. Figure 1: Circuit Function Codes (Examples) For Training Purposes Only Issue: August 2014 Page 321 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 The systems themselves are marked with the circuit function codes as shown in Figure 1. As there is a broken wire, for example, the identification stamped on the wire must be looked for. Then the system, where the wire belongs to, can be found and troubleshooting can be continued. Refer to Figures 2 to 10. Figures 2 to 10 show examples of electric circuits as laid down in aircraft wiring diagrams. Note: The pitot heating circuit (Figures 4 and 5), the overhead panel lighting wiring diagram (Figures 6, 7 and 8) and the electrical diagram of the overhead panel lighting (Figures 9 and 10) are too large to be shown on one page. They have been divided into two or three parts. The encircled letters in these figures indicate the connections to the following (or previous) part. Figure 3: Fuel Pump Circuit of a Helicopter (Example) Figure 2: Fuel Valve Circuit of a Helicopter (Example) For Training Purposes Only Issue: August 2014 Page 322 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 Figure 4: Typical Pitot Heating Circuit (Left–hand Part) For Training Purposes Only Issue: August 2014 Page 323 of 926 Modul 7 Engineering Drawings, Diagrams and Standards PART 66 – Basic Training Cat B1 – Module 7 Figure 5: Typical Pitot Heating Circuit (Right–hand Part) Figure 6: Overhead Panel Lighting Wiring Diagram (Left–hand Part) For Training Purposes Only Issue: August 2014 Page 324 of 926 Modul 7 Engineering Drawings, Diagrams and Standards Figure 7: Overhead Panel Lighting Wiring Diagram (Center Part) For Training Purposes Only PART 66 – Basic Training Cat B1 – Module 7 Figure 8: Overhead Panel Lighting Wiring Diagram (Right –hand Part) Issue: August 2014 Page 325 of 926 Modul 7 Engineering Drawings, Diagrams and Standards Figure 9: Overhead Panel Lighting, Electrical Schematic (Left– hand Part) For Training Purposes Only PART 66 – Basic Training Cat B1 – Module 7 Figure 10: Overhead Panel Lighting, Electrical Schematic (Righthand Part) Issue: August 2014 Page 326 of 926 Modul 7 Fits and Clearances 7.6 Fits and Clearances 7.6.1 Tolerances 7.6.1.1 Basics of Tolerances and Fits PART 66 – Basic Training Cat B1 – Module 7 Dimensional Deviations Refer to Figure 1. It is necessary that the dimensions, shape and mutual position of surfaces of individual parts of mechanical engineering products are kept within a certain accuracy to achieve their correct and reliable functioning. Routine production processes do not allow maintenance (or measurement) of the given geometrical properties with absolute accuracy. Actual surfaces of the produced parts therefore differ from ideal surfaces prescribed in drawings. Deviations of actual surfaces are divided into four groups (dimensional, shape, position and surface roughness) to enable assessment, prescription and checking of the permitted inaccuracy during production. Actual dimensions will always be slightly different from the nominal dimensions. In an industrial approach, the necessary tolerances are already designed –in to control these deviations and to guarantee specification, function and performance of the tooling for all production pieces over the whole lifetime of the tooling. Tight tolerances are expensive. Efficient tolerancing means to apply tight tolerances only when and where they are really necessary. Therefore, different tolerances are applied to different dimensions, special tolerances (narrower and more expensive) to the critical dimensions of a design. Other, less important dimensions get (wider) general tolerances. Figure 1: Typical Dimensional Deviations For Training Purposes Only Issue: August 2014 Page 327 of 926 Modul 7 Fits and Clearances PART 66 – Basic Training Cat B1 – Module 7 Basic Terms of a Fit Refer to Figure 2. Figure 2: Tolerances of a Coupling Fit For Training Purposes Only Issue: August 2014 Page 328 of 926 Modul 7 Fits and Clearances PART 66 – Basic Training Cat B1 – Module 7 It is principally impossible to produce machine parts with absolute dimensional accuracy. In fact, it is not even necessary or useful. It is quite sufficient that the actual dimensions of a part are between two limiting values and a permissible deviation is kept during production to ensure correct functioning of engineering products. The required level of accuracy in the production of a part is given by the dimensional tolerance which is prescribed in the drawing. The production accuracy is prescribed with regards to the functionality of the product and to the economy of production. Figure 2 shows a coupling of two parts which create a fit whose functional character is determined by differences in their dimensions before their coupling. Refer to Figure 3. Example: Figure 3 shows a fit example of a shaft with a tolerance of 13 mm. The coupled hole has a tolerance of 21 mm. Furthermore it can be seen that the loosest fit has a maximum clearance of 34 mm and the tightest fit an allowance of 0 mm. For Training Purposes Only Issue: August 2014 Page 329 of 926 Modul 7 Fits and Clearances PART 66 – Basic Training Cat B1 – Module 7 Figure 3: Limiting Dimensions of a Coupling Fit (Example) For Training Purposes Only Issue: August 2014 Page 330 of 926 Modul 7 Fits and Clearances PART 66 – Basic Training Cat B1 – Module 7 Causes for Tolerances Type of Fits Fabrication Tolerances Refer to Figure 4. Each machining (or other workshop) process has a certain process capability. Therefore, the corresponding fabrication tolerances should be allowed when applying such a process. Process capability and required tolerances should match. On an individual case –to –case basis, it is possible to exceed the standard process capability. An experienced machinist can perform a kind of artist’s work to make one or few workpieces more accurate. But this is a risky and probably costly method which should be avoided in professional designs. Material Tolerances Figure 4: Types of Fits Depending on the mutual position of tolerance zones of the coupled parts, three types of fit can be distinguished: Clearance fit This is a fit that always ensures a clearance between the hole and shaft in the coupling. The lower –limit size of the hole is greater or at least equal to the upper –limit size of the shaft. Transition fit This is a fit where (depending on the actual sizes of the hole and shaft) both clearance and interference may occur in the coupling. Tolerance zones of the hole and shaft interfere partially or completely. Interference fit This is a fit having always some interference between the hole and the shaft in the coupling. The upper –limit size of the hole is smaller or at least equal to the lower –limit size of the shaft. For Training Purposes Only During machining (or other processes), engineering materials are subject to mechanical stress, heat, lubricants etc. After machining, the workpiece tends to react to these effects: it may change its size and volume, i.e. it expands or shrinks it may change its shape, i.e. it warps or bends. Some of these changes happen very soon after machining, but in some cases it takes days or even weeks (which makes it very difficult to control the changes). These changes can be caused by different phenomenons, for example: already existing stresses and inhomogenities in the raw material can become visible after machining structural changes during heating –up resp. heat –treatment swelling and shrinking of plastics due to changes in water content. Issue: August 2014 Page 331 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Fits and Clearances General Tolerances Thermal Tolerances Each material has a thermal expansion coefficient which describes the expansion and contraction under temperature changes. Tolerance Control When defining tolerances in a design it may be helpful to make use of proven standards. The German standard DIN 7168 provides sets of general tolerances, in three groups ’fine’, ’medium’ and ’coarse’, and depending of the dimension value (all values in mm): Tolerance control is the design task to make all parts of a tooling fit and work together (functional tolerance) taking into account reasonable restrictions coming from engineering material and workshop processes. Dimension range (mm) Fine Medium Coarse Up to 6 ± 0.05 ± 0.1 ± 0.2 For more complicated toolings, tolerance control may be a complicated task when looking at the interaction of the different parts of the tooling. Above 6 up to 30 ± 0.1 ± 0.2 ± 0.5 Above 30 to 120 ± 0.15 ± 0.3 ± 0.8 Above 120 up to 315 ± 0.2 ± 0.5 ± 0.8 Above 315 up to 1,000 ± 0.3 ± 1.2 ± 2.0 Two basic problems have to be solved by tolerance control: The hole - shaft problem: A shaft has to fit into a hole with a certain clearance. The ’ISO System of Limits and Fits’ is a very valuable support to control this problem. The distance - between - holes problem: The tolerance of the distance between two holes (and the distance between the corresponding shafts) must allow the two hole/shaft pairs to fit within their clearance limits. Efficient tooling recommends: For Training Purposes Only Issue: August 2014 for not too complicated parts, the 6 –mm to 30 –mm range can be used for all dimensions generally, the tolerance group ’fine’ should be used for high – precision parts only generally, the tolerance group ’medium’ should be used for semi –precision parts and critical machine spare parts generally, the tolerance group ’coarse’ should be used for all other parts. Page 332 of 926 Modul 7 Fits and Clearances PART 66 – Basic Training Cat B1 – Module 7 Special Tolerances Some guide –lines should be observed when defining special tolerances: tight tolerances should be applied to critical and some functional dimensions only. Poor tolerance control is not a good reason for narrow tolerances but proof of an unprofessional design fabrication and material tolerance conditions must be observed. Extensive use should be made of the ISO fit system which is an excellent support for tolerance control. nominal dimensions and tolerances should never be mixed up: use asymmetric tolerances instead. Example: The diameter of an undersized shaft should be −0,2 −0,5 instead of ∅ 29.65 ± 0.15 indicated as ∅ 30 7.6.1.2 Standards for Fits and Clearances ISO Standard 286 ’System of Limits and Fits’ Refer to Figure 5. The ISO standard 286 is identical with the European standard EN 20286 and defines an internationally recognised system of tolerances, deviations and fits. The ISO 286 is used as an international standard for linear dimension tolerances and has been accepted in most industrially developed countries in identical or modified wording as a national standard (e.g. JIS B 0401 (Japan), DIN ISO 286 (Germany), BS EN 20286 (UK), CSN EN 20286 (Canada)). Figure 5: ISO Tolerances For Training Purposes Only Issue: August 2014 Page 333 of 926 Modul 7 Fits and Clearances PART 66 – Basic Training Cat B1 – Module 7 The ISO 286 can be applied in tolerances and deviations of smooth parts and for fits created by their coupling. It is used particularly for cylindrical parts with round sections. Tolerances and deviations in this standard can also be applied in smooth parts of other sections. Similarly, the standard can be used for coupling (fits) of cylindrical parts and for fits with parts having two parallel surfaces (e.g. fits of keys in grooves). The term ’shaft’ as used in this standard has a wide meaning and serves for specification of all outer elements of the part, including those elements which do not have cylindrical shapes. Also, the term ’hole’ can be used for specification of all inner elements regardless of their shape Tolerance of a Basic Size for Specific Tolerance Grade The tolerance of a size is defined as the difference between the upper and lower limit dimensions of the part. In order to meet the requirements of various production branches for accuracy of the product, the ISO 286 implements 20 grades of accuracy. Each of the tolerances of this system is marked ’IT’ with attached grade of accuracy (IT01, IT0, IT1 ... IT18) The ISO 286 defines the following tolerance grades: IT01 to IT6 IT5 to IT12 IT11 to IT16 IT16 to IT18 IT11 to IT18 dimensions. For production of gauges and measuring instruments For fits in precision and general engineering For production of semi –products For structures For specification of limit deviations of non –tolerated Hole Tolerance Zones Refer to Figure 6. For Training Purposes Only Figure 6: Position of the Tolerance Zones to the Basic Line Issue: August 2014 Page 334 of 926 Modul 7 Fits and Clearances A tolerance zone is defined as a spherical zone limited by the upper and lower limit dimensions of the part. The tolerance zone is therefore determined by the amount of the tolerance and its position related to the basic size. The position of the tolerance zone, related to the basic size (basic line), is determined in the ISO 286 by a so –called basic deviation. The ISO 286 defines 28 classes of basic deviations for holes. These classes are marked by capital letters (A, B, C, ... ZC). PART 66 – Basic Training Cat B1 – Module 7 tolerance zones is used. An overview of tolerance zones for general use is shown in Figure 8. Though the general sets of basic deviations (A ... ZC) and tolerance grades (IT1 ... IT18) can be used for prescriptions of hole tolerance zones by their mutual combinations, in practice only a limited range of tolerance zones is used. Refer to Figure 7. An overview of tolerance zones for general use is shown in Figure 7. The tolerance zones not included in this table are considered to be special zones, and their use is recommended only in technically well –grounded cases. Shaft Tolerance Zones The ISO 286 defines 28 classes of basic deviations for shafts. These classes are marked by lower –case letters (a, b, c, ... zc). The tolerance zone for the specified dimensions is prescribed in the drawing by a tolerance mark, which consists of a letter marking of the basic deviation and a numerical marking of the tolerance grade (e.g. h7, h6, g5, etc.). Refer to Figure 8. Though the general sets of basic deviations (a ... zc) and tolerance grades (IT1 ... IT18) can be used for prescriptions of shaft tolerance zones by their mutual combinations, in practice only a limited range of For Training Purposes Only Issue: August 2014 Page 335 of 926 Modul 7 Fits and Clearances PART 66 – Basic Training Cat B1 – Module 7 Figure 7: Hole Tolerance Zones According to ISO 286 For Training Purposes Only Issue: August 2014 Page 336 of 926 Modul 7 Fits and Clearances PART 66 – Basic Training Cat B1 – Module 7 Figure 8: Shaft Tolerance Zones According to ISO 286 For Training Purposes Only Issue: August 2014 Page 337 of 926 Modul 7 Fits and Clearances System of Fits PART 66 – Basic Training Cat B1 – Module 7 Although there can be generally coupled parts without any tolerance zones, only two methods of coupling of holes and shafts are recommended due to constructional, technological and economic reasons. Refer to Figure 9. Basic Hole System The desired clearances and interferences in the fit are archived by combinations of various shaft tolerance zones with the hole tolerance zone ’H’. In this system of tolerances and fits, the lower deviation of the hole is always equal to zero. Basic Shaft System The desired clearances and interferences in the fit are archived by combinations of various hole tolerance zones with the shaft tolerance zone ’h’. In this system of tolerances and fits, the upper deviation of the hole is always equal to zero. The option of the system for the specified type of product or production is always influenced by the following factors: construction design of the product and the methods of assembly production procedure and costs for machining the part V type of semi - product and consumption of material. Recommended Fits Refer to Figures 10 and 11. Figure 9: System of Fits For Training Purposes Only Note: The shown lists of recommended fits given are for information only and cannot be taken as a fixed listing. The enumeration of actually used fits may differ depending on the type and field of production, local standards and national usage and last but not least, depending on the plant practices. Issue: August 2014 Page 338 of 926 Modul 7 Fits and Clearances Properties and field of use of some selected fits are described in Figures 10 and 11. When selecting a fit it is often necessary to take into account not only constructional and technological views, but also economic aspects. Selection of a suitable fit is important particularly in view of those measuring instruments, gauges and tools which are implemented in the production. Therefore, when selecting a fit, proven plant practices should be followed. PART 66 – Basic Training Cat B1 – Module 7 The parts can be easily slid one into the other and turn. The tolerance of the coupled parts and fit clearance increases with increasing class of the fit. The ANSI B4.1 standard (established in the USA) defines a system of dimensional tolerances and prescribes a series of those preferred fits of cylindrical parts, which are specified for preferred use. Tolerance of a Basic Size for Specific Tolerance Grades The ANSI B4.1 standard implements 10 tolerance grades to meet the requirements of various production branches for accuracy of products. The system of tolerances is prescribed by the standard for basic sizes up to 200 inches. Types of Fit The standard ANSI B4.1 divides the series of preferred fits into three basic groups according to the type and field of use. Running or Sliding Fits [RC] Refer to Figure 12. This group includes fits with guaranteed clearances which are specified for movable couplings of those parts which have to run or slide one against the other. Fits with guaranteed clearance designed for movable couplings of parts (pivots, running and sliding fits of shafts, guiding bushings, sliding gears and clutch discs, pistons of hydraulic machines, etc.). For Training Purposes Only Issue: August 2014 Page 339 of 926 Modul 7 Fits and Clearances PART 66 – Basic Training Cat B1 – Module 7 Figure 10: Recommended Clearance Fits For Training Purposes Only Issue: August 2014 Page 340 of 926 Modul 7 Fits and Clearances PART 66 – Basic Training Cat B1 – Module 7 Figure 11: Recommended Transition and Interference Fits For Training Purposes Only Issue: August 2014 Page 341 of 926 Modul 7 Fits and Clearances PART 66 – Basic Training Cat B1 – Module 7 Figure 12: Running or Sliding Clearance Fits (RC) For Training Purposes Only Issue: August 2014 Page 342 of 926 Modul 7 Fits and Clearances PART 66 – Basic Training Cat B1 – Module 7 Locational Fits [LC, LT, LN] Refer to Figure 13. Figure 13: Selection of Locational Transition and Force or Shrink Fits For Training Purposes Only Issue: August 2014 Page 343 of 926 Modul 7 Fits and Clearances This group includes clearance or interference fits specified for precise locational positioning of coupled parts. The coupled parts must be fixed mechanically to prevent one moving against the other during assembly. Depending on the locational positioning of tolerance zones of the coupled parts, 3 types of these fits may be distinguished: locational clearance fits [LC]: fits with guaranteed clearances, designed for unmovable couplings where easy assembly and disassembly is required (precise fits of machines and preparations, exchangeable wheels, bearing bushings, retaining and distance rings, parts of machines fixed to shafts using pins, bolts, rivets or welds, etc.). The coupled parts must be fixed mechanically to prevent one moving against the other during assembly. These fits are defined by the standard in a wide range of tolerances and clearances, from tight fits with negligible clearances designed for precise guiding and centering of parts [LC 1, LC 2] up to free fits with great clearances and maximum tolerances [LC 10, LC 11] where easy assembly is the primary requirement. The tolerance of coupled parts and fit clearance increases with increasing class of the fit locational transition fits [LT]: These types include clearance or interference fits designed for demountable unmovable couplings where precision of fits of the coupled parts is the main requirement. The part must be fixed mechanically to prevent one moving against the other during assembly locational interference fits [LN]: Fits with small interferences designed for fixed couplings where precision and rigidity of fits of the coupled parts is the main requirement. These fits cannot be used for transfers of torsional moments using friction forces only; the parts must be secured to prevent one moving against the other. The parts For Training Purposes Only PART 66 – Basic Training Cat B1 – Module 7 can be assembled or disassembled using cold pressing and greater forces or hot pressing. Force or Shrink Fits [FN] Fits with guaranteed interferences designed for fixed (undetachable) coupling of parts (permanent couplings of gears with shafts, bearing bushings, flanges, etc.). These fits are designed for transfers of torsional moments using friction forces between shafts and hubs. The amount of interference (loading capacity of the fit) increases with increasing class of the fit. Mounting of the parts using cold pressing with great pressing forces at different temperatures of the parts. ISO 2768 –1 ’General Tolerances for Linear and Angular Dimensions Without Individual Tolerance Indications’ The ISO 2768 –1 standard is designed for tolerancing of dimensions of machine parts produced by using cutting operations or forming of sheets. It is advisable to use limit deviations defined here also with non –metallic materials. This standard prescribes limit deviations of linear and angular dimensions in four classes of accuracy. When choosing a tolerance class it is necessary (in addition to the constructional aspects) to also take into account the usual accuracy of the production shop. Refer to Figure 14. Issue: August 2014 Page 344 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Fits and Clearances General limit deviations according to ISO 2768 –1 are divided into 3 groups: limit deviations for linear dimensions limit deviations for broken edges limit deviations for angular dimensions. Figure 14 shows the ISO 2768 –1 table of limit deviations for linear dimensions, broken edges and angular dimensions. 7.6.1.3 Inspection Tools Go/Nogo Gauge Refer to Figure 15 and 16 Figure 14: General Tolerances for Linear and Angular Dimensions (ISO 2768 – 1) For Training Purposes Only Issue: August 2014 Page 345 of 926 Modul 7 Fits and Clearances PART 66 – Basic Training Cat B1 – Module 7 Figure 15: Types of Go/Nogo Gauges For Training Purposes Only Issue: August 2014 Page 346 of 926 Modul 7 Fits and Clearances PART 66 – Basic Training Cat B1 – Module 7 Figure 16: Types of Gap Gauges – Go/Nogo Design For Training Purposes Only Issue: August 2014 Page 347 of 926 Modul 7 Fits and Clearances A go/nogo gauge refers to an inspection tool used to check a workpiece against its allowed tolerances. Its name is derived from its use, because actually the gauge provides two tests: the check involves the workpiece’s having to pass one test (’go’) and to fail the other (’no go’). The use of a go/nogo gauge is an integral part of the quality process that is used in the manufacturing industry to ensure interchangeability of parts between processes, or even between different manufacturers. A go/nogo gauge is a measuring tool that does not return a size in the conventional sense, but instead returns a state. The state is either acceptable (the part is within tolerances and may be used) or it is unacceptable (and must be rejected). These gauges are well suited for use in the production area of a factory as they require little skill or interpretation to be used effectively and have few, if any, moving parts to be damaged in the often hostile production environment. PART 66 – Basic Training Cat B1 – Module 7 Example: If a hole is drilled, the maximum metal condition will be when the hole is small and extra metal is ‘left behind’. The minimum metal condition would be when the hole has been overdrilled and as little metal as possible is left behind. The tolerances often set the acceptable maximum and minimum metal conditions. If the features are external, the maximum metal condition is their largest size and the minimum metal condition is their smallest size. Gauge Tolerances Because gauges have to be manufactured themselves, they must also have tolerances assigned. The Unilateral System is very popular: Basic Concepts The go gauge is made near the maximum metal condition. The go gauge must be able to slip inside/over the feature (hole or shaft) of the test specimen without obstruction. a general tolerance of 10% of the work tolerances is applied to both go and nogo gauges if work tolerances are above 0.0035 in., a wear allowance of 5% of the work tolerance is added to the go gauge only all gauge tolerances are made to fall within the work tolerance zones. The effect is that the gauges will always be between the maximum tolerance limits, and no bad parts should be accepted. The only disadvantage is that some good parts will also be rejected. Types of Go/Nogo Gauges The nogo gauge is made near the minimum metal condition. The nogo gauge must not be able to slip inside/over the feature of the test specimen. Plug Gauge Refer to Figure 15 again. Note: The terms ’minimum metal condition’ and ’maximum metal condition’ are used to describe the tolerance state of a workpiece. For Training Purposes Only Plug gauges are used in the manner of a plug. They are generally assembled from standard parts where the gauge portion is interchangeable with other gauge pieces (obtained from a set of pin – Issue: August 2014 Page 348 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Fits and Clearances type gauge blocks) and a body that uses the collet principle to hold the gauges firmly. To use this type of gauge, one end is inserted into the part first and, depending on the result of that test, then the other end is tried. The tolerance of the part checked by this gauge is 0.18 mm where the lower size of the hole is 12.00 mm and the upper size is 12.18 mm. Every size outside this range is out of tolerance. This may be initially expressed on the parts drawing. Refer to Figure 15 again. A thread gauge is screwed into the part to be tested, the go end will enter fully into the part, the nogo end will not. Gap Gauge Refer to Figure 16 again. Figure 16 shows the following types of gap gauges: double –jaw gap gauge: this gap gauge is a measurement tool to check the outside dimension of shafts, bolts etc. The go side of the double –jaw gap gauge is used to measure the upper limit size of the shaft, and the nogo side is to measure the lower limit size of the shaft. single –jaw gap gauge: the usage of this gap gauge may be more intuitive than the use of the plug type. A correctly machined part will pass the upper limit of the jaws and stop at the lower limit of the jaws double pair of jaws thread gauge: For Training Purposes Only 7.6.1.4 Rolling Bearing Shaft and Housing Fits Bearing Fit and Tolerance Refer to Figure 17. In order for a ball or roller bearing to perform satisfactorily, the fit between the inner ring and the shaft, and the fit between the outer ring and the housing must be suitable for the application. Thread Gauge this gauge has four jaws, the outer pair is set using the upper limit (tolerance) of the part and the inner pair is set using the lower limit of the part. Example: Too loose a fit could result in a corroded or scored bearing bore and shaft, while too tight a fit could result in unnecessarily large mounting and dismounting forces, and too great a reduction in internal bearing clearance. All rolling bearing manufacturers make bearings to standardised tolerances set forth by the Anti Friction Bearing Manufacturers Association (AFBMA) and the International Standards Organization (ISO). A proper fit can only be obtained by selecting the proper tolerances for the shaft. Each tolerance is designated by a letter and a numeral. The small letter is for shaft fits, and the capital letter is for housing bores. They locate the tolerance zone in relation to the nominal dimensions, the numeral gives the magnitude of the tolerance zone. Issue: August 2014 Page 349 of 926 Modul 7 Fits and Clearances PART 66 – Basic Training Cat B1 – Module 7 Refer to Figure 18. In Figure 18, detail a), the letter ’X’ indicates the bearing bore tolerance and ’Y’ the bearing outside diameter tolerance. The sectional rectangles indicate the locations and magnitudes of the various shaft and housing tolerance zones which are used for ball and roller bearings. Bearing manufacturers’ catalogues show the specific size for each tolerance zone. The selection of fit is dependent on the character of the load, the bearing dimensions, the bearing operating temperature, the heat expansion of the shaft and other parts, the design and the required running accuracy. The choice of tolerances for bearing housings is influenced by the material and housing wall thickness. Also, consideration must be given to the fact that the shaft deforms differently when it is solid than if it were hollow. Figure 17: Ball Bearing Fit For Training Purposes Only Issue: August 2014 Page 350 of 926 Modul 7 Fits and Clearances PART 66 – Basic Training Cat B1 – Module 7 Refer to Figure 17 again. The dimensions of the abutments provided by the shaft and the housing shoulder must be sufficient in order to get a precise fit, an exact alignment and an axial control with axial loads. On the other hand the abutment surfaces should not come into contact with the shields. The values damin and Damax for the abutment surfaces are indicated in the bearing tables. These tables also mention the minimum fillet radius ramin of each ball bearing. The abutment surfaces fillet radii must consequently be smaller than rsmin.. Refer to Figures 19 and 20. Figure 18: Bearing Fits For Training Purposes Only Issue: August 2014 Page 351 of 926 Modul 7 Fits and Clearances PART 66 – Basic Training Cat B1 – Module 7 Figure 19: Shaft Fit Tolerances For Training Purposes Only Issue: August 2014 Page 352 of 926 Modul 7 Fits and Clearances PART 66 – Basic Training Cat B1 – Module 7 Figure 20: Housing Fit Tolerances For Training Purposes Only Issue: August 2014 Page 353 of 926 Modul 7 Fits and Clearances PART 66 – Basic Training Cat B1 – Module 7 The tables shown in Figures 19 and 20 indicate the machining tolerances of the shafts and the housings which allow appropriate fits. The tolerances (in mm) are only valid with shaft and housing materials, which have the same expansion coefficient. An equivalent condition occurs with a loose –fitted outer ring if there is relative motion between the load direction and the outer ring. Outer ring creeping in a housing is often encountered in applications where there are unbalanced loads. Fits are valid for normal operating temperatures. At high temperatures, it is advisable to check that the radial clearance is not too high. In extreme conditions it is necessary to try to find the best compromise. In both cases, press fits are required to prevent excessive bearing wear. Bearing Wear If a shaft has been correctly designed, the aspects of shaft quality that affect the bearing performance are geometric and dimensional accuracy, surface finish, deflections, material and hardness. Refer to Figure 18 again. To facilitate bearing assembly, many bearings are fitted loosely, i.e. not exactly within the given tolerances, to either the shaft or housing. This will cause considerable wear from differential rolling (or: creeping). Creeping occurs when the loose –fitted ring is rotating with respect to the load direction (see Figure 18, detail b)). The inner ring is held between the shaft and the rolling elements. The velocity of any point on the shaft outside diameter would be equal to the velocity of the inner ring bore, if the motion was pure rolling. But since the shaft circumference is less than the inner ring bore circumference, the inner ring revolves slightly less than one revolution for each full revolution of the shaft, i.e. a relative linear movement occurs. The longer the inner ring creeps, the creeping increases and, consequently, more wear occurs. Example: A bearing fitted 508 mm loose on a shaft rolls a distance of 508 mm per revolution. With an 1,800 rpm shaft speed, the inner ring can creep around the shaft a total distance of 1.7220 km in 100 hours of operation. For Training Purposes Only Bearing Performance The tolerances for geometric accuracy of a shaft are: out –of –round and taper tolerance:1/2 the recommended shaft outside diameter (OD) tolerance runout of shaft shoulder: recommended shaft OD tolerance concentricity of one bearing seat to the other: recommended shaft OD tolerance conformity of bearing seat to a straight edge: 80%. Note: For recommended shaft OD tolerance see manufacturer’s documentation. Out – of – roundness of the shaft can affect the dynamic accuracy of bearing rotation and affect the vibration of a machine. Dimensional accuracy requirements are necessary for both the shaft diameter and the axial locations of the shoulders: Issue: August 2014 out of tolerance shoulder locations can result in excessive axial loading of the bearings Page 354 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Fits and Clearances shoulders out of squareness can result in misalignment oversize bearing seats can cause overheating or preloading of the bearing undersize shafting can cause creeping. Shaft tolerance for adapter mountings (in inches) Nominal diameter Diameter limits Over Incl. A rough surface finish on the shaft will cause a loss of press fit and excessive wear of the bearing seat. A maximum surface finish of 0.063 inch is required for bearing seats. When a seal contacts the shaft surface, a finish of 0.016 inch for both the bearing seat and the seal surface is required. A plunge ground and not a centerless ground shaft (that develops a helical pattern) should be used for the seal surface, otherwise there may be seal leakage. 0.5 1 +0 –0.002 1 2 +0 –0.003 2 4 +0 –0.004 Bearing Installation 4 8 +0 –0.005 8 10 +0 –0.006 For installations on needle roller bearings and cylindrical roller bearings, the shaft surface is sometimes substituted for the inner ring. The shaft hardness must be Rockwell C59 minimum and a maximum roughness of 0.015 inch. Bearings with tapered bores generally require a tighter fit on the shaft than bearings with a cylindrical bore. The inner ring of the bearing is secured by forcing it up a tapered shaft or a tapered adapter, or by driving a tapered sleeve between it and the shaft. An inner ring installed in this manner expands and the bearing internal clearance is reduced which is a measure of the amount of interference fit. Bearing Seat check The bearing seat on the shaft should be checked for diameter, roundness, taper, conformity to a straight edge and squareness of the shoulders according to specifications. Refer to Figure 21. Shaft sizes for adapter –mounted bearings and tapered sleeves are shown in the table below: For Training Purposes Only tolerance Issue: August 2014 Page 355 of 926 Modul 7 Fits and Clearances PART 66 – Basic Training Cat B1 – Module 7 Any nicks should be removed with a file or fine emery and then the shaft should be wiped with a lint –free cloth. Seal contact surfaces on the shaft should be free of any wear. Selection of Bearing Fit The following questions should be asked before determining the shaft size or housing size: which part rotates: inner ring or outer ring? The part that rotates gets the press fit which bearing will be the fixed bearing and which one will be the floating bearing? Note: A floating bearing is necessary to prevent parasitic thrust loads from thermal expansion of the shaft. The fixed bearing locates the assembly. Refer to Figure 21 again. Figure 21: Hints for Ball Bearing Installation Example: To check for shaft conformity to a straight edge, obtain a piece of 1/8” (3.175 mm) gauge stock that has a length 1/2” (12.75 mm) longer than the bearing seat. Apply a thin coating of Prussian blue to the 1/8” (3.175 mm) surface. Then move the gauge stock axially back and forth 1/4” (2.35 mm) on the shaft and look for a transfer of the blueing to the shaft (Figure 21, detail a)). There should be at least 80 % transfer of blueing. If there is less than 80 %, the shaft should be reworked. For Training Purposes Only The fillet radius on the shaft and in the housing (Figure 21, detail b)) should be made according to the bearing manufacturers’ specification. A typical shaft installation is shown in Figure 21, detail c). The fixed bearing is shown at ’B’. This bearing locates the shaft already. The free or floating bearing is at ’A’ and allows the shaft to either expand or contract depending on the temperature. Issue: August 2014 Page 356 of 926 Modul 7 Fits and Clearances 7.6.2 Methods for Checking Aircraft Parts 7.6.2.1 Wear Inspection of Engine Parts PART 66 – Basic Training Cat B1 – Module 7 Measuring Tools and Table of Limits Refer to Figures 1 and 2. The correct measuring tools (such as micrometers, calipers and plastigauges) and dial indicators are to be used to measure each part and to determine that the fits are within the limits established by the manufacturer and published in the overhaul manual. Note: The values given in the manufacturer’s table of limits are clearance dimensions. Very few actual part sizes appear. The limits are specified as the fit of one part into another. Example: ’Piston pin in piston’ means measuring the diameter of the piston pin and measuring the diameter of the hole in the piston where the pin fits. The limit given is the maximum difference between these two values, i.e. the serviceable limit is 0.003L. The limit is reduced to between 0.003L and 0.0013L on new parts. Note: The ’L’ following the dimension indicates that the fit is ’loose’, meaning that the inside diameter of the bearing is larger than the outside diameter of the crankshaft journal. Figure 1: Table of Limits for a Piston Engine (Example) For Training Purposes Only Issue: August 2014 Page 357 of 926 Modul 7 Fits and Clearances PART 66 – Basic Training Cat B1 – Module 7 Standard Methods for Checking Engine Parts Cylinders Refer to Figures 3 and 4. The cylinder barrel is to be inspected for wear, using a dial bore indicator and a micrometer or an inside micrometer. Dimensional inspection of the barrel consists of the following measurements: maximum taper of cylinder walls maximum out –of –roundness bore diameter step fit between piston skirt and cylinder. All measurements involving cylinder barrel diameters must be taken at a minimum of 2 positions 90• apart, in the plane being measured. Taper of the cylinder walls is the difference between the diameter of the cylinder barrel at the bottom and the diameter at the top. The cylinder is usually worn larger at the top than at the bottom. This taper is caused by the natural wear pattern. At the top of the stroke, the piston is subjected to greater heat and pressure and more erosive environment than at the bottom of the stroke. There is greater freedom of movement at the top of the stroke. Taper can be measured in any cylinder by a cylinder dial gauge as long as there is not a sharp step. This dial gauge tends to ride up on the step and causes inaccurate readings at the top of the cylinder. Figure 2: Assignment of Areas for the Table of Limits For Training Purposes Only Issue: August 2014 Page 358 of 926 Modul 7 Fits and Clearances PART 66 – Basic Training Cat B1 – Module 7 The measurement of out –of –roundness is usually taken at the top of the cylinder. A reading should also be taken at the skirt of the cylinder to detect dents or bends caused by careless handling. The cylinder flange is to be checked for warpage by placing the cylinder on a suitable surface plate. It is to be checked that the flange contacts the plate all the way around. The amount of warp can be checked by using a feeler gauge. A cylinder whose flange is warped beyond its allowable limits should be rejected. Figure 3: Wear, Taper and Out – of – Roundness Figure 4: Checking of Cylinder Limits For Training Purposes Only Issue: August 2014 Page 359 of 926 Modul 7 Fits and Clearances PART 66 – Basic Training Cat B1 – Module 7 Pistons and Rings Refer to Figures 5 and 6. Figure 5: Checking of Piston Limits (I) For Training Purposes Only Figure 6: Checking of Piston Limits (II) Issue: August 2014 Page 360 of 926 Modul 7 Fits and Clearances If it is permissible to re - use the pistons, they must be carefully inspected. The pistons must have been cleaned and all of the carbon removed from the ring grooves and the oil relief holes in the lower ring groove. When applicable, the piston head is to be checked for flatness by using a straight edge and a thickness gauge. If a depression is found, the inside of the piston is to be double - checked for cracks. The outside of the piston is to be measured by means of a micrometer. Measurements must be taken in several directions and on the skirt as well as the lands. These sizes are to be checked against the cylinder (check at the sizing point as some pistons are oval –shaped). A new set of piston rings may be installed after first measuring the end gap by placing the ring in the cylinder barrel, squaring it up with the piston and using a feeler gauge to measure the gap between the two ends of the ring. If the gap is correct, the rings may be installed on the piston. PART 66 – Basic Training Cat B1 – Module 7 The pin is to be checked for curvature by using vee - blocks and a dial indicator on a surface plate. The fit of the plugs in the pin is to be measured. It is an important consideration for smooth operation of the engine that the piston weights are as close as possible to one another. The maximum allowable weight difference is shown in the manufacturer’s table of limits. New pistons may be purchased in matched sets whose weight differences are considerably below the manufacturer’s maximum. Valves and Valve Springs Some valves may not be re - used and the manufacturer’s service information will clearly indicate if that is the case. Where valves may be re - used, they must be carefully examined for any indication of overheating that could make them unserviceable. Refer to Figure 7. The new rings should be installed on the piston with the part number on the ring toward the top of the piston. The piston rings must carefully be fitted using a ring expander so that the piston is not scratched by the ends of the ring. When all of the rings are installed, the clearance between the rings and the side of the ring groove is to be checked. If tapered rings are installed, a straight edge is to be held against the side of the piston and the side clearance is to be measured with a thickness gauge. Piston Pin The clearance between the piston pin and the bore of the piston pin bosses is to be checked by means of a telescoping gauge and a micrometer. For Training Purposes Only Issue: August 2014 Page 361 of 926 Modul 7 Fits and Clearances PART 66 – Basic Training Cat B1 – Module 7 Any nicks or scratches in the valve stem near the spring retainer groove is cause for rejection of the valve. Valve stretch is also cause for rejection and is indicated by a valve whose stem diameter at the center measures less than the diameter at the spring end (waisting). If the valve is in an acceptable condition, the valve margin (dimension A in Figure 7, detail b)) should be examined to determine if refacing is possible. If there is sufficient margin, the valve may be refaced by grinding to the correct angle. Material just enough to clean up any wear marks or pits on the valve face is to be removed. It must be ensured that the surfaced valve has at least the minimum edge thickness (margin) when the grinding is complete. If the overhaul manual specifies that an interference fit is to be ground between the valve face and the valve seat, the face is ground between 0.5° and 1° flatter than the seat. This is done to ensure that the valve will seat with a line contact at its outer edge. The valve springs are to be examined for cracks, rust, broken ends and compression. Cracks can be located by visual inspection or the magnetic particle method. Compression is tested with a valve spring tester. The spring is compressed until its total height is that specified by the manufacturer. The dial on the tester should indicate the pressure required to compress the spring to the specified height. This pressure must be within the limits established by the manufacturer. Connecting Rods Refer to Figure 8. Figure 7: Checking of Valve Limits For Training Purposes Only Issue: August 2014 Page 362 of 926 Modul 7 Fits and Clearances PART 66 – Basic Training Cat B1 – Module 7 To check for parallel (bend), a new bearing insert is installed in the large end and arbors are installed in both ends of the connecting rod. A measurement is made, using a parallelism gauge to check for a bent rod. This will be indicated if the 2 arbors are not exactly in parallel (Figure 8, detail a)). With the arbors still installed, the rod is to be laid across parallel blocks on a surface plate and to be checked for squareness (twist) (Figure 8, detail b)). This is done by trying to pass a feeler gauge between the arbor and the parallel block. The amount of twist is determined by the thickness of the gauge leaves that can be inserted. If the rod is twisted or bent beyond specified limits, it must be replaced. A new rod is installed so that it is matched to the rod on the opposite side of the engine within one - half ounce to minimise vibration. Figure 8: Checking of Connecting Rods For Training Purposes Only Issue: August 2014 Page 363 of 926 Modul 7 Electrical Wiring Interconnection System 7.7 PART 66 – Basic Training Cat B1 – Module 7 Electrical Wiring Interconnection System 7.7.1 Maintenance Practices on Electrical Cables and Connectors 7.7.1.1 Wire Installation and Routing Refer to Figure 1. Wires carrying AC radiate enough energy to interfere with some of the sensitive electronic circuits. Some of the more sensitive control circuits can be disturbed by stray electric fields that are always present in the aircraft. To prevent the wires from radiation of these fields, the wires may be shielded. The insulated wire is covered with a braid of tinned copper or aluminium. This braid is often covered with an abrasion–resisting nylon outer cover. The shielding is grounded at only one end to stop a flow of current within the shield itself. This ground connection should be made by attaching a ground lead to the shield with a crimped–on connector. The ground lead should never be soldered to the shielding, as there is the danger of overheating the insulation and causing it to break down. Figure 1, details a) to c) show how a cable is correctly connected to the shielding. Detail d) shows the completed assembly. Figure 1: Attachment of a Ground Lead to a Shielded Wire with Crimped–On Sleeve For Training Purposes Only Issue: August 2014 Page 364 of 926 Modul 7 Electrical Wiring Interconnection System Solder Sleeve Shield Terminations PART 66 – Basic Training Cat B1 – Module 7 Procedure: 1. 2. 3. 4. 5. 6. 7. 8. 9. While taking care not to damage the braid, strip the insulation to the dimensions shown in Figure 2, detail a). Comb the shield braid to one side and then trim the shield (detail b)). Re–group the shield and fold it back to one side (detail c)). Cut the grounding wire to the length required, keeping the wire as short as practical (100 mm maximum unless otherwise specified). Strip the insulation of the grounding wire to the same dimensions as the trimmed shield braid (detail d)). Untwist or flatten the strands at the stripped end of the grounding wire. Position the ground wire below the folded shield braid (detail e)). The grounding wire may also be positioned on the top side of the folded shield braid when the opposite direction is required (detail g)). Select the appropriate direction of the ground wire to keep it to a minimum length. Select a solder sleeve that will fit freely but will not be too loose over the assembly. Position the solder ring of the solder sleeve so it is centered over the grounding wire and the shield braid junction. Figure 2: Sleeve Connection For Training Purposes Only Issue: August 2014 Page 365 of 926 Modul 7 Electrical Wiring Interconnection System Do not touch the heat gun reflector when you heat – shrink a solder sleeve. You can get burned. 10. 11. 12. 13. 14. Select the correct reflector for the solder sleeve, as specified by the manufacturer. Place the assembly, with the solder sleeve in position, into the center of the heat gun reflector. Apply heat to the solder sleeve until the solder ring turns shiny and the solder begins to flow axially (details f) and h)). Note: The solder ring may close before the flow of solder. When the solder flow stops, slowly remove the assembly from the heat and allow the solder to solidify. The stripped end of the replacement wire should have the same length of unshielded center conductor and the same length of cut and bared shield as the wire being replaced. On new connection, the center conductor length is determined by the requirements of the equipment. For Training Purposes Only PART 66 – Basic Training Cat B1 – Module 7 Termination of Two or More Shielded Wires to Common Ground Refer to Figure 3. Note: Do not connect grounding wires from separate harness assemblies to the same closed end terminal solder sleeve or through a common grounding wire. Figure 3, details a) to c) show different methods of joining two and more shielded conductors to a common grounding wire. Issue: August 2014 Page 366 of 926 Modul 7 Electrical Wiring Interconnection System PART 66 – Basic Training Cat B1 – Module 7 Figure 3: Termination: of Two or More Wires to a Common Ground For Training Purposes Only Issue: August 2014 Page 367 of 926 Modul 7 Electrical Wiring Interconnection System PART 66 – Basic Training Cat B1 – Module 7 Floating Shield (No Ground Lead) Termination Refer to Figure 4. Terminate shield: Push back shield braid into a flat disc (step A). Using diagonal cutters, trim braid to approx. 0.4 mm of jacket (step B). Fit heat-shrinkable tubing (step C). Figure 4: Termination of Shield without Ground Lead For Training Purposes Only Issue: August 2014 Page 368 of 926 Modul 7 Electrical Wiring Interconnection System Bonding and Grounding General Procedures Essentially, bonding is the connection of equipment to ground, normally using a braid or some type of flexible uninsulated wire. In some cases, the bonding connection also acts as the ground connection for an electrical component. PART 66 – Basic Training Cat B1 – Module 7 If it is not possible to avoid dissimilar metal junctions, a bonding jumper has to be used that is more susceptible to corrosion than the structure it bonds. Before connecting a jumper to an anodised aluminium alloy part, the oxide coating which protects the metal must be removed as this coating is an insulator. After the connection is made, an appropriate protective coating is to be used. When fitting bonding jumpers, it must be ensured that they are as short as practical and have a resistance of no more than approx. 3 milliohms (0.003 ohms). If the bonding strap carries very much ground return current, it must be ensured that there is no appreciable voltage drop across the bonding connection. If the component that is bonded is shock mounted it must be ensured that there is sufficient slack in the bonding braid so that it will not be under a strain when the unit flexes to the maximum extent allowed by the shock mounts. Since the bonding braid carries current, special care must be taken to prevent it from flowing through dissimilar metals, which would cause corrosion. Aluminium alloy jumpers are used for connections between an aluminium alloy structure and an aluminium alloy component. Cadmium-plated copper is used for bonding stainless steel, cadmiumplated steel or brass. Figure 5: Bonding Braid For Training Purposes Only Issue: August 2014 Page 369 of 926 Modul 7 Electrical Wiring Interconnection System PART 66 – Basic Training Cat B1 – Module 7 Testing In general, most bonding jumpers or ground straps must have each connection made to have 0.003 ohms or less in resistance. This measurement must be taken between the surface being bonded and the bonding jumper. This test can be carried out by using a highly sensitive ohmmeter or a bonding tester. It should be done any time a connection has been modified, added to or temporarily disconnected. Figure 6: Testing a Bonding Jumper For Training Purposes Only Issue: August 2014 Page 370 of 926 Modul 7 Electrical Wiring Interconnection System 7.7.1.2 Lacing and Tying of Wire Bundles PART 66 – Basic Training Cat B1 – Module 7 Refer to Figure 7 and 8 Lacing wire bundles with either a single- or double-lace is approved. It is faster than tying the bundle with individual spot ties. But it is not as neat and has the disadvantage that if the lacing cord is broken, a good portion of the bundle will be without ties. Figure 8: Spot–Tying with Lacing Figure 7: Lacing Method of Securing Wire Bundles For Training Purposes Only Issue: August 2014 Page 371 of 926 Modul 7 Electrical Wiring Interconnection System PART 66 – Basic Training Cat B1 – Module 7 An item that makes wire bundling fast and neat is a patented nylon strap called a ’Tyrap’. This small nylon strap is wrapped around the wire (Figure 9, detail a)). One end is passed through a slot in the other end and pulled tight (details b) and c)). The strap locks itself in place and the end is cut off (detail d)). Areas of high vibration on many aircraft require special attention to the routing, lacing and tying of wire bundles. Areas of high vibration include the wing, engine, engine struts, wheel well, landing gear, empennage and airconditioning bay. The wires routed in these areas are subject to high vibrations and must be fitted in accordance with the appropriate service data. In general, wires in this area should not be bundled with plastic wire wraps (Tyraps). They require special knotting of the string-type lace cord. Additional abrasion protection is also provided for wiring fitted in high vibration areas. Figure 9: Spot – Tying with Cable Tie For Training Purposes Only Issue: August 2014 Page 372 of 926 Modul 7 Electrical Wiring Interconnection System PART 66 – Basic Training Cat B1 – Module 7 7.7.1.3 Wire Termination Stripping Wire To attach a wire to its terminal or connection, the protective insulation must be removed. This insulation is removed by cutting the insulation and gently pulling it from the end of the wire. This process is known as ’stripping the wire’. The stripping process should be done to expose as little of the conductor as necessary to make the connection. It must be done in such a way that the conductor is not damaged beyond certain limits. Procedure of stripping wires when hand wire strippers are used: 1. Insert wire into strippers’ cutting slot. Ensure wire is centered into cutting slot (Figure 10, detail a)) 2. Squeeze strippers handles together until stripper jaws have removed insulation. 3. Release handles, allowing gripping jaws to open (detail b)). 4. Remove stripped wire (detail c)). 5. Ensure wire meets requirements. Procedure of stripping wires when knives are used: 1. Cut around wire at desired strip length. Do not cut completely through the insulation so that wire strands are not damaged. 2. Make a slit along the stripped length. Do not cut completely through insulation. 3. Peel off insulation from conductor. Figure 10: Stripping Wire with Hand Strippers For Training Purposes Only Issue: August 2014 Page 373 of 926 Modul 7 Electrical Wiring Interconnection System PART 66 – Basic Training Cat B1 – Module 7 The most common damage to a conductor often occurs when the insulation is being cut. The cutting tool may cut or nick one or more of the conductor strands if improperly used or if the tool is out of adjustment. The limits of the allowable nicked or broken strands on any conductor are specified by the relevant authorities. As shown in Figure 11 a AWG 20 copper wire with 19 strands is allowed two nicks and no broken strands. In general, the larger the number of strands or the larger the conductor, the greater the acceptable number of broken or nicked strands. Figure 11: Allowable Nicked or Broken Strands For Training Purposes Only Issue: August 2014 Page 374 of 926 Modul 7 Electrical Wiring Interconnection System PART 66 – Basic Training Cat B1 – Module 7 Solderless Terminals and Splices The wiring of a modern aircraft is assembled in the factory on jig boards and tied together in bundles. Groups of wires normally terminate with quick-disconnect plugs, and individual wires have terminals staked (or crimped) onto the wire. The terminal is attached to a screw-type lug on a terminal strip or on the electrical component itself. Wire Terminals The commercial electric industry uses many different shapes of terminals. But the one most generally used for aviation is the ringtype, either of the pre-insulated or non-insulated type, made of cadmium-plated copper. The ring-type terminal is the system of choice because the ring terminal is held onto its specific connection with a locknut or lockwasher nut assembly. This type of connection is less likely to fail than slide-on-type terminals. It is very important to be sure that the materials of the splice are compatible to eliminate the possibility of dissimilar metal corrosion. On copper wire, always copper or copper-alloy terminals are to be used. Aluminium wire must be terminated with aluminium terminals or a metal alloy which does not adversely affect the aluminium. Since most of the aluminium wires used in an aircraft are large, the terminals cannot be staked on with hand tools. Most wire manufacturing facilities use pneumatic squeezers that produce enough pressure to ensure a proper connection For Training Purposes Only Figure 12: Connection of Pre – Insulated, Crimped – On Wire Terminals Issue: August 2014 Page 375 of 926 Modul 7 Electrical Wiring Interconnection System PART 66 – Basic Training Cat B1 – Module 7 Splicing Figure 13: Double –Tape Wrap Method of Insulating a Wire Splice Splices are often used in situations where a portion of a wire has been damaged or must be lengthened. Solderless splices are typically used. It is also important to keep splices to a minimum and stagger any splices in a wire bundle. If a splice or a terminal is fitted on a wire it should always be insulated to protect it from shorting to another circuit or ground. On noninsulated terminals, a heat-shrinkable insulation sleeve or double-tape wrap should be installed to protect the exposed wire and terminal. The double-tape wrap method approved for many commercial aircraft uses is shown in Figure 13. It is also important to use an approved terminal or splice in areas subjected to high heat, vibration or moisture conditions. For Training Purposes Only Figure 14: Nickel–Plated (In–Line) Splice with Inspection Window The more common type of splice is shown in Figure 14. The junction is made with a socket that is crimped on both wires which have to be connected. Then the sleeve is pushed over the splice and shrunk with a heat gun. Issue: August 2014 Page 376 of 926 Modul 7 Electrical Wiring Interconnection System Pre-Insulated Terminals PART 66 – Basic Training Cat B1 – Module 7 Crimping Tools for Splices Pre-insulated terminals have become common in aircraft industry due to their ease of installation and proven effectiveness. On pre-insulated terminals and splices, a colour-coded insulator (typically made of nylon) covers the barrel of the terminal and is crimped when the terminal is crimped onto the wire. A second crimp on the insulation below the terminal barrel causes the terminal to grip the insulation of the wire. This does not only provide good electrical protection but helps to stop any vibrating stresses from being concentrated where the barrel grips the wire. The colour of the terminal insulation identifies the wire sizes which the terminal houses. Red terminals are used on wire of AWG-22 through-18, blue terminals are used on AWG-16 and-14 wire, and yellow terminals are used on AWG-12 and -10 wires. The following procedures are to be carried out to fit a terminal: 1. Strip the insulation from the end of the wire so that the end of the strands just sticks through the barrel. 2. Be sure to use a stripper with the proper size notch so that none of the strands is nicked. 3. Slip the stripped end of the wire into the barrel of the terminal. 4. Put the terminal in a crimping tool until the barrel rests against the stop in the tool. 5. Squeeze the handles of the tool together. Figure 15: Crimping Tools for Splices (Examples) For Training Purposes Only Issue: August 2014 Page 377 of 926 Modul 7 Electrical Wiring Interconnection System There is an increasing number of types of crimping tools available, but the best ones have a ratchet mechanism (detail a)) that does not allow them to open until they have crimped the terminal to the proper size. These tools should periodically be calibrated against a standard so that it is ensured that the terminal is properly fitted. If a terminal is properly crimped on the wire, the wire will break before the terminal slips off. For limited uses, the non-ratchet-type tool (detail b)) can be used; however, the technician should be sure to close the tool completely for a proper crimp. In production-type uses, many factories use a pneumatically operated machine. 7.7.1.4 Maintenance Practices on Electrical Connectors PART 66 – Basic Training Cat B1 – Module 7 Contact Extraction Procedure for extracting front release contacts: 1. Remove rear hardware from connector and slide it back over wire bundle. 2. Select correct extraction tool to fit contact. 3. Place tip of spring-release sleeve over tip of contact to be removed. Hold tool perpendicular to the face of the connector. Do not use extraction tool in any contact hole unless contact is locked in place. 4. Push tool handle so that spring-release sleeve enters contact hole and releases contact retaining (holding) spring. 5. Move plunger forward and push contact out of retaining spring. Maintain pressure on tool handle to hold retaining spring in unlocked position and move thrust assist collar forward. 6. Continue pushing thrust assist collar forward to completely extract contact. If contact extraction fails remove tool from contact hole, rotate tool approximately one quarter turn and repeat extraction procedures. Procedure for extracting rear release contacts: 1. Remove rear hardware from the connector and slide it back over wire bundle. 2. Select correct tool for extracting rear release contact. 3. Press the wire into the end of tool so that tool slides easily along wire. 4. To release contact retaining spring, push tool wire until it bottoms out in the contact hole. 5. Push the contact out of connector from the front end, using a push rod. Figure 16: Front Release Contact Extraction For Training Purposes Only Issue: August 2014 Page 378 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Electrical Wiring Interconnection System Wire/Contact Termination Procedure for crimp terminations (Figure 17, detail a)): 1. Strip wire to the dimensions given in the specification for the individual connector. 2. Where crimping (termination) requires the use of a smallersize wire in a connector contact, additional wire(s) of the same gauge must be added according to the following table: Contact Size Wire Size (AWG) 24 22 20 18 16 4 1 0 0 6 3 1 0 6 16 12 8 4 0 14 12 10 8 0 3 1 1 1 6 3 1 1 6 4 2 0 0 3 1 0 - 3. Insert the stripped wire into the contact. 4. After crimping, trim the added wires flush with the end of the contact. 5. Check that the wire can be seen through inspection hole on the side of the contact. 6. Keep a positive pressure on the wire to stop it from coming out of the contact. Insert the contact into locater. Keep positive pressure on the wire and press crimping tool handles closed. Note: The handles will not open to release crimped contact until crimping cycle has been completed. 7. Remove contact and wire from locater. Check that the wire can still be seen through the inspection hole (detail b)) Figure 17: Typical Crimp Termination For Training Purposes Only Issue: August 2014 Page 379 of 926 Modul 7 Electrical Wiring Interconnection System PART 66 – Basic Training Cat B1 – Module 7 Procedure for solder terminations: 1. Strip the wire so that a proper gap between the contact and the wire termination is obtained when the wire is inserted into the contact. 2. Solder the wire into the contact. Figure 18: Method of Soldering Wires into the Solder Pots of an MS Connector For Training Purposes Only Issue: August 2014 Page 380 of 926 Modul 7 Electrical Wiring Interconnection System PART 66 – Basic Training Cat B1 – Module 7 Contact Insertion The following general procedures apply to standard crimp contacts. Contacts are more easily loaded from the center outward concentrically. 1. Insert the contact by hand into grommet hole at rear of the connector until the shoulder of the contact is exposed (Figure 19, detail a)). Note: When reworking a connector in a wire bundle, it may be desirable first to place the contact in the insertion tool. 2. Apply correct insertion tool to the contact as follows (detail b)): When inserting a contact of the size AWG 16 or larger, position insertion tool so that tip of tool bears against back of wire barrel with wire in groove of tool. When inserting a contact of the size AWG 20 or smaller, position insertion tool so that tip of tool fits into shroud barrel between insulation and shroud wall with wire in groove of tool. 3. Ensure that the tool is perpendicular with connector’s insert surface. Push the tool straight into contact hole, applying firm, steady pressure until contact snaps into place (detail c)). 4. After all wired contacts have been fitted, fill any empty holes with unwired contacts. Then insert applicable sealing plugs as listed in the following table: Figure 19: Contact Insertion For Training Purposes Only Issue: August 2014 Page 381 of 926 Modul 7 Electrical Wiring Interconnection System Contact Size 22 20 16 12 8 4 0 PART 66 – Basic Training Cat B1 – Module 7 Figure 20, detail a) shows the lock-wiring of a connector to adjacent structure, while detail b) gives an example of lock-wiring of saddle clamp screws. Sealing Plug Part Number Military Standard Colour Code MS27488 –22 Green/ Black MS27488 –20 Red MS27488 –16 Blue MS27488 –12 Yellow MS27488 –8 Red MS27488 –4 Blue MS27488 –0 Yellow Note: Sealing plugs MS3187 are acceptable substitutes for the plugs listed above. 5. Check that the contact has properly been fitted in by pulling gently on the wire. 6. Replace the rear hardware (detail d)). Lock-Wiring of Electrical Connectors Refer to Figure 20. Note: In civil aviation, the term ’safety-wiring’ is used instead of ’lockwiring’. Do not lockwire selflocking connectors which have a mechanical lock, as the lockwiring acts against locking. Note: Self-locking connectors are connectors with bayonet or balldetent-type coupling rings. For Training Purposes Only Issue: August 2014 Figure 20: Lock-Wiring of Electrical Connectors (I) Page 382 of 926 Modul 7 Electrical Wiring Interconnection System PART 66 – Basic Training Cat B1 – Module 7 General procedure: Lock-wire the following connector parts as required: coupling ring backshell saddle clamp screws. Use an Inconel wire with a diameter of 0.02 inch (0.5 mm) for all connector lock-wiring applications. Refer to Figure 21. Lock-wire the coupling rings on all connectors located in high vibration areas and nacelles. Note: Connector coupling rings should be lock-wired to aircraft structure. Do not lock-wire from coupling ring to backshell. Lock-wire each connector separately. Do not lock-wire one connector to another without need. Figure 21 shows different types of connectors, such as: MS connector (detail a)) SM connector (detail b)) DM and DS connectors (detail c)) 90o connector (detail d)). Figure 21: Lock-Wiring of Electrical Connectors (II) For Training Purposes Only Issue: August 2014 Page 383 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Electrical Wiring Interconnection System Tying Wires to Connectors with Strain Relief Arm 7.7.1.5 Grommets On connectors with strain relief arm (such as MS27670) the wire bundle is tied with cable tie MS3367 to the strain relief arm. The double loop technique is used as shown in Figure 22. Note: On connectors with a strain relief arm mounted 90° to the connector, avoid placing strain on the wire termination when tying wire to the arm. It may be necessary to form wire individually over the arm before tying the wire bundle. Figure 22: Tying Wires to Strain Relief Arms For Training Purposes Only Figure 23: Typical Grommets Issue: August 2014 Page 384 of 926 Modul 7 Electrical Wiring Interconnection System Grommets (Figure 23, detail a)) are used to prevent abrasion chaffing of cables, when passing through holes in metal structures components. The grommet also secures the cable at the point entry (or exit) without allowing excessive movement and risk chaffing. or or of of Different shapes and sizes of grommets are available. The materials used for manufacturing grommets range from rubber, nylon or fuelresistant material. 7.7.1.6 PART 66 – Basic Training Cat B1 – Module 7 Heat-Shrink Material, Types, Application Tools and Techniques There is a need to provide environmental and mechanical protection to aircraft wiring systems, connection and termination devices. The required protection can be carried out in many ways. One way is to use heat-shrink materials. Heat-shrink tubing can also be used for cable bundles. Heat-shrink Concept A grommet is shaped to mould around the sharp edges of a hole and has a centrally located hole to allow the cable(s) to pass through it without excessive movement or freedom. To select the correct grommet for a given cable size the following information is required: size of the hole where the grommet is to fit thickness of the chassis, metal or wall cable diameter (to determine cable hole size of the grommet). Solid grommets, not cable holes, are used to seal cable entry holes in components or metal structures. Flexible grommet strips are also available made from nylon or similar material. The grommet strip used for unusual size holes is cut to size. The flexible strip is then placed around the hole to prevent the sharp edges from chafing the cable. The basic concept of heat-shrink materials is that a plastic material, when manufactured, is subjected to some form of radiation which expands the material. The expanded material remains in that way until, subjected to a flow of hot air, a controlled shrinking of the material takes place. This shrinkage or recovery takes place fairly quickly and when completed, the material will remain in that form permanently. Heat-Shrink Materials Refer to Figure 24. Detail b) shows a cable clamp and grommet at bulkhead holes. For Training Purposes Only Issue: August 2014 Page 385 of 926 Modul 7 Electrical Wiring Interconnection System PART 66 – Basic Training Cat B1 – Module 7 The heat-shrink materials (Figure 24, detail a)) are supplied as tubing of different diameters and wall thicknesses (detail b)) Figure 25: Installation of a Straight Boot pre-moulded shapes, e.g. ’Y’, ’T’ and boots for connectors. The shapes are expanded (or over-expanded) when they are required to be positioned over an already terminated conductor tape, for use where tubing or performed shapes are impracticable or unsuitable. The tape when wound around the cable, connector, and then heated will shrink to form a continuous tube or boot. The heat-shrink materials generally used are plastics, such as Neoprene, PTFE, polyolefin polythene and polyvinyldene fluoride. Figure 24: Heat Shrinking For Training Purposes Only Issue: August 2014 Page 386 of 926 Modul 7 Electrical Wiring Interconnection System The materials have different working temperature ranges, shrink temperature and shrinkage values. They are also manufactured in a range of tube diameters, moulded shape sizes and tape widths. PART 66 – Basic Training Cat B1 – Module 7 Heat Sources: Figure 25 shows an example of an installation of a straight boot. Figure 26, detail a) shows the shrinking of convolex tubings, detail b) shows the installation of a transition. Figure 26: Application of Convolex Tubing For Training Purposes Only Figure 27: Heat – Shrinking Tools Issue: August 2014 Page 387 of 926 Modul 7 Electrical Wiring Interconnection System Heat-shrink materials require an indirect heat source to produce the shrink characteristic. The heat sources are electrically heated with an air supply. The air supply comes from an integral fan blower. The electrical heating element heats the air which is passed over the heat-shrink material. The hot air must be controlled within a temperature range of 135oC to 175oC for the shrink process to take place. Some heat sources have temperature selectors fitted. The heat sources have a range of shaped heat deflectors which fit over the nozzle of the heat source and localise the heat to the area required or the nozzle alone can be used if required. PART 66 – Basic Training Cat B1 – Module 7 Heat-Shrink Procedure The correct procedure for heat-shrink materials and heat sources is found in the maintenance manuals, but they can be summarised as follows: Figure 27, detail a), shows an example of a heat gun. Detail b) shows examples of different heat reflectors. Examine the area, or component, to which the heat-shrink material is to be applied to ensure it withstands the temperatures involved in the process. Select the appropriate size of the correct material or moulded shape, to suit the task. The size to be considered is the ’recovered’ shrunk size. A good rule is that the diameter of the component should not be 1.4 times greater than that of the recovered tubing. Select the appropriate heat source and deflectors and the correct temperature for the material. Apply the heat, starting at the center of the tubing or moulded shape, working outwards to allow air and moisture to escape. When applying heat a distance between the nozzle and the material is to be maintained when only the nozzle is used. Note: Heat damage to the surround area must be avoided by the use of heat shields or the use of heat for only the length of time it takes to shrink. For Training Purposes Only Issue: August 2014 Page 388 of 926 Modul 7 Riveting 7.8 Riveting 7.8.1 Riveting Tools 7.8.1.1 Special Assembly Tools PART 66 – Basic Training Cat B1 – Module 7 There are many devices used by sheet metal technicians to assist them while assembling an aircraft. Prior to the final fastening operation, holding tools are needed to temporarily hold aircraft parts together. The tools used are called clamps. The types most commonly used by aircraft sheet metal technicians are Cleco fasteners, wing -nut fasteners and ’G’ - clamps. Before a sheet metal aircraft structure is riveted together, it must be assembled to be sure that all of the parts fit together as they should. It is standard practice to drill all of the rivet holes in the clamped parts with a pilot drill of the nominal size of the rivet. After the part is assembled, a drill of the size needed for the rivet is passed through the holes. This assures that there will be no misalignment of the holes that could prevent the rivet seating properly. Sheet Fasteners Refer to Figure 1. Figure 1: Sheet Fastener For Training Purposes Only Issue: August 2014 Page 389 of 926 Modul 7 Riveting PART 66 – Basic Training Cat B1 – Module 7 Because of the necessity for holding sheets of metal close together during the riveting process, a fastener of some type is essential or the rivet will tend to expand between the sheets and leave a gap. Such a gap reduces the strength of the joint and promotes the accumulation of moisture between the sheets, which leads to corrosion. The tool designed to meet the need is called a ’sheet fastener’ (or: gripping pin) and can be quickly and easily installed. Sheet fasteners are commonly called ’CLECOs,’ a trade name applied by an early manufacturer. Sheet fasteners have been designed and used in many styles and shapes. However, they are presently limited to relatively few designs. Figure 1 shows the internal construction of a sheet fastener. The fastener consists of a machined steel body in which a plunger, coil spring, locking wires and a spreader are installed. Refer to Figure 2. When the plunger is depressed with the fastener pliers, the locking wires extend beyond the spreader and ’toe in’, i.e. they reduce their diameter. The locking wires can then be inserted in a drilled hole of the proper size. Figure 2: Inserting a Sheet Fastener in a Drill Hole For Training Purposes Only Issue: August 2014 Page 390 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Riveting Refer to Figure 3. When the pliers are released, the locking wires are drawn back over the spreader. This causes the wires to separate and grip the sides of the drilled hole. Removal of the fastener is accomplished by reversing the process of installation. Sheet fasteners are available in the sizes for all of the commonly used rivets and in even one size larger. They are colour –coded to identify the size hole through which they fit: 2.4 mm3/32” 3.2 mm 1/8” 4.0 mm 5/32” 4.8 mm3/16” 6.4 mm1/4” silver copper black brass copper. Wing –Nut Fasteners Refer to Figure 4. Figure 3: Locking Wires Gripping Sheet Metal For Training Purposes Only Issue: August 2014 Page 391 of 926 Modul 7 Riveting PART 66 – Basic Training Cat B1 – Module 7 Wing nut fasteners are used prior to the final assembly for those aircraft parts which need to be held extra tightly in place before re riveting is started. During the re - assembly of an aircraft structure, it is important that all parts be fitted and aligned before any riveting is begun. The wing nut fastener, when hand tightened, will clamp the metal together thus ensuring against any possible slippage. It holds its work tighter than a Cleco clamp, and it is installed by hand. G - Clamps There are times when small G -clamps are handy to hold metal parts together, especially before holes are drilled through both pieces so a Cleco fastener can be used. Refer to Figure 4 again. The G - clamp is a tool widely used by a machinist, which has been borrowed by the sheet metal technician for holding work together on metal aircraft. It is useful for holding sheet metal in place before the drilling operation is begun. The G - clamp is available in many sizes, usually the smaller sizes are used by the sheet metal technician. The G - clamp looks like the letter ’G’, thus the reason for its name. The frame has a steady rest on its lower end and a threaded end at the top. Through the threaded end passes a threaded bolt with a steady rest and T - Handle. Before using a G - clamp, cover both the end of the anvil and the floating end of the screw with a generous pad of masking tape to prevent the clamp from marring the metal. Note: G - clamps are sometimes called ’C - clamps’ as well. Figure 4: Sheet Metal Fastener For Training Purposes Only Issue: August 2014 Page 392 of 926 Modul 7 Riveting Hole Finder (Blind Riveter) Refer to Figure 5. PART 66 – Basic Training Cat B1 – Module 7 A hole finder (or: blind riveter) is used for locating new rivet holes in undrilled skins. When an aircraft is disassembled for a repair, the damaged parts are removed leaving good parts with previously drilled holes remaining. These previously drilled holes serve as the line - up points for the new skin. Once a fresh skin is fitted over the old hole, they are difficult to locate. The holes are found by using a hole finder. The hole finder is equipped with a pin of the size of a rivet attached to one side and a hole or pointed machine screw lined up on the rivet center on the other side. By inserting the rivet pin into one of the original holes and placing the new skin on top of the line - up pin, it places the center of the hole in line with the hole/machine screw which is directly over the rivet. At this point the technician can either use a transfer punch or a light mallet to mark the center of the rivet hole onto the new skin. Cut a notch near the end of the strip and fasten some sort of handle to the other end to make it easy to hold. To use it, just reach in between the skins and rack the chips out so the sheets will fit together. Chip Chaser Refer to Figure 6. It is sometimes impossible to disassemble the skins after drilling a hole. As a result, there are chips between the skins that would prevent them fitting flat together when the rivet is driven. A handy tool to remove these offending chips, a ’chip chaser’, can be made of a strip of feeler - gauge stock. Use a piece that is thin enough to get between the sheets and yet stiff enough to pull out the chips. Figure 5: Use of a Hole Finder For Training Purposes Only Issue: August 2014 Page 393 of 926 Modul 7 Riveting PART 66 – Basic Training Cat B1 – Module 7 Figure 6: Chip Chaser 7.8.1.2 Rivet Guns Types of Rivet Guns Refer to Figure 7. Rivet guns are available in various sizes, starting with ’1X’, the smallest, which is used for rivets of 1/16 inch (”) (1.59 mm) and 3/32” (2.38 mm) in diameter. The size of rivet guns increases progressively for rivets of larger diameter, the most commonly used size being ’3X’, which is used for rivets from 3/32” (2.38 mm) to 5/32” (3.97 mm) in diameter. For larger size rivets, 4X and 5X rivet guns may be used. There are several larger sizes of rivet guns used for larger rivets than the ones mentioned so far. Figure 7: Types of Rivet Guns For Training Purposes Only Issue: August 2014 Page 394 of 926 Modul 7 Riveting Function of a Rivet Gun Refer to Figure 8. PART 66 – Basic Training Cat B1 – Module 7 When the trigger (or throttle, as it is sometimes called) is pulled, air enters the sliding valve and drives the piston forward against the stem of the rivet set. When the piston reaches the end of its stroke, a port is uncovered by the valve that directs air to the forward end of the piston and moves it back so it can get air for another driving stroke. As long as the trigger is held down, the gun will reciprocate (or hammer) on the rivet set. A regulator either built into the handle of the gun or in the hose restricts the flow of air into the gun. If the regulator is wide open, the gun will hit hard and fast. By restricting the airflow, you can make the gun hit slower and softer. Rivet Sets Refer to Figure 9. There must be a rivet set for each rivet size and each rivet head style. Fortunately, the universal head rivet can be used to replace almost any protruding head rivet. So a technician will rarely need more rivet sets than those that fit the various sizes of universal head rivets. Figure 9 shows a selection of rivet sets. Figure 8: Construction of a Rivet Gun For Training Purposes Only Issue: August 2014 Page 395 of 926 Modul 7 Riveting PART 66 – Basic Training Cat B1 – Module 7 Care of the Rivet Gun Rivet guns and rivet sets perform better work and will last longer if they are properly handled and serviced, i.e. permanent good care, including lubricating, cleaning, etc., is necessary. A rivet set should not be placed against steel or other hard metal when the air power is on. This will damage the rivet set severely. A rivet set can be dangerous. If it is placed in a rivet gun without a set retainer spring and the throttle of the gun is open, the rivet set may be ’shot’ out of the gun like a bullet. This may cause either severe injury to a person or the destruction of equipment. A few drops of light machine oil should daily be put in the air intake of the rivet gun. Depending upon use, the rivet gun should be disassembled and cleaned, worn parts replaced and then reassembled and lubricated. Figure 9: Rivet Sets For Training Purposes Only Issue: August 2014 Page 396 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Riveting 7.8.1.3 For best results, the technician should choose a bucking bar of the proper weight and shape for a particular application. A common rule of thumb is that the bucking bar should weigh approx. 0.5 kg less than the size of the rivet gun being used multiplied by 0.5 kg. Bucking Bars Refer to Figure 10. Example: The rivet gun being used is of the size ’3X’. The number 3 multiplied by 0.5 kg makes 1.5 kg. The bucking bar to be used with this rivet gun should weigh 1.5 kg minus 0.5 kg = approx. 1 kg. Refer to Figure 11. Figure 11: Expanding Bucking Bars Figure 10: Bucking Bars (Examples) A bucking bar is a smooth steel bar made up in a variety of special shapes and sizes. It is used to form a head on the shank of a rivet while the rivet is being driven by a rivet gun. The edges are slightly rounded to prevent marking of the material. Its surface is perfectly smooth. The face of the bar, placed against the shank of the rivet, is flat. Bucking bars are sometimes called ’dollies’, ’reaction bars’, ’bucking irons’ or ’bucking blocks’. For Training Purposes Only Expanding bucking bars are steel blocks whose diameters or widths can be adjusted. A bucking bar of this type is attached to the end of a hollow steel shaft which contains a bar that can be twisted to expand or reduce the width of the block. It is used to buck (form, upset) rivets on the inside of tubular structures or in similar spaces that cannot be reached by regular bucking bars. The space for one side of the partly expanded block must be small enough to press against the tip of the rivet’s shank, and for the other side to press against a strong supporting surface. Expanding bucking bars speed up the process of riveting the skin on the wing section. Issue: August 2014 Page 397 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Riveting 7.8.1.4 Standard rivets are installed with the rivet head inside the metal skin. The shank of the rivet is driven to form a head in the conical depression on the outer surface. The forming of the rivet shank, necessary to fill the depression, can be done with a standard rivet gun and a smooth - faced bucking bar. During production, it is often done with automatic machines as well. Rivet Shaver Tool Refer to Figure 12. After the rivet has sufficiently been driven to fill the countersunk hole completely, the excess of rivet material projecting above the surface of the skin is shaved with a small rotary mill, called ’rivet shaver’. With this tool, the surface of the skin and the rivet are made extremely smooth, so that drag will be reduced to a minimum. For the manual process, the rivet shaver is held in the hand like a drill motor. It is prevented from cutting too deep by means of a stop which is carefully to be adjusted. 7.8.2 Riveting Techniques 7.8.2.1 Riveted Joints Selection of the Proper Rivet Figure 12: Rivet Shaver Tool On modern, high speed aircraft, it is necessary to remove every possible cause of drag from the outer surface of the aircraft skin. For years, flush (countersunk type) rivets were installed in skin and other structural sections exposed to airflow. To obtain an almost perfect surface, shaved riveting techniques were developed. In preparation for shaved riveting, standard rivet holes are drilled in the metal to be riveted. This may be done manually or, automatically by programmed machines. On the outer surface of the metal the holes are countersunk with a 60o tool instead of the conventional 100o countersink. For Training Purposes Only When a repair is made to an aircraft structure, it must be restored to the condition of structural integrity and aerodynamic shape that was needed for its original certification. The easiest way to be sure that the repair meets these criteria is to match the manufacturer’s methods and use the same material he used. When a rivet is choosen for a particular repair, the shear strength of the rivet must match with the bearing strength of the material being riveted. These 2 values should almost the same, but the bearing strength should be slightly higher than the shear strength. Refer to Figure 1. Issue: August 2014 Page 398 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Riveting Single –shear Strength of Aluminium Alloy Rivets (Pounds) Composition of rivet (alloy) Ultimate strength of rivet metal (pounds per square inch) Diameter of rivet (inches) 1/16 3/32 1/8 5/32 3/16 1/4 5/16 3/8 AD 2771 27,000 83 186 331 518 745 1,325 2,071 2,981 D 2017 30,000 92 206 368 573 828 1,472 2,300 3,313 DD 2024 35,000 107 241 429 670 966 1,718 2,684 3,865 Figure 1: Shear Strength of Aluminium Alloy Rivet For Training Purposes Only Issue: August 2014 Page 399 of 926 Modul 7 Riveting PART 66 – Basic Training Cat B1 – Module 7 In Figure 1, there is the single –shear strength of aluminum alloy rivets shown. It can be noticed that a 1/8” AD rivet will support a load of 331 lbs. (1,500 N), and a 1/8” DD rivet will take a load of 429 lbs. (1,950 N) before it shears. If there is a double - shear load, that is one in which 3 pieces of material are held together, the values in the chart will be doubled. Refer to Figure 2. Figure 2: Bearing Strength of 2024 – T3 Clad Aluminium Alloy For Training Purposes Only Issue: August 2014 Page 400 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Riveting A commonly used rule of thumb for selecting the rivet size is to choose a rivet whose diameter D is at least 3 times the thickness of the thickest sheet being joined. Example: If we are joining 2 pieces of 0.040” (1 mm) 2024.T3 clad aluminum sheet, we would use a rivet whose diameter is at least 0.120” (3 mm). The nearest standard rivet to this size has a diameter of 1/8” (3.2 mm). Now, when we check the shear strength and bearing strength charts, we find that the shear strength of the 1/8” AD rivet is 331 lbs. (1,500 N) and the bearing strength for the sheet with a 1/8” rivet is 410 lbs. (1,864 N). This means that when the joint fails, it will be by the rivet shearing rather than the sheet tearing at one of the rivet holes. Now that we have chosen our rivet diameter, we must find the rivet length. For a rivet to have enough material to form a head that is 0.5D thick and spread out to a diameter of 1.5 times the shank diameter, the rivet must be long enough to go through the material and protrude for 1.5D. Figure 3: Rivet Cutter Rivet Cutters Layout of Rows of Rivets Refer to Figure 3. Rivet cutters are used to cut rivets to their proper installation lengths. All rivet lengths are obtained in increments of 1/16” (1.6 mm). They usually must be cut to their required installation size. The correct rivet length is determined by adding the rivet grip length to 1.5D, then cutting the rivet to the correct length. For Training Purposes Only Refer to Figure 4. It is important when making a riveted repair that the rivet be installed in such a way that it will develop the maximum strength of the repair. To get this strength, not only the relationship between the strength of the rivet and the sheet must be considered, but the rivets must be spaced so that the holes will not weaken the joint. Furthermore, the limits shown in Figure 4 must be observed. Issue: August 2014 Page 401 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Riveting Figure 4: Dimension Limits of a Rivet Edge Distance Refer to Figure 5. It is important when installing a row of rivets that they are placed neither too close to the edge of the sheet nor too far away. If they are too close to the edge, the sheet is likely to tear. But if they are too far back, the edge of the sheet will lift. The normally accepted practice is to place the center of the hole not closer than 2D from the edge and no further back than 4D. A good rule is to place the center of the holes approx. 2.5D back from the edge of the sheet. Note: The distance between the edge of a sheet and the first row of rivets is called ’land’. Figure 5: Measurement of Edge Distance and Rivet Pitch Rivet Pitch Pitch The distance from the center of one rivet to the center of the nearest one on the same or adjacent (next) row is called the pitch. In order that the sheet not be weakened by too many holes in a row, the adjacent rivets should be no closer than 4D to each other and to prevent the sheet buckling between rivets, they should be no further apart than 10D to 12D. For Training Purposes Only Issue: August 2014 Page 402 of 926 Modul 7 Riveting PART 66 – Basic Training Cat B1 – Module 7 Gauge or Transverse Pitch The distance between the rows of rivets in a multi –row layout should be approx. 75 % of the pitch, and the rivets in adjacent rows should be staggered. Guide to Rivet Pitch and Position The rivet pitch of a joint will depend on the type and structural strength of the joint. For practical purposes, the minimum distances are as follows: minimum pitch is 4D minimum distance between rows of chain rivets is 4D minimum distance between staggered rows is 4D minimum distance between rivet centers and the edge of a sheet (known as the ’land’) is 2D; for countersunk rivets this is increased to 2.5D to ensure sufficient material available. Usually, the maximum pitch (i.e. the space between rivets in a single row) is limited to 24 times the thickness of the sheet metal. Example: If the thickness of the sheet metal is 2.1 mm the maximum pitch should not be more than 24 x 2.1 mm = 50.4 mm. Rivet Layout Refer to Figure 6. Assuming that two 3.75” - (95 mm –) straps of 0.040” (1 mm) sheet aluminum alloy shall be joined with 11 MS20470AD4 - 4 rivets, it can immediately be seen that more than one row of rivets is needed, because for one row, the spacing would be so close that the joint would be weakened. So, two rows can be used with six rivets in the first row and five in the second. For Training Purposes Only Issue: August 2014 Figure 6: Rivet Layout for a Two – Row Splice Page 403 of 926 Modul 7 Riveting PART 66 – Basic Training Cat B1 – Module 7 Sequence of Working Steps V First, mark off the edge distance of 2.5D (5/16“(8 mm)) from the end of the sheet. Mark this with a soft lead pencil so you will not scratch the metal. Measure 5/16” (8 mm) from both edges of the sheet along the line to locate the end rivets so they will have the correct edge distance from both the end and the sides. Mark both of these locations with a prick punch. Then, with a pair of dividers, divide the distance between these two locations into five equal spaces. This gives the location of the six rivets for the first row. These rivets will be 5/8” (15.9 mm) apart, which is 5D and is well within the allowable spacing of between 3D and 12D. The gauge (= distance between the rows) should be approx. 75 % of the pitch and, in this case, will be 0.468” (11.9 mm). To be practical, 0.50” (12.7 mm) will be entirely adequate. Mark a line across the strap 0.5” (12.7 mm) from the first row of rivets and locate the five holes needed on this line. These holes should be centered between the rivets in the first row. Mark the location of all rivet holes with a prick punch. Rivets Required for a Repair The number of rivets required in any repair is determined by the strength necessary for the riveted joints. This strength is based upon 2 considerations. First, the shear strength of the rivets must be determined. Refer to Figure 7. For Training Purposes Only Figure 7: Shear on a Rivet Note: The shear on a rivet is the load that tends to cut the rivet in 2 parts. Secondly, the tensile strength of the sheet metal must be determined. These 2 forms of strength in combination constitute the basis for determining how many rivets are necessary. The shear strength of rivets and the tensile strength of materials may be determined from engineering tables. When these values are known, it is possible to determine the number of rivets required by dividing the shear strength of one rivet into the required tensile strength of the joint. Example: The shear strength of a 3.2 mm 2117.T3 (AD) rivet is 1,530.8 N. It is necessary to provide a tensile strength of 24,920 N to a joint. The number of rivets required will be 24,920 𝑁 = 16.24. 1,530.8 𝑁 To make sure that the strength is adequate, it would be best to use 17 rivets. Issue: August 2014 Page 404 of 926 Modul 7 Riveting In making a riveted seam, both the shear strength of the rivet and the bearing strength of the metal sheet must be taken into consideration. The bearing strength is the amount of force applied to a rivet installed in metal sheet which will cause the rivet to elongate the rivet hole in the sheet. If the bearing strength is greater than the shear strength of the rivet, the rivet will shear before the hole is elongated. If the shear strength of the rivet is greater than the bearing strength of the metal, the metal will yield and the rivet will pull through the metal. PART 66 – Basic Training Cat B1 – Module 7 Number of rivets required per 2.54 cm (1 inch) width W of repair: Refer to Figure 8. Tables have been prepared to designate the number of rivets necessary to restore the strength to a given section of sheet aluminium alloy when using 2117.T3 rivets. Figure 8 is an example for rivets from 2.38 mm to 6.35 mm in diameter and aluminium alloy sheet thicknesses from 0.406 mm to 3.25 mm. When such tables are available it is a simple matter to determine the number of rivets necessary for any particular repair. Example: If it is desired to repair a 50.8 mm break in a sheet of 0.635 mm aluminium alloy skin, the number of rivets can be determined as follows: Select the size of rivet: Since the riveted sheet is 0.635 mm thick, the rivet diameter must be at least 3 times this thickness. This requires a rivet with a diameter of at least 1.91 mm. The next larger standard rivet has a diameter of 2.38 mm; hence this is the size to be used. Figure 8 shows that with a thickness T of the sheet of 0.635 mm, the number of 2.38 mm rivets should be at least 8.6 per 25.4 mm of width W. The break to be repaired is 50.8 mm long; hence 17.2 rivets are required (mathematically). Therefore, 18 rivets on each side of the repair are to be used to restore the required strength. For Training Purposes Only Example: Issue: August 2014 Thickness T of sheet: Length (width) W of repair: Rivet diameter: calculated: available: Required number of rivets per 2.54 cm: Number of rivets for W: calculated: to be used: Figure 8: Required Number of Rivets Page 405 of 926 0.635 mm 50.8 mm 1.91 mm 2.38 mm 8.6 17.2 18. PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Riveting Hole Preparation for Protruding Head Rivets Note: The dimensions stated here are for guidance only. They are not meant to indicate an absolute requirement. The experienced technician will adjust the dimensions to get the best results for the job at hand. Refer to Figure 9. Refer to Figure 10. Figure 9: Dimensions for a Correctly Ground Drill Point To make a good riveted joint, it is essential that the rivet hole is drilled properly. The first requirement for a perfectly drilled hole is the use of a drill that is accurately ground. New drills usually have a satisfactory point (tip), but after they are worn they should be sharpened or discarded. The dimensions for a correctly ground point are a drill –point angle of 118o and a drill rake angle of 12o. For materials which are soft (e.g. soft aluminium, lead, wood and plastics) it is better to have the drill sharpened with a smaller drill point angle such as 90 for medium soft materials and 45 for very soft materials. For very hard and tough materials such as steel, stainless steel and titanium, a larger drill – point angle (125o to 150o) and a smaller drill rake angle (10o) are recommended. For Training Purposes Only Figure 10: Drill and Cutting Speeds Drill speed is also an important factor for getting good results. The proper speed for aluminium alloy will not produce the best results with stainless steel or titanium. ’Drill speed’ determines the rate at which the outer cutting edge of the drill is moving through the material being cut. Issue: August 2014 Page 406 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Riveting Example: A 3.2 mm –drill with a diameter of 9.97 mm which turns at the rate of 1,222 rpm has a cutting speed of 1,219 cm/min. When harder materials are drilled, slower speeds are required. In addition, a cutting and cooling lubricant is needed. Lubricating oil, lard oil, water –soluble oil and others are used. For holes which must be held within extremely close tolerances, a drill - jig is normally used. This device holds the drill accurately in position while the hole is being drilled. Refer to Figure 11. Figure 10 shows drill and cutting speeds for various sized drills. This table provides information for commonly used drill sizes at various recommended cutting speeds. For values not shown on the chart, it is necessary to obtain values from the ones shown. Note: It must be stated that the values given in Figure 10 are not required but are recommended for optimum results. A cutting speed of 3,048 cm/min is recommended for aluminium alloys. However, lower speeds can be used very satisfactorily. For stainless steel and titanium, a cutting speed of 914 cm/min is recommended, but a lower or higher speed can be used as well. Care must be taken with the harder and tougher materials to avoid too much speed and pressure which will result in overheating the drill and rendering it useless. In drilling larger holes (i.e. 4.8 mm or more), it is useful to drill a pilot hole first. The pilot drill should not be more than 1/2 of the diameter of the final hole. This is particularly true when drilling harder materials. Before using a drill, the technician should examine it to check that it is straight, that the point conforms to required standards and that the shank is not scored or otherwise damaged. The location of a hole to be drilled may be indicated by marking with a pencil or, in the case of heavy sheet stock, by making a slight indentation with a center punch. Figure 11: Correct Method for Starting a Drill For Training Purposes Only Issue: August 2014 Page 407 of 926 Modul 7 Riveting When beginning to drill a hole, the technician must be very careful to hold the drill perpendicular to the material being drilled. Additionally, he must hold the drill and motor steady so that the drill will not move away from the correct position and damage the adjacent material. It is common practice to start the drill by placing it in position and turning it by hand before turning on the electric or air power to operate the motor. By this method the hole will be started and the drill will usually remain in the proper position. Figure 11 shows a technician holding the drill properly for starting to drill a hole. PART 66 – Basic Training Cat B1 – Module 7 A hole is not complete until it is both drilled and deburred. Deburring is the process of removing rough edges and chips from a newly drilled hole. It is usually done by hand with a drill larger than the hole, or it can be done with a special deburring tool which is merely a piece of metal with sharp edges. Refer to Figure 13. Refer to Figure 12. Figure 12: Properly and Improperly Drilled Holes Figure 12 illustrates properly and improperly drilled holes. The left and middle drawings show holes that are clean and in good alignment. The right drawing shows two holes which were drilled at an angle and would not be suitable for riveting. Figure 13: Deburring Tools For Training Purposes Only Issue: August 2014 Page 408 of 926 Modul 7 Riveting PART 66 – Basic Training Cat B1 – Module 7 Removal of burrs from drilled holes (deburring) may be accomplished with a manufactured deburring tool, a countersink using a very light cut or other tool which will clear the edges of a drilled or punched hole. Care must be taken to remove only the rough edges and chips from the hole. Refer to Figure 14. Figure 14: Material between Sheets of Metal When two or more sheets are drilled at the same time, it is necessary to remove chips and burrs from between the sheets as well. This is usually done with a chip chaser. Refer to Figure 15. Figure 15 illustrates the results of leaving material between drilled sheets. Figure 15: Chip Chaser For Training Purposes Only Issue: August 2014 Page 409 of 926 Modul 7 Riveting Hole Preparation for Flush Rivets It is extremely important for high speed aircraft that the skin be as smooth as possible. In order to have the rivet heads fit flush with the surface, we must prepare the skin by either cutting away a portion of the metal to match the taper of the rivet head, or by bending (or forming) the edges of the hole to fit the rivet head. PART 66 – Basic Training Cat B1 – Module 7 same. Because of this, one cutter will work for all size rivets. To countersink holes of different sizes only the pilot needs to be replaced. The body and stop fit over the cutter shaft and may be held still while the cutter is driven by the drill motor. The flush rivet used almost exclusively in modern aircraft is the AN426 (MS20426) rivet. It has a head angle of 100o. Countersinking Refer to Figure 16. If the top sheet of the metal being joined is thicker than the tapered portion of the rivet head the material should be countersunk; that is, it should be cut with a tapered cutter. The thinnest material that can be countersunk for the various rivets is given overleaf: Rivet diameter Minimum skin thickness 3/32” (2.38mm) 1/8” (3.2mm) 5/32” (4.0mm) 3/16” (4.8mm) 0.032” (0.8mm) 0.040” (1.0mm) 0.051” (1.3mm) 0.064” (4.63mm). A standard countersink can be used in a drill motor. But the difficulty in cutting the hole to the correct depth makes this tool impractical when more than one or two holes are to be countersunk. The stop countersink is used far more than the standard countersink. A cutter shaft fits into the chuck of a 1/4” (6.35mm) air or electric drill motor, and the cutter screws onto this shaft. Pilots are available for all of the popular rivet sizes and the shank of all of the pilots are the For Training Purposes Only Issue: August 2014 Figure 16: Types of Countersinks Page 410 of 926 Modul 7 Riveting Sequence of Working Steps PART 66 – Basic Training Cat B1 – Module 7 upper side. The pressure on the dies coins (or forges) the edges of the hole to exactly fit the shape of the dies. Adjust the countersink to cut the proper depth by using a piece of scrap metal with the thickness of the top sheet being riveted. Drill some holes of the size used for the rivet and adjust the stop of the countersink by screwing it up or down on the body and locking it with the locknut. Hold the stop with one hand and run the countersink into a hole until the fibre collar touches the sheet and then take it out Slip the proper rivet into the hole. It should fit so that its top is flush with the skin. When the stop is adjusted and the locknut is tightened against it, the countersink should cut all of the holes to a uniform depth. Coin dimpling gives the hole sharply defined edges that almost resemble machine countersinking. Both the top and the bottom of the dimple are formed to a 100° angle so dimples may be stacked (or: nested). Note: When using the stop, be sure to keep it from spinning and marking the metal. Dimpling If the skin is too thin for countersinking, the edges of the hole may be formed to accommodate the head of the rivet by using a set of dimpling dies. There are two methods of dimpling sheet metal: coin dimpling which forges (or coins) the metal into the dies, and radius dimpling, which folds the material down to form the dimple. There is no sharp break at the edge of a radius dimple. Coin Dimpling Refer to Figure 17. In coin dimpling, the male die fits through the rivet hole in the material. The coining ram in the female exerts a controlled pressure on the underside of the hole while the male die is forced into the For Training Purposes Only Issue: August 2014 Figure 17: Coin Dimpling Page 411 of 926 Modul 7 Riveting Radius Dimpling PART 66 – Basic Training Cat B1 – Module 7 will crack when the dimple is formed. To prevent this cracking, the material is heated as the dimpling is done. In this form of dimpling, the pilot on the male die is passed through the hole in the material and the male die is pressed into the female die. The dimple formed in this way does not have parallel sides, as the lower side has an angle greater than 100°. So these dimples cannot be nested unless the radius dimple is used only as the bottom member of the stack. Radius dimpling is done because its equipment is smaller than that needed for coin dimpling and can be used in locations where coin dimpling cannot. Hot Dimpling The equipment for hot dimpling is similar to that used for either coin or radius dimpling except that the dies are heated. The material is put in place, and heat and pressure are applied. The heat from the dies transfers into the metal and softens it, then the pressure is increased to form the dimple and the pressure is released. The amount of heat and the time the heat is applied (the dwell time) is carefully controlled to prevent destroying the temper condition of the metal being dimpled. Rivet Installation Procedures Each of the many thousands of rivets must carry its share of the total load in an aircraft structure. If one is not properly installed, it can force the adjacent rivets to carry more load than they are designed to take and a failed structure can result. In addition to the proper preparation of the hole for the rivet, the strength of a riveted joint is determined by the way the rivets are driven. Essentially, they should be driven with as few blows as possible so the materials will not work –harden and crack. The shop head should be concentric with the shank, and it should be as thick as one –half the diameter of the shank and should spread out 1.5 shank diameters. Refer to Figure 18. Hand Riveting Refer to Figure 19. Figure 18: Dimple Formed with Heat Magnesium and some of the harder aluminum alloys such as 7075 cannot be successfully cold dimpled, as the material is so brittle that it For Training Purposes Only Issue: August 2014 Page 412 of 926 Modul 7 Riveting PART 66 – Basic Training Cat B1 – Module 7 Almost all rivets are driven with either a rivet gun or a squeeze riveter. But there are times when building small components that it is convenient to drive a rivet by hand. The process used for driving aircraft rivets is not the same as that used by commercial sheet metal workers. Aircraft rivets driven in flat sheets are never peened over, but the shank is collapsed with a hand set in the same way it is done by the other riveting methods. To drive a rivet by hand, the material to be joined is prepared by drilling and deburring the holes. The rivet that is selected will stick through the combined sheets by 1.5 diameters. A bucking bar with the proper cupped depression in its head is clamped in a vice with the cup upward. The rivet is put through the holes in the metal and the rivet head is put in the cup of the bucking bar. A draw set is slipped over the rivet shank and tapped lightly with the hammer to draw the sheets of material tightly together. Now, hold the hand set on the top of the rivet shank so it is perfectly straight up and hit it sharply with the hammer. Be sure to use the hand set rather than striking the rivet directly with the hammer. Upset the shank with as few blows as possible to prevent work – hardening it. Compression Riveting Figure 19: Hand Riveting For Training Purposes Only When there is a large number of rivets to be driven along the edge of a sheet or in a stringer, a compression (or squeeze) riveter can reduce the time required. It will produce a far more uniform row of rivets than can be driven by a rivet gun and bucking bar. A squeeze riveter consists of a pair of jaws, one stationary and the other moved by a piston in an air cylinder. A rivet set with a cup that fits the rivet head is put into the stationary jaw. A flat set is fitted with a movable Issue: August 2014 Page 413 of 926 Modul 7 Riveting PART 66 – Basic Training Cat B1 – Module 7 jaw. When the handle is depressed or the trigger is pulled, air flows into the cylinder and squeezes the jaws together. Shims placed between the jaws and the rivet sets control the separation of the sets at the end of the piston stroke. This determines the height of the shop head formed on the rivet. The number of shims needed is determined by trial and error, using scrap material of the same thickness as that to be riveted. Once the rivet sets are adjusted, all of the rivets will have exactly the same height and diameter. The smooth compressive pressure used to upset the rivet will have a minimum strain - hardening effect on it. Gun Riveting Hand riveting and compression riveting are used for special conditions. But most of the rivets used in aircraft construction are driven by a reciprocating air hammer, more commonly called a ’rivet gun’. Types of Rivet Guns There is a number of different types of guns used. But these can be divided into two basic categories: fast - hitting, short - stroke guns which produce light blows, and guns with long strokes that produce heavy blows. The fast - hitting guns are usually used for 3/32” (2.4mm) or 1/8” (3.2mm) rivets. The bodies of these guns are made of aluminum alloy castings so they are light enough that the user will not be fatigued after using the gun all day. The long - stroke gun may be of either the slow - hitting reciprocating type, or it may be a one - shot gun that drives the rivet set only one blow each time the trigger is pulled. These guns are used to drive the larger rivets. They are much heavier than the fast - hitting gun. Figure 20: Types of Pneumatic Rivet Guns Refer to Figure 20. For Training Purposes Only Issue: August 2014 Page 414 of 926 Modul 7 Riveting There is a number of handle styles used with both types of guns. The pistol grip and the offset handle are the most popular styles, with the push -button type available for special applications where neither of the more popular guns will fit. PART 66 – Basic Training Cat B1 – Module 7 If the set is too small, it will produce a similar type of mark on the head of the rivet. Refer to Figure 21. The various rivet guns can be adjusted to deliver the required blow for each size of rivet. The most desirable practice is to adjust the gun so that the formed head of the rivet will be properly shaped by using as few blows of the rivet gun as possible. When the rivet gun is adjusted with too light a blow, the rivet may be work -hardened to such a degree that the head will not be formed properly without cracking the rivet. A rivet gun can be severely damaged if the trigger is pulled when there is no rivet set in the gun, or if the set is not pressed tightly against either a rivet or a piece of scrap wood. Without the proper restraint, the piston will be damaged. A rivet gun can drive the rivet set from the gun and convert it into a lethal projectile. Never use a rivet gun without a set –retaining ’beehive’ spring in place. Even with this spring in use, NEVER POINT THE GUN AT ANY PERSON OR OBJECT AND PULL THE TRIGGER! Rivet Sets It is important when selecting a rivet set for the job that you use the correct size. The radius of the depression in the set must be larger than that of the rivet head so the force of the blow will be concentrated at the center of the rivet head rather than on the side. If the set is too large, it will produce small indentations in the skin around the rivet head. These are called ’smiles’ and must be avoided. For Training Purposes Only Issue: August 2014 Figure 21: Types of Rivet Sets Page 415 of 926 Modul 7 Riveting Not only must the rivet set have the correct size and shape of depression, but it must fit squarely on the rivet head. Because the structure inside an aircraft sometimes makes it difficult to align the gun exactly with the rivet, rivet sets are made in many lengths and shapes; some straight, some having a single offset and some even having two offsets. PART 66 – Basic Training Cat B1 – Module 7 Bucking bars must be polished and free from any scratches or tool marks that would be impressed on the upset end of a rivet. Note: Be sure to use a rivet set that will allow you to direct the blows from the gun straight in line with the rivet. Bucking Bars A rivet is actually not driven by the rivet gun, but by the bucking bar. This hardened and polished steel bar is held against the end of the rivet shank and pressure is applied as the gun vibrates the rivet against the bar. The position of the bucking bar is critical in the formation of the shop head or bucked head. If the bar is tipped slightly, the rivet will dump over and will not form a concentric head. If too much pressure is held on the bar or if the bar is too large, the shop head will be driven too thin. If the bar is too small or is not held tightly enough, the hammering of the rivet gun will distort the skin. There are many sizes and shapes of bucking bars used in aircraft maintenance and yet each job presents the challenge of finding a bar that will clear the structure and fit squarely on the end of the rivet shank. Refer to Figure 22. Figure 22 shows several of the more commonly used shapes of bucking bars, along with a chart to indicate the weight of the bucking bar best suited for the various diameters of rivets. Figure 22: Bucking Bars for Driving Solid Rivets For Training Purposes Only Issue: August 2014 Page 416 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Riveting Setup and Adjustment of the Rivet Gun N.A.C.A. Method of Flush Riveting Skill must be developed to be able to drive rivets effectively. This skill can only be developed by driving rivets. Refer to Figure 23. Drill a number of holes in a piece of scrap metal, deburr the edges and clamp the material in a padded - jaw vice. Put the correct rivet set in the gun and be sure to screw a beehive spring onto the end of the gun to hold the set in place. Now, attach an air hose to the gun, hold the set tightly against a piece of scrap wood and pull the trigger. Adjust the airflow through the regulator until the set makes a good depression in the wood, but does not shatter it. This is a good starting pressure but will most probably have to be adjusted further when you start driving the rivet. Driving the Rivet Put a rivet of the correct length through the hole in the scrap metal and hold the rivet set against its manufactured head. The set must be directly in line with the rivet, and it must not touch the skin. Hold a bucking bar flat against the end of the rivet shank and develop a good feeling of the balance of forces between that on the gun and that on the bucking bar. These forces should almost be in balance, with just enough extra force on the gun to hold the rivet head firmly against the skin. Now, pull the trigger. You want to upset the rivet with the fewest blows possible so you will not work - harden it and cause it to crack. Therefore, adjust the airflow to get the proper impact with the gun. For Training Purposes Only Figure 23: N.A.C.A. Method of Flush Riveting It is possible to drive a rivet in such a way that the shop head will be flush with the outside skin and the protruding manufactured head will be on the inside of the structure. This method is called ’N.A.C.A. method of flush riveting’ (N.A.C.A. = National Advisory Committee for Aeronautics (USA)). The hole is dulled and countersunk as it would be for the normal installation of a flush rivet. But the rivet is installed from the inside of the structure so its shank sticks out through the countersunk hole. When the rivet is driven, the shank is upset to fill the countersunk hole and is allowed to stick up above the surface for just a few thousandths of an inch. When all of the rivets are driven, a miller is set up to mill the upset ends of the rivet shanks flush with the skin. This type of riveting produces the maximum smoothness and uniformity of the surface. Issue: August 2014 Page 417 of 926 Modul 7 Riveting PART 66 – Basic Training Cat B1 – Module 7 Team Riveting Refer to Figure 24. When skins are riveted onto a complete airframe or a large component, it is necessary for the rivet bucker to be on one side of the structure and the driver on the other side. There are often many teams working on the same structure and the noise makes communication difficult. A code is used between the bucker and the driver to allow them to communicate with only a series of taps on the rivet. The driver is responsible for putting the rivets into the holes and driving each of them the same amount. As soon as the driver puts the rivet in the hole, he puts the gun on it and holds pressure against it. When the bucker is ready, he taps the rivet one time as he puts the bar against the rivet shank and the driver drives the rivet. As soon as the driver stops the gun the bucker removes the bucking bar and examines the rivet. If it has been driven correctly, he taps on the rivet twice with the bucking bar and the driver goes on to the next rivet. But if the rivet needs to be driven more, the bucker will tap only one time and immediately get the bucking bar back on the rivet and the driver drives the rivet with another burst from the gun. If the rivet is dumped over or for any other reason is not satisfactory, the bucker will tap on the rivet 3 times and the driver will circle the rivet head with a grease pencil so it can be removed. In the high - speed production needed to build modern aircraft, good, well coordinated teams of riveters can keep a production line moving effectively. Figure 24: Tapping Code for Team Riveting For Training Purposes Only Issue: August 2014 Page 418 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Riveting Direct and Indirect Riveting Inspection of Riveted Joints Refer to Figure 25. Evaluating the Rivet Refer to Figure 26. Figure 25: Direct/Indirect Riveting Depending on the direction of the stroke, riveting can either be direct or indirect. Direct riveting means that the closing head of the rivet is formed by striking the shaft end. If the manufactured rivet head is struck and the closing head formed by pressing the shaft end against a bucking bar, this is called indirect riveting. Figure 26: Improperly Driven Solid Rivets For Training Purposes Only Issue: August 2014 Page 419 of 926 Modul 7 Riveting PART 66 – Basic Training Cat B1 – Module 7 In the process of developing skill in riveting, a student will drive some rivets improperly. A good technician must be able to identify those that are good and those that are not and know the cause of improperly driven rivets. A properly formed shop head is one - half the shank diameter high, its diameter is 1.5 times that of the shank and it is concentric with the hole. This concentricity can be checked by placing a straight edge along a row of shop heads that have been driven in a straight row of holes. Every shop head should touch the straight edge. The end of the rivet shank should leave a series of marks on the top of the shop head. If these marks are not concentric, the shop head is not concentric with the shank. The manufactured head of the rivet must be perfectly flat against the metal. If you can slip a thin feeler gauge blade between the manufactured head and the skin, the rivet must be removed and the cause of the improper fit determined. The rivet may be cocked in its hole by a small burr. Removal of Bad Rivets Refer to Figure 27. Figure 27: Removal of a Solid Rivet For Training Purposes Only Issue: August 2014 Page 420 of 926 Modul 7 Riveting PART 66 – Basic Training Cat B1 – Module 7 If a rivet has been badly fitted, it should be removed and a new one installed. To remove a rivet, the center of the manufactured head is lightly indented with a center punch. It must be ensured that the shop head is backed up with a bucking bar when center - punched so the skin is not distorted. A drill should be used whose diameter is slightly smaller than the rivet diameter. Carefully drill through the manufactured head. Now, you may either use a pin punch with the size of the drill to pry the head off. Back up the side of the skin near the shop head with a bucking bar or a piece of wood and, using a pin punch slightly smaller than the shank, gently drive the rivet from the skin. When the rivet is out, examine the hole. If it is not elongated, another rivet of the same size may be used as a replacement. If the hole is damaged, pass a drill that is correct for the rivet of the next size larger through the hole and install the larger rivet. If you must use a larger rivet, be sure that the pitch, gauge and edge distance values are all satisfactory. Make sure that the hole is deburred before fitting a new rivet. For Training Purposes Only Issue: August 2014 Page 421 of 926 Modul 7 Pipes and Hoses 7.9 Pipes and Hoses 7.9.1 Pipes 7.9.1.1 Working Rigid Tubing PART 66 – Basic Training Cat B1 – Module 7 taken not to apply too much pressure at one time, as it could deform the tube or cause excessive burring. When it is necessary to replace a rigid fluid line, a replacement tube assembly may be obtained from the aircraft manufacturer or may be fabricated in the shop. Most shops have the necessary tools to fabricate replacement lines, and all technicians must be familiar with their operation and limitations. Once cut, all burrs should be removed with a special deburring tool. The end of the tube must be smooth and polished so that no sharp edges can produce stress concentrations and cracks when the tube is flared. After the tube has been cut and deburred, it must be blown out with compressed air to remove metal chips that could have become imbedded in the tube. Tube Cutting Refer to Figure 1. When cutting a new piece of tubing, it should always be cut approx. 10 % longer than the tube being replaced. This provides a margin of safety for minor variations in bending. After determining the correct length, the tubing is cut with either a fine - tooth hacksaw or a roller – type tube cutter. A tube cutter is most often used on soft metal tubing such as copper, aluminium, or aluminium alloy. However, they are not suitable for stainless - steel tubing because they tend to work -harden the tube. To use a tube cutter, the tube must first be marked with a felt - tip pen or scriber. Next, the tubing must be placed in the cutting tool and the cutting wheel be aligned with the cutting mark. Once aligned, the cutting wheel should be gently tightened onto the tube using the thumbscrew. When the cutting wheel is snug, the cutter is to be rotated around the tube and the pressure on the cutting wheel gradually increased every 1 to 2 revolutions. Care must be For Training Purposes Only Issue: August 2014 Figure 1: Tube Cutting Page 422 of 926 Modul 7 Pipes and Hoses Tube Bending PART 66 – Basic Training Cat B1 – Module 7 Some applications require rigid lines with complex bends and curves. When duplicating these lines, bends must be produced that are 75 % of the original tube diameter and free of kinks. Any deformation in a bend affects the flow of fluid. Refer to Figure 2. Refer to Figure 3. To help reduce the chance of making a bad bend, there are several charts that illustrate standard bend radii for different size tubes. The information on these charts should be adhered to closely. Figure 2: Tube Bending For Training Purposes Only Issue: August 2014 Page 423 of 926 Modul 7 Pipes and Hoses PART 66 – Basic Training Cat B1 – Module 7 Figure 3: Standard Bend Radii For Training Purposes Only Issue: August 2014 Page 424 of 926 Modul 7 Pipes and Hoses Refer to Figure 4. PART 66 – Basic Training Cat B1 – Module 7 Tubing under 1/4 inch (6.35 mm) made of soft metal and having a thin wall can usually be bent by hand. This is accomplished by using a tightly wound steel coil spring that fits snugly around the tubing to keep it from collapsing. In an emergency, a tube can be bent by first packing it full of clean, dry sand, sealing the ends and then making the bends. However, when using this method, it is extremely important that every particle of sand be removed from the tube before it is installed. A variation of the sand method of bending is used in some factories for making complex bends. This process involves filling a tube with an extremely low melting point metal alloy such as Wood’s metal or Cerrobend. These alloys are melted in boiling water and then poured into the tube. Once the alloy sets, the tube is bent. When the bending operation is completed, the tube is placed back in a vat of boiling water where the alloy melts and drains out of the tube. Tubing larger than 1/4 inch (6.35 mm) in diameter typically requires bending tools to minimise flattening and distortion. Small diameter tubing of between 1/4 inch (6.35 mm) and 1/2 inch (12.70 mm) can be bent with a hand bending tool. When using a hand bender, the tube is inserted between the radius block and the slide bar and held in place by a clip. The slide bar handle is then moved down to bend the tubing to the angle needed. The number of degrees the tube is bent is read on the scale of the radius block, opposite the incidence mark on the slide bar. Refer to Figure 5. Figure 4: Hand – Held Tubing Bender For Training Purposes Only Issue: August 2014 Page 425 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Pipes and Hoses 7.9.1.2 Joining Rigid Tubing Sections of rigid tubing can be joined to another tube or to a fitting by several methods. These include single and double flare connectors, flareless connectors, or a hose and clamps over a beaded tube. The type of fittings used is determined by the pressure range, the routing, and the material being used for the lines. Whenever a fitting must be replaced, care must be taken to select a fitting made of the same material as the original. Tube Flaring Refer to Figure 6. Figure 5: Production –Type Tube Bender Production bending is done with a tube bender similar to the one illustrated in Figure 5. A tube is clamped between the radius block and the clamp bar, and the radius block is turned by a gear which is driven by the handle. As the radius block turns, the tube is bent between the radius block and a guide bar. The degree of bending is determined by the amount the radius block is turned. Thin wall tubing is kept from collapsing by using a mandrel, which is a smooth round – end bar that fits into the tube at the bend point. It holds the tube so that it cannot collapse. Figure 6: Tube Flaring For Training Purposes Only Issue: August 2014 Page 426 of 926 Modul 7 Pipes and Hoses PART 66 – Basic Training Cat B1 – Module 7 Much of the rigid tubing used in modern aircraft is connected to components by flaring the tube ends and using flare type fittings. A flared tube fitting consists of a sleeve and a B - nut. Using this type of connector eliminates damage to the flare caused by the wiping or ironing action as the nut is tightened. The sleeve provides added strength and supports the tube so that vibration does not concentrate at the flare. The nut fits over the sleeve and, when tightened, draws the sleeve and flare tightly against a male fitting to form a seal. The close fit between the inside of the flared tube and the flare cone of the male fitting provides the actual seal. Therefore, these 2 surfaces must be absolutely clean and free of cracks, nicks, and scratches. Aircraft fittings have a flare angle of 37o and are not interchangeable with automotive type fittings, which have a flare angle of 45o. The flare provides the sealing surface and is subject to extremely high pressures. Because of this, flares must be properly formed to prevent leaks or failures. A flare which is made too small, produces a weak joint and may leak or pull apart. On the other hand, if a flare is too large, it may interfere with the installation of the nut and result in leakage. In either case, if a fitting leaks when properly torqued, the flare and fitting components should be inspected for proper manufacture and assembly. Note: A leaky fitting must not be overtightened. Refer to Figure 7. Figure 7: Single - and Double - Flared Ends For Training Purposes Only Issue: August 2014 Page 427 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Pipes and Hoses There are 2 types of flares used in aircraft plumbing systems: single flare double flare. Single Flare Refer to Figure 8. A single flare is formed with either an impact - type flaring tool, or one having a flaring cone with a rolling action. To form a flare using an impact - type flaring tool, the tube must be cut squarely and the ends polished. Before the tube is flared, a B - nut and sleeve are slipped on the tube. The tube is then placed in the proper size hole between the halves of the flaring blocks and the plunger is centered over the tube. Once centered, the end of the tube should project approx. 1/16 inch (1.59 mm) above the blocks. The blocks are then clamped in a vice and the plunger is driven into the tube with several light blows of a hammer, making sure the plunger is rotated 1/2 turn after each blow. It is important to use as few blows as possible, since too many blows can work –harden the tubing. Refer to Figure 9. Figure 9: Roll – Type Flaring Tool For Training Purposes Only Issue: August 2014 Page 428 of 926 Modul 7 Pipes and Hoses PART 66 – Basic Training Cat B1 – Module 7 Roll –type flaring tools are quite popular in aviation maintenance shops because they are entirely self contained and produce a good flare. A typical roll - type tool can flare tubing from 1/8 inch (3.175 mm) to 3/4 inch (19.05 mm) outside diameter. To use this tool, the dies must be rotated until the 2 halves of the correct size are aligned and then the tube should be inserted against the stop. Once the dies have been clamped together, the flaring cone must be lubricated. The flaring cone is then turned into the end of the tube and rollers in the cone burnish the metal as it expands into the die. When the flare is formed, the handle is reversed to release the dies, and the tube is removed from the tool. Refer to Figure 10. Single flares must be made to certain tolerances. Specifically, both the diameter and the radius of the flare must be within specified ranges to ensure a durable, leak - free connection. A flare that is too small or too large can leak or lead to failure. Figure 10: Dimensions of Single – Flared Tubing For Training Purposes Only Issue: August 2014 Page 429 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Pipes and Hoses Double Flare Soft aluminium tubing with an outside diameter of 3/8 inch (9.525 mm) or smaller can be double - flared to provide a stronger connection. A double flare is smoother and more concentric than a single flare and, therefore, provides a better seal. Furthermore, a double flare is more durable and resistant to the shearing effect of torque. Refer to Figure 11. Refer to Figure 12. Tube size nominal outside diameter (inch) 1/8 3/16 1/4 5/16 3/8 B Radius +0.010 (inch) 0.032 0.032 0.032 0.032 0.046 Figure 12: Dimensions of Double – Flared Tubing Figure 11: Double Flare For Training Purposes Only A Diameter +0.010 −0.010 (inch) 0.224 0.302 0.359 0.421 0.484 Issue: August 2014 Page 430 of 926 Modul 7 Pipes and Hoses PART 66 – Basic Training Cat B1 – Module 7 To double - flare a piece of tubing, it must be cut off in the same manner as a single flare, all burrs should be removed, and the end be polished. Next, the tubing is to be inserted into the flaring die to the depth allowed by the stop pin and then the dies are to be clamped. The upsetting tool must be inserted into the die and, with as few blows of a hammer as possible, the tubing must be upset. Once the flare is started, the flaring tool should be inserted and by striking it with a hammer the metal should be folded down into the tubing and the double flare be formed. Flareless Fittings Refer to Figure 13. Figure 13: Flareless Fittings For Training Purposes Only Issue: August 2014 Page 431 of 926 Modul 7 Pipes and Hoses The heavy wall tubing used in some high –pressure systems is difficult to flare. For these applications, the flareless fitting is designed to provide leak - free attachments without flares. PART 66 – Basic Training Cat B1 – Module 7 Furthermore, the ferrule should be slightly bowed to provide the proper sealing against the edge of the fitting. Beading Although the use of flareless fittings eliminates the need to flare the tube, a step referred to as ’presetting’ is necessary prior to installation of a new flareless tube assembly. Presetting is the process of applying enough pressure to the sleeve to cause it to cut into the outside of the tube. To preset a flareless fitting, lubricate a nut and sleeve, sometimes called a ferrule slip them over the end of a tube screw the nut onto the presetting tool, making sure the tube is square against the bottom of the tool screw the nut down by hand until it tightens the ferrule against the presetting tool. Refer to Figure 14. Large - diameter lines carrying low - pressure fluids, such as engine return oil and cooling air, are typically joined by a rubber hose that is slipped over the tube ends and held in place with screw - type hose clamps. However, for this to be effective the tube must be beaded first. This can be accomplished with either a power header or a hand beading tool. The diameter and wall thickness of the tube being beaded determine which is used. The final tightening depends upon the tubing. Example: For aluminium alloy tubing up to and including 1/2 inch (12.70 mm) outside diameter, the nut must be tightened from 1 to 1 1/6 turns. For steel tubing and aluminium alloy tubing over 1/2 inch (12.70 mm), the nut should be tightened from 1 1/6 to 1 1/2 turns. Figure 14: Beading Tool Once this is done, the tube is to be removed from the presetting tool and the ferrule examined. The tube should have a uniform indentation, or ’bite’, around its end, indicating that the tube is square and has bottomed evenly into the tool. Example: A hand - beading tool is used with tubing having 1/4 inch (6.35 mm) to 1 inch (25.40 mm) outside diameter. In addition, the bite should be even and the tube material should raise to a height of at least 50 % of the ferrule thickness. The ferrule may rotate on the tube, but it should not move back and forth. When using a hand beading tool, the bead is formed by a header frame with the proper rollers. The sizes, which are marked on the rollers in sixteenths of an inch, correspond with the outside tube diameter. Separate rollers are required for the inside of different sized tubing so care must be taken to use the correct parts when beading. For Training Purposes Only Issue: August 2014 Page 432 of 926 Modul 7 Pipes and Hoses PART 66 – Basic Training Cat B1 – Module 7 The beading tool operates somewhat like a tube cutter in that the roller is screwed down while rotating the beading tool around the tubing. However, the inside and outside of the tube must be lubricated with a light oil to reduce friction during beading. Refer to Figure 15. When joining 2 beaded tubes, first the hose is to be slipped over the beads and the hose clamps are to be centered between the ends of the hose and the beads. Then the clamps are to be tightened finger – tight followed by 1 1/2 to 2 complete turns using a wrench or pliers. When doing this, care must be exercised not to overtighten the clamps and thus cause excessive ’cold - flow’, which is indicated by deep, permanent impressions in the hose. Figure 15: Joining 2 Beaded Tubes For Training Purposes Only Issue: August 2014 Page 433 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Pipes and Hoses 7.9.1.3 Rigid Tubing Installation 1/2 –8 150 –250 450 –500 Before installing a tube assembly in an aircraft, the tube must be inspected carefully for nicks, scratches and dents. In addition, the fittings and tube should be inspected for cleanliness. 5/8 –10 200 –350 650 –700 3/4 –12 300 –500 900 –1,000 7/8 –14 500 –600 1,000 –1,100 Note: Never should sealing compound or anti - size be applied to a fitting’s sealing surfaces since these surfaces depend on metal to metal contact to seal. If any foreign matter is present it should be removed so that the seal is not compromised. 1 –16 500 –700 1,200 –1,400 1 1/4 –20 600 –900 1,200 –1,400 1 1/2 –24 600 –900 1,500 –1,800 1 3/4 –28 850 –1,050 2 –32 950 –1,150 Before securing a line assembly in place, it must be checked if it is properly aligned. Furthermore, since rigid tubing expands and shifts when pressurised, an installation that is under tension is undesirable. Note: Never should an assembly be pulled into alignment by tightening the nut. Since overtightening a fitting may damage the sealing surface or cut off a flare, fittings should always be installed to the specified torque using a torque wrench. Tubing outside diameter (inch) Fitting size Aluminium alloy tubing, nut torque (inch lbs.) 1/8 –2 20 –30 3/16 –3 30 –40 90 –100 1/4 –4 40 –65 135 –150 5/16 –5 60 –85 180 –200 3/8 –6 75 –125 270 –300 For Training Purposes Only Steel tubing, nut torque (inch lbs.) Refer to Figure 16. Installation of a properly preset flareless fitting is made by tightening the fitting by hand until it bottoms. If this is not possible, a wrench may be used. However, the first signs of bottoming must carefully be watched. Final tightening, on the other hand, is completed with a wrench by turning the nut 1/6 of a turn. When doing this, a wrench must be used on the male fitting to prevent it from turning. Some manufacturers specify torque limits for this type of fitting. Issue: August 2014 Page 434 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Pipes and Hoses Refer to Figure 17. Figure 17: Rigid Tubing Installation (Example) On completion of all connections, the system should be pressure tested. If a connection leaks, some manufacturers allow the nut to be tightened an additional 1/6 turn. Figure 16: Table of Standard Torque Values For Training Purposes Only Since rigid tubing flexes and expands under pressure, all runs of tubing must have at least one bend between the fittings to absorb these strains. Furthermore, all bends must be located in such a way that they can be supported by clamps so that the stress from vibrations and from expansion and contraction is not placed on a fitting. Issue: August 2014 Page 435 of 926 Modul 7 Pipes and Hoses Routing and Securing All fluid lines should be routed through the aircraft in such a way that they have the shortest practical length. Furthermore, for the sake of appearance and ease of attachment, all fluid lines should follow the structural members of the aircraft and should be secured with appropriate clamps. Example: All fuel lines must be bonded to the structure with integrally bonded line support clamps. Tube outside diameter (inch) Distance between supports (inch) 1/8 –3/16 9 1/4 –5/16 12 3/8 –1/2 16 5/8 –3/4 22 1 –1 1/4 30 1 1/2 –2 40 PART 66 – Basic Training Cat B1 – Module 7 By the same token, routing fluid lines through passenger compartments should be avoided. However, if a fluid line must be routed through a passenger, crew or baggage compartment, it must be supported and protected against damage or installed in such a way that it cannot be used as a hand - hold. Support Clamps Refer to Figure 18. Support clamps are used to secure fluid lines to the aircraft structure, or to assemblies in the engine nacelle. In addition to providing support, these clamps prevent chafing and reduce stress. The 2 clamps most commonly used are the rubber - cushioned clamp and the plain clamp. The rubber - cushioned clamp secures lines which are subject to vibration. The clamp’s rubber cushion reduces the transmission of vibrations to the line and prevents chafing. In areas subject to contamination by fuel or phosphate - ester type hydraulic fluid, cushioned clamps utilising Teflon are used. Although these do not provide the same level of cushion, they are highly resistant to deterioration. The plain clamp is used in areas that are not subject to vibration. It typically consists of a metal band formed into a circle. It is important that no fluid line be allowed to chafe against any control cable or aircraft structure. Furthermore, every effort should be made to prevent fluid lines from coming in contact with electrical wiring bundles or conduit carrying electrical wires. However, if it is impossible to separate fluid lines from electrical wire bundles, the wire bundle must be routed above the fluid line, and it must be clamped securely to the structure. A third type of clamp used to secure metal fuel, oil, or hydraulic lines is the bonded clamp. Bonded clamps have an electrical lead that is connected to the aircraft structure to ground a tube. When installing a bonded clamp, any paint or anodising must have been removed from the tube where the bonding clamp is fastened. Unbonded clamps should be used only to secure wiring. Note: Under no circumstances should a wire bundle be supported by a fuel line or any line carrying flammable fluid. For Training Purposes Only Issue: August 2014 Page 436 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Pipes and Hoses 7.9.1.4 Repair of Rigid Tubing The most common problem encountered with fluid lines is leakage. If a fluid line leaks at a fitting, pressure should be removed from the line and the fitting checked for proper torque. It is never proper to overtorque a fitting in an attempt to stop a leak. If a fitting leaks after it is determined to be properly torqued, the nut should be unscrewed and the sealing surfaces carefully examined. If there is any sign of damage, the fitting must be replaced. Any crack or deformity in a flare is cause for rejection. Minor dents and scratches in tubing may be repaired. Scratches or nicks in aluminium alloy tubing that are no deeper than 10 % of the wall thickness and not in the heel of a bend can be repaired by burnishing. However, tubing with severe die marks, seams or splits must be replaced. A dent less than 20 % of the tube diameter is permitted if it is not in the heel of a bend. Refer to Figure 19. Figure 18: Support Clamps For Training Purposes Only Figure 19: Repairing Rigid Tubing (I) Issue: August 2014 Page 437 of 926 Modul 7 Pipes and Hoses PART 66 – Basic Training Cat B1 – Module 7 To remove dents, the tubing must be removed from the aircraft and a bullet of the proper size drawn through the tube using a short length of cable. The bullet can also be pushed through the tube using a dowel rod. The ’bullet’ used for this operation may be a ball bearing or a slug made of steel or some other hard metal. In soft aluminium tubing, a bullet made of hardwood can be used. Refer to Figures 20 and 21. Figure 21: Repairing Rigid Tubing (III) Damaged sections of tubing are replaced by cutting out the damaged area and splicing in a new section. This is accomplished by carefully removing the damaged section and inserting a replacement section of the same size and material. When doing this, both ends of the undamaged tube and replacement tube are flared and secured using standard unions, sleeves and nuts. Figure 20: Repairing Rigid Tubing (II) For Training Purposes Only Issue: August 2014 Page 438 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Pipes and Hoses Permaswage Fittings The basic element of the Permaswage repair technique is the Permaswage fitting, which is mechanically swaged onto the tube by a hydraulically operated tool. Permaswage fittings are designed for use by all levels of maintenance, and are available in various configura tions. There are different sets of Permaswage tube repair equipment available. They differ mainly in the size of fittings, range of tube sizes and pressure rate. The Permaswage swaging tools can produce permanent tubing joints by swaging Permaswage fittings onto compatible tubing. The fittings may be unions, tees, crosses, separable fittings, reducer fittings and other special fittings. Refer to Figure 23. Refer to Figure 22. Figure 23: Permaswage Hydraulic Power Supply Figure 22: Permaswage Toolkit For Training Purposes Only Issue: August 2014 Page 439 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Pipes and Hoses Hydraulic pressure supplied by a portable hydraulic power supply causes the segments inside the swaging tool to swage. range of tubing sizes and types of fittings by changing the die block assemblies and/or fitting locators. Refer to Figure 24. The die block assemblies are supplied in sets, consisting of upper and lower die blocks, dies and locators. The lower die block is retained on the basic swage tool assembly to ensure automatic retraction and consistant repeatability. The upper die block assembly is removable for easy loading. Permaswage Fitting Repair Note: Tube assembly repair using Permaswage fittings and techniques is considered to be a permanent repair. Before a damaged tube is cut, a line is drawn with a marking pen parallel to the tube and across the section to be cut. Then the tubing is cut. If a tube is to be replaced, it must be ensured that the line is placed in the same location on the new tube as on the tube section that has been removed: draw a line across the fitting install the tube run and locate the fitting fingertighten any end fittings Note: One end of the fitting may be swaged on the bench if possible Figure 24: Basic Swage Tool Assembly The basic swage tool assembly contains an actuating piston and a locking latch which ensures the retention of the upper die block during the swage cycle. The swaging tool is designed to operate over a For Training Purposes Only place the swaging tool on the first ed being swaged and line up the line on the tube end being swaged with the line on the fitting repeat the procedure with the other end(s to be swaged torque the fittings. Refer to Figure 25. Issue: August 2014 Page 440 of 926 Modul 7 Pipes and Hoses PART 66 – Basic Training Cat B1 – Module 7 Figure 25 : Swaged Tube Fitting (Example) For Training Purposes Only Issue: August 2014 Page 441 of 926 Modul 7 Pipes and Hoses 7.9.2 PART 66 – Basic Training Cat B1 – Module 7 Hoses Note: For details on the construction and types of flexible hoses refer to EASA - Part 66, Module 6.6. 7.9.2.1 Flexible Hose Installations Refer to Figures 1 and 2. Figure 1: Flexible Hose Installations (I) For Training Purposes Only Issue: August 2014 Page 442 of 926 Modul 7 Pipes and Hoses PART 66 – Basic Training Cat B1 – Module 7 Before installing a hose assembly, it must be verified that the aircraft manufacturer specifies a flexible hose is appropriate. If a flexible hose is permitted, the replacement hose must be inspected carefully. It must be checked for proper type and length, physical damage and cleanliness. Furthermore, it must be ensured that the hose cure date and assembly date are within the limits for that type of material. Part number, cure date, and assembly date of hose assemblies are found on the hose identification tag. It is important that the lay line be straight when the hose is installed. Any spiralling is an indication that the hose is twisted and is under an undue amount of strain when there is pressure in the line. A flexible hose should be installed so that it is subject to a minimum of flexing during operation. Although a hose must be supported at least every 24 inches, closer supports are desirable. A flexible hose must never be stretched tightly between 2 fittings. The minimum bending radius for a flexible hose is determined by the type of hose being used and its size. Bends that are too sharp reduce the bursting pressure of a flexible hose below its rated value. Figure 2: Flexible Hose Installations (II) For Training Purposes Only Issue: August 2014 Page 443 of 926 Modul 7 Pipes and Hoses PART 66 – Basic Training Cat B1 – Module 7 Minimum bending radius (inch) Dash number –4 3 –5 3 3/8 –6 5 –8 5 3/4 –10 6 1/2 –12 7 3/4 –16 9 5/8 Protective Sleeves In certain areas, the flexible hose must be protected from wear caused by abrasion or extreme heat. Example: If a fluid line must pass near a hot exhaust manifold, the line must be protected with a suitable fire shield. On the other hand, if a fluid line rubs against another part, an abrasion sleeve is appropriate. There are a number of products on the market designed for this type of application. Some of the more common protective sleeves include heat shrink, nylon spiral wrap and Teflon. Caution should be used when replacing fire sleeves on older aircraft, as many early products consisted of asbestos braid. For Training Purposes Only Issue: August 2014 Page 444 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Pipes and Hoses 7.9.3 In handling large size hoses, dollies should be used whenever possible; slings or handling rigs, properly placed, should be used to support heavy hoses as used in oil suction and discharge service. Testing Equipment General The service life of a hose assembly depends on the application and the environment in which it is used. Most hose assembly failures result from kinking, chafing, impact, flexing and temperature cycling. They also age and become brittle due to molecular changes with time and reactions with both the internal and external fluids with which they come into contact. One of the catastrophic modes of failure is when the hose comes out of its end fittings. This is primarily because of the permanent set that the hose material undergoes which reduces the retention forces on the end fittings and is the underlying reason for specifying a calendar time life for the hoses. 7.9.3.2 General Test and Inspection Procedures for Hose An inspection and hydrostatic test should be made at periodic intervals to determine if a hose is suitable for continued service. A visual inspection of the hose should be made for loose covers, kinks, soft spots which might indicate broken or displaced reinforcement. The couplings or fittings should be closely examined and, if there is any sign of movement of the hose from the couplings, the hose should be removed from service. Hoses should not be subjected to any form of abuse in service. They should be handled with reasonable care. The periodic inspection should include a hydrostatic test for one minute at 150% of the recommended working pressure of the hose. During the hydrostatic test, the hose should be straight, not coiled or in a kinked position. Hoses should not be dragged over sharp or abrasive surfaces unless specifically designed for such service. A regular schedule for testing should be followed and inspection records maintained. Care should be taken to protect hoses from severe end loads for which the hose or hose assembly were not designed. Safety Warning 7.9.3.1 General Care and Maintenance of Hoses Hoses should be used at or below their rated working pressure; any changes in pressure should be made gradually so as to not subject the hose to excessive surge pressures. Before conducting any pressure tests on hoses, provisions must be made to ensure the safety of the personnel performing the tests and to prevent any possible damage to property. Hoses should not be kinked or be run over by equipment. For Training Purposes Only Issue: August 2014 Air or any other compressible gas must never be used as the test media because of the explosive action of the hose should Page 445 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Pipes and Hoses a failure occur. Such a failure might result in possible damage to property and serious bodily injury. Air should be removed from the hose by bleeding it through an outlet valve while the hose is being filled with the test medium. Hose to be pressure tested must be restrained by placing steel rods or straps close to each end and at approximate 10 foot (3m) intervals along its length to keep the hose from”whipping” if failure occurs; the steel rods or straps are to be anchored firmly to the test structure but in such a manner that they do not contact the hose which must be free to move. The outlet end of hose is to be bulwarked so that a blown –out fitting will be stopped. Provisions must be made to protect testing personnel from the forces of the pressure media if a failure occurs. Testing personnel must never stand in front of or in back of the ends of a hose being pressure tested. When liquids such as gasoline, oil, solvent, or other hazardous fluids are used as the test fluid, precautions must be taken to protect against fire or other damage should a hose fail and the test liquid be sprayed over the surrounding area. The safety limitations, hose design and the installation environment that could cause a defect to develop determines the inspection requirements. Following is a list of defects with guidelines for minor and major defects categorisation. Refer to Figure 1. Testing Procedure Visual Inspection Inspection of hose assemblies may be carried out in at the intervals specified in the aircraft maintenance schedule. Considering the potential consequences of a major hose failure a maintenance schedule that does not include hose inspection should be viewed as deficient and should be amended. During each inspection the date of manufacture and date of pressure test should be checked. The inspected hoses are to be identified by part number and location and the details of the inspection findings and corrective actions recorded, where feasible. For Training Purposes Only Issue: August 2014 Figure 1: Visual Inspection of Hoses Page 446 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Pipes and Hoses Kinks and Twists This defect is usually caused by incorrect installation or handling, is permanent damage restricting flow and the hose should be replaced. Broken Braids Isolated random breakage of the braid wires is a minor defect. If breakage of several wires are concentrated in one area, or two or more wires in a braid is broken, it is a major defect. Chafing and cuts Light scuffing, cuts and abrasion of the outer cover, with the braids not exposed is a minor defect. Minor adjustment of the hose clamps to avoid chafing is recommended, (unless otherwise approved clamping of pipes should be in accordance with aircraft type design Corrosion Light local corrosion of braids and end fittings, due to oxidation or chemical attack, may be a minor defect to be monitored in subsequent inspections. Brittleness High temperatures and long service may harden hoses and make them brittle and should be replaced. This may also point to incorrect type of hose for the application and should be investigated. Contamination Instances of significant hardening, discoloration or sponginess of the outer rubber cover may indicate chemical contamination and could require replacement of the hose. Leakage Any leakage from fittings that retains the flexible element is a major defect and the hose should be replaced. Damaged fire sleeve Localised cuts and abrasions where the hose is not exposed is a minor defect for further monitoring. For Training Purposes Only Blisters Puncture the blister and if the operating fluid leaks out, it is a major defect. Testing of Hoses Issue: August 2014 During overhaul or major refurbishment of the engines, all hoses should be tested. A test interval of six years is recommended for airframe hoses. Before testing hoses should be inspected. In general the serviceability criteria for hose assembly when not installed (i.e. at piece part level) should be more stringent than when it is installed on the aircraft. Removable fire sleeves should be removed during this inspection. Hoses should be tested for internal restriction or kinking by passing a steel ball in both directions. Hoses should be hydraulic pressure tested at 1.5 times the maximum system pressure without leakage. Vacuum hoses should be tested to 28 inches of mercury vacuum and the hose should not collapse after it has been tested for leakage. Hoses with Teflon lining, or hoses that have undergone a permanent set should be restrained in their preset shape using lock wiring during the test to ensure that they do not flex. After test, the hose should be cleaned, ends blanked and marked with the date of test, and test pressure, along with direction of fluid flow and type of fluid where applicable. Data may be stencilled on the external surface, or impressed on a metal band secured to the hose. Hoses should be suitably preserved. Page 447 of 926 Modul 7 Pipes and Hoses PART 66 – Basic Training Cat B1 – Module 7 Internal Inspection A hose can pass both a visual inspection and a hydrostatic test but still have imperfections to its internal structure. These imperfections could cause it to fail shortly after being tested. For important hoses or pipes it is necessary to inspect the inside of the hose or tube. Refer to Figure 2. Figure 2, details b) and c), show pictures of internal inspection of hoses with an endoscope. To compare, the hole in the convolution is no bigger than that of a pin head. Handling and Storage of Hoses Hoses with Teflon lining, or hoses that have undergone permanent set should be restrained during handling and storage. Suitable sealing blanks should be fitted. Protective coating should be applied to the end fittings to prevent corrosion. Rubber and synthetic rubber hoses where storage life is specified by the manufacturer and should be adhered to. Excessive bending should be avoided during handling and storage. Hoses should be stored in individually sealed plastic wraps below 26oC. Figure 2: Pictures of Pipe and Hose Inspections For Training Purposes Only Issue: August 2014 Page 448 of 926 Modul 7 Pipes and Hoses PART 66 – Basic Training Cat B1 – Module 7 7.9.3.3 Types of Testing Equipment Manual Pressure Tester Refer to Figure 3. Figure 3 shows types of hand operated pressure testers. The hand pump pressure tester on the top is a typical hose tester with integrated reservoir. In the middle, a typical hand operated pressure tester is shown for system components, e.g. pipe system with fittings and valves. The test unit consists of a plunger pump with hand lever, a test pressure gauge, a connecting hose, a drain valve and a water tank. For protection of the piston pump for debris there is an inlet filter installed in the suction pipe. The hydraulic hoses test bench at the bottom of the figure is equipped with a plunger hand pump, which supplies the necessary test pressure, a pressure gauge, a manifold for hose adapter and an oil tank. The bench has a lightweight design and is very easy to operate. Figure 3: Types of Manual Pressure Tester For Training Purposes Only Issue: August 2014 Page 449 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Pipes and Hoses General Operating Instructions For operation of a hand - operated pressure tester the following instructions can be applied: Connect the hydro test hose to the portable tester. Ensure that the hoses used are rated for the maximum operating pressures. Crack open the drain valve from the manifold block to ensure that all the air is vented from the pump. Observe the component under test for leaks. Observe the hydro test gauge. Stop operating the handpump and check for pressure loss from the test gauge. When hydrostatic testing is completed, open the drain valve to release the test pressure. Ensure that all pressure is vented before the component is removed from the test hose. Hose Proof Tester Refer to Figure 4. The hose proof tester is designed for underwater proof pressure and leakage testing of aircraft tubing manifolds and assemblies, but could be applicable to a wide variety of products requiring similar tests. The standard unit consists of a portable sheet metal tank on casters with a built in test sink and optional waterproof light. The test sink is covered by a polycast acrylic hinged cover. For Training Purposes Only Figure 4: Hose Proof Tester General Instructions The operator opens the cover, attaches the unit to be tested to the test ports with hoses (included), and begins pressure testing. The unit has a sloped control panel for ease of sight to the operator and contains analogue displays for internal pressure circuits. Air –Driven Hydrostatic Tester Hydrostatic testers are used for both proof hydrostatic testing and burst hydrostatic testing. By simply connecting the hydrostatic tester to a workshop air supply, safe hydrostatic testing can be accomplished with hydrostatic test output pressures available to 15,000 psi. Issue: August 2014 Page 450 of 926 Modul 7 Pipes and Hoses PART 66 – Basic Training Cat B1 – Module 7 Hydraulic Hose Tester Refer to Figure 5. The purpose of this equipment is to provide a source of high pressure oil for proof testing hydraulic hoses after assembly. The unit is air operated and will supply an outlet pressure up to 15,000 psi from an air supply of 100 psi. The unit is completely self contained and is supplied with adapters to accommodate both flared and flare less hydraulic fittings. The discharge pressure is regulated by controlling the inlet pressure at the unit by means of its regulator. The discharge pressure will be increased in the ratio of 150 to 1 over the inlet air pressure. The stainless reservoir has a usable capacity of 5 gallons with an allowance for fluid expansion. Racks are provided on the reservoir assembly for storage of hose connection adapters. Figure 5: Hydraulic Hose Tester For Training Purposes Only Issue: August 2014 Page 451 of 926 Modul 7 Pipes and Hoses Mobile Hydrostatic Tester Refer to Figure 6. Features Heavy duty roll frame 1’’ square tubular, powder coated, with wheels. Panel mounted controls Dual 4’’ gauges for two gauge verification, panel mounted pump regulator, air and water valves and drain valve. Air - driven piston pump Non - lubricated air - driven pump suitable for explosive environments, pump adjustable entire range, automatically stalls at preset pressure, starts when pressure drops below set pressure, enabling the pump to be left unattended. Rear mounted ports 3/8’’ air, water and drain ports. 1/4’’ FNPT (Fine National Pipe Thread) test port stainless steel. 5 gallon reservoir Stainless steel with fill/vent cap, sight gauge and drain. PART 66 – Basic Training Cat B1 – Module 7 Ensure that the pump regulator adjusting knob is turned to the full counter - clockwise position before turning on the air supply valve to the pump. Turn on the air supply valve to the tester and rotate the pump regulator clockwise until the desired test pressure is obtained. Observe the component under test for leaks. Observe the hydro test gauges. Turn off the air supply to the pump and check for a pressure loss from the test gauges. If the component under test shows a visible external leakage, the air to the hydro pump may be left open to maintain the test pressures. When hydrostatic testing is completed, turn off water and air to the hydro pump and open the drain valve to release the test pressure. Ensure that all pressure is vented before the component is removed from the test hose. Operating Instructions Connect air, water and the hydro test hose to the portable tester. Ensure that the hoses used are rated for the maximum operating pressures. Turn on the water supply to the hydro pump. Water can flow through the pump even if it is not running. Vent all the air from the component being tested. Crack open the drain valve from the manifold block to ensure that all the air is vented from the pump. For Training Purposes Only Issue: August 2014 Page 452 of 926 Modul 7 Pipes and Hoses PART 66 – Basic Training Cat B1 – Module 7 Figure 6: Mobile Hydrostatic Tester For Training Purposes Only Issue: August 2014 Page 453 of 926 Modul 7 Springs 7.10 Springs 7.10.1 Maintenance of Springs 7.10.1.1 Visual Inspections The indications of corrosive attack can take several forms depending on the type of metal and the length of time the corrosion has had to develop. Corrosion deposits on aluminium and magnesium are generally a white powder, while ferrous metals vary from red to dark reddish brown stains. A visual inspection is the most widely used technique and an effective method for the detection and evaluation of corrosion. Visual inspection employs the eyes to look directly at an aircraft surface or, at a low angle of incidence, to detect corrosion. Using the sense of touch of the hand is also an effective inspection method for the detection of hidden well developed corrosion. Other tools used during a visual inspection are mirrors, endoscopes, optical micrometers and depth gauges. Refer to Figure 1. PART 66 – Basic Training Cat B1 – Module 7 Sometimes when the inspection areas are obscured by structural members, equipment installations or for some other reason, they are awkward to be checked visually. Adequate access for inspections must be obtained by removing access panels and adjacent equipment, cleaning the area as necessary, and removing loose or cracked sealants and paints. Mirrors, endoscopes and fibre optics are useful in providing the means of observing obscure areas. Spring Defects Refer to Figure 2. Cracked Springs Apart from load support problems associated with them, broken springs can cause personnel injury if parts of them are ejected during transit. Missing Spring Seat/Stops Spring seats and stops hold each spring in position. Spring seat designs vary from manufacturer to manufacturer, but function in a similar way to hold the springs in place. Figure 1: Example of Visual Inspection For Training Purposes Only Issue: August 2014 Page 454 of 926 Modul 7 Springs A broken seat or stop will cause the spring fall down and/or to get lost. A missing spring is a defect and the equipment should not be used, moved or loaded in this condition. A missing spring is spotted easily due to the empty area enclosed by the spring seat/stops. Figure 2 shows locations where both the inner and outer springs are held in position by spring stops. PART 66 – Basic Training Cat B1 – Module 7 Fatigue Loading If a compression spring is designed with the yield limit above the solidity limit and manufactured correctly then the only way it can fail is through fatigue. Refer to Figure 3. Figure 2: Spring Defect For Training Purposes Only Issue: August 2014 Page 455 of 926 Modul 7 Springs PART 66 – Basic Training Cat B1 – Module 7 Figure 3: Fatigue Loading of Compression Springs For Training Purposes Only Issue: August 2014 Page 456 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Springs The leftmost photograph of a typical fatigue failure surface reveals a crack source near the inner, more highly stressed surface of the wire. If stress raisers occur due to poor manufacture or to corrosion as illustrated in the other photographs, then fracture is likely to emanate from the stress raisers thereby reducing fatigue life. Corrosion of Springs Refer to Figure 4. Compression spring corrosion is one of the most neglected factors that can affect performance. All too often corrosion of microscopic proportion is the origin of compression spring failure, but its presence goes undetected and the cause of failure is erroneously attributed to something else. Compression springs made of uncoated steel must be given some kind of corrosion protection. The degree of protection of the compression spring depends on the nature of the application. 7.10.1.2 Spring Testing Refer to Figure 5. Compression Spring Testing Compression spring testing is the process whereby the spring tester crosshead begins at a predetermined ’start’ position and then moves in a downward direction to a predetermined ’end’ position. Figure 4: Corrosion on Coil Springs For Training Purposes Only A spring located on the spring tester plate above the load cell will be compressed, producing an increasing reaction force as the crosshead continues to move downwards. Issue: August 2014 Page 457 of 926 Modul 7 Springs PART 66 – Basic Training Cat B1 – Module 7 The spring tester acquires both force and position data simultaneously for every point between the start and end positions. Force data is then available for any spring deflection or deflected height. Furthermore the data is used to present the results of the spring free length and the spring constant. Extension Spring Testing Extension spring testing is the process whereby the spring tester crosshead begins at a predetermined ’start’ position and then moves in an upward direction to a predetermined ’end’ position. A spring with hooks located between pins on the spring tester load cell and on the spring tester crosshead will be extended, producing an increasing reaction force as the crosshead continues to move upwards. The spring tester acquires both force and position data simultaneously for every point between the start and end positions. Force data is then available for any spring extension or extended height. Furthermore the data is used to present the results of the spring free length, initial tension and the spring constant. Figure 5: Spring Testing Procedures For Training Purposes Only Issue: August 2014 Page 458 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Springs Torsion Spring Testing Torsion spring testing is the process whereby the spring tester head begins rotating at a predetermined start position and then continues rotating in either a clockwise or counter clockwise direction to a predetermined end angle. A spring located between the spring tester torque head and the spring tester torsion load cell fixtures will produce an increasing reaction torque as the crosshead continues to rotate. The spring tester acquires both torque and position angular data simultaneously for every point between the ’start’ and ’end’ positions. Torque data is then available for any spring rotational angle. Furthermore the data is used to present the results of the spring free angle and the spring constant 7.10.1.3 Spring Testing Equipment Spring testing equipment includes: compression spring testers extension spring testers V torsion spring testers. Compression Spring Testers Refer to Figure 6. Figure 6 shows two types of hand –operated valve spring testers. Hand Lever Compression Spring Tester Refer to Figure 7. For Training Purposes Only Figure 6: Hand – Operated Valve Spring Tester with Torque Wrench Issue: August 2014 Page 459 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Springs The rugged cast aluminium spring tester is specifically designed for compression spring testing in addition to crush, collapse and pressure testing. Features Load is applied by a simple rack and pinion lever system ideal for rapid and repetitive testing. Force is measured in both pounds and kilograms with an accuracy of 1 % of full scale. The mounted stainless steel ruler measures deflection in both inches and centimeters. The large 4 inch dial features dual graduations in pound and kilogram and an adjustable peak force hold pointer that also functions as a fixed tolerance marker for measuring pressure or breaking forces. The zero adjusts simply by moving a small lever at the bottom of the dial. Construction Rugged cast aluminium construction Mounting holes provided in base plate for bench mounting Large 4 inch diameter dial with dual lb/kg graduations Upper plate: 2 inch diameter Lower plate: 3 inch diameter Accepts specimens to 2 inch outside diameter and 4 inch free length Mounted stainless steel ruler graduated in both inches and centimeters. Figure 7 : Hand Lever Compression Spring Tester For Training Purposes Only Issue: August 2014 Page 460 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Springs Operation Features Load is rapidly applied by a recoil protected rack and pinion lever. Zero adjust lever is located at lower dial. Adjustable pointer holds peak force readings or sets tolerance points. Adjustable collar on column provides a fixed stop for repetitive testing. Compression testing of force and length Tracking or peak modes (2,000 samples /s) Load cell and frame deflection compensation V Mechanical and software overload protection V Built –in shunt calibration verification Backlit digital LCD display of force and length Wipe –clean embossed key face plate Push –button force and length zeroing. Coil Spring Tester Safety and Use Considerations Refer to Figure 8. Figure 8 shows a typical coil spring tester which is used for testing hydraulic forces. Description The coil spring tester (CST) is a low cost alternative for high capacity springs. Springs can be tested up to 1,500 lbs and good force /length results can be gained from this sturdy two –post frame. The CST uses LCD readouts for easy viewing of highly accurate length and force measurements. The length measurement units can be selected to read in inches or millimeters while force measurement is selectable to read in pounds, kilograms or newtons. The CST measures flexible items in compression only. The CST is made with a rugged two post steel frame and instrumented with a precision load cell for force, a glass scale for length and related precision electronics for analysis and display of exact measurements. For Training Purposes Only Issue: August 2014 Remember that a compressed or extended spring has stored potential energy proportional to the spring constant. Use care and release this energy in a controlled manner to avoid possible injury. Do not apply more force than the tester is designed for the tester has overload stops to protect it to twice the rated capacity. Force readings are not accurate above the rated limit. Be sure the operating location is clean and dry and all springs to be tested are free of oil and contaminants. Wear appropriate eye protection. Use appropriate fix turning to prevent springs from flying out due to buckling under load. Keep your equipment away from any source of liquid. Keep these instructions for handy reference. Follow all instructions and warnings concerned with the use of the hydraulic compression spring tester. Page 461 of 926 Modul 7 Springs PART 66 – Basic Training Cat B1 – Module 7 Figure 8: Coil Spring Tester with Electronics Box For Training Purposes Only Issue: August 2014 Page 462 of 926 Modul 7 Springs Manual Extension Spring Tester PART 66 – Basic Training Cat B1 – Module 7 Refer to Figure 9. Figure 9: Manual Spring Extension Tester For Training Purposes Only Issue: August 2014 Page 463 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Springs Description Torsion Spring Tester The manual spring extension tester provides smooth movement and precise alignment with a rack and pinion lever elevating mechanism travelling on two guide posts with precisely fitted bushings. The large test area provides a generous horizontal clearance platform. Refer to Figure 10. The lever provides rapid application of load in tension to 100 lbs. The elevating mechanism locks into position with a locking screw. Right – or left –hand operation is available by moving the lever to either side of the load beam. Several mounting holes are provided on the work area and tension hooks are provided. The unique plug –and –lock gauge mounting plate is quickly unlocked and removed with the locking screw located on the upper surface of the load beam. The mounting plate moves straight out on two pilot pins. Mounting the force gauge onto the mounting plate is easily accomplished off the test stand. Description The torsion spring tester (TST) is a manually operated torque/angle tester. LCD readouts are used for easy viewing of highly accurate angle and torque measurements. This tester can select a variety of measuring units for versatility and ease of use. Angles are measured in degrees and torque can be measured in inch pounds, newton millimeters, gram millimeters and ounce inches. The torsion spring tester measures flexible items in a rotary motion both clockwise and counter –clockwise. The torsion spring tester features a high degree of built –in precision and accuracy to assure excellent repeatability and reproducibility. Main Features Operation The manual spring extension tester is designed for testing to 100 lbs. Repetitive overloads will cause deterioration to the smooth mechanical functioning of the test stand. Also, shock loads can damage the force gauge and test stand. Forces must be applied to the force gauge only in an axial manner. Applying a load at an angle can cause an error in readings and possibly damage the gauge. Lubrication of the vertical posts and gear rack is recommended with light oil sparingly applied with paper towel. For Training Purposes Only Issue: August 2014 Clockwise and counter clockwise testing capabilities Hand cranking capability: 1:1 ratio or 40:1 ratio for micro adjust Carriage stop for repetitive testing Rotational stops for setting angle test points Interchangeable torque cartridges Interchangeable universal and custom tooling with absolute angle zeroing Angle deflection compensation. All load cell movement is automatically compensated internally for accurate angle measurements. 100 % load cell overload protection. Software alarm and mechanical stops pre-vent undue stress on the load cell. RS 232 port available for connecting to a printer, computer or datalogger. Page 464 of 926 Modul 7 Springs PART 66 – Basic Training Cat B1 – Module 7 Figure 10: Torsion Spring Tester For Training Purposes Only Issue: August 2014 Page 465 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Springs Control Features Safety Precautions The control board includes a digital display and touch screen with the following keys: F1 F2 Options Zero Angle Zero Torque Test Mode Units Store Send On/Clear. Do not apply more force than the tester is designed for. The tester has overload stops to protect it but damage can result from excessive loads. Force readings are not accurate above the rated limit. Be sure the operating location is clean and dry and all springs to be tested are free of oil and contaminants. Keep your equipment away from any source of liquid. Keep these instructions handy for reference. Follow all instructions and warnings concerned with the use of the torsion spring tester. The F1, F2 and Options keys are used for setting up parameters such as: angle offset torque offset date, time company name on printout torque damping peak damping calibration modes dumping datalogger V RS 232/printer settings V print summary. The internal datalogger can store up to 2000 test points prior to downloading to a computer or printer. For Training Purposes Only Issue: August 2014 Page 466 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Bearings 7.11 Bearings 7.11.1 Bearing Handling and Maintenance 7.11.1.1 Rules of Bearing Maintenance Note: Good bearing maintenance starts with safety first! Safety Never spin a bearing with compressed air. The force of the compressed air may cause the rollers to be expelled with great velocity, creating a risk of serious bodily harm. Proper bearing maintenance and handling practices are critical. Failure to follow installation instructions and failure to maintain proper lubrication can result in equipment failure, creating a risk of serious bodily harm. Do not wash or clean bearings in an enclosed area. Solvent fumes are toxic and explosive. Make absolutely certain of adequate ventilation and no open flame, welding or smoking in the area. Rubber gloves and eye protectors should always be worn to protect the skin and eyes from solvents. If a hammer and mild steel bar are used for bearing removal, fragments from the hammer, bar or bearing can be released with sufficient velocity to create a risk of serious bodily harm including damage to your eyes. When installing or removing bearings, always wear eye protectors to protect your eyes from flying fragments. Do not mix parts. If either a cup or cone needs to be replaced, both should be changed. Do not use the old cones with new cups or vice versa. The old component has a distinct pattern worn into its raceway, and mixing with a new mating component will set up edge stresses along the races. For Training Purposes Only Lubrication: Efficient lubrication is of utmost importance. Too little, too much or inadequate lubrication can result in early bearing damage. Make sure the right lubricant is applied, at the right time and in the right quantity Never use a welding torch to heat a bearing. Torch heat is extremely hot and difficult to distribute evenly. In a matter of seconds the bearing metallurgy could be altered and begin to soften. Use insulated, fireproof gloves to hold a heated cone against the shoulder until the cone seats. A hot cone has a tendency to pull away from a cold shoulder unless it is held in position. Use a feeler gauge to ensure proper seating against the shoulder. The cone should be lubricated after it is properly seated on the shaft and temperature stabilises the ambient. Cleanliness One of the most common sources of trouble in anti friction bearings is debris that contaminates the lubrication environment. Debris can be a major cause of abrasive damage which can lead to reduced bearing life. That is why cleanliness is so important to bearing maintenance and longevity. Cleanliness does not just mean clean bearings. It means clean housings and shafts, clean tools, clean solvents and flushing oils. It also means putting bearings on a clean surface and using clean rags to wipe bearings. To avoid corrosion, use a cleaning solution such as kerosene or mineral spirits rather than steam or hot water. Never wash or clean bearings in an enclosed area. Solvent fumes are toxic and explosive. Make absolutely certain there is adequate ventilation and no open flame, welding or smoking in the area. Wear rubber gloves to protect skin and eye protectors to protect eyes from the solvents. Issue: August 2014 Page 467 of 926 Modul 7 Bearings Storage Do not open the box early! The bearing packaging is designed to protect bearings against dirt and moisture during shipping and storage. Let the package do its job, and leave replacement bearings in their original containers. Store them in a clean, dry area until ready for use. Avoid temperature changes in the storage area; dramatic temperature swings can cause condensation and damage the bearing. Sealing Seals are vital to the performance of any bearing. Replace worn or damaged seals; they allow contaminants such as dirt and water to enter the bearing and they allow lubrication to escape. In most cases, it is good practice to replace all seals by new ones during tear - down. A film of lubricant should be applied to the seal lip contact surface during assembly. This will help to prevent seal damage during installation and at initial start up. It also will reduce rolling torque. Handling The less, the better: fingerprints can cause rust, so handle bearings only when necessary. Never drop or handle these precision components roughly. Any sign of a bent cage renders replacement. 7.11.1.2 PART 66 – Basic Training Cat B1 – Module 7 During inspection, bearings also receive a feel test. This is accomplished by an experienced technician who compares the rotational feel of one bearing against the feel of a new one. After inspection many measurements checks are performed on the bearings with special measurement devices provided by the manufacturer. Magnetic Check After inspection, bearings are checked for the presence of magnetism with a device called a field detector. If magnetism is present, it must be removed with a suitable degauser to prevent the attraction of foreign ferrous particles into the bearing during engine operation. It has been determined that magnetism occurs mainly from the effects of bearing rotation at high speeds, and from lightning strikes absorbed by the aircraft. Another possible cause of bearing magnetism is electric arc welding of the assembled engine, and improper grounding of the equipment. The ground lead of the welding equipment must not be secured to an outer casing, but rather to the part being welded in a manner that prevents high electrical current flow through the entire engine. The result is that ferrous particles generated by normal engine wear in bearings and other ferrous materials will adhere to the bearing surfaces rather than be flushed away to the oil system filters. Bearing Handling Bearings tend to gain work - hardness over time. They are often checked for excessive hardness with special equipment procedures because this condition makes bearings susceptible to chipping. For Training Purposes Only Issue: August 2014 Page 468 of 926 Modul 7 Bearings PART 66 – Basic Training Cat B1 – Module 7 Bearing Installation Refer to Figure 1. Bearings are stored in vapour - proof paper until ready to install. The most popular method of bearing installation is thermal expansion. By heating the inner ring of the bearing to a specified temperature it can be easily slipped onto the shaft, even when an interference fit is indicated. The safest and most effective tool available for expansion is the induction heater. A magnetic field heats only the metallic components of the bearing with even distribution. A de - magnetising cycle at the end of the heating process prevents the possibility of bearing contamination. After expansion and subsequent installation, the bearing cools and contracts back to its original size. In doing so, the bearing ’face’ may shrink back away from the shaft shoulder or spacer ring. To ensure proper operation, this ’face’ must be re - seated against the shoulder. An acceptable method for accomplishing this task is to place a tube or ring against the opposite face of the bearing inner ring and tap it with an anti - bounce hammer. For Training Purposes Only Issue: August 2014 Page 469 of 926 Modul 7 Bearings PART 66 – Basic Training Cat B1 – Module 7 Figure 1: Bearing Installation Tools For Training Purposes Only Issue: August 2014 Page 470 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Bearings 7.11.1.3 Bearing Failures Bearings are among the most important components in the vast majority of machines. Therefore, rolling bearing technology has developed into a particular branch of science. surface distress smearing corrosion cracks. Wear Among the benefits resulting from this research has been the ability to calculate the life of a bearing with considerable accuracy, thus making it possible to match the bearing life with the service life of the machine involved. Unfortunately it sometimes happens that a bearing does not attain its calculated rating life. There may be many reasons for this, e.g. heavier loading than has been anticipated, inadequate or unsuitable lubrication, careless handling, ineffective sealing or fits that are too tight, with resultant insufficient internal bearing clearance. Each of these factors produces its own particular type of damage and leaves its own special imprint on the bearing. Consequently, by examining a damaged bearing, it is possible, in the majority of cases, to find the cause of the damage and to take the requisite action to prevent a recurrence. Different Types of Bearing Damage Each of the different causes of bearing failure produces its own characteristic damage. Such damage, known as primary damage, gives rise to secondary, failure - inducing damage - flaking and cracks. Even the primary damage may necessitate scrapping the bearings on account of excessive internal clearance, vibration, noise etc. A failed bearing frequently shows a combination of primary and secondary damage. In normal cases there is no appreciable wear in rolling bearings. Wear may, however, occur as a result of the ingress of foreign particles into the bearing or when the lubrication is unsatisfactory. Vibration in bearings which are not running also gives rise to wear. Wear Caused by Abrasive Particles Small, abrasive particles, such as grit or swarf, that have entered the bearing by some means or other, cause wear of raceways, rolling elements and cage. The surfaces become dull to a degree that varies according to the coarseness and nature of the abrasive particles. Sometimes worn particles from brass cages become verdigrised and then give light - coloured grease a greenish hue. The quantity of abrasive particles gradually increases as material is worn away from the running surfaces and cage. Therefore the wear becomes an accelerating process and in the end the surfaces become worn to such an extent as to render the bearing unserviceable. However, it is not necessary to scrap bearings that are only slightly worn. They can be used again after cleaning. The abrasive particles may have entered the bearing because the sealing arrangement was not sufficiently effective for the operating conditions involved. They may also have entered with contaminated lubricant or during the mounting operation. Typical bearing damages are as follows: Refer to Figure 2. Wear For Training Purposes Only Issue: August 2014 Page 471 of 926 Modul 7 Bearings PART 66 – Basic Training Cat B1 – Module 7 Figure 2, detail a), shows that the outer race of a spherical roller bearing with raceways has been worn by abrasive particles. It is easy to feel where the dividing line goes between worn and unworn sections. Wear Caused by Inadequate Lubrication If there is not sufficient lubricant, or if the lubricant has lost its lubricating properties, it is not possible for an oil film with sufficient carrying capacity to form. Metal - to - metal contact occurs between rolling elements and raceways. In its initial phase, the resultant wear has roughly the same effect as lapping. The peaks of the microscopic asperities that remain after the production processes are torn off and, at the same time, a certain rolling - out effect is obtained. This gives the surfaces concerned a varying degree of mirror - like finish. At this stage, surface distress can also arise. If the lubricant is completely used up, the temperature will rise rapidly. The hardened material then softens and the surfaces take on blue to brown hues. The temperature may even become so high as to cause the bearing to seize. Figure 2, detail b), shows that the outer ring of a spherical roller bearing has not been adequately lubricated. The raceways have a mirror finish. Wear Caused by Vibration Figure 2: Bearing Wear For Training Purposes Only When a bearing is not running, there is no lubricant film between the rolling elements and the raceways. The absence of lubricant film gives metal - to - metal contact and the vibrations produce small relative movements of rolling elements and rings. As a result of these movements, small particles break away from the surfaces and this leads to the formation of depressions in the raceways. This damage is Issue: August 2014 Page 472 of 926 Modul 7 Bearings PART 66 – Basic Training Cat B1 – Module 7 known as false brinelling, sometimes also referred to as washboarding. Balls produce sphered cavities while rollers produce fluting. In many cases, it is possible to discern red rust at the bottom of the depressions. This is caused by oxidation of the detached particles, which have a large area in relation to their volume, as a result of their exposure to air. There is never any visible damage to the rolling elements. The greater the energy of vibration, the more severe the damage. The period of time and the magnitude of the bearing internal clearance also influence developments, but the frequency of the vibrations does not appear to have any significant effect. Roller bearings have proved to be more susceptible to this type of damage than ball bearings. This is considered to be because the balls can roll in every direction. Rollers, on the other hand, only roll in one direction; movement in the remaining directions takes the form of sliding. Cylindrical roller bearings are the most susceptible. Where machines subject to constant vibration are concerned, it is essential that the risk of damage to the bearings be taken into consideration at the design stage. Consequently, where possible, ball bearings should be selected instead of roller bearings. Figure 2, detail c), shows that the inner and outer ring of a cylindrical roller bearing has exposed to vibration. The inner ring has changed position. Further, the outer ring of a self - aligning ball bearing has damaged by vibration. The bearing has not rotated at all. Surface Distress Figure 3: Surface Distress Refer to Figure 3. For Training Purposes Only Issue: August 2014 Page 473 of 926 Modul 7 Bearings PART 66 – Basic Training Cat B1 – Module 7 If the lubricant film between raceways and rolling elements becomes too thin, the peaks of the surface asperities will momentarily come into contact with each other. Small cracks then form in the surfaces and this is known as surface distress. In thrust ball bearings, smearing may occur if the load is too light in relation to the speed of rotation. Note: These cracks must not be confused with the fatigue cracks that originate beneath the surface and lead to flaking. Refer to Figure 4. The surface distress cracks are microscopically small and increase very gradually to such a size that they interfere with the smooth running of the bearing. These cracks may, however, hasten the formation of sub - surface fatigue cracks and thus shorten the life of the bearing. Corrosion Rust will form if water or corrosive agents reach the inside of the bearing in such quantities that the lubricant cannot provide protection for the steel surfaces. This process will soon lead to deep seated rust. Another type of corrosion is fretting corrosion. Deep Seated Rust If the lubrication remains satisfactory throughout, i.e. the lubricant film does not become too thin because of lubricant starvation or viscosity changes induced by the rising temperature or on account of excessive loading, there is no risk of surface distress. A thin protective oxide film forms on clean steel surfaces exposed to air. However, this film is not impenetrable and if water or corrosive elements make contact with the steel surfaces, patches of etching will form. This development soon leads to deep seated rust. Smearing Deep seated rust is a great danger to bearings since it can initiate flaking and cracks. Acid liquids corrode the steel quickly, while alkaline solutions are less dangerous. The salts that are present in fresh water form, together with the water, an electrolyte which causes galvanic corrosion, known as water etching. Salt water, such as sea water, is therefore highly dangerous to bearings. When 2 inadequately lubricated surfaces slide against each other under load, material is transferred from one surface to the other. This is known as smearing and the surfaces concerned become scored, with a ’torn’ appearance. When smearing occurs, the material is generally heated to such temperatures that rehardening takes place. This produces localised stress concentrations that may cause cracking or flaking. In rolling bearings, smearing primarily occurs at the roller end - guide flange interfaces. Smearing may also arise when the rollers are subjected to severe acceleration on their entry into the load zone. If the bearing rings rotate relative to the shaft or housing, this may also cause smearing in the bore and on the outside surface and ring faces. For Training Purposes Only Issue: August 2014 Page 474 of 926 Modul 7 Bearings PART 66 – Basic Training Cat B1 – Module 7 Fretting Corrosion If the thin oxide film is penetrated, oxidation will proceed deeper into the material. An instance of this is the corrosion that occurs when there is relative movement between bearing ring and shaft or housing, on account of the fit being too loose. This type of damage is called fretting corrosion and may be relatively deep in places. The relative movement may also cause small particles of material to become detached from the surface. These particles oxidise quickly when exposed to the oxygen in the atmosphere. As a result of fretting corrosion, the bearing rings may not be evenly supported. This has a detrimental effect on the load distribution in the bearings. Rusted areas also act as fracture notches. Cracks Refer to Figure 5. Cracks may form in bearing rings for various reasons. The most common cause is rough treatment when the bearings are being mounted or dismounted. Hammer blows, applied directly against the ring or via a hardened chisel, may cause fine cracks to form, with the result that pieces of the ring break off when the bearing is put into service. Excessive drive - up on a tapered seating or sleeve is another cause of ring cracking. The tensile stresses, arising in the rings as a result of the excessive drive - up, produce cracks when the bearing is put into operation. The same result may be obtained when bearings are heated and then mounted on shafts manufactured to the wrong tolerances. Figure 4: Bearing Corrosion For Training Purposes Only Flaking, that has occurred for some reason or other, acts as a fracture notch and may lead to cracking of the bearing ring. The same applies to fretting corrosion. Issue: August 2014 Page 475 of 926 Modul 7 Bearings PART 66 – Basic Training Cat B1 – Module 7 Figure 5: Examples of Bearing Cracks For Training Purposes Only Issue: August 2014 Page 476 of 926 Modul 7 Transmissions 7.12 Transmissions 7.12.1 Inspection of Transmission Components 7.12.1.1 Gears PART 66 – Basic Training Cat B1 – Module 7 Inspection of Gears in the Workshop Visual Examination The first step to check a gear for its condition is to inspect it visually. A magnifying glass should be used to have a close look to the surface. If there is pitting or other damages, the gear is unserviceable and must be replaced. Gears with damaged surfaces are noisy and will, sooner or later, fail. In any case, the limits given by the manufacturer are to be adhered to. Composite Check Using a Master Gear Refer to Figure 1. The most widely used method of determining relative accuracy in a gear is to rotate it through at least one complete revolution in intimate cntact with a master gear on known accuracy. The gear to be tested and the master gear are mounted on a variable - center - distance fixture. The resulting radial displacements i.e., the changes in the distance from teh center during rotation, are measured by a suitable device. Figure 1: Gear Tooth Contact Patterns Test For Training Purposes Only Issue: August 2014 Page 477 of 926 Modul 7 Transmissions Except for the effect of backlash, this so called composite check simulates the action of the gear under operating conditions and allows the exploration of the following errors: runout pitch erro tooth - thickness variation profile error lateral run out (or: wobble). Inspection of Gears on Site Preparing for Inspection Before visiting the failure site, a contact person located at the site should be contacted and told about what to be inspected: the gearbox including related personnel, equipment and working conditions. A skilled technician should be requested to disassemble the equipment under the supervision of the inspector. No work must be done on the gearbox until arrival of the inspecting person, i.e. neither disassembly nor cleaning. Otherwise, a well meaning technician could inadvertently destroy evidence. The gearbox drawings, disassembly tools and adequate inspection facilities must be available. PART 66 – Basic Training Cat B1 – Module 7 Example: The condition of seals and keyways must be recorded before disassembly. Otherwise, it will be impossible to determine when any damage may have occurred to these parts. Gear tooth contact patterns should be taken before completely disassembling the gearbox. After the external examination, the gearbox is disassembled and all internal components, both failed and undamaged, inspected. The functional surfaces of gear teeth and bearings should be examined closely and their condition recorded. Before cleaning the parts, a check for signs of corrosion, contamination and overheating must be carried out. After the initial inspection, the components are to be washed with solvents and re - examined. This examination should be as thorough as possible because it is often the most important phase of the investigation and may yield valuable clues. A low - power magnifying glass and pocket microscope are helpful tools for this examination. It is important to inspect the bearings because they often provide clues as to the cause of gear failure. Example: Bearing wear can cause excessive radial clearance or end play that misaligns the gears. Bearing damage may indicate corrosion, contamination, electrical discharge or lack of lubrication. Plastic deformation between rollers and raceways may indicate overloads. Visual Examination Before disassembling the gearbox, its exterior is thoroughly to be inspected. An inspection form should be used as a guide to ensure that important data are recorded that would otherwise be lost once disassembly begins. Gear failure often follows bearing failure. Gear Tooth Contact Patterns Refer to Figure 2. For Training Purposes Only Issue: August 2014 Page 478 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Transmissions Note: The following step must be completed before the gearbox components are disassembled for inspection. The way, in which mating gear teeth contact each other, indicates how well they are aligned. If practical, the tooth contact patterns should be recorded under unloaded conditions. For no - load tests, the teeth of one gear are painted with marking compound. Then, the teeth are rolled through the mesh so the compound transfers the contact pattern to the unpainted gear. Determining the Type of Failure Refer to Figure 3. Several failure modes may be present and it will be necessary to identify which is the primary mode, and which are secondary modes that may have contributed to failure. Six general classes of gear failure modes exist: bending fatigue Hertzian fatigue Wear Scuffing Overload cracking. Bending Fatigue This common type of failure is a slow, progressive failure caused by repeated loading. It occurs in three stages: Figure 2: Types of Failures on Gear Teeth For Training Purposes Only Issue: August 2014 Crack initiation Plastic deformation occurs in areas of stress concentration or discontinuities, such as notches or inclusions, leading to microscopic cracks. Page 479 of 926 Modul 7 Transmissions PART 66 – Basic Training Cat B1 – Module 7 Crack propagation A smooth crack grows perpendicular to the maximum tensile stress. Fracture When the crack grows large enough, it causes sudden fracture. Figure 3: Backlash Testing of a Bevel Gear Assembly For Training Purposes Only Issue: August 2014 Page 480 of 926 Modul 7 Transmissions As a fatigue crack propagates, it leaves a series of ’beach marks’ (visible to the naked eye) that correspond to positions where the crack stopped. The origin of the crack is usually surrounded by several concentric curved beach marks. Most gear tooth fatigue failures occur in the tooth root fillet where cyclic stress is less than the yield strength of the material and the number of cycles is more than 10,000. This condition is called high cycle fatigue. A large part of the fatigue life is spent initiating cracks, whereas a shorter time is required for the cracks to propagate. PART 66 – Basic Training Cat B1 – Module 7 In one type, called spelling, the pits coalesce and form irregular craters over a large area. In flake macropitting, thin flakes of material break out and form triangular pits that are relatively shallow, but large in area. Micropitting has a frosted, matte or gray stained appearance. Under magnification, the surface is shown to be covered by very fine pits. Metallurgical sections through these pits show fatigue cracks that may extend deeper than the pits. Wear Stress concentrations in the fillet often cause multiple crack origins, each producing separate cracks. In such cases, cracks propagate on different planes and may join to form a step, called a ratchet mark. Gear tooth surface wear involves removal or displacement of material due to mechanical, chemical or electrical action. The three major types of wear are: Contact Fatigue In another failure mode, called contact or Hertzian fatigue, repeated stresses cause surface cracks and detachment of metal fragments from the tooth contact surface. The most common types of surface fatigue are macropitting (visible to the naked eye) and micropitting. Macropitting occurs when fatigue cracks start either at or below the surface. As the cracks grow, they cause a piece of surface material to break out, forming a pit with sharp edges. Based on the type of damage, macropitting is categorised as non progressive, progressive, spall or flake. The non - progressive type consists of pits less than 1 mm diameter in localised areas. These pits distribute load more evenly by removing high points on the surface, after which pitting stops. Adhesion Adhesion is the transfer of material from the surface of one tooth to that of another due to welding and tearing. It is confined to oxide layers on the tooth surface. Adhesion is categorised as mild or moderate, whereas severe adhesion is termed scuffing. Abrasion Abrasion is caused by contaminants in the lubricant such as sand, scale, rust, machining chips, grinding dust, weld splatter and wear debris. It appears as smooth, parallel scratches or gouges. Abrasion ranges from mild to severe. Mild abrasion consists of fine scratches that do not remove a significant amount of material from the tooth contact surface, whereas moderate abrasion removes most of the machining marks. Progressive macropitting consists of pits larger than 1 mm diameter that cover a significant portion of the tooth surface. For Training Purposes Only Issue: August 2014 Page 481 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Transmissions Severe abrasion, which removes all machining marks, can cause wear steps at the ends of the contact surface and in the dedendum. Tooth thickness may be reduced significantly, and in some cases, the tooth tip is reduced to a sharp edge. Polishing Polishing is fine - scale abrasion that imparts a mirror - like finish to gear teeth. Magnification shows the surface to be covered by fine scratches in the direction of sliding. Polishing is promoted by chemically active lubricants that are contaminated with a fine abrasive. Moderate scuffing occurs in patches that cover significant portions of the teeth. If operating conditions do not change, it can be progressive. Severe scuffing occurs on significant portions of a gear tooth (for example, the entire addendum or dedendum). In some cases, surface material is plastically deformed and displaced over the tooth tip or into the tooth root. Unless corrected, it is usually progressive. Inspection of a Bevel Gear Assembly of a Helicopter Visual inspection Examine each part for these types of damage: Polishing ranges from mild to severe. Its mild form, which is confined to high points on the surface, typically occurs during run –in and ceases before machining marks are removed. Moderate polishing removes most of the machining marks. Severe polishing removes all machining marks from the tooth contact surface. The surface may be wavy or it may have wear steps at the ends of the contact area and in the dedendum. Corrosion deterioration to protective treatmen distortion and/or crack wear or fretting scores, dents or burrs unserviceable screw threads parts of permanent assemblies not correctly attached. Test Procedures Scuffing Severe adhesion or scuffing transfers metal from the surface of one tooth to that of another. Typically, it occurs in the addendum or dedendum in bands along the direction of sliding, though load concentrations can cause localised scuffing. Surfaces have a rough or matte texture that, under magnification, appears to be torn and plastically deformed. These tests are to ensure that the unit functions within the required limits. Free Running Test Check that the unit rotates freely and smoothly in each direction at no - load conditions, throughout the full revolution. Scuffing ranges from mild to severe. Mild scuffing occurs on small areas of a tooth and is confined to surface peaks. Generally, it is non - progressive. For Training Purposes Only Issue: August 2014 Page 482 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Transmissions Breakout Torque Test 7.12.1.2 Using a hand torque meter inserted into the input shaft, and with no restrictions applied to the output drive, measure the torque necessary to initiate output shaft displacement in each direction. Belt Inspection Backlash Test If a belt exhibits any of the following signs of wear, it should be replaced: Mount the unit in the backlash checking adaptor Use the lockout device to prevent movement of input shaf Insert the indicator arm into the output shaft Apply a torque of 6 Nm to the output shaft Perform operation in both directions Record backlash at the indicator arm using a dial test indicator gauge. Refer to Figures 4, 5 and 6. Note: Recorded backlash should be between 0.08 mm and 0.18mm (0.003 in. to 0.007 in.). For Training Purposes Only Belts and Pulleys Issue: August 2014 Small cracks normally occur along the length of a rib or ribs. This type of wear typically occurs after more than 50.000 miles (approx. 80,000 km) of service or under extreme operating conditions. Excessive cracking may occur if the belt is exposed to a period of severely cold weather of – 30°C or below. Friction, caused by a loose belt slipping in the pulley, gives the belt side walls a glazed or slick and shiny appearance. If the belt is slipping, cracking and chunking also will accelerate. If belt material has sheared from the ribs, it builds up in the belt grooves. The grooved surface becomes uneven, which causes vibration, belt noise and belt slip. In severe cases, the debris may cause the belt to ’walk off’ the drive. Grease, oil, coolant and other engine fluids can soak the belt sidewalls, resulting in a glazed belt that slips and makes noise. Prolonged contact with petroleum products can also cause premature belt failure. Before installing a replacement belt, identify and repair the source of the fluid leak or leaks that damaged the original. High - mileage belts may ’chunk - out’ as pieces or chunks of rubber material break away from the belt. A belt with this much wear can fail at any moment, and should be replaced immediately. Page 483 of 926 Modul 7 Transmissions PART 66 – Basic Training Cat B1 – Module 7 In addition to normal wear, belts may be damaged or their service life shortened by a variety of other factors. An incorrectly installed belt may show ribs that have begun separating from the joined strands. The belt also may have been accidentally cut during other repair work. Various mechanical problems also can cause accelerated belt wear or failure. If the back side of a belt appears shiny or glazed, look for an object such as a flange or bolt in its path that may be making contact. A seized idler bearing may cause the belt to stop turning for a time. Look for a melted or glazed section. V–belts may twist out of the upright position and turn over due to pulley misalignment, excessive belt span vibration or excessive pulley or belt wear. In addition to signalling belt wear, belt noise may also alert the user/inspecting person to underlying damage to tensioners, bearings, pulleys and other components. The two major causes of belt noise are: improper tension misalignment. Figure 4: Typical Failures of Belt Drive For Training Purposes Only Issue: August 2014 Page 484 of 926 Modul 7 Transmissions PART 66 – Basic Training Cat B1 – Module 7 Figure 5: Pulley Wear Conditions For Training Purposes Only Issue: August 2014 Page 485 of 926 Modul 7 Transmissions PART 66 – Basic Training Cat B1 – Module 7 Improper Tension Belts require very little maintenance. However, all belt types must be properly tensioned initially. Additionally, V - belts should be re checked periodically (within three to six months). Synchronous belts require correct tensioning when installed, but then only need occasional monitoring because they have a tensile cord that does not stretch over time like a V - belt does. When troubleshooting for improper V - belt tension, it must be ensured that the drive is turned off and locked down. Then the checking person should look for glazed or hardened belt sidewalls that indicate the belt is slipping in the drive. Improperly tensioned synchronous belts will have unusually heavy wear on the fabric tooth surface. The calculated tension range at which belts should be installed depends on the drive components, and the load and speed of the drive. The belt manufacturer’s recommendations should be followed to determine the calculated installation tension values. Due to system inefficiencies, belt drives are often carrying far less load than they were selected to carry. The ideal tension for a V - belt drive is the lowest tension at which the belt will not slip at the highest load condition. For synchronous belts, ideal tension is the lowest tension that properly seats the belt in the driven sprocket on the slack side. Ideal tension for both types of belt will result in the best belt life and lowest bearing loads for a given power transmission application. Figure 6: Belt Tension Meters (Examples) For Training Purposes Only Refer to Figure 7. Issue: August 2014 Page 486 of 926 Modul 7 Transmissions PART 66 – Basic Training Cat B1 – Module 7 Figure 7: Types of Belt Misalignment For Training Purposes Only Issue: August 2014 Page 487 of 926 Modul 7 Transmissions PART 66 – Basic Training Cat B1 – Module 7 Several tools can be used for accurate tensioning. These include a pencil - type spring force tension gauge that measures static belt tension by indicating force at a specified deflection of the belt span. Sophisticated electronic sonic tension meters work on the theory that a belt vibrates at a particular frequency based on its mass and span length. To test the tension, the belt is simply strummed to make it vibrating, and the meter records the resulting oscillating sound wave. For newly installed and tensioned V - belts, a run - in procedure is recommended. This process consists of starting the drive, letting it run under full load and then stopping, checking and re - tensioning to the recommended values. Running belts under full load allows them to seat themselves into the grooves. Once properly installed, synchronous belts rarely need re - tensioning. Misalignment Refer to Figure 8. There are three types of misalignment of belts: horizontal angular (pigeon - toed) vertical angular (angle or cocked) parallel (off - set). Horizontal Angular Misalignment Horizontal angular misalignment has either the driver or the driven pulley twisted out of alignment with the other pulley. For example, if a motor shaft is not parallel with the compressor shaft, the drive is out of alignment. Sidewall wear is visible, and again, both roll - over and groove - hopping is likely. For Training Purposes Only Issue: August 2014 Figure 8: Assembly of Bearing into Pulley Page 488 of 926 Modul 7 Transmissions Vertical Angular Misalignment PART 66 – Basic Training Cat B1 – Module 7 with water is used to spray the belt with a light mist while the engine is running. Vertical angular misalignment has either the driver or the driven pulley twisted out of alignment with the other pulley. For example, if a motor leans inward, the drive sheave, or pulley, is tilted out of alignment with the flywheel, or driven pulley. Sidewall wear would occur, both would roll over and/or hop off their grooves, etc. Once again, users may experience this and believe that banded belts are the answer. They are not. Their use in this application may temporarily mask misalignment, but proper alignment is the remedy. If the noise increases right after the belt is misted and does not become louder, incorrect tension may be to blame. The belt may also be worn or misrouted. If the noise decreases for a few seconds, then returns even louder, the problem is likely due to misalignment. Noise caused by belt misalignment will not be corrected by increasing tension or simply replacing the belt. All pulleys and tensioner assemblies should be checked for proper installation and alignment to correct the problem. Parallel Misalignment Handling Parallel misalignment has the belts misaligned by not having the driver or the driven pulley grooves in a straight line with each other and the V - belts. By using a string and running it from the far side of a drive groove to the opposite end of a matching driven pulley groove and along a V - belt connecting the groove, installers easily see gaps indicating the misalignment. When installing new belts, force must never be used nor did the belts prise on sheaves or pulleys. This could break the internal cord reinforcement or damage the outside of the belt. Rather, the center distance on the drive should be reduced or the idler released to relieve the tension. If necessary, one of the pulleys should be removed to install the belt. After the new belts have been installed and tensioned, the drive is to be rotated by hand for a few revolutions, and the tension re - checked. If necessary, the tension should be adjusted and the motor mounting bolts secured to the recommended torque values. When used to eliminate parallel misalignment, banded belts often develop torn areas between the belts. This is caused by unwanted flexing during normal running time, especially during loading and unloading. Note: This happens during all three kinds of misalignment listed above. Never crimp (i.e. bending the belts below their minimum recommended diameter) or twist belts. This, too, could damage the internal cord reinforcement. Misalignment belt noise is generally loudest at idle speed and becomes less with increasing engine rpm. High humidity (or a damp belt) often increases misalignment noise. To diagnose belt noises caused by misalignment and/or improper tension, a spray bottle filled With proper storage, rubber belts have a shelf life of approx. eight years. Belts are to be stored in a cool area with no direct sunlight, at temperatures less than 30oC and at a relative humidity below 70%. For Training Purposes Only Issue: August 2014 Page 489 of 926 Modul 7 Transmissions ZIf the belts are packed individually in their own boxes, they should be stored in their original shipping cartons. V - belts may be stored by hanging them on properly designed belt racks or hooks. Synchronous belts should be stored on their sides on shelves. Belts can be damaged by coiling them too tightly or by bending them sharply. PART 66 – Basic Training Cat B1 – Module 7 free movement of the bearing is retained after all assembly work is completed. Do not allow the belts to become contaminated by oil, grease or other chemicals. Also, keep belts away from ozone sources such as arc welders and other electrical equipment or motors. Assembly of Bearing into Pulley Refer to Figure 9. When assembling the bearing into a pulley, it should be observed that the pulley hole has the correct diameter and depth to suit the bearing jointing compound is applied to the outer face of the bearing housing and to the pulley hole the bearing is correctly positioned, bearing assembly tools are positioned and held by the clamp bolt the clamp bolt, while tightening, presses only on the outer part of the bearing the clamp bolt is kept at right angles to the pulley hole, while tightening, until the bearing is fully seated the assembly tool (clamp bolt) is only removed after the bearing has been correctly positioned the retaining plate (with bolts and nuts) is fitted according to the engineering drawing For Training Purposes Only Issue: August 2014 Page 490 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Transmissions Problems Cut or crack from inner side Belt turned over Wear out Belt breaks Excess elongation Probable causes Remedies Pulley diameter less than minimum recommended Select proper drive Excess belt slip Check belt tension and number of belts. Temperature too high on the drive Save belt from heat through different means Foreign particle(s) on the pulley Clean away foreign particles Very high tension to belt Re—tension Excess belt flap Use idler Jerk load Tension should be proper Pulley groove not proper Use correct pulley Misalignment Do proper alignment Pulley groove not proper Use correct pulley Mismatched belts Use preset belts Pulley size not proper Use recommended pulley size Misalignment Align properly Due to slip Tension properly Foreign material Remove foreign particles Foreign obstruction Install guard on the drive Less number of belts Use complete set as per real design of the drive Wrong belt selection Use proper belt section as per drive requirement Jerk load Check belt tension and design Belt forcefully installed over pulley Reduce center distance then install and tension New and old belts Change complete set Belts of different manufacturers Use complete set of one manufacturer Belts of different codes Use preset belts on the drive Figure 9: Troubleshooting Chart of Belt Drive For Training Purposes Only Issue: August 2014 Page 491 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Transmissions Refer to Figure 10. 7.12.1.3 Figure 10 shows a troubleshooting chart of possible failures of belt drives. The first column includes typical belt drive problems, the second shows probable causes and the third gives remedies to correct the failures. All chain drives should receive regular maintenance. Each drive should be inspected after the initial 100 hours of operation. Thereafter, most drives may be inspected at 500 - hour intervals. However, drives subjected to shock loads or severe operating conditions should be inspected at 200 - hour intervals. Chains and Sprockets The components of a chain are hardened parts. Striking these parts may cause metal chips to break off from the chain or the tools in use which may result in personal injury. During all stages of chain disassembly and assembly, safety goggles must be worn to prevent metal parts or chips from entering the eyes. Personnel in the immediate area must do likewise. Chain Disassembly When disassembling it is necessary to remove the pin first. Refer to Figure 11. If the chain is of the cotterpin - type construction, the cotters must be removed. If the chain is a riveted - type construction, the pin heads must be ground off so that the pin ends are flush with the linkplate. The pins are driven out of the linkplate by using a pin extractor. Some multiple - strand chains or large - pitch models will require a hammer and a punch or a press to remove the pins. Figure 10 : Types of Chain Pin Retractor For Training Purposes Only Issue: August 2014 Page 492 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Transmissions Chain Inspection During each inspection, the following items should be checked and corrected, if necessary: Lubrication On slow - speed drives, where manual lubrication is used, be sure the lubrication schedule is being followed. If the chain is covered with dirt and debris, clean the chain with kerosene and relubricate it. Never use gasoline or other flammable solvents to clean a chain. A fire may result. If drip lubrication is used, check for adequate oil flow and proper application to the chain. With bath or pump lubrication, check oil level and add oil if needed. Check oil for contamination and change oil if needed. Change oil after the first 100 hours of operation and each 500 hours thereafter. If pump lubrication is used, check each orifice to be sure it is clear and is directing oil onto the chain properly. Figure 11: Hints of Chain Installation For Training Purposes Only Issue: August 2014 Chain tension Check chain tension and adjust as needed to maintain the proper sag in the slack span. If elongation exceeds the available adjustment, remove two pitches and reconnect the chain. Chain wear Measure the chain wear elongation and if elongation exceeds functional limits or is greater than 3% (0.36 inches in one foot) replace the entire chain. Do not connect a new section of chain to a worn chain because it may run rough and damage the drive. Page 493 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Transmissions Do not continue to run a chain worn beyond 2% elongation because the chain will not engage the sprockets properly and it may damage the sprockets. Sprocket tooth wear Check for roughness or binding when the chain engages or disengages from the sprocket. Inspect the sprocket teeth for reduced tooth section and hooked tooth tips. If these conditions are present, the sprocket teeth are excessively worn and the sprocket should be replaced. Do not run new chain on worn sprockets as it will cause the new chain to wear rapidly. Conversely, do not run a worn chain on new sprockets as it will cause the new sprockets to wear rapidly. Sprocket alignment If there is noticeable wear on the inside surface of the chain roller linkplates, the sprockets may be misaligned. Realign the sprockets as outlined in the installation instructions to prevent further abnormal chain and sprocket wear. Drive interference Check for interference between the drive and other parts of the equipment. If there is any, correct it immediately. Interference can cause abnormal and potentially destructive wear on the chain or the interfering part. If the edges of the chain linkplates impact against a rigid part, linkplate fatigue and chain failure can result. Check for and eliminate any buildup of debris or foreign material between the chain and sprockets. For Training Purposes Only Note: A relatively small amount of debris in the sprocket roll seat can cause tensile loads great enough to break the chain if forced through the drive. Failures Inspect the chain for cracked, broken or deformed parts. If any of these conditions are found, replace the entire chain, even though portions of the chain appear to be in good condition. In all likelihood, the entire chain has been damaged. Chain Installation Refer to Figure 12. To obtain maximum service - life and efficiency from a chain drive, it is necessary that certain precautions in installation be taken. Chain drive installation is relatively simple and good results may be obtained when the following conditions are met: Issue: August 2014 the roller chain, sprockets and other components are in good condition the sprockets are properly aligned provision is made for adequate lubrication the chain is correctly tensioned Page 494 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Transmissions Condition of Components Shafting, bearings and foundations should be supported rigidly to maintain the initial alignment. The roller chain should be free of grit and dirt. Drive Alignment Misalignment results in uneven loading across the width of the chain and may cause roller linkplate and sprocket tooth wear. Drive alignment involves two things: Parallel shaft alignment: Shafts should be parallel and level. This condition may be readily checked by the use of a feeler bar and a machinist’s level. Axial sprocket alignment If there is axial movement of the shaft (as in the case of an electric motor), lock the shaft in the normal running position before aligning the sprockets. Aligning Shafts Sprocket axial alignment can be checked with a straight edge which will extend across the finished sides of the two sprockets. Normally, it is good practice to align the sprockets as close to the shaft bearing as possible. For long center distances, use a taut cord or a wire long enough to extend beyond each of the sprockets. Figure 12: Sprocket Assembly Methods For Training Purposes Only Issue: August 2014 Page 495 of 926 Modul 7 Transmissions Installing the Chain The installation process is as follows: Recheck all preceding adjustments for alignment and make certain that all setscrews, bolts and nuts are tight. Fit the chain around both sprockets and bring the free ends together on one sprocket for connection. The sprocket teeth will hold the chain end links. Install the connecting link, the connecting link coverplate and the spring clip or cotter pins. On larger pitch chains or heavy multiple strand, it may be necessary to lock the sprockets for this operation. Note: When press fit coverplates are used, be careful not to drive the plate on so far as to grip the roller links. Stiff joints can result if this is done. On drives with long spans, it may be necessary to support the chain with a plank or bar as the connection is made. PART 66 – Basic Training Cat B1 – Module 7 to dissipate any heat generated to flush away foreign materials to lubricate chain - sprocket contact surfaces to retard rust or corrosion. With proper lubrication, a separating wedge of lubrication is formed between the pins and bushings in the chain joints much like that formed in journal bearings. The viscosity of the lubricant greatly affects its film strength and its ability to separate moving parts. The highest - viscosity oil which will flow between the chain linkplates and fill the pin –bushing areas will provide the best wear life. This is essential to minimise metal to metal contact and, if supplied in sufficient volume, the lubricant also provides effective cooling and impact dampening at higher speeds. When lubricating multiple strand chains, it is important that the lubricant is directed to each row of chain linkplates. In conveyor applications oil should be directed between the rollers and bushings as well as between the chain linkplates. The following table indicates the lubricant viscosity recommended for various surrounding temperatures: Lubrication A roller chain consists of a series of connecting travelling metallic bearings, which must be properly lubricated to obtain the maximum service life of the chain. Although many slow - speed drives operate successfully with little or no lubrication beyond the initial factory lubrication, proper lubrication will greatly extend the useful life of every chain drive. The chain drive requires lubrication for the purposes listed below: to resist wear of the pin -bushing joint to cushion impact loads For Training Purposes Only Recommended Grade Temperature, oC SAE 5 –45 to + 10 SAE 10 –30 to + 27 SAE 20 –12 to + 43 SAE 30 –7 to + 54 SAE 40 –1 to + 60 SAE 50 +4 to + 65 Issue: August 2014 Page 496 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Transmissions There are three basic types of lubrication for roller chain drives: manufacturer should be contacted for recommendations on guarding before using the equipment. Manual or drip lubrication Oil should be applied periodically between the chain linkplate edges with a brush, spout can or drip lubrication. Oil bath or oil slinger With bath lubrication the lower strand of the chain runs through a sump of oil in the drive housing. The oil level should reach the pitch line of the chain at its lowest point while operating. Only a short length of chain should run through the oil. Oil Stream Lubrication This type of lubrication is required for large horsepower, high speed drives. An oil pump should be provided to spray the oil across the lower span of chain in a continuous stream. Orifices should be placed so that oil is sprayed across each strand of the chain. Assembly of Sprockets Assembly of Sprockets to Tubes Refer to Figure 13. Sprockets may have to be fitted to tubes in some cases. This is done as follows: the sprocket is slid onto the tube to the required position suitably sized holes are drilled in both tube and sprocket, spaced 90o apart from each other the sprocket is removed and all holes deburre jointing compound is applied to all holes the sprocket is re - positioned and riveted to the tube. Chain Tension Assembly of Sprockets to Splined Shafts The chain tension should be checked to be certain that the slack span has 4 % to 6 % mid span movement in horizontal drives and 2 % to 3 % in vertical drives Figure 13, detail b), shows how sprockets are to be fitted to splined shafts: Chain Installation on Equipment You may be seriously injured if you attempt to install chain on equipment under power. Shut off power and lock out gears and sprockets before starting the installation. Once installed, the chain drive must be guarded to prevent personal injury or property damage in the event the chain separates during operation. If the chain drive is not guarded, the equipment For Training Purposes Only Issue: August 2014 jointing compound is applied to the contact surfaces the sprocket is aligned with the master spline and slid onto the shaft; the splines of the shaft should not protrude beyond the face of the sprocket the sprocket is secured by means of a washer and a slotted nut the shaft end is drilled and the slotted nut secured by means of a split pin. Page 497 of 926 Modul 7 Transmissions Condition/symptom PART 66 – Basic Training Cat B1 – Module 7 Possible cause Remedies Dirt or foreign material in chain joints Clean and relubricate chain Inadequate lubrication Replace chain. Re--establish proper lubrication Misalignment Replace sprockets and chain if needed. Realign sprockets Internal corrosion or rust Replace chain. Eliminate cause of corrosion or protect chain Overload bends pins or spreads roller Replace chain. Eliminate cause of overload Exposed to moisture Replace chain. Protect from moisture Water in lubricant Change lubricant. Protect lubrication system from water. Replace chain Inadequate lubrication Provide or re--establish proper lubrication. Replace chain, if needed Turned Pins Inadequate lubrication Replace chain. Re--establish proper lubrication Enlarged Holes Overload Replace chain. Eliminate cause of overload Broken pins Extreme overload Replace chain. Replace sprockets if indicated. Eliminate cause of overload or redesign drive for larger pitch chain Speed too high Replace chain. Reduce speed Sprockets too small Replace chain. Use larger sprockets, or possibly redesign drive for smaller pitch chain Chain riding too high on sprocket teeth Replace chain. Retension chain more often Inadequate lubricatio Reduce speed or load. Possibly redesign drive for smaller pitch chain. Provide or re—establish proper lubrication Tight Joints Rusted chain Broken, cracked or deformed rollers Pin galling Figure 13: Troubleshooting Chart of Roller Chain Drive (I) For Training Purposes Only Issue: August 2014 Page 498 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Transmissions Condition/symptom Chain climbs sprocket teeth Missing or broken cotters Excessive noise Wear on insider roller link plates and one side of sprockets For Training Purposes Only Possible cause Remedies Excess chain slack Retension chain Excessive chain wear Replace and retension chain Excessive sprocket wear Replace sprockets and chain Excessive overload Replace chain. Eliminate cause or overload Cotters installed improperly Install new cotters per manufacturer’s instructions Vibration Replace chain. sprockets Excessively high speed Replace chain. Reduce speed. Redesign drive for smaller pitch chain Chain striking an obstruction Replace chain. Eliminate interference Loose casing or shaft mounts Tighten fasteners Excess chain slack Retension chain Excessive chain wear Replace and retension chain Excessive sprocket wear Replace sprockets and chain Sprocket misalignment Replace chain and sprockets, if needed. Realign sprockets Inadequate lubrication Replace chain if needed. Re--establish proper lubrication Chain pitch too large Redesign drive for smaller pitch chain Too few sprocket teeth Check to see if larger sprockets can be used. If not, redesign drive Reduce vibration. Use larger Replace sprockets and chain if needed. Realign drive. Retension chain Figure 14: Troubleshooting Chart of Roller Chain Drive (II) Sprocket misalignment Issue: August 2014 Page 499 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Transmissions Troubleshooting Refer to Figures 14 and 15. Figures 14 and 15 show troubleshooting charts of possible failures of roller chain drives. The first column includes the condition/symptom, the second shows possible causes and the third gives remedies to correct the failures. 7.12.1.4 Jacks and Lever Devices Inspection of Screw Jacks Check that there is no pitting, hardening or scaling of chrome on grooves of threading. If these defects are significant, check the contours of the threading at all points along the nut: - it is permissible to touch up the contour within the maximum clearance listed in the reference documentation and to re do the chromium plating. Check for any scoring, corrosion or hardening, particularly on the thread grooves: If defects are significant, check the contour of the threading at all points along the screw: - It is permissible to touch up the contour within the maximum clearance listed in the reference documentation and to re - do the chromium plating after touch up of the screw. Figure 15: Inspection of Screw Jack For Training Purposes Only Issue: August 2014 Page 500 of 926 Modul 7 Transmissions PART 66 – Basic Training Cat B1 – Module 7 Figure 16: Inspection of Push - Pull Rod System For Training Purposes Only Issue: August 2014 Page 501 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Transmissions Inspection of Screw/Nut Axial Play Refer to Figure 16. Install the screw/nut assembly not fitted with ice breakers and seals, and with the nut positioned at approx. 2/3 from the end of the screw on inspection tool. Fasten the screw onto the tool using two V - flanges provided for this purpose. Check that the movable table is in the neutral position, i.e. control wheel in neutral. Fasten the nut using two flanges provided for this purpose. The flanges attach the nuts to the movable table by means of nut tenons. Then screw in the radial locking screw until it comes into contact with the nut, making sure that the movable table can freely move in all directions. The point of a dial indicator is set by pressing on the bar of the movable table, to read the axial play. Make sure that the object being tested is hooked to the lower ring of the wheel pin. Press on the lever to release the object being tested and turn the control wheel to put the roller against the rocker opposite the dial indicator. Reset the dial indicator. Actuate the lever two or three times to check the dial indicator setting. Press the lever to lift up the object being tested and turn the wheel by 180° to bring the roller against the corresponding rocker. Release the lever and read the value of the dial indicator; the reading should represent the screw/nut axial play. The play should be between 0.04 mm and 0.10 mm (0.00157 in. to 0.0039 in.). Activate the lever and set the wheel to the neutral position. Install the point of dial indicator (2) on one side of the movable table. Press on the lever and turn the wheel so that the roller For Training Purposes Only is brought in contact with the rocker opposite the dial indicator. Zero the dial indicator. Activate the wheel two or three times to make sure the dial indicator is properly zeroed. Press on the lever and turn the wheel by 180° in order to bring the roller in contact with the corresponding rocker. Release the lever and read the value of the dial indicator. The reading is the screw/nut radial play, including the screw elasticity deviation caused by the radial force that is applied. The screw/nut play actually allowed is between 0.030 mm and 0.055 mm (0.00117 in. and 0.00214 in). Since the elasticity deviation value of the tool is equal to 0.08 mm (0.00314 in.), the dial indicator reading must be between 0.110 mm and 0.135 mm (0.0433 in. and 0.0531 in.). In the event that the axial and/or radial plays are too great, install balls with the next higher diameter value. If necessary use balls with even greater diameters in order to return the play values within the given tolerances. Note: The ball quantity may be decreased with increasing diameters. If the plays still cannot be returned within the tolerances when the maximum diameter value has been reached, the nut must be replaced. Note: The functional play must be greater than the diameter of a ball. Inspection of Push – Pull Rod Systems Adjustable Rod End Clevis Rivets Refer to Figure 17. Issue: August 2014 Page 502 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Transmissions Helicopters use so many push - pull rods in their control systems that only a small amount of wear in each of the fittings will be amplified and can cause serious control vibration. It is important when checking the rigging of a helicopter that there is no slack in the control rods. The anti - friction rod - end bearings are usually of the self - aligning type. But when one is installed, it must be ensured that it is squarely in the center of the groove in which it fits so there will be no tendency for the bearing to contact the housing and rub at the extremes of its travel. Bell cranks are used extensively in push - pull tubing systems to change direction of travel and to gain or decrease the mechanical advantage of the control movement. Pinning of Lever to Shaft Figure 17: Assembly Methods of Control Lever Refer to Figure 18. Many aircraft and almost all helicopters use push - pull rods rather than control cables for the systems. Figure 17 shows a typical push pull rod using a clevis rod end and a rod - end bearing. The tubes themselves are usually made of seamless heat - treated aluminium alloy tubing with threaded rod ends riveted into the ends, and fittings screwed onto these threads. To be sure that the rod ends are screwed far enough into fitting, each of the fittings has a small hole drilled in it. If a piece of safety wire can be passed through the hole, the rod end is not screwed in far enough. A cheek nut is screwed onto the rod end and when the length of the rod is adjusted, the cheek nut is screwed up tightly against the end of the fitting to hold it in place. For Training Purposes Only Figure 18 illustrates the pinning of a lever to a shaft as a common type of assembly work. The procedure is as follows: Issue: August 2014 the lever is first positioned on the shaft a hole is drilled through both lever and shaft and reamed a pin is driven through the hole to maintain alignment a second hole is drilled and reamed the lever is now separated from the shaft; all holes are deburred the lever is re - fitted to the shaft after applying jointing compound to the mating surfaces pins are driven through the holes to pin the lever to the shaft the ends of the pins are cut such that they protrude slightly the protruding ends of the pins are flattened. Page 503 of 926 Modul 7 Control Cables 7.13 Control Cables 7.13.1 Control Cable Inspections 7.13.1.1 Control Cable Basics PART 66 – Basic Training Cat B1 – Module 7 Even if no snags occur this is no positive evidence that broken wires do not exist. So, the cable should be removed and bent, thereby making sure that no kinks get into the wire so that it can be re installed if the cable is found to be in good condition. Bowden Cable Control cables play a big part in aircraft. They are items that should not be taken for granted and for that reason should be inspected properly. Periodical Inspections of all control cables are important. The inspections should not only consist of checking the cable ends and making sure that the bell cranks hit their stops. But the proper way to inspect a cable is to inspect it inch by inch. Refer to Figure 1. Control cables are generally fabricated of carbon steel or corrosion resistant steel wire. They may consist of either flexible or non -flexible type construction. Control cables are made up of many wires twisted together to form a strand. Many strands are then twisted together to form the cable. Aircraft cable systems are subject to a variety of environmental conditions and forms of deterioration. Some can be easily recognised in form of wire or strand breakages. Other types of wear are not so easily visible when caused by corrosion. Critical areas for wire breakage are those sections of a cable which pass through fairleads and around pulleys. Cables are to be examined for broken wires by passing a cloth along the full length of the cable. This will clean the cable for a visual inspection and, at the same time, will detect broken wire if the cloth snags. When snags do occur, the cable must closely be examined to determine the full extent of the damage. Figure 1: Typical Bowden Cable For Training Purposes Only Issue: August 2014 Page 504 of 926 Modul 7 Control Cables Invented by Frank Bowden, a bowden cable is a type of flexible cable used to transmit mechanical force or energy by the movement of an inner cable (most commonly of steel or stainless steel) relative to a hollow outer cable housing. The cable housing is generally of composite construction, consisting of a spiral steel wire, often coated with plastic, and with a plastic outer sheath. The linear movement of the inner cable is generally used to transmit a pulling force, although for very light applications over shorter distances (such as the indexed shifting system on a bicycle) a push may also be used. Usually provision is made for adjusting the cable tension using an inline hollow screw (often called a ’barrel adjuster’), which lengthens or shortens the cable housing relative to a fixed anchor point. Lengthening the housing (turning the barrel adjuster out) tightens the cable; shortening the housing (turning the barrel adjuster in) loosens the cable. Cable Wear Cable wear from pulleys or fairleads will normally extend along the cable equal to the distance that the cable moves at that location. This may occur either on one side or the entire circumference. Cables should be replaced when signs of wear are visible. As wear is taking place on the exterior surface of a cable, the same thing is happening internally, particularly in the section of the cable that passes over the pulley or quadrant. This wear is caused by the relative motion between the inner wire surfaces. Another type of cable wear is due to corrosion. Cables must therefore be checked for broken wires in areas where the cable is not in contact with any other component. During inspection, particular attention must be taken in areas where cables pass through areas of moisture such For Training Purposes Only PART 66 – Basic Training Cat B1 – Module 7 as in wheel wells, battery compartments and any other areas where moisture or chemicals come into contact with cables. Inspection Guide When doing an inspection, the following should be carefully checked: Cable runs: Should be checked for incorrect routing or areas where cables make contact with other objects. Have someone move the controls so you can see if contact is being made in any extreme or travel. Cable end fittings, e.g. swaged terminals: Should be examined for distortion or broken strands. Ensure that all bearing and swivel fittings pivot freely to prevent binding and subsequent failure. Turnbuckles: must be checked for proper thread exposure and broken or missing safety wire or clips. Pulleys: Should be inspected for wear, making sure that they all move freely and that safety pins are installed over them to prevent cables from popping off. Loose bolts and missing cotter pins. Cable travel: whether being sufficient to hit the stops. Cable tension: too loose or too tight? This could cause sloppy or stiff control movement. After having inspected the entire cable system, the inspector should sit in the cockpit and make sure that all controls move freely and in the correct direction. This will assure that nothing has been disturbed during the inspection. Issue: August 2014 Page 505 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Control Cables 7.13.1.2 Installation of Swaged End Fittings Control cables can be fitted with a wide range of end fittings. It is possible to install such fittings inhouse if the correct tools and test equipment are available. A fitting is swaged onto a cable as follows: Cut the cable to the proper length using a cable cutter Kink the end of the cable to prevent sliding out during swaging. Insert the cable end into the terminal until it reaches the bottom. Compress the terminal with the correct swaging tool. Check the swaged terminal using a ’Go/No - go’ gauge. Test the cable by using a test load. Cutting the Cable Refer to Figure 2. Cables are normally stored on a reel. The length of cable is to be unwound as specified in the manual. The cable should be cut off with a cable cutter as shown in Figure 2. Any burrs are to be removed from the cable ends by using a grinding machine or other suitable equipment. Figure 2: Cable Cutter (Examples) Inserting the Cable into the Fitting Choose a fitting which matches to the cable and insert it into the terminal until it is stopped by the bottom of the fitting. The distance between opening of the terminal and its bottom must be measured before the swaging process. For Training Purposes Only Issue: August 2014 Page 506 of 926 Modul 7 Control Cables PART 66 – Basic Training Cat B1 – Module 7 Swaging Methods Cable fittings can be swaged by using different tools. Note: It must be kept in mind that some types are not allowed to be used on comer - cial aircraft, e.g. the hand – and the hydraulically operated squeezers. The known tools are: Refer to Figure 3. hand - operated squeezer hydraulically, hand - operated squeezer Figure 3: Hand – Operated Squeezer (Example) For Training Purposes Only Issue: August 2014 Page 507 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Control Cables Refer to Figure 4. Rotary swager. For professional manufacturing of control cables, only the rotary swaging method is used. Figure 5: Changeable Dies Used in Rotary Swagers In a classical rotary swager, there are dies rotating around the workpiece. While rotating, the dies move in and out delivering slight ’beats’ to the workpiece. This operation continues several times. It results in a reduction of the cross section of the fitting. The correct set of dies must be installed in the swager to obtain a satisfactory result. Checking the Swage Refer to Figure 6. Figure 4: Rotary Swager (Example) After the swaging process has been finished, the swage dimensions must be within given limits according to the relevant manual. This check can be done with a ’Go/No Go’ gauge or by using a micrometer. Rotary Swager Refer to Figure 5. For Training Purposes Only Issue: August 2014 Page 508 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Control Cables Figure 7: Test Rig for Proof Loading (Example) Protection and Storage Cables are often dipped in a bath of warm conservation fluid to protect it against corrosion. Cables should be stored horizontally on a flat surface. When the cable is rolled up, it is to be ensured that the radius is not too small, i.e. that no sharp bends occur. Figure 6: Checking the Swage Proof Loading 7.13.1.3 Control Cable Installation Refer to Figure 7. Cables which are ’ready to install’ must be clearly identified according to their specification prior to installation. After installation of the end fittings, the cable must be proof loaded to ensure safe operation. The cable will be installed in a manual test rig (see Figure 7) or in a hydraulically operated rig. The Cable should be tested by loading it to 60 % of its breaking strength, with the load applied gradually and held for at leats 5 sec. Before installation, threads shall be cleaned with an applicable solvent (as specified in the manual) and dried with a clean cloth. Furthermore, dirt, moisture or other contamination shall be removed with a clean cloth. Terminal threads shall be protected to prevent thread damage during installation. A small kink in the cable may be worked out manually. For Training Purposes Only Issue: August 2014 Page 509 of 926 Modul 7 Control Cables PART 66 – Basic Training Cat B1 – Module 7 Cable Clearances To prevent cables from chafing or riding, certain clearances must be obtained. In general, the clearance to structural members such as pipes, ducts and electrical conduit installations shall not be less than the minimum specified in the relevant manuals. The permissible clearance of cables depends on the type of cable and the adjacent part. Critical elements with regard to clearances are: hydraulic lines fuel and oil lines bleed air and pneumatic ducts electrical conduits and wires V barometric and oxygen lines high - pressure lines, pipes, hoses. In certain cases, installation of nylon chafing strips is approved and limited contact is acceptable. However, the degree of acceptable rubstrip contact is defined by specification. Refer to Figure 8. Cables routed through fairlead grommets may also have limited contact. Again, the degree of acceptable contact is defined by the applicable specificatiion or manual. Figure 8: Typical Grommets For Training Purposes Only Issue: August 2014 Page 510 of 926 Modul 7 Control Cables Measuring the Cable Tension In long cable runs, tension regulators are installed to maintain the cable tension. In short cable runs, there are no regulators installed. Instead, turnbuckles are used to adjust tension and rigging. Note: In long cable runs, turnbuckles are used only to adjust the system rigging, but not to adjust the tension. PART 66 – Basic Training Cat B1 – Module 7 Cable tension is determined by measuring the amount of force required to make an offset in the cable which is fixed between the two steel blocks (the so - called ’anvils’) of a tension meter. A riser is pressed against the cable to form the offset, as shown in Figure. Refer to Figure 10. Each tension meter has a scale for indication of the pressure applied. Furthermore, there is a cable tension chart with each type of tension meter (see Figure 10). The following procedure applies for use of such a conversion chart: Refer to Figure 9. 1. determine the size of the cable to be adjusted 2. determine the ambient temperature 3. find the intersection of the temperature line and the pressure curve 4. find the appropriate rigging load at the right side of the chart. Example: The cable to be checked is a 7 x 19 cable, 1/8 inch in diameter. The ambient temperature is 85oF. What is the maximum rigging load in pounds? Starting at the bottom of the 85oF line, we follow the line upwards to where it cuts the curve for the 7 x 19 cable size. From there, we draw a horizontal line to the right until reaching the edge of the chart. Here we find the rigging load as being 70 lbs. Tension meters used on nylon - coated cable shall be calibrated using a riser which corresponds to the outside diameter of the nylon coating. Figure 9 : Cable Tension Meter (Example) For Training Purposes Only Example: Inner steel cable without nylon coating: Nylon - coated cable: Issue: August 2014 Page 511 of 926 3/32”. 5/32”. Modul 7 Control Cables use the riser size for a 5/32” cable read the tensiomete follow the temperature line until it intersects with the curve for a 3/32” cable. Occasionally, surface protective coating has to be removed from the cable to perform a thorough check. The folloing has to be borne in mind: Note: Tension meters shall bear the current calibration date. Prior to the use of tension meters, their serviceability is to be checked by the technician. 7.13.1.4 Cable Inspections Cleaning Cables are constantly exposed to effects like PART 66 – Basic Training Cat B1 – Module 7 repeated bending stress loads internal friction corrosion. Never use metallic wool or solvent to clean cables. Metallic wool contain dissimilar metal particles which will cause and even intensify further corrosion. To remove the protective coating, always use an approved cleaning agent as specified in the relevant manual. Do not saturate the control cables and/or the cores with the cleaning agent or solvent. Solvent penetration of the cable core destroys the cable lubrication and permits corrosion and rapid wear. Unfavourable results can occur when using gycol detergents, high water pressure during maintenance and/or misuse of cleaning agents/solvents. Sooner or later, these factors will lead to the breakage of wires. Such breaks occur most frequently where cables pass over pulleys and through fairleads. Further cable damage occurs due to chafing over structural parts or friction between cables. Corrosion is one of the most critical damages to control cables because its effect on the cable strength is hard to be determined. Tehrefore corrosion should be prevented by proper application of protective coating. To inspect a cable correctly, the following steps should be followed: cleaning cable corrosion inspection inspection of installation surface protection. For Training Purposes Only Issue: August 2014 Page 512 of 926 Modul 7 Control Cables PART 66 – Basic Training Cat B1 – Module 7 Figure 10: Determination of the Cable Tension For Training Purposes Only Issue: August 2014 Page 513 of 926 Modul 7 Control Cables PART 66 – Basic Training Cat B1 – Module 7 Corrosion, Wear and Damage Inspection Refer to Figure 11. If the surface of a control cable is corroded, a more detailed inspection must be carried out. It is often necessary to release the cable tension to check the damaged area completely and in detail. During inspection the cable should be moved the full length of travel because damaged areas may be hidden in e.g. a pulley groove. One way to inspect the interior strands is to carefully force the cable to open by reverse twisting and visual inspection of the cable core. A magnifying glass and a bright light should always be used. If there is minor corrosion only and no indications of internal damage, the external corrosion should be removed with a fibre brush or a lint free cloth. Corrosion on the interior strands of a cable indicates a failure and requires replacement of the cable. When inspecting the cable for broken wires it is helpful to run a cloth along the cable in both directions. If there are broken wires, the cloth will snag. Figure 11: Inspection and Wear Pattern of Steel Control Cables WearTolerances For Training Purposes Only Issue: August 2014 Page 514 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Control Cables Refer to Figure 12. Extra flexible 7 x 19 wires (Form B) may show up to 6 broken wires on a length of one inch, thereof three or less per strand. If more wire ends are visible, the cable is no longer usable. The maximum allowable number of broken wires shall not occur on any consecutive inch of length. The critical fatigue area is the working length of a cable, mainly caused by the bending stress arising at pulleys and fairlead grommets. When broken wires appear in such areas the tension should immediately be released and the cable carefully checked for further defects. Inspection of Installation Several components are installed along a cable run. Cables should therefore be inspected for broken wires, cable wear and corrosion especially in such sections and areas where they are in contact with pulleys, fairleads and pressure seals or where they are close to toilets, galleys and other areas where water condensation occurs. To thoroughly inspect the cable, it must be moved in full length of travel to expose damaged areas. The following should be considered: Figure 12: Typical Cable Wear Tolerances Note: The following cable wear tolerances can be used as a guide only for allowable wear tolerances on aircraft in service. The actual limits as well as different values for line checks and overhaul inspections are given in the applicable specifications and aircraft related maintenance manuals. Flexible 7 x 7 wires (Form A) may have up to three broken wires in a section of one inch in length to be still usable, thereof a maximum of two on one strand. With more than three broken wires in total the cable must be replaced. For Training Purposes Only Issue: August 2014 check safety and condition of all pulley brackets ensure that all pulley guard pins are in place check for broken or cracked pulleys and pulley flanges whenever tension is relieved check pulleys for free rotation ensure that all cotter pins are installed correctly examine fairlead grommetsand rubstrips; replace all damaged or worn ones examine all firewall fairlead grommets and check for proper alignment to prevent cable wear Page 515 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Control Cables grommets should be rigidly clamped in retainer after some cable tension has been applied; grommets should not be allowed to swivel or rotate check that all turnbuckles are correctly safetied ensure that cable terminal threads meet the visual inspection requirements check thtat the gapbeetwin guardpin/bushing and flange of any pulley (sector or drum) is within the applicable limits ensure that the cable is coated with corrosion preventive component which meets the characteristic stated in the relevant specification check that the cable clearances atre in accordance with applicable specifications check the compete cable for prober alignment (no ’pull - offs’) check cable clearances in accordance with general rules (see above). In case of nylon coated cables, a protective compound shall be applied to the area where the nylon has been stripped. 7.13.1.5 Bowden Controls Refer to Figure 13. Surface Protection After completion of cleaning and inspection, corrosion preventive surface coating must be applied to the cable as specified in the relevant manual. The surface of a control cable is to be checked for lack of protective coating. Such areas are to be cleaned with a clean cloth moistened with a specified cleaning agent. Protection coating shall be applied by using a clean brush or sprayed as detailed by the manufacturer. At fairleads, grommets, pressure seals etc., excessive build up of coating should be avoided. This would increase cable friction force. When working at installed cables, the portion(s) which is (are) to be recoated shall be wiped clean before applying the coating. For Training Purposes Only Figure 13: Typical Bowden Control Bowden controls consist of a stainless steel wire housed in a flexible sleeve or conduit. The control is intended for ’pull’ operation only. Issue: August 2014 Page 516 of 926 Modul 7 Control Cables PART 66 – Basic Training Cat B1 – Module 7 Therefore the cable is returned by a spring on release of the control lever. Note: Do not mix up a bowden control with a push - pull cable. The latter is able to transmit a force in both directions. The flexible cable of a bowden control is made up of several strands of stainless steel wire. Brass nipples are soldered or swaged to the ends. The conduit consists of a coiled wire, covered with a waterproof coating. Metal caps are fitted to the ends. For sections with long runs, metal tubing may be used. At the transmitting end, an operating lever is fitted which engages with the nipple at the end of the cable. At the receiving end, the cable passes through an adjustable stop and the nipple engages with the component operating lever. Guide for Inspection and Servicing Check the cable ends for fraying and corrosion. Inspect the conduit for kinks and signs of wear, especially at the ends, where the cable tends to wear the conduit bell mouth, unless the cable and the conduit exactly line up. Adjust the slackness of the cable, i.e. increase the length of the conduit by screwing the adjustable end to take up slackness of the cable. Check locking of adjacent nuts (locknut, adjustable stop). Lubricate the assembly with recommended grease. For Training Purposes Only Issue: August 2014 Page 517 of 926 Modul 7 Material Handling 7.14 Material Handling Marking – Out 7.14.1 Cutting and Forming used in Sheet Metal Work Refer to Figure 1. Sheet Metal and Sheet Metal Work Sheet metal is used in all fields of engineering, e.g. for the production of chassis, as supporting structure for constructional elements and modules, for switch cabinets and panels. Front covers, guards and housings can be additionally produced from sheet metal. Switch cabinets, panels and larger housings are usually manufactured from sheet steel (constructional steel). Aluminium mainly serves as material for chassis, smaller housings and covers in communication technique. Cores, e.g. for repeaters, transformers and coils are made of sheet plates with specific magnetic properties. In addition, sheet plates are required in all fields of engineering and everyday use. Sheet metal is delivered in plates or coils. Sheet metal work comprises the following applications: Cutting Forming Joining. Prerequisites for a successful sheet metal work are accuracy in performance and preparation of the work. This includes, besides workshop safety, marking - out of workpieces as well as the choice of the correct tools. For Training Purposes Only PART 66 – Basic Training Cat B1 – Module 7 Marking - out is the transfer of drawing dimensions onto the workpiece. It serves as preparation for further processing. Marking out is nearly exclusively used in the small scale production of workpieces. Marking - out for mass production is uneconomical and is therefore replaced by special devices and machines. Marking - out is usually performed with a scriber although a soft pencil is sufficient for most of the markings on sheet metal plates. Pencilled lines are very well visible and can be removed easily after completion of the work. In addition, the surface of the workpiece is not damaged by deep marking lines and cannot tear under stress at these positions. Marking - out always starts from the same reference line. A steel ruler and a try square are sufficient for simple markings. It is a presupposition that the workpiece to be processed has 2 straight reference edges rectangular to one another. First of all all dimensions which are positioned in one direction (e.g. all vertical dimensions) are measured by means of the ruler and the try square by putting the try square against one reference edge and aligning it to the other reference edge by means of the ruler (Figure 1, step 1). Now the marking - out is performed. When all vertical dimensions are marked out all horizontal dimensions are marked out in the same manner (Figure 1, step 2). Issue: August 2014 Page 518 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Material Handling 7.14.1.1 Cutting Cutting is an operation performed without creating chips or waste products. This procedure leaves a clean edge on the piece of metal that is cut or sheared. Cutting Process Cutting is the common term for a method used for cutting sheet metal. It largely depends on the thickness of the metal. Very thin sheets of metal (called ’foils’) may be cut with household scissors but common sheet metal requires special tools and special methods. Refer to Figure 2. The cutting process can be divided into 3 basic stages: Deformation Shearing Fracture. Figure 1: Marking – Out Principles For Training Purposes Only Issue: August 2014 Page 519 of 926 Modul 7 Material Handling PART 66 – Basic Training Cat B1 – Module 7 Deformation The metal is placed between the upper and lower blades of a cutting tool. The blades are forced together and the elastic limit of the material is reached as the blades penetrate the metal. Shearing Shearing is indicated by small deformations on the surface of the metal which extend into the interior of the metal from 5 % up to 40 % of its thickness. The penetration of the shear zone depends on the type of metal being sheared. Fracture The fractures start at the cutting edge of each blade, the point of greatest stress concentration. As the blades decline further, the small fractures meet and the metal is then cut. Cutting Thin Sheet Metal For cutting thin sheet metal the operator either uses tinners’ snips, nippers or shears for this purpose. Basically there are no special shears for right –handed or left – handed persons but there are shears applicable either for right –hand use or for left –hand use. They are called right –hand shears and left –hand shears. Right –hand shears have the lower screw die on the right side in cutting direction, whereas left –hand shears have it on the left side. Blade Clearance and Aperture Angle Figure 2: Cutting Process For Training Purposes Only Refer to Figure 3. Issue: August 2014 Page 520 of 926 Modul 7 Material Handling PART 66 – Basic Training Cat B1 – Module 7 Blade Clearance The distance between the 2 blades is called ’blade clearance’. Its task is to prevent the blade edges from coming into contact with each other and to ensure only a little friction between them. Due to the light bend of the blades the required blade clearance is only present at the place of cutting. The shears do not cut correctly if the blade clearance is too large and the material might be jammed or edged (detail a)). Aperture Angle Figure 3 detail b) shows the aperture angle. It should be less than 20•. The shears do not grasp when the aperture angle is larger. A wider angle would push away the workpiece. Types of Tinner’s Snips Refer to Figure 4. Tinners’ snips are very much like scissors but because metal is harder than paper the handles of the snips are much longer than the blades, so that the operator can apply greater force to the cutting edge of the snips. Figure 3: Blade Clearance and Aperture Angle For Training Purposes Only Issue: August 2014 Page 521 of 926 Modul 7 Material Handling PART 66 – Basic Training Cat B1 – Module 7 Shears for Continuous Cuts These shears are used for shearing long distances with large curves and straight edges. Hole Cutting Shears Hole cutting shears are mainly used for cutting inner curves but are also suitable for outer curves. Blade Tinners’ Snips These shears are especially suitable for not easily accessible cutting lines. The jaws of the shears may have an offset up to 45o. Tinners’ Snips with Narrow Blades for Cutting Intricate Shapes These shears are produced with or without lever transmission and are used for cutting complicated inner and outer cuts. Furthermore, these shears are used for cutting objects, bows and circles. Pipe Shears These shears are used for cutting pipes made of thin sheet metal in radial direction. Wire Cutter These shears are produced with or without lever transmission. They are used for cutting stronger wires. Stock Shears Figure 4: Types of Tinner’s Snips For Training Purposes Only These shears are suitable for short cuts of thicker sheet plates. Issue: August 2014 Page 522 of 926 Modul 7 Material Handling 7.14.1.2 PART 66 – Basic Training Cat B1 – Module 7 Forming The term ’forming’ is understood as the non - cutting deformation of materials because there is no waste of material during forming. The Volume of the not - machined part is maintained in the finished part. Bending Refer to Figure 5. The main characteristic of all bending processes is that stresses in the metal occur only in specific areas. For example, bending metals in a bending machine results in stretching and upsetting stresses appearing in the bending area only. The outside of the bend will undergo stretching stresses (tensile strain), and the inside of the bend will always be placed under upsetting stresses (compressive strain). In between the stretching and the upsetting area there is the neutral fibre which maintains its length during the bending process. The forming or bending stresses of the metal have to be lower than the ultimate tensile strength of the metal. If the metal is stretched too far, it will crack and the piece will be ruined. In bending, however, the part of the metal not being bent is not stressed during any forming operation. Figure 5: Bending Stress and Bending Crack For Training Purposes Only Issue: August 2014 Page 523 of 926 Modul 7 Material Handling PART 66 – Basic Training Cat B1 – Module 7 Bending Radius The rolling direction of the workpiece has to be observed when bending sheet plates. The bending edge should cross the rolling direction, especially when the bending radius is small. If there are 2 bends to be made on one workpiece situated at an angle to each other, the rolling direction has to be oblique to them. During bending processes the following must always be avoided: excessive compressive strain exceeding the stability bending fractures Calculation of the Stretched Length Refer to Figure 6. The stretched length is the length of a material in stretched condition. It is exactly the length of the neutral fibre of the finished workpiece. For evaluation of the stretched length all lengths of the straight segments and of the bent segments are added. The lengths of the bent segments have to be calculated with the radius of the neutral fibre, that means, half of the thickness of the workpiece has to be added to the bending radius of the drawing (Figure 6). Example: Calculate the stretched length of the bow. The workpiece is divided into straight and bent segments for this reason. The bent segments are calculated by means of the formula used for calculating the periphery of a circle. For Training Purposes Only Issue: August 2014 Figure 6: Stretched Length Page 524 of 926 Modul 7 Material Handling PART 66 – Basic Training Cat B1 – Module 7 2∙ 𝜋 ∙𝑟 The term r is designated as the radius of the neutral fibre. It is calculated by adding the bending radius of the drawing and half of the material thickness. 𝑟 = 𝑅3 + 1.5 = 4.5 For rectangular bends the length of the bent segment is 1/4 of the circle. 2∙ 𝜋 ∙ 𝑟 4 For the length of each bent segment (B) it follows: 𝐵=2 ∙ 𝜋 ∙ 4.5 4 Now the lengths of the 4 bent segments are added to the straight segments for calculating the stretched length (L): 𝐿 = (4 ∙ 𝐵) + (2 ∙ 𝑥) + (2 ∙ 𝑦) + 𝑧 𝑥 = 30 − 6 = 24 𝑦 = 54 − 12 = 42 𝑧 = 120 − 6 = 114 𝐿 = (4 ∙ 7.07) + (2 ∙ 24) + (2 ∙ 42) + 114 = 274.28 𝑚𝑚 Resilience during Bending Refer to Figure 7. Figure 7: Resilience during Bending For Training Purposes Only Issue: August 2014 Page 525 of 926 Modul 7 Material Handling PART 66 – Basic Training Cat B1 – Module 7 After bending, a resilience arises. The resilience depends on the material, bending radius and rolling direction. The reason for resilience is, that not all crystals in the bending zone exceed the yielding point. As soon as the bending forces do not have an effect any more, the crystals return to their initial position and the material flies back. Therefore the workpiece has to be bent approximately 1 % to 3 % in addition to the desired bending angle to achieve the correct bending angle after resilience. Making Straight Bends A straight bend is a bend made along a straight line or edge. It may be a slight bend or a large bend. The method used will depend upon the size of the job and the equipment available. The types of equipment which can be used are: Stakes edge of the bench hand bending machine pliers. Stakes Refer to Figure 8. There are 4 types of stakes on which straight bends can be made: beak iron square bottom stake hatchet stake creasing stake. Figure 8: Types of Stakes For Training Purposes Only Issue: August 2014 Page 526 of 926 Modul 7 Material Handling PART 66 – Basic Training Cat B1 – Module 7 A beak iron is generally used for making parallel bends, such as the opposite ends of a box, or for rounding of short metal parts. A square bottom stake is used for making adjacent bends, such as folding the ends of a box or working in a corner. A hatchet stake is used for making acute angle bends. A creasing stake is used for making straight strengthening creases in sheet metal. Therefore a bar of a size slightly smaller than the width of the crease required is placed on the metal over the creasing groove and tapped into shape with a hammer. Edge of the Bench If the edge of the bench is furnished with an angle iron it can be used as a giant folding bar. The metal is placed over the edge of the bench and clamped on top of the bench. The metal is then folded down with a mallet. Hand Bending Machine A hand - operated bending machine is used for making parallel bends, such as the opposite sides of a box. It can fold angles up to acute angles. It is particularly useful for long bends as it folds the metal evenly and so stops distortion. Pliers Very small pieces of sheet metal can be bent with pliers. Bending in the Vice Figure 9: Bending in the Vice Refer to Figure 9. For Training Purposes Only Issue: August 2014 Page 527 of 926 Modul 7 Material Handling PART 66 – Basic Training Cat B1 – Module 7 A bending block with the desired bending radius is required for this bending operation. The workpiece is clamped between the bending block and the vice jaws and is bent over the bending block. Direct hits with a hammer onto the workpiece have to be avoided. They can easily cause dents or notches. A smooth surface is achieved with a shim as intermediate piece or with a mallet for soft materials. Refer to Figure 10. When bending a double strapped pipe clamp with the bending block the procedure is as follows: First of all, the hoop - steel is marked in the center and slightly prebent at this position. Afterwards, the hoop - steel is fixed centrically and rectangularly to the bending block in bending position, approx. 5 mm beneath the upper edge of the vice jaw. The first bow is then bent. The second bow is bent by means of an additional bending block until the U - form is achieved. Finally, the bending positions for both straps are marked and the hoop - steel is bent over the bending jaws to the desired bending radius. Figure 10: Bending with the Bending Block For Training Purposes Only Issue: August 2014 Page 528 of 926 Modul 7 Material Handling PART 66 – Basic Training Cat B1 – Module 7 Raising Sinking Refer to Figure 11. Refer to Figure 12. The raising process is another method of forming work. When using this method, metal is drawn over a suitably shaped steel or wooden head. A bossing mallet or raising mallet should be used for striking the blows. Sinking is a process like hollowing, differing in the fact that a flat rim is left on the material. The edge of the disk is kept against the pins and the work is slowly rotated on the block while being hammered. Figure 11: Raising Figure 12: Sinking For Training Purposes Only Issue: August 2014 Page 529 of 926 Modul 7 Material Handling PART 66 – Basic Training Cat B1 – Module 7 Crimping Refer to Figure 13. Sheet metal walls and bottoms easily bend. The modulus of elasticity of thin sheet plates can be increased by crimping webs (beads). The material becomes harder and more solid by cold forming. A stiffening of the workpiece is achieved by crimping. The corrugated sheet plate is an example of crimping. The beads may be angular or semicircular. When processing sheet metal, beads are usually manufactured semicircularly with a crimping machine. Figure 13: Crimping For Training Purposes Only Issue: August 2014 Page 530 of 926 Modul 7 Material Handling PART 66 – Basic Training Cat B1 – Module 7 Planishing Curving Refer to Figure 14. Refer to Figure 15. Planishing is the finishing process in which the workpiece is smoothed and finally set to its correct shape. By means of curving, specified parts of the workpiece are extended by concerted straightening. The aim of curving is to deform a straight sheet metal stripe into a bow type stripe. The thickness of the sheet metal decreases to the outer rim of the stripe. All hammers and stakes used for planishing must be maintained in a highly polished state, because any blemish on the working surface will be reproduced on the surface of the workpiece. As a general rule, flat - faced hammers are used on convex surfaces and convex hammers are used on flat or slightly concave surfaces. Figure 15: Curving Figure 14: Planishing For Training Purposes Only Issue: August 2014 Page 531 of 926 Modul 7 Material Handling PART 66 – Basic Training Cat B1 – Module 7 Contracting Flanging Refer to Figure 16. Refer to Figure 17. During contracting, specific parts of the workpiece are shortened by concerted upsetting of the workpiece. Contracting is the contrary to curving, and is used for: Flanging means the upright setting of narrow rims on sheet parts. Curved rims are produced by curving inside and by contracting outside. rounding of sheet metal sections, sometimes used in connection with curving reducing pipe diameters. Curving is performed on a plane, square steel shim and is executed with the pane of a fitter’s hammer. While contracting a rim it is bent with a wooden mallet over the bordering tool, over a round steel or over a bordering disk with counter disk. Figure 16: Contracting For Training Purposes Only Issue: August 2014 Page 532 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Material Handling Beading Refer to Figure 18. The bead is the simplest way to achieve a stiffening rim at sheet plates. Beads serve to avoid sharp - edged sheet plate rims. They are divided in: simple bead double bead hollow bead roller bead. During beading, the rim of the sheet plate is bent by approximately 180o. The finished bead must form a small hollow space. Beading is performed in 2 working steps: Prebending with a beading tool Finishing the bead on a steel plate. Edging Refer to Figure 19. Edging of sheet metal can be performed over every sharp edge. A minimum bending radius should always be observed to avoid bending fractures. The minimum bending radius depends on the sheet metal thickness. Note: Raising, sinking and crimping on sheet metal are not used in aircraft manufactur-ing or aircraft repairing. Figure 17: Flanging For Training Purposes Only Issue: August 2014 Page 533 of 926 Modul 7 Material Handling Figure 19: Edging and Bulbs Figure 18: Beads For Training Purposes Only PART 66 – Basic Training Cat B1 – Module 7 Issue: August 2014 Page 534 of 926 Modul 7 Material Handling 7.14.2 Application and Repair of Composite Materials 7.14.2.1 Minor Repair with Adhesive PART 66 – Basic Training Cat B1 – Module 7 If possible the repair is to be carried out in a dust - free room at a temperature of 18 oC to 23 oC (64 oF to 73 oF) and a relative humidity of 75 %. The required materials are to be prepared in accordance with the component repair instruction. Damage Classification Contour Molds In cases of damaged plastic, fibre or fibreglass an investigation of the damage must be carried out to classify the damage. This is necessary for the selection of the correct repair procedure. This classification has to be carried out according to the equipment/manufacturers’ procedures to assess the extent of the damage and its effect on the airworthiness of the aircraft. Extensive damage on shaped components often requires a mold to maintain the contour of the component under repair. Molds can be made from steel, aluminium, wood, plaster or fibre reinforced plastic, depending on the extent of the damage and the heating system used. Parting compound must be applied to the mold before applying laminations. Minor Repairs Preparing the Damaged Area for Repair Minor repairs on composite, plastic parts are to prevent entering of water or humidity through the damaged surface, as humidity or water between laminates will impair the quality of the repair. The damaged area is to be cut out in circular or oval shapes up to the edge of the damage. This includes the outer layer and the core layer. When cutting out a damaged area, care must be taken to avoid delamination of the undamaged layers. It must be ensured that the full extent of the damage is removed and no further delaminations are evident. Note: In case of minor repairs on plastic, fibre and fibreglass only the skin should be restored. The lamination under repair must be ground extremely flat to form a chamfered butt joint. The uniformity of the chamfer will be indicated by the individual layers of the lamination which show up like contour lines on a map. Application of ’Wet Lay - Up’ Materials 7.14.2.2 Introduction The hand –laminating process consists of applying ’wet’ layers of mat impregnated with resin. A mold can be used if necessary to maintain the contour of the component. The choice of resin will dictate whether the curing process is to be carried out without pressure, under vacuum or under pressure. For Training Purposes Only The safety precautions are to be obeyed when working with resin and hardener. The repair mats are to be laid out according to the layers and quantity required for the component under repair and the direction of the fibres. A technique suitable for hand lamination is as follows: Issue: August 2014 Page 535 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Material Handling Firstly a large piece of mat is laid out on a sheet of foil and impregnated using a paint roller or brush. The degree of impregnation can be determined from the fibres (fibres which have a dull shine have too little resin; too much resin is indicated when the structure of the mat weave can no longer be recognised). A second sheet of foil is then laid over the mat and the excess resin and all air bubbles squeezed out to the sides using a wooden spatula or a rubber roller. The repair blanks are now cut to shape between the two sheets of foil where they remain until they are needed. 7.14.2.3 Standard Composite Repair by Hot Curing Procedure: Lay the vacuum heater blanket over the repair. Press sealing lips down by hand around the blanket so that the blanket fits closely. Connect suction hose to blanket and start vacuum pump. Connect temperature sensors and heater element. Set temperature control to the required curing temperature and adjust with temperature sensors. Different thicknesses produce temperature differences, i.e. thinner laminations heat up more quickly than thicker ones. Refer to Figure 1. General Remarks Larger repairs require an even application of pressure to improve the contour and to avoid bubbles, creases etc. If the geometry of the component permits, the pressure can be applied using a vacuum procedure, otherwise a pressure device (e.g. tensioned rubber cords) must be used. Vacuum Procedure for a Damaged Area After sticking a suction foil to the repaired area, the air is removed from between the foil and the component using a suction pump. The foil must press onto the component with no creases. If heat is to be applied at the same time as the vacuum, it is recommended that a combined vacuum/heater blanket is used. Note: A higher curing temperature may be required when using heat curing resins in a wet application process or when using prepregs. For Training Purposes Only Applying a Vacuum Heater Blanket Switch off heater element at the end of curing time and allow the repair to cool under vacuum. Disconnect temperature sensors after the repair has cooled. Switch off vacuum pump and disconnect suction hose. Remove vacuum heater blanket. Electrostatic charges can build up on the repair during the curing process. For this reason do not disconnect the heater element until the blanket has been removed from the repair. Disconnect heater element cable. General Procedure for Curing a Repair Using the Vacuum bag Method The general routine is to cover the repair with layers of ’peel ply’ and ’bagging’ material. Then a vacuum is formed over the repair by using the sealing strip. The vacuum is made large enough so that the vacuum connector will not directly overlay the repair. Issue: August 2014 Page 536 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Material Handling A layer of bleed material is put into the vacuum layer, and the whole repair area is covered by a ’bagging’. A vacuum is applied slowly to the area via a line attached to the connector on the bag. 7.14.2.4 Repair of Plastic, Fibre and Materials in Sandwich Structures Fibreglass Replacement of Damaged Honeycomb Structures Once full vacuum is reached, the repair is checked for correct fit and the ’bleed’ fabric for creases, which would cause defects in the repair. The constant vacuum remains applied throughout the cure. Temperature sensors are fitted at the connector point to monitor the repair temperature. Refer to Figure 2. Procedure: Remove damaged laminate to gain access to the honeycomb. Note: When honeycomb is removed from one side only, ensure that the lower laminate does not become damaged. Cut out and remove damaged honeycomb. Prepare epoxy resin and thickening agent and fill in damaged honeycomb structure. Note: In case of repair with honeycomb structure, always select a smaller structure honeycomb than that found in the component which is to be repaired. Cut and fit new honeycomb, bond new honeycomb into position with epoxy resin. Repair surface laminate as described in the appropriate manual. Note: The normal procedure after damage removal is to fill out the damaged structure using a Nomex patch or microballoons. Then the surface repair is continued as normal. Figure 1: Composite Repair Vacuum Bagging For Training Purposes Only Issue: August 2014 Page 537 of 926 Modul 7 Material Handling PART 66 – Basic Training Cat B1 – Module 7 Figure 2: Repair of Honeycomb (Example) For Training Purposes Only Issue: August 2014 Page 538 of 926 Modul 7 Welding, Brazing, Soldering and Bonding 7.15 Bonding Welding, Brazing, 7.15.1 Soldering 7.15.1.1 Principles of Soldering Soldering PART 66 – Basic Training Cat B1 – Module 7 and The term ’welding’ refers to the process of joining metals by heating them to their melting temperature and causing the molten metal to flow together. Introduction Soldering is the joining of two or more metal components by using a solder. This solder might be another metal or an alloy. It must have a lower melting point compared to the parts which have to be joined. The molten solder is flowing between the warmed - up but solid metals. Soldered joints are non - detachable joints. Working Temperature Refer to Figure 1. Figure 1: Reaction of Solder According to Different Temperature Ranges For Training Purposes Only Issue: August 2014 Page 539 of 926 Modul 7 Welding, Brazing, Soldering and Bonding Before bonding the material, workpieces and solder must be heated up to the working temperature. The working temperature is reached, if the solder moistens, i.e. it is accepted by the material flows, i.e. it is spreaded over the material bonds, i.e. it forms an undetachable joint with the material. PART 66 – Basic Training Cat B1 – Module 7 Combustion heat is produced by burning solid combustibles like charcoal and solid spirit or by burning liquid combustibles like gasoline, spirit or crude petroleum or gases like propane, acetylene and coal - gas. Electric heat might be produced by resistors or induction with high frequency devices. Refer to Figures 2 and 3. Material and solder must have reached this working temperature to guarantee a correct soldering event. The working temperature is always above the melting temperature of the solder. Moistening and flowing of solder often is a very fast event taking place at the same time. If the temperature of the material is below the working temperature, flowing of solder is not guaranteed, although the solder is liquefied. The material will be not or only insufficiently moistened by the solder. The source of heat which is responsible for the production of the required soldering heat has to correspond to the working temperature of the type of soldering. In addition, the source of heat has to be adapted to the amount of soldering, the dimensions of the workpiece, the elimination of heat. If the temperature of the material is above the working temperature, flux and solder will become unsuitable. Oxidation and dissolution of solder prevent perfect soldering. As a result of low working temperatures, the various types of sources of heat used for soft soldering, might be applied directly or indirectly by heat accumulators, like soldering iron or splashing. Observing the correct working temperature depends on the compound of the solder and structure of the materials to be soldered. As a result of higher working temperatures during brazing, only a few sources of heat, like flame, furnace and high frequency devices with sufficient heat amount are suitable. Soldering Heat Soldering heat which is necessary to reach the working temperature and solder might be produced in the form of combustion heat electric heat. For Training Purposes Only The productivity of the source of heat must be such that the event of soldering will take place in a sufficiently short time. In the case of too low heat transport and a respective long heating time, the fluxing agent will become unsuitable because of the deficiency of oxidation protection. Issue: August 2014 Page 540 of 926 Modul 7 Welding, Brazing, Soldering and Bonding PART 66 – Basic Training Cat B1 – Module 7 In case of excessive heat application a local overheating may take place. To avoid local overheating, the flame of the torch has to be adjusted smoothly by moving the torch to achieve an equal warming - up of the surface to be soldered. Note: Normally the produced heat is applied to the workpiece, while fluxing agent and solder receive the required heat to reach the working temperature from the workpiece. Figure 2: Melting Temperatures of Materials and Solders, Examples of Heating Sources For Training Purposes Only Issue: August 2014 Page 541 of 926 Modul 7 Welding, Brazing, Soldering and Bonding PART 66 – Basic Training Cat B1 – Module 7 If the slit between the two surfaces to be soldered is small enough, the solder is sucked yeastily into the slit after having reached the working temperature. The narrower the slit, the deeper the solder is soaked up. Even if the slit is arranged vertically the solder climbs up despite the force of gravity. The suction effect depends on the width of the soldering joint, but at a width above 0.25 mm and more this effect ceases. The characteristic of solder flowing and its penetration depth is influenced by the type of solder and the fluxing agent. For every type of solder a minimum width of slit exists. Actual widths may not go beyond these limits. From this results, that size and width of the soldering slit have to be coordinated with the type of solder. An exception is pure copper filler metal which penetrates even driving fits. Figure 3: Comparison of Local Heat Distribution between Soldering and Welding In soldering slits the fluxing agent opposes a certain resistance to the flowing solder. Particularly on two - dimension soldering this event may lead to fluxing agent occlusions. At the margins the fluxing agent can proceed better, compared to the center of the soldering joint. Therefore the solder flows more easily at the margins and surrounds the fluxing agents which now cannot be edged out. Capillar Soldered Joint Refer to Figures 4 and 5. The suction ability of a soldered joint depends on the moistening and flowing event of the solder, as well as on the capillary effect of the soldering slit. For Training Purposes Only To avoid these occlusions which weaken the solidity of the joint, solder, heat application and size of the workpieces have to be conformed to the solder and fluxing agent. Issue: August 2014 Page 542 of 926 Modul 7 Welding, Brazing, Soldering and Bonding Figure 4: Capillar Soldering Joint For Training Purposes Only PART 66 – Basic Training Cat B1 – Module 7 Figure 5: Driving Fit Soldering and Soldering Occlusion Basic Work Rules for Soldering Issue: August 2014 Page 543 of 926 Modul 7 Welding, Brazing, Soldering and Bonding The lowest melting point of one of the materials which have to be soldered is important for the choice of the solder which has to be applied. The soldered seam has to be purified carefully before soldering Before soldering all components have to be fitted closely together. All members have to be warmed up to working temperature before soldering. After soldering all residues of the fluxing agent have to be removed carefully. The maximum soldering temperature must not be exceeded. PART 66 – Basic Training Cat B1 – Module 7 Chemical Agents Chemical agents used for fluxing agents and cleaning solvents are: acids – hydrochloric acid – sulphuric acid – dilute nitric – acid mixtures solvents – benzene – soda solution – trichlorethylen. Cleaning of Soldering Joints Before soldering, all parts have to be cleaned to a pure metallic condition. Cleaning of the soldering joint mechanical cleaning with tools chemical cleaning with acids or solvents may be necessary before and/or after soldering. The selection of the cleaning material depends on size and dimension of workpiece type of material type of fluxing agent. After soldering most of the cleaning and fluxing agents have to be washed off, to avoid corrosion by disacidification of acids and alkaline solutions. For Training Purposes Only Issue: August 2014 Page 544 of 926 Modul 7 Welding, Brazing, Soldering and Bonding 7.15.1.2 PART 66 – Basic Training Cat B1 – Module 7 Silver Soldering (Hard Soldering) Types of Soldering Iron Soldering Refer Figure 6. The solder, normally a tin - lead alloy, is liquefied at temperatures between 210 oC and 450 oC and applied to the purified junction point. The soldering iron can be heated up by electricity or gas. It is useful to apply a soldering paste or other soldering fluxes. "Hard soldering" or "silver soldering" is used to join precious and semi-precious metals such as gold, silver, brass, and copper. The solder is usually referred to as easy, medium, or hard. This refers to its melting temperature, not the strength of the joint. Extra-easy solder contains 56% silver and has a melting point of 618°C. Extra-hard solder has 80% silver and melts at 740 °C. If multiple joints are needed, then the jeweler will start with hard or extra-hard solder and switch to lower temperature solders for later joints. The joining of electronic parts needs acid free soldering fluxes. Silver solder is absorbed by the surrounding metal, resulting in a joint that is actually stronger than the metal being joined. The metal being joined must be perfectly flush, as silver solder cannot normally be used as a filler and any gaps will remain. Another difference between brazing and soldering is how the solder is applied. In brazing, one generally uses rods that are touched to the joint while being heated. With silver soldering, small pieces of solder wire are placed onto the metal prior to heating. A flux, often made of boric acid and denatured alcohol, is used to keep the metal and solder clean and to prevent the solder from moving before it melts. When silver solder melts, it tends to flow towards the area of greatest heat. Jewelers can somewhat control the direction the solder moves by leading it with a torch; it will even run straight up along a seam. Figure 6: Electric Soldering Iron For Training Purposes Only Issue: August 2014 Page 545 of 926 Modul 7 Welding, Brazing, Soldering and Bonding Torch Soldering Refer to Figur 7. Torch soldering utilises a fuel gas flame as the heat source in the soldering process. The fuel gas is mixed with either air or oxygen to produce the flame, which is applied to the materials to be soldered until the assembly reaches the proper soldering temperature. Solder filler metal, which melts at temperatures below 1450o C (Steel material) or 840o C (Bronze base alloy), is added to the assembly to bond it. Successful torch soldering is accomplished when parts are clean and fit together closely, and when oxides are not excessive. PART 66 – Basic Training Cat B1 – Module 7 The selection of a gas torch is controlled by the size, mass, and configuration of the assembly to be soldered. When fast soldering is necessary, a flame is frequently used. The flame temperature is controlled by the fuel mixture used. Fuel gas burned with oxygen gives the highest flame temperature possible with that gas. The highest flame temperatures are attained with acetylene. Lower temperatures are obtained with propane, butane, natural gas, and manufactured gas. Multiple flame tip, or burners, often have shapes that are suitable to the work. They can be designed. From this it follows, that three methods of soldering can be distinguished: punctual soldering surface soldering progressive soldering. Refer to Figure 8. The table depicted in Figure 8 shows a comparison of the major characteristic features in respect of soldering joint source of heat event of soldering solder feed application. Figure 7: Torch Soldering For Training Purposes Only Issue: August 2014 Page 546 of 926 Modul 7 Welding, Brazing, Soldering and Bonding 7.15.1.3 PART 66 – Basic Training Cat B1 – Module 7 Fluxing Agents and Solder Materials Fluxing Agents Refer Figure 9, 10 and 11 Fluxing agents are non - metallic materials, which remove oxide layers from soldering surfaces or avoid new oxidation of the respective parts, during the warming - up period. Their melting temperature has to be lower than the melting temperature of the solder, because of the preparation of the soldering joint when the solder is melting. Working temperature and fluxing agent have to be coordinated such that the effective temperature will neither fall below nor exceed the appropriate temperature. Fluxing agents and protective gases make the moistening of soldering surfaces possible during the effective temperature range. Fluxing agents are available in the form of paste powder liquid mixtures hard solder with fluxing agent core fluxing agent filling in pipe soft solder. Figure 8: Characteristics of Different Soldering Methods For Training Purposes Only Issue: August 2014 Page 547 of 926 Modul 7 Welding, Brazing, Soldering and Bonding Solder Materials Solder materials are alloys, rarely pure metals in the form of wire sheet metal rods chips grain powder paste. Special Soft Solders Special soft solders contain indium and bismuth, some of these solders have working temperatures below 38°C. The application of these types of solder needs no fluxing agents (they are self - flowing). They are sticking to glass and ceramics. Active Solders the melting range, which is the temperature range from the beginning of melting until the total liquefaction, from the solidus to the liquidus temperature the working temperature, which is the lowest temperature at the soldering joint, when the solder is spread over the soldering surface and connects with the basic material to be soldered the highest permissible soldering temperature, which is at least 50oC below the melting point of the basic metal. Soft Solders Soft solders predominantly consist of heavy metals with low melting points, like: bismuth, and the eutectic lead - tin alloys (tin - solder) with liquidus temperatures up to approx. 300oC. The operating range is determined by PART 66 – Basic Training Cat B1 – Module 7 Active solders enable joints between ceramic materials and metal as well as soldering joints of graphite, diamond, glass and material which is difficult to moisten. Solder and fluxing agents may be used as solder paint solder paste wire combination, like flux - cored solder, covered wires. Protective gases protect material and solder from oxidation. They also reduce the build - up of oxide layers on material and solder before reaching working temperature. lead tin zinc cadmium antimony For Training Purposes Only Issue: August 2014 Page 548 of 926 Modul 7 Welding, Brazing, Soldering and Bonding PART 66 – Basic Training Cat B1 – Module 7 Figure 11: Solder Paint (Example) Figure 9: Rosin used as Flux for Soldering (Example) Figure 10: Electrical Solder with a Core For Training Purposes Only Issue: August 2014 Page 549 of 926 Modul 7 Welding, Brazing, Soldering and Bonding 7.15.2 PART 66 – Basic Training Cat B1 – Module 7 Alternating current, sometimes applied in shielded metal arc welding, is provided by a transformer. The components to be welded are earthed. The ground is connected to the negative terminal of the generator. Shielded Metal Arc Welding Introduction Shielded metal arc welding (SMAW), also known as manual metal arc (MMA) welding (or, informally; as ’stick welding’), is a manual arc welding process that uses a consumable electrode coated in flux to lay the weld. An electric current, in the form of either alternating current or direct current from a welding power supply, is used to form an electric arc between the electrode and the metals to be joined. As the weld is laid, the flux coating of the electrode disintegrates, giving off vapors that serve as a shielding gas and providing a layer of slag, both of which protect the weld area from atmospheric contamination. Thus, when the tip of the electrode is placed against the work, a flow of current is established. The arc is then ’struck’ by lifting the end of the electrode slightly from the metal. This ’short circuit’ creates resistance across the arc and causes the temperature to rise up to many thousands of degrees Celsius, in some cases up to 6,000oC. Usually, the temperature is approx. 3,300oC. Both, the base metal in the components to be welded and the filler metal, combine and form the welding bead. Because of the versatility of the process and the simplicity of its equipment and operation, shielded metal arc welding is one of the world’s most popular welding processes. It dominates other welding processes in the maintenance and repair industry, and though flux – cored arc welding is growing in popularity, SMAW continues to be used extensively in the construction of steel structures and in industrial fabrication. The process is used primarily to weld iron and steels (including stainless steel) but aluminum, nickel and copper alloys can also be welded with this method. 7.15.2.1 Principle of SMAW Refer to Figure 1. The principle of shielded metal arc welding is quite simple. An electric circuit is established, connecting the electrode to a motor generator which provides direct current. For Training Purposes Only Issue: August 2014 Page 550 of 926 Modul 7 Welding, Brazing, Soldering and Bonding PART 66 – Basic Training Cat B1 – Module 7 Figure 1: Shielded Metal Arc Welding Principle For Training Purposes Only Issue: August 2014 Page 551 of 926 Modul 7 Welding, Brazing, Soldering and Bonding If a bare electrode is used, the weld is exposed to the air surrounding it. Oxygen in the air may convert elements of the base metal into oxides which form on the top of the weld as slag; nitrogen in the air makes the weld brittle. Therefore most arc welding is shielded from the air. In hand welding, the electrode is covered by a flux, which when heated, surrounds the weld with a protective veil of gas. 7.15.2.2 Many companies have developed automatic welding machines which operate on the electric arc principle. A machine moves along a long joint automatically and feeds a bare wire electrode, mounted on a reel, into the work. The weld is shielded from the air by a granular substance (flux or melt) which flows over the weld. This completely shields it from the air. When this machine is in use, no sparks or splutter, usually associated with shielded metal arc welding, can be seen. The granular substance is swept up by hand (or picked up by a vacuum device) and reused. Some of the melt fuses on top of the welding bead, but is easily knocked off, exposing a smooth reliable weld. SMAW Equipment Refer to Figure 2. A complete shielded metal arc welding set consists of the following: A carbon electrode is usually used for joining cast iron. Since the electrode does not provide a filler metal, a rod of metal is held in the arc and melts into the weld. Carbon is absorbed by the cast iron during this process increasing the tensile strength of the iron. PART 66 – Basic Training Cat B1 – Module 7 welding machine – AC power supply – DC rectifier – DC rotary transformer electrode holde electrode electric cable ground cable ground clamp connection to mains supply. Machine welding can be used to best advantage on long flat plating like deck seams. Where shell plating is assembled in panels of the ways, shell seams can be, and usually are, machine –welded. The difference between machine and hand welds is easily seen, the hand weld being very rough in appearance. For Training Purposes Only Issue: August 2014 Page 552 of 926 Modul 7 Welding, Brazing, Soldering and Bonding PART 66 – Basic Training Cat B1 – Module 7 Figure 2: Arc Welding Equipment For Training Purposes Only Issue: August 2014 Page 553 of 926 Modul 7 Welding, Brazing, Soldering and Bonding PART 66 – Basic Training Cat B1 – Module 7 Types of SMAW Machines A shielded metal arc welding machine may be an AC (alternating current) or DC (direct current) machine. Combinations (AC/DC machines) are also available. The AC or AC/DC machine is generally a power transformer that alters the incoming 220 V - 440 V to a low voltage, high amperage current for welding. The DC machine is usually motor - driven. Both types of machines are rated by maximum output in amperes. The higher the output, the heavier the welding the machine will perform. Polarity Refer to Figure 3. Two common terms used in DC shielded metal arc welding are ’straight polarity’ and ’reverse polarity’. Reverse polarity means that the current is travelling from the work, up through the arc to the electrode and electrode holder. Straight polarity means that the current travels from the electrode holder (often called a ’stinger’) through the electrode, across the arc, to the work. For a straight polarity hookup, the electrode holder cable, unless a polarity switch is used, is plugged into the hole marked with the straight (negative) symbol (–). For a reverse polarity hookup, the electrode holder cable is plugged into the crossed (positive) symbol (+). Polarity is not a factor in AC welding as the current is constantly reversing itself (50 times per second). For Training Purposes Only Issue: August 2014 Page 554 of 926 Modul 7 Welding, Brazing, Soldering and Bonding PART 66 – Basic Training Cat B1 – Module 7 Figure 3: Current Travel with Straight and with Reverse Polarity For Training Purposes Only Issue: August 2014 Page 555 of 926 Modul 7 Welding, Brazing, Soldering and Bonding PART 66 – Basic Training Cat B1 – Module 7 Electrodes and Electrode Coating The electrode has a metal core whose composition is usually similar to the workpiece. The coating surrounding the core varies depending on the workpieces to be joined by welding. Functions of Electrode Coating Refer to Figure 4. The main functions of electrode coating are as follows: to act as a flux protecting the surfaces being welded from impurities to form a slag over the weld, which does the following: – protecting the molten metal from contact with the air – slowing down the cooling rate of the weld, thus helping to prevent brittleness of the weld – providing a smoother surface by preventing ripples caused during the welding process to form a neutral gas atmosphere, which helps to protect the molten weld pool from oxygen and nitrogen in the surrounding air to help to stabilise the arc, allowing AC to be used to add certain constituents to the weld by replacing any lost during the welding process, if necessary to speed up the welding process by increasing the speed of the metal and the electrode, if necessary. Figure 4: Effects of Electrode Coating For Training Purposes Only Issue: August 2014 Page 556 of 926 Modul 7 Welding, Brazing, Soldering and Bonding PART 66 – Basic Training Cat B1 – Module 7 Technical Data Standard The standard of electrodes for shielded metal arc welding is laid down in e.g. DIN 1913 (DIN stands for ’German Engineering Standards’) and other standards. Standards like DIN and ISO (International Standardization Organization) help to identify standardised products. Diameter The common diameters of electrodes are 2, 2.5, 3.25, 4, 5, 6 and 8 mm. Length The lengths of the electrodes are from 200 mm up to 450 mm, depending on their diameter. Marking (Specification) of Electrodes Refer to Figure 5. Generally, the marking of electrodes by the manufacturer is positioned on the coating close to the upper end (clamp end) with stamped letters and written on the outside of the package. The identification by the DIN - code informs about the type and the characteristics of the electrode. The key to the DIN - code is illustrated in Figure 5, which shows an excerpt of possible markings of electrodes. For Training Purposes Only Issue: August 2014 Figure 5: Marking of Electrodes (DIN) Page 557 of 926 Modul 7 Welding, Brazing, Soldering and Bonding PART 66 – Basic Training Cat B1 – Module 7 Refer to Figure 6. Electrodes must be handled with care in order not to break the coating. Electrodes with broken coating should not be used as the weld deposit will not be evenly protected by gases as the coating burns away. Storage of Electrodes To avoid damages, electrodes should be stored in sealed packages in a dry, well ventilated store. Moisture in the electrode coating causes holes (porosity) in the weld and/or cracking in the parent metal close to the weld. Where electrodes cannot be stored in ideal conditions, a moisture absorbent material, such as silica gel, should be placed inside each electrode container. Where low hydrogen electrodes are used it is normal practice for them to be baked for a predetermined period before they are issued to the welder. This is to ensure that as much moisture as possible is removed. Low hydrogen electrodes may be issued to welders in quivers to protect them from damage and to keep them dry. Working Place Figure 6: Marking of Electrodes (BS) Refer to Figure 7. Another example is given in Figure 6 representing the identification as of the British standard (BS). It can be seen that the coding according to BS is similar to the coding according to DIN. For Training Purposes Only The operating position (working place) for shielded metal arc welding indoors is featured in Figure 7. Issue: August 2014 Page 558 of 926 Modul 7 Welding, Brazing, Soldering and Bonding 7.15.2.3 PART 66 – Basic Training Cat B1 – Module 7 Workshop Safety Introduction It is most essential that the welder should ensure that he is personally adequately protected during shielded metal arc welding operations. The danger to unprotected skin cannot be over - emphasised. This danger is present in two forms: from the arc rays on the one hand from molten metal in the form of spatter on the other hand. To ensure that the operator suffers no injury the skin must be covered completely. Particular attention must be paid in this respect to eyes, hands, face, arms and neck. Furthermore it is of utmost importance that the operator strictly observes the general safety precautions. Protective Clothing Normal Dress Refer to Figure 8. Outer clothing should be free from oil, grease or flammable substances. The forearms should be protected from exposure to arc rays; sleeves should not be rolled up. Cuffs on overalls, turn - ups on trousers, exposed long hair and low – cut shoes are likely lodging places for sparks or globules of hot metal and slag. Figure 7: Arc Welding Working Place For Training Purposes Only Issue: August 2014 Page 559 of 926 Modul 7 Welding, Brazing, Soldering and Bonding PART 66 – Basic Training Cat B1 – Module 7 Face Shields For most operations a face shield made of lightweight, insulating and non - reflecting material can be used (detail b)). It must have an approved ’filter glass’. Goggles alone do not give adequate protection for shielded metal arc welding and cutting operations. The screen is of a size and shape to shield face, throat, wrist, and hand. Where it is necessary to protect the head or to have both hands free, a helmet type screen fitted with an approved filter should be used. The shields are made of fire proof material and fitted with dark glass, protected by clear glass. No metal fittings should be incorporated in their designs because of the risk of electric shocks. Gloves or Mitts Suitable leather gloves to protect wrists and hands and industrial (leather) boots have to be worn. The gauntlet type should have a covering of at least 150 mm to 200 mm to protect wrist and arm. Arm Protectors Arm protectors are made of chrome leather and designed to protect the arm from wrist to shoulder. Aprons Figure 8: Protective Clothing and Face Shield For Training Purposes Only The front of the body from throat to knees is to be protected by a suitable leather cape and an apron. If only an apron is worn this must provide full protection. Issue: August 2014 Page 560 of 926 Modul 7 Welding, Brazing, Soldering and Bonding Aprons are made of chrome leather, either split or full at the front. The split type gives more space of action during welding in a confined space. Special Protective Clothing The following protective clothing is rather of a special nature and is usually only worn when carrying out vertical and overhead welding: capes, made of chrome leather and designed to protect the shoulders skull caps, made from chrome leather and designed to protect the top of the head spats, usually made from leather and designed to protect the top of the foot by ensuring that hot metal does not enter the boot. 7.15.2.4 General Safety Precautions PART 66 – Basic Training Cat B1 – Module 7 Hold the electrode holder with just sufficient grip to give control - tight gripping will cause muscle fatigue. Position yourself to avoid stretching and the risk of overbalancing. Support the arm holding the electrode holder by keeping it near the body. Check that portable screens are in position. Warn unscreened observers before the arc is struck. Ensure that the face shield is in front of the eyes before striking the arc; keep it there until the arc is broken. Place the electrode holder in a safe place when not in use. Use goggles when chipping off hot slag. Ensure that all slag and spatter is removed from fusion faces and previously deposited material before starting the next run. Switch off the power source when not in use. Switch off the mains supply to the power source at the end of the work period. Leave the work area in a tidy and orderly manner and ensure that the equipment is properly stowed. Always: Refer to Figure 9. Comply with the prescribed safety precautions and fire prevention procedure. Check that the return and earth leads are firmly connected to the bench or workpiece and to the power source. Check that the welding lead is connected to the power source and that the connection to the electrode holder is tight and sound. Check that the power source is switched on Use effective protective equipment and wear the necessary protective clothing. Concentrate on watching the welding operation. Have full control of the movements of the electrode and hold it steady. For Training Purposes Only The power supply for shielded metal arc welding may be either AC or DC. The voltages used are in the order of up to 100 V and the currents of up to 600 A. It is therefore essential that the adequate precautions are observed to protect both, the operator and other personnel in the area, from the risks associated with electricity. The following rules should be observed when using shielded metal arc welding equipment: Issue: August 2014 Make sure that the welding circuit is correctly earthed. The welding cables should be adequately insulated. Never use damaged cables (detail a)). Page 561 of 926 Modul 7 Welding, Brazing, Soldering and Bonding PART 66 – Basic Training Cat B1 – Module 7 Ensure that the welding cables are free from kinks and that they do not become crushed or pinched under heavy loads (detail b)). Check that the power source is disconnected from the supply before attaching the cables to the terminals. Always use a fully insulated electrode holder when welding in confined spaces, or where it is difficult to get access to the weld without touching the surrounding metal (detail c)). avoid electric shock, adhere to the following rules Turn off machines when they are not in use. Wear gloves when handling equipment. Keep all equipment dry. Do not stand in water when welding as water is an excellent conductor of electricity. Be careful of dampness of any kind. Even perspiration inside gloves on a very hot day can cause electric shock. Figure 9: Safety in Arc Welding For Training Purposes Only Issue: August 2014 Page 562 of 926 Modul 7 Welding, Brazing, Soldering and Bonding 7.15.2.5 PART 66 – Basic Training Cat B1 – Module 7 SMAW Procedures and Techniques Welding Arc, Striking, Operating and Breaking Refer to Figure 10. Before the current is switched on an electrode is placed in the holder. When the current is switched on the electrode end is placed in firm contact with the workpiece. Now the current flows through the circuit. This flow is interrupted when breaking the contact with the workpiece. When the gap is narrow, and if the open - circuit voltage of the power source is high enough, the current leaps across the gap and creates an electric arc. When the arc is struck, the voltage falls to what is known as the arc voltage. The arc voltage is between 20 V and 25 V for most types of electrodes at normal arc length. When the arc is made, the end of the electrode and the local area of the workpiece rapidly reach fusion temperature. The electrode core wire melts. The molten metal is transferred across the arc gap to fuse with the workpiece. Figure 10: Welding Techniques For Training Purposes Only Issue: August 2014 Page 563 of 926 Modul 7 Welding, Brazing, Soldering and Bonding Striking an Arc Refer to Figure 11. The end of the electrode is struck against the workpiece with a short, scratching motion. When the arc is forming, the electrode is pulled away to the recommended distance. PART 66 – Basic Training Cat B1 – Module 7 1. Ensure that the electrical contact between plate and bench is good. The plate should be in a flat position. 2. Insert the grip end of the electrode in the electrode holder only when wearing gloves. 3. Point the electrode downwards, and away from the body at an angle of 65° -75° to the plate surface (detail a)). 4. Lower the electrode holder until the electrode striking end is approx. 25 mm away from the plate at the point where welding is to start. 5. With the welding screen in position, lower the electrode until the striking end touches the plate (perform a movement similar to that of gently striking a match). 6. Contact of the electrode end with the plate closes the electrical circuit and current begins to flow. Immediately withdraw the electrode a slight distance off the plate to establish the welding arc (detail b)). Note: Difficulty is often experienced in making the arc. The electrode end may be withdrawn too far or allowed to fuse to the plate, because it is not withdrawn quickly enough. If fusing occurs the electrode holder must be given a sharp twist to wrench the electrode free. The welding screen is to be kept in front of the eyes. Figure 11: Striking an Arc If the electrode is not freed, the electrode holder jaws should be opened immediately and the holder taken away from the electrode (or the welding current switched off). The electrode is to be removed with a chisel. Refer to Figure 12. The six main steps of striking an arc are as follows: For Training Purposes Only Issue: August 2014 Page 564 of 926 Modul 7 Welding, Brazing, Soldering and Bonding PART 66 – Basic Training Cat B1 – Module 7 Operating Procedures Refer to Figure 13. Figure 12: Arc Welding Striking For Training Purposes Only Figure 13: Arc Welding Procedure Issue: August 2014 Page 565 of 926 Modul 7 Welding, Brazing, Soldering and Bonding PART 66 – Basic Training Cat B1 – Module 7 The correct way of guiding the electrode while surfacing is shown in Figure 13. To start surfacing strike the tip of the electrode in a distance of approx. 15 mm from the beginning of the weld. Refer to Figure 14. When the base metal puddles (melts), move the electrode slowly forward. Some electrodes may be held steady while others require a whipping motion. When whipping, move the electrode out of the molten puddle until the puddle starts to freeze (i.e. it solidifies – it turns from a shiny wet look to a dull sheen) then immediately move it part way back into the puddle. When the puddle is fluid again, hold the electrode in place for a split second, then whip it out again. Repeat this process. Viewed from the top, the whipping process can either form a straight line or a C shape, depending on the need. Whipping is handy in controlling burn –through in thin metal, or when working with wide gaps. The electrode should be held at right angles to the work with the top of the electrode tilted 5° – 15° towards the direction of travel. Whipping should be done by flexing the wrist. The whipping motion produces a series of circular ridges along the top of the weld. It will be difficult, for a while, to maintain the correct arc length. Continued practice will enable you to develop skill. Always use recommended machine settings. Occasionally a weaving motion will be required. This will help to bridge wider gaps and will deposit weld metal over a wider surface. Figure 14: Electrode Manipulation For Training Purposes Only Issue: August 2014 Page 566 of 926 Modul 7 Welding, Brazing, Soldering and Bonding Weld Pool and Slag PART 66 – Basic Training Cat B1 – Module 7 Note: When welding the workpiece, the weld pool should not be covered with slag. Refer to Figure 15. After welding the welded joint has to be covered with slag to prevent blisters inside the joint. Adjustment of the Correct Welding Current Refer to Figure 16. When the operating current for welding has been adjusted correctly, the penetration depth (d) is approximately half the height (thickness, h) of the joint. The formula is: 𝑑= ℎ 2 The weld thus formed has good penetration and can easily be controlled. The arc then has a steady crackling sound. Figure 15: Weld Pool and Slag For Training Purposes Only Issue: August 2014 Page 567 of 926 Modul 7 Welding, Brazing, Soldering and Bonding PART 66 – Basic Training Cat B1 – Module 7 Breaking the Arc Refer to Figure 17. The correct technique of lifting the electrode to interrupt welding is illustrated in the example in Figure 17. A simple withdrawal of the electrode end breaks the arc. For breaking the arc pause for a short moment holding the electrode in position. Then move the electrode quickly sideways and away from the plate surface. The above procedure avoids the formation of cavities blisters porosity or fine cracks in the crater which result from premature or hasty arc breaking. Figure 16: Correct Welding Current For Training Purposes Only Issue: August 2014 Page 568 of 926 Modul 7 Welding, Brazing, Soldering and Bonding PART 66 – Basic Training Cat B1 – Module 7 Fillet Welding The technique for correctly starting, interrupting and finishing fillet welding is the same as previously stated for surfacing. Flat Fillet Welding Refer to Figure 18. In flat fillet welding, tack welding is used to prevent distortion. Figure 17: Breaking the Arc For Training Purposes Only Issue: August 2014 Page 569 of 926 Modul 7 Welding, Brazing, Soldering and Bonding PART 66 – Basic Training Cat B1 – Module 7 Oblique Fillet Welding Refer to Figure 19. Oblique fillet welding also requires tack welding before fastening the workpieces together. Figure 19: Oblique Fillet Welding Figure 18: Flat Fillet Welding For Training Purposes Only Issue: August 2014 Page 570 of 926 Modul 7 Welding, Brazing, Soldering and Bonding PART 66 – Basic Training Cat B1 – Module 7 When a visual examination of a fillet welding is made, several welds might turn out to be incorrect. Examples of imperfect welds are illustrated in Figure 20. Visual Examination Refer to Figure 20. Butt Welding Refer to Figure 21. Square - butt welding is only possible when thin sheets (up to 3 mm) are available (detail a)). If the thickness of the material exceeds 3 mm a V - butt joint is performed. For this purpose the edges of the face ends must be scarfed (60°) as shown in detail b). If the thickness of the material is more than 10 mm, a double V - butt welded joint is to be used (detail c)). Figure 20: Welding Errors For Training Purposes Only Issue: August 2014 Page 571 of 926 Modul 7 Welding, Brazing, Soldering and Bonding PART 66 – Basic Training Cat B1 – Module 7 Factors Influencing Manual SMAW Refer to Figure 22. Current Too Low If the current value is too low the resulting weld has poor penetration. On account of inadequate heating a complete fusion cannot take place. The weld filler metal tends to heap up on the surface of the plate instead of fusing with it, and the arc has an unsteady sputtering sound. Figure 21: Preparation of Butt- Welded Joints For Training Purposes Only Issue: August 2014 Page 572 of 926 Modul 7 Welding, Brazing, Soldering and Bonding PART 66 – Basic Training Cat B1 – Module 7 Arc Length Refer to Figure 23. The arc length is the distance between the tip of the electrode and the surface of the weld pool. It should be approximately equal to the diameter of the wire core of the electrode being used. When the distance is correct the electrode metal is deposited in a steady stream of metal particles in the weld pool. If the arc length is reduced it becomes difficult to maintain the arc, due to the increase in welding current that takes place. As a result the electrode may become welded to the weld pool. On the other hand, if the arc length is increased, the welding current is reduced. This results in a poor weld being produced since the protective gas shield produced by the electrode and surrounding the weld pool cannot efficiently prohibit the formation of oxides, etc., in the weld. Figure 22: Changes in Welding Current For Training Purposes Only Issue: August 2014 Page 573 of 926 Modul 7 Welding, Brazing, Soldering and Bonding Figure 23: Arc Length For Training Purposes Only PART 66 – Basic Training Cat B1 – Module 7 Figure 24: Arc Speed Issue: August 2014 Page 574 of 926 Modul 7 Welding, Brazing, Soldering and Bonding PART 66 – Basic Training Cat B1 – Module 7 Speed of Travel Refer to Figure 24. A fast rate of travel results in a thin deposit of the filler metal and thus in an insufficient fusion of the filler metal with the base metal. The surface of the weld has elongated ripples and a porous crater. A travel rate which is too slow leads to a thick deposit of the filler metal and allows the slag to flood the weld pool thus making it difficult to deposit the filler metal. The surface of the weld shows coarse ripples and has a flat crater. For Training Purposes Only Issue: August 2014 Page 575 of 926 Modul 7 Welding, Brazing, Soldering and Bonding PART 66 – Basic Training Cat B1 – Module 7 7.15.3 Gas Arc Welding MAG Welding 7.15.3.1 Gas Metal Arc Welding MAG welding is a development of the MIG welding process. Instead of argon, a cheaper shielding gas is used: carbon dioxide or a made up mixture of argon, carbon dioxide and oxygen. Fundamentals Gas metal arc welding (GMAW) (sometimes referred to by its subtypes, metal inert gas (MIG) welding or metal active gas (MAG) welding) is a semi - automatic or automatic arc welding process in which a continuous and consumable wire electrode and a shielding gas are fed through a welding gun. A constant voltage, direct current power source is most commonly used with GMAW, but constant current systems, as well as alternating current, can be used. There are four primary methods of metal transfer in GMAW, called globular, short circuiting, spray and pulsed spray, each of which has distinct properties and corresponding advantages and limitations. The MAG process is particularly suitable for welding unalloyed and low alloy steel sheets, either on an industrial scale or as a manual operation. It is used in automobile repair and construction workshops because even thin sheet, for example car body panels, can be welded quickly and with little distortion. MAG welding is the most widely used gas shielded arc welding process. MIG Welding Refer to Figure 1. The arc is struck between a melting wire electrode and the workpiece. The wire electrode is fed to the welding torch through a flexible tube from a coil of wire, using a feed motor. Direct current is used for welding, supplied to the wire electrode just ahead of the welding point. The shielding gas is argon or helium. High current density at the relatively thin wire electrode gives excellent melting performance, a high welding speed and deep penetration. MIG welding is mainly used for thick sheets of high alloy steel, copper and its alloys and aluminium and its alloys. For Training Purposes Only Issue: August 2014 Page 576 of 926 Modul 7 Welding, Brazing, Soldering and Bonding PART 66 – Basic Training Cat B1 – Module 7 Figure 1: Gas Metal Arc Welding Process For Training Purposes Only Issue: August 2014 Page 577 of 926 Modul 7 Welding, Brazing, Soldering and Bonding PART 66 – Basic Training Cat B1 – Module 7 Equipment and Accessories for GMA Welding GMA Welding Plant Refer to Figure 2. The GMA welding plant consists of wire feed device shielding gas cylinder welding current source welding torch. Rectifiers are exclusively used as source of current. In GMA welding only direct current is used, and the positive pole is at the electrode. Figure 2: Equipment of GMA Welding For Training Purposes Only Issue: August 2014 Page 578 of 926 Modul 7 Welding, Brazing, Soldering and Bonding Refer to Figure 3. PART 66 – Basic Training Cat B1 – Module 7 Wire Feed Device The wire feed device enables the welding wire to be fed automatically and evenly to the welding torch. It can be located in the housing of the rectifier. This provides a compact unit, or, alternatively, a wire dispenser may be provided as an independent unit. The wire electrode is made to different diameter and quality specifications and it is wound on standard coils. The diameters are 0.6, 0.8, 1.0, 1.2, 1.6, 2.4 and 3.2 mm. The advantage compared with manual arc welding with rod electrodes is that a deposition performance of melting power is achieved, which is 3 or 4 times greater. This means the working speed is faster. For active –gas metal arc welding, special alloyed wires must be used. When selecting the additional materials, it must be noted that considerable amounts of alloying elements, such as carbon, manganese, silicon, etc., are burnt out in the intensive welding arc. Welding Torch Refer to Figure 4. Figure 3: Wire Feed Device For Training Purposes Only Issue: August 2014 Page 579 of 926 Modul 7 Welding, Brazing, Soldering and Bonding PART 66 – Basic Training Cat B1 – Module 7 The welding torch has the following tasks: guiding the wire electrode passing the welding current to the electrode through the contact tube conducting the shielding gas to the welding spot. A distinction is made between gas - cooled torches water - cooled welding torches. In the case of gas - cooled torches, the cooling is effected by the shielding gas. Gas - cooled torches are light, but are limited in their use. Water - cooled torches are suitable for greater loads, but their disadvantage is their heavier weight. Welding Techniques Basics Refer to Figure 5. There are two different types of welding arc used for GMA welding, known as ’short arc’ and ’spray arc’. The basic differences between both arcs are the heat input to the base material and the metal transfer. Figure 4: Welding Gun For Training Purposes Only Issue: August 2014 Page 580 of 926 Modul 7 Welding, Brazing, Soldering and Bonding PART 66 – Basic Training Cat B1 – Module 7 Spray Arc Spray arcs (detail a)) can be identified by an intense arc between the welding wire and the workpiece. The metal transfer is in the form of a continuous spray of melted metal droplets from the wire tip through the arc to the surface of the melted pool. The arc is almost spatter – free and provides deep penetration in the base material. The deposit rate is high, and this arc type is used for material thicknesses above 3 mm. To obtain a spray arc, it is necessary to establish the welding current above a certain minimum value called ’transition current’. This current level depends on the shielding gas, the alloy and the size of the welding wire. As a guideline, a 0.8 mm solid steel wire will provide a spray arc if the welding current is above approx. 150 A. At currents below this level, the steady spray will have gradually larger droplets which, finally, can no longer be used to obtain a spray arc. Short Arc Short - arc welding (detail b)) is also called ’short - circuit transfer’ or ’dip - arc welding’. No metal is transferred through the arc with this technique. The material is transferred through fast short circuits between wire and workpiece. The wire touches the workpiece and the welding current increases immediately, melting off a drop of filler material. As this drop is melted off, the arc is re - established, heating the wire tip and base material until the wire feed speed again pushes the wire into contact with the workpiece. This procedure repeats itself without stopping 100 times per second, providing a concentrated arc with low heat input to the workpiece and quickly solidifying metal. Figure 5: Spray—Arc and Short—Arc Welding Principles For Training Purposes Only Issue: August 2014 Page 581 of 926 Modul 7 Welding, Brazing, Soldering and Bonding The short - arc method is very good for sheet metal welding, and also for filling large spaces in misaligned joints. The quickly solidifying metal also makes short - arc welding easy in any welding position. Refer to Figure 6. The guide values for spray - arc and short - arc welding are obtainable from the diagram in Figure 6. PART 66 – Basic Training Cat B1 – Module 7 Travel Speed and Direction The speed with which the torch is moved along the weld bead decides the bead size and width, and will also determine the heat input per distance to the base material. Welding may be done with the rightward or leftward technique, depending on welding position and alloy. For steel and stainless steel, both techniques are used, often with preference for rightward welding with solid welding wire, and leftward for flux –cored wire. Refer to Figure 7. Leftward Welding The leftward welding technique (detail a)) is identified by the following: more stable arc less spatter deeper penetration better visual control of the deposit. Rightward Welding The rightward welding technique (detail b)) is identified by the following: more spatter less penetration better visual control of the weld joint good cleaning action when welding aluminium alloys. Figure 6: Guide Values for Different Arc Types For Training Purposes Only Issue: August 2014 Page 582 of 926 Modul 7 Welding, Brazing, Soldering and Bonding To avoid oxides in the deposit, the rightward technique is normally used for all welding of aluminium and aluminium alloys. PART 66 – Basic Training Cat B1 – Module 7 Techniques in GMA Welding Torch Angles Refer to Figure 8. Torch angles may be defined as longitudinal angle which is the angle between torch and workpiece along the weld, and transverse angle which is the angle between torch and workpiece sideways from the weld. The longitudinal angle will affect the penetration and bead form. Too small angles should be avoided as the shielding gas flow may drag air in between torch and workpiece, contaminating the weld. For horizontal welding an angle between 70° and 80° is frequently used. The transverse angle will normally be 90° on a flat workpiece, and 45° for fillet welds. When multiple passes are used, the transverse angle is increased or decreased to place the metal deposit correctly in the joint. Figure 7: Leftward and Rightward Welding For Training Purposes Only Issue: August 2014 Page 583 of 926 Modul 7 Welding, Brazing, Soldering and Bonding PART 66 – Basic Training Cat B1 – Module 7 Preparation for Welding The GMAW processes require that the welder and welder’s assistant use the correct protective equipment and face shields with correct shade filter glass. Preparing the Equipment Before welding starts: make sure that correct protective (shielding) gas is available in sufficient quantity check that the equipment is set for correct polarity according to the wire, normally positive pole (+) to torch if massive wires are used, and negative pole ( –) to torch for some flux cored wires ensure that the ground clamp is properly fastened to the workpiece, with good electrical contact. Poor ground connection will not help the equipment to work correctly. Mounting the Wire Spool Refer to Figure 9. Figure 8: Torch Angles in GMA Welding For Training Purposes Only Issue: August 2014 Check, and if required clean the wire feed rolls and the wire liner in the torch cable. Make sure that the rolls and liner are of correct size and quality for the wire to be used. Check that the torch contact tip and nozzle are free from spatter (detail a)), and that the contact tip is of correct size for the wire to be used (detail b)). Worn contact tips or liners should be replaced (detail c)). When aluminium wire is used the contact tip should have a slightly larger inner diameter than with other alloys, to allow for the heat expansion in aluminium. Page 584 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Welding, Brazing, Soldering and Bonding Insert the wire spool in the wire feed device and straighten approx. 10 to 15 cm of the wire end. To avoid damaging the liner or getting the wire stuck when feeding it through the liner, it may be required to round off the wire end with a file (detail d)). Then insert the wire in the torch cable liner, fasten the feeder rolls and feed the wire until it comes out from the torch. Checking the Wire Feed Function Refer to Figure 10. Figure 10: Wire Preparation Figure 9: Preparation for Welding For Training Purposes Only Issue: August 2014 Page 585 of 926 Modul 7 Welding, Brazing, Soldering and Bonding PART 66 – Basic Training Cat B1 – Module 7 Check and if required adjust the wire spool resistance. Even at the highest wire feed speed the spool shall stop immediately when the torch microswitch is released, without uncoiling excessive wire between spool and feed rolls. The feed roll pressure should be adjusted to a pressure where they slide on the wire if the wire is stopped at the torch. This is checked by stopping the wire at the torch nozzle while keeping the feed button depressed. Do not touch the wire when testing this unless the equipment has a cold feed switch. The roll pressure may be tested by cutting the wire level with the torch nozzle and using an electrically insulating material to hold the wire back. Before welding starts the wire should be cut off at an angle 10 to 15 mm away from the nozzle tip to provide best conditions for arc starting. The sharp point will provide a better starting point for the arc than a flat wire tip surface, especially for larger wire diameters. Shielding the Workplace Refer to Figure 11. Figure 11: Shielding the Workplace Strong wind may disturb the protective gas flow and cause welding faults. When required the weld bead should be shielded. Welding fume extractors must be positioned with care to make sure that they do not affect the shielding gas. Start Welding Refer to Figure 12. Set the correct controls given for the base material, wire and shielding gas that are to be used. These controls include For Training Purposes Only Issue: August 2014 gas flow rate (1) wire feed speed (2) amperage or voltage setting (3). Page 586 of 926 Modul 7 Welding, Brazing, Soldering and Bonding PART 66 – Basic Training Cat B1 – Module 7 When setting the gas flow rate, allow the gas to flow for a while to make sure that the gas supply system is purged. If in doubt of the actual wire feed speed at a certain setting on the machine, this can be checked by pressing the torch microswitch and start wire feed for exactly 6 seconds. Measure the wire length that has been fed, multiply by 10 and you will have the feed rate per minute. When doing this check keep the wire away from contact with the workpiece. When feeding in this way the wire will be electrically live and an arc will occur if contact is made. While welding, the welder controls five items: wire stickout (4) travel speed (5) V torch angles (6) weaving (7) direction (5). Wire Stickout Wire stickout is the distance between the contact tip and the workpiece. This distance decides the length of the current carrying part of the welding wire. The electrical resistance and voltage drop in the wire increases with increasing stickout. This voltage drop is part of the measured arc voltage, and the welding current will decrease with increasing stickout. Too long stickout may result in too cold arc and not enough gas shield which must be avoided. Figure 12: Welding Parameters For Training Purposes Only Issue: August 2014 Page 587 of 926 Modul 7 Welding, Brazing, Soldering and Bonding Too short stickout may overheat the contact tip and will also allow more spatter to reach the nozzle. This may cause turbulence in the gas flow, and not enough shielding. Depending on the type of the power source, the welder may use the stickout to adjust the welding conditions while welding. Increasing stickout will When finishing the weld, the heat input should be reduced to reduce penetration depth and weld pool size. This may be done by increasing travel speed and/or stickout for the last 3 to 5 cm of the weld, and releasing the torch switch immediately when the stop point is reached. Keep the torch in position over the weld until the gas flow stops, in order to protect the deposit until the metal has gone solid. 7.15.3.2 decrease penetration increase deposition rate increase bead size decrease bead width. PART 66 – Basic Training Cat B1 – Module 7 Gas Tungsten Arc Welding Description Refer to Figure 13. Weaving To obtain a wider weld deposit than obtainable with a straight welding pattern, the torch may be moved along the groove in a side –to –side movement (weaving). When this technique is used the side –to –side movement must be stopped shortly at each side to make sure that there is enough deposit at the sides of the weld. Weaving in a continuous movement may easily result in not enough deposit and undercut, which will weaken the joint. Arc Starting and Stopping When starting the arc on a cold workpiece, penetration may not be enough to provide binding for a short moment before the weld pool is properly started. To avoid a weakness in the joint, the arc may be started on a plate fixed to the workpiece at the beginning of the joint, or the welder may increase the heat input. This may be done by starting the arc 2 to 3 cm after the beginning of the weld, moving the arc quickly back to the actual starting point and continuing welding over the slightly preheated area. Reduced electrode stickout for the first 1 to 2 cm will improve heat input. For Training Purposes Only Gas tungsten arc welding (GTAW), commonly known as tungsten inert gas (TIG) welding, is an arc welding process that uses a non consumable tungsten electrode to produce the weld. The weld area is protected from atmospheric contamination by a shielding gas (usually an inert gas such as argon), and a filler metal is normally used, though some welds, known as autogenous welds, do not require it. A constant - current welding power supply produces energy which is conducted across the arc through a column of highly ionised gas and metal vapours known as a plasma. GTAW is most commonly used to weld thin sections of stainless steel and light metals such as aluminium, magnesium, and copper alloys. The process grants the operator greater control over the weld than competing procedures such as shielded metal arc welding and gas metal arc welding, allowing for stronger, higher quality welds. However, GTAW is comparatively more complex and difficult to master, and furthermore, it is significantly slower than most other welding techniques. A related process, plasma arc welding, uses a Issue: August 2014 Page 588 of 926 Modul 7 Welding, Brazing, Soldering and Bonding slightly different welding torch to create a more focused welding arc and as a result is often automated. PART 66 – Basic Training Cat B1 – Module 7 Features The process is suitable for welding light gauge materials and for the root runs of butt joints in thick metal. The clear clean weld pool, high concentration of heat, absence of spatter, precise control of heat input, ability to weld with or without filler metal together with ease of control over penetration in all positions make sure of good quality welding. Gas tungsten arc welding is used for fusing the root runs in butt joints where very high quality is required, e.g. stainless steel piping for nuclear energy applications. A completely de - oxidised filler wire is required and the composition should be balanced such to achieve a self –fluxing weld pool. Wires suitable for oxy - acetylene welding are generally appropriate for GTA welding. Equipment Power Source An AC or DC power source with standard generators, rectifiers or transformers is used. GTAW Torch Refer to Figure 14. Figure 13: Gas Tungsten Arc Welding Process For Training Purposes Only Issue: August 2014 Page 589 of 926 Modul 7 Welding, Brazing, Soldering and Bonding PART 66 – Basic Training Cat B1 – Module 7 Figure 14: GTA Welding Torch For Training Purposes Only Issue: August 2014 Page 590 of 926 Modul 7 Welding, Brazing, Soldering and Bonding PART 66 – Basic Training Cat B1 – Module 7 GTA welding torches are designed for either automatic or manual operation and are equipped with cooling systems using air or water. The automatic and manual torches are similar in construction, but the manual torch has a handle while the automatic torch normally comes with a mounting rack. The angle between the centerline of the handle and the centerline of the tungsten electrode, known as the head angle, can be varied on some manual torches according to the preference of the operator. Filler Rod Air cooling systems are most often used for low current operations (up to about 200 A), while water cooling is required for high current welding (up to about 600 A). The torches are connected with cables to the power supply and with hoses to the shielding gas source and where used, the water supply. The gas supply is usually provided from gas cylinders as well as from a detached supply through pipes. Argon of 99.99 % purity is used. The electrodes are usually made of tungsten. The internal metal parts of a torch are made of hard alloys of copper or brass in order to transmit current and heat effectively. The tungsten electrode must be held firmly in the center of the torch with an appropriately sized collet, and ports around the electrode provide a constant flow of shielding gas. The body of the torch is made of heat resistant, insulating plastics covering the metal components, providing insulation from heat and electricity to protect the welder. Refer to Figure 15. The size of the welding torch nozzle depends on the size of the desired welding arc, and the inside diameter of the nozzle is normally at least three times the diameter of the electrode. The nozzle must be heat resistant and thus is normally made of alumina or a ceramic material, but fused quartz, a glass like substance, offers greater visibility. Devices can be inserted into the nozzle for special applications, such as gas lenses or valves to control shielding gas flow and switches to control welding current. For Training Purposes Only The filler wire is selected to match parent metal compositions, except with materials which give hot cracking in the weld pool when a single phase alloy is produced for example high nickel stainless steels etc. Special compositions are then required. The wires must be clean. Gas Welding Practice Either DC or AC are used, depending on the metal to be welded, thickness and welding speed. DC is normally employed, but metals which readily form oxides, such as aluminium, magnesium, aluminium - bronze or beryllium - copper are welded with AC. On work where good weld quality is required, a superimposed high frequency current may be used to assist arc striking when AC welding. When AC is used the positive cycle has a cleaning action in breaking up and dispersing oxide films. AC transformer systems for GTA welding must be specially designed to overcome current rectification, this frequently being accomplished with high frequency stabilisation. In manual welding practice the arc can be struck by scratching the work lightly but in machine welding high frequency striking is usual. Many manual equipments use high frequency arc striking because it eliminates the risk of contaminating the tungsten electrode with parent metal which is very important for high quality work. Issue: August 2014 Page 591 of 926 Modul 7 Welding, Brazing, Soldering and Bonding PART 66 – Basic Training Cat B1 – Module 7 Figure 15: Gas Tungsten Arc Welding For Training Purposes Only Issue: August 2014 Page 592 of 926 Modul 7 Welding, Brazing, Soldering and Bonding 7.15.3.3 PART 66 – Basic Training Cat B1 – Module 7 Practical Exercises Rules It is important that the welder makes sure he is protected during welding operations. The danger to unprotected skin is very important. This danger is present in two forms: from the arc rays and from molten metal in the form of spatter. To make sure that the operator suffers no injury the skin must be covered completely. Particular attention must be paid to eyes, hands, face, arms and neck. It is very important that the operator observes the safety precautions. Protective Clothing Normal Dress Refer to Figure 16. Outer clothing should be free from oil, grease or flammable substances. Arms should be protected from exposure to arc rays. Sleeves should not be rolled up. Cuffs on overalls, turn –ups on trousers, exposed long hair and low – cut shoes are likely lodging places for sparks and hot metal. Face Shields For most operations a face shield made of lightweight, insulating and non –reflecting material can be used (detail b)). It must have the correct ’filter glass’. Figure 16: Protective Clothing and Face Shield For Training Purposes Only Issue: August 2014 Page 593 of 926 Modul 7 Welding, Brazing, Soldering and Bonding The screen is of a size and shape to protect face, throat, wrist, and hand. Where it is important to protect the head or to have both hands free, a helmet type screen fitted with the correct filter should be used. The shields are made of fire proof material and fitted with dark glass, protected by clear glass. No metal fittings should be used in their designs because of the risk of electric shocks. Capes, made of leather and designed to protect the shoulders Skull caps, made from leather and designed to protect the top of the head Spats, usually made from leather and designed to protect the top of the foot by ensuring that hot metal does not enter the boot. Goggles alone do not give adequate protection for GMA welding. Special Safety Precautions Gloves or Mitts Always: Leather gloves to protect wrists and hands and industrial (leather) boots should be worn. The gauntlet type should have a covering of at least 150 mm to 200 mm to protect wrists and arms. Arm Protectors Arm protectors are made of leather and designed to protect the arm from wrist to shoulder. Aprons The front of the body from throat to knees should be protected by a suitable leather cape and an apron. If only an apron is worn this must provide full protection. Aprons are made of leather, either split or full at the front. The split type gives more space for action during welding in a confined space. Special Protective Clothing The following protective clothing is of a special nature and is only worn when carrying out vertical and overhead welding: For Training Purposes Only PART 66 – Basic Training Cat B1 – Module 7 1. Follow safety precautions and fire prevention procedure. 2. Check that the return and earth leads are firmly connected to the bench or workpiece and to the power source. 3. Check gas level and the adjusted gas flow rate. 4. Check the wire type and quantity and that the correct feed rate is preset. 5. Check that the power source is switched on. 6. Use protective equipment and wear the protective clothing 7. Concentrate on watching the welding operation 8. Have full control of the movements of the torch or gun and hold it steady. 9. Hold the torch holder with enough grip to give control – tight gripping will cause muscle fatigue. 10. Position yourself to avoid stretching and the risk of overbalancing. 11. Support the arm holding the torch by keeping it near the body. 12. Check that portable screens are in position. Warn unscreened observers before the arc is struck. 13. Ensure that the face shield is in front of the eyes before striking the arc; keep it there until the arc has stopped. 14. Place the torch in a safe place when not in use. 15. Switch off the power source when not in use. Issue: August 2014 Page 594 of 926 Modul 7 Welding, Brazing, Soldering and Bonding PART 66 – Basic Training Cat B1 – Module 7 16. Switch off the mains supply to the power source at the end of the work period. 17. Leave the work area in a tidy manner and make sure the equipment is stored correctly. 18. Make sure that the welding circuit is correctly earthed 19. The welding cables should be insulated. Never use damaged hose sets 20. Ensure that the hose set is free from twists or bends and that it does not become crushed or pinched under heavy loads. To Avoid Electric Shock 21. Turn off machines when they are not in use. 22. Wear gloves when handling equipment. 23. Keep all equipment dry. Do not stand in water when welding as water is an excellent conductor of electricity. 24. Be careful of dampness of any kind. Even perspiration inside gloves on a very hot day can cause electric shock. For Training Purposes Only Issue: August 2014 Page 595 of 926 Modul 7 Welding, Brazing, Soldering and Bonding PART 66 – Basic Training Cat B1 – Module 7 Oxy –Acetylene Welding and Brazing 7.15.4 Introduction In oxy - acetylene welding (gas fusion welding) the edges of two pieces of metal are heated up to or above their melting point. Often a filler material is added to the weld. The composition of the filler rod must be equal or superior in quality to the materials to be welded. Oxy - acetylene welding is applied in pipefitting, chassis –frame construction and thin –sheet metal welding (up to 6 mm). Mostly materials, like non alloyed and low alloyed steels and non ferrous materials (e.g. copper, brass) are joined using oxy - acetylene welding. Oxygen and acetylene are used as sources of heat. Refer to Figure 1. Figure 1: Comparison of Welded Joint and Riveted Joint For Training Purposes Only Issue: August 2014 Page 596 of 926 Modul 7 Welding, Brazing, Soldering and Bonding PART 66 – Basic Training Cat B1 – Module 7 Welding has many advantages in comparison with other joining techniques. These advantages (in comparison with riveting) can be seen in Figure 1. These advantages are: non –weakening through holes of rivets or screws equal stress distribution over the whole length of the weld (detail b)) electrical power is not require the finished workpiece is lighter (through avoidance of overlaps) V less material required (detail a)) (economical light design). 7.15.4.1 Oxy –Acetylene Welding Equipment Refer to Figure 2. A complete set for oxy –acetylene welding consists of oxygen cylinder oxygen pressure regulator oxygen hose acetylene cylinder acetylene pressure regulator acetylene hose flashback arrester welding torch with mixing handle and nozzle set of interchangeable nozzles cutting attachment and set of interchangeable cutting nozzles nozzle cleane filler rods and fluxes keys and spanners to fit the equipmen spark lighter trolley for transport/storage of the cylinders (if not stationary). For Training Purposes Only Figure 2: Oxy--Acetylene Welding Equipment (German (DIN) and British Type (BS)) Issue: August 2014 Page 597 of 926 Modul 7 Welding, Brazing, Soldering and Bonding Oxygen Cylinder Refer to Figure 3. PART 66 – Basic Training Cat B1 – Module 7 The oxygen cylinder is painted blue (German type) or painted black (British type). Its filling pressure is 200 bar with a volume of 50 liters, which would be 10,000 l (10 m3) pure oxygen at ambient pressure. Acetylene Cylinder Characteristic of Acetylene Refer to Figure 4. Acetylene (C2H2) has a high flame temperature. Figure 4: Flame Temperatures of Different Cylinder Construction Refer to Figure 3 again. Figure 3: Size and Handling of Cylinders For Training Purposes Only Issue: August 2014 Page 598 of 926 Modul 7 Welding, Brazing, Soldering and Bonding The acetylene cylinder is painted yellow (German type) or painted maroon (British type). These cylinders are filled with a porous material and acetone. PART 66 – Basic Training Cat B1 – Module 7 Hoses Refer to Figure 5. The acetylene cylinder can be filled up to a pressure of 18 bar and transported without danger. Without the acetone –acetylene solution in the porous material, acetylene is a high explosive gas (largest explosive range of all gases; 2.5 – 93.5 % acetylene content in the normal atmosphere) which cannot be compressed higher than to 2 bar, because above 2 bar the gas might explode by heat or ignition. The operating pressure should never go above 1.5 bar. Pressure Regulators for Oxygen and Acetylene Pressure regulators are to reduce a high pressure to a low pressure and to maintain a constant gas/compressed air discharge pressure irrespective of the gas flow. These regulators are to be found on all steel cylinders holding oxygen or acetylene. The connections for the pressure regulators on oxygen cylinders are equipped with right hand threads and the connections for the acetylene cylinders with left hand threads. This prevents the regulators being connected to the wrong cylinders. The right hand gauges indicate the cylinder pressure, while the left hand gauges indicate the working pressure at the nozzle. The nozzle pressure is controlled by adjusting the control handles. Before connecting the regulators to the cylinders, the valve on each cylinder must be cracked (open slightly) shortly for a small amount to blow out dust or other dirty material. The acetylene valve must not be cracked near any open flame or near a welding operation. The regulators have to be connected to their respective cylinders and gently tightened. For Training Purposes Only Issue: August 2014 Figure 5: Hose Fittings Page 599 of 926 Modul 7 Welding, Brazing, Soldering and Bonding PART 66 – Basic Training Cat B1 – Module 7 The acetylene hose is normally red and the oxygen blue. Acetylene fittings have left –hand threads while oxygen fittings have right hand threads. Flashback Arrester Refer to Figure 6. All draw - off places must be equipped with a flashback arrester. Figure 6 shows the function in operation and during a flashback. In the case of a flashback, the flashback arrester will be closed. This stops the continuous supply of gas and prevents the spread out of the flame in the distributing main. For Training Purposes Only Issue: August 2014 Page 600 of 926 Modul 7 Welding, Brazing, Soldering and Bonding PART 66 – Basic Training Cat B1 – Module 7 Figure 6: Flashback Arrester For Training Purposes Only Issue: August 2014 Page 601 of 926 Modul 7 Welding, Brazing, Soldering and Bonding PART 66 – Basic Training Cat B1 – Module 7 Welding Torch Mixing Handle Refer to Figure 7. The mixing handle should be attached to the hose end. An over tightening of the mixing handle or regulator end hose connections has to be avoided. Nozzle Sizes The correct selection of the nozzle size depends on the thickness of the material. Size Material (Thickness) 1 0.5 – 1mm 2 1 – 2mm 3 2 – 4mm 4 4 – 6mm 5 6 – 9mm Figure 7: Welding Torch with Mixing Handle and Nozzles Filler Rods Classification Filler rods are classified into seven classes. Generally, they are all stamped (each 250 mm) to ensure identification. These rods are marked with Roman numerals from I to VII. The main difference between the rods is their particular chemical composition. For Training Purposes Only Issue: August 2014 Page 602 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Welding, Brazing, Soldering and Bonding Surface G VI VI green The filler rods are covered with a thin copper skin to prevent corrosion before application. During welding the copper burns without any effect to the weld. G VII VII silver Material The material of the filler rod core must consist of the same type of material to be joined. Diameter The required diameter of the welding rod depends on the workpieces to be joined. Dimensions of Filler Rods Length of the welding rod: Diameter: Working Place 1,000 mm 2, 3 ,4 and 5 mm. Refer to Figure 8. Extract from DIN 8554 Filler rod class The working place components are: Stamp Marked colour (on the welding rod) GI I - G II II grey G III III gold G IV IV red GV V yellow For Training Purposes Only Issue: August 2014 welding work table swivel stool water tank welding torch holder filler rod holder. Page 603 of 926 Modul 7 Welding, Brazing, Soldering and Bonding PART 66 – Basic Training Cat B1 – Module 7 Clothing Note: During welding the appropriate protective clothing has to be worn. Refer to Figure 9. The protective clothing for welding consists of: protective heat resistant hat (helmet) coloured goggles trousers and coat/jacket made of 100 % cotton with long legs and arms spats gloves apron (leather) industrial boots. During welding small particles of glowing hot iron spread onto the body. If the welder is not heat - protected they will burn his skin and eyes and cause severe injuries. Goggles Goggles should be fitted with approved lens. Lens supplied for oxy acetylene welding must never be used for arc welding. Figure 8: Welding Working Place Dress Clothing should be free from oil, grease or flammable substances. Cuffs on overalls, and turn - ups on trousers, are possible lodging places for sparks or globules of hot metal. For Training Purposes Only Issue: August 2014 Page 604 of 926 Modul 7 Welding, Brazing, Soldering and Bonding PART 66 – Basic Training Cat B1 – Module 7 Special Protection The protective clothing worn depends upon the type of the work. Industrial boots with spats should be worn when cutting work. Leather gloves should be worn for all welding operations involving the handling of hot metal. Gauntlet gloves and leather apron should be worn when welding, especially when working in the vertical and overhead positions. Safety Precautions for Oxy - Acetylene Welding Equipment Gas Cylinders General Remarks When in use, the acetylene cylinder should stand upright, otherwise acetone is pulled with the gas out of the cylinder. This reduces the acetone content and increases the danger of explosions at refilling. It is dangerous to use copper fittings or pipes on acetylene systems. Copper material causes a chemical reaction (copper acetylide). Never use pure copper or high copper alloys for acetylene pipe systems or acetylene hose repairs. Safety Precautions Figure 9: Protective Clothing For Training Purposes Only Issue: August 2014 Store oxygen and fuel gas cylinders separately. Handle cylinders carefully. Take care that they are not dropped or allowed to fall from a height. Page 605 of 926 Modul 7 Welding, Brazing, Soldering and Bonding Cylinders should be used in an upright position and fastened to prevent them from falling. Do not allow any flame near cylinders. Do not allow any electric arc welding to be done near the cylinders If fire breaks out try to remove all gas cylinders to a safe place Close cylinder valves when not in use. If gas leaks out: – Move the cylinder outside away from electric motors, sparks or heat. – No smoking or naked flames. – Make sure that suppliers are informed immediately. In an oxygen - enriched atmosphere, clothing and any combustible material can be ignited easily by a spark and will burn easily. Regulators Acetylene and other fuel gases are highly flammable and form explosive mixtures with air and oxygen. Fuel gas leaks are a source of fire risk. Store acetylene cylinders in a cool dry place away from heat and direct sunlight. Do not mix acetylene with oxygen cylinders. Keep them separate. Switches and lamps must be flame proof. Do not use regulators with broken gauges. Do not stand in front of gauge faces when opening a cylinder valve. Select the correct regulator for the work being done. Do not use: – low –pressure regulators on dissolved acetylene cylinders – dissolved acetylene regulators on hydrogen cylinders – compressed air regulators on oxygen cylinder. Never use oil on regulators. Do not handle gas welding equipment with oily or greasy hands, and do not wear oil soaked clothing. Oxygen Cylinders Oil, in the presence of pure oxygen, becomes highly Do not breathe oxygen from the cylinder. Do not use it as a method of ventilation. Do not allow it to leak. Do not use oxygen as a substitute for compressed air. Never allow oil or grease to be on cylinder valves or cylinder fittings. Oxygen reacts explosively with oil or grease. flammable. Release the pressure control handle on each regulator (counter-clockwise) until the internal diaphragm is relaxed. Hoses For Training Purposes Only PART 66 – Basic Training Cat B1 – Module 7 Issue: August 2014 Use only pressure type rubber canvas hoses in good condition and fitted with the correct type of connections. Do not allow hoses to twist, bend or tangle and obstruct the gas flow. Page 606 of 926 Modul 7 Welding, Brazing, Soldering and Bonding Keep hoses clear of abrasive surfaces, sharp edges, and hot metal. Do not allow equipment to pass over them. Do not pass oxygen through a hose previously filled with compressed air. Use the correct fittings for extending hoses or when repairing damaged hoses. When using the equipment, hoses have to be kept apart from hot sparks, flames, oil, grease, etc. Never use copper pipe on acetylene hose connections. 7.15.4.2 Adjusting the Gas Pressure Before adjusting the gas pressure make sure that all connections between oxy - acetylene cylinder and welding torch are tightened well and free of oil, grease and dirt. Oxy - acetylene welding should be performed in areas free from fire risk. Wooden floors should be covered with non - combustible material and kept clean and free from litter within 10 m of welding and cutting operations. Make sure that there is good natural ventilation during welding operations. Make sure that correct fire - extinguishing equipment, including buckets of dry sand, is available and maintained in good condition. Safety Precautions Concerning the Performance of Work Oxy –Acetylene Welding Techniques Adjusting the Gas Pressure and Igniting the Flame Safety Precautions Concerning the Working Area PART 66 – Basic Training Cat B1 – Module 7 Clean the joint area before welding. Place the workpieces on an heat - proof support when welding, so that heat is not conducted. After screwing on the correct nozzle, make sure that the regulator pressure control handles are turned (counterclockwise) completely off. Open the cylinder valves very slowly. Open the acetylene cylinder valve about one turn. Open the oxygen cylinder valve completely in order to prevent leakage around the valve stem. Leave the acetylene spanner/key on the on/off valve to use in an emergency. Shut the acetylene mixing valve. Open the oxygen mixing valve. Turn the oxygen regulator handle in (clockwise) until the desired working pressure is obtained (read low pressure gauge). Purge (clear the hose of air or other gases) the oxygen hose line by allowing oxygen to flow from the hose momentarily. Shut off the oxygen mixing valve. Open the acetylene mixing valve (oxygen valve off) and adjust the acetylene regulator to the desired pressure. Purge the acetylene hose and close the acetylene mixing valve. Purging lines is very important. If this is not done acetylene can enter the oxygen hose and oxygen can enter the For Training Purposes Only Issue: August 2014 Page 607 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Welding, Brazing, Soldering and Bonding acetylene hose. This, of course, creates a combustible mixture inside the hose and can cause a flashback (fire burning inside the hose). Pressure Indicators The correct indications of the cylinder pressures are as follows: Refer to Figure 10. oxygen acetylene 200 bar 18 bar. Refer to Figure 11. The correct indications of the working pressures are as follows: oxygen acetylene 2.5 bar between 0.2 and 0.5 bar. Figure 10: Oxygen and Acetylene Cylinder Pressure Indicators For Training Purposes Only Issue: August 2014 Page 608 of 926 Modul 7 Welding, Brazing, Soldering and Bonding PART 66 – Basic Training Cat B1 – Module 7 Igniting the Flame Characteristics of the Flame Refer to Figures 12 and 13. The following three types of flames are used by the welder: Neutral Flame This type of flame is produced when equal volumes of oxygen and acetylene are burnt together. In this flame there are two distinct zones, the inner white cone, which is clearly defined, and the outer envelope. The neutral flame is applied at 3,200 oC at a distance between workpiece and flame cone between 2 and 5 mm. The neutral flame is used when welding steel, stainless steel, cast iron, copper, etc. Carburising Flame If the amount of oxygen being supplied to the neutral flame is reduced, the resulting flame has more acetylene. It has more carbon and is capable of yielding carbon to the steel being welded. Its effect is to reduce the melting temperature of the steel in the localised area of the weld. The carburising flame is recognised by the ragged bluish white feather surrounding the large central cone. The carburising flame is used for surface hardening and for welding cast iron and aluminum. Figure 11: Working Pressure Indicators For Training Purposes Only Issue: August 2014 Page 609 of 926 Modul 7 Welding, Brazing, Soldering and Bonding PART 66 – Basic Training Cat B1 – Module 7 Oxidising Flame If the neutral flame is adjusted until it burns with more oxygen, the flame produced is called an oxidising flame. It can be recognised by the small cone surrounded by the ragged bluish white feather. It tends to be hotter than the neutral flame. The oxidising flame is used for welding brass. Figure 12: Types of Flames For Training Purposes Only Issue: August 2014 Page 610 of 926 Modul 7 Welding, Brazing, Soldering and Bonding PART 66 – Basic Training Cat B1 – Module 7 Figure 13: Flame Distance (Neutral Flame) Before igniting the oxy –acetylene gas, make sure that the mixer handle is kept in downwards position and away from everybody. Refer to Figure 14. Before igniting the flame, check the nozzle. Possibly the hole is blocked by slag, so cleaning has to be done with the correct nozzle cleaner. Care must be taken, that the hole is not widened or notched, because that affects the gas flow. Figure 14: Igniting the Flame For Training Purposes Only Issue: August 2014 Page 611 of 926 Modul 7 Welding, Brazing, Soldering and Bonding PART 66 – Basic Training Cat B1 – Module 7 First open the oxygen cylinder valve for approximately one eighth to one fourth revolution. After the acetylene mixer valve has been opened for a small amount, ignite the flame with a spark lighter. If the gas does not ignite, the supply of acetylene must be increased. When the acetylene ignites, adjust the flame until it is approx. 3 to 4 mm from the nozzle. Open the oxygen valve and adjust the flame. Note: It is most important when welding that the correct flame is selected to complete the welding process. Welding Techniques Surfacing Surfacing, also called ’deposit welding’, is a special term which describes the melt in its liquid form on the surface of a material (plate), adding filler material (rod) at the same time. Refer to Figure 15. Figure 15: Surfacing (Deposit Welding) The symbol of surfacing is shown in Figure 15. Visual Inspection of Surfacings In welding representations/workshop abbreviations stand for: G w h = = = gas welding flat welding position horizontal position. drawings the following Refer to Figure 16. If the speed of the welding flame and the application of the filler rod are done correctly, then a good welded joint will result (detail a)). Incorrectly welded joints are shown with two examples in details b) and c). For Training Purposes Only Issue: August 2014 Page 612 of 926 Modul 7 Welding, Brazing, Soldering and Bonding PART 66 – Basic Training Cat B1 – Module 7 Fillet Welding Refer to Figure 17. Figure 17: Fillet Welding Figure 16: Visual Inspection of Surfacing Welds For Training Purposes Only Issue: August 2014 Page 613 of 926 Modul 7 Welding, Brazing, Soldering and Bonding PART 66 – Basic Training Cat B1 – Module 7 Fillet welding can be done using any angle, for example 90°, 30° or 120o. Tack Welding Procedure Tack welding must be done before fillet welding to avoid the distortion of the two workpieces. Figure 17 shows an example of two workpieces which are first tack welded and then fillet welded at an angle of 90o. Tack welds should be on the side to be welded and in the line of the joint. The number of tacks is not standardised. Heat a small area with the welding torch to melt the parent metal where the tack weld is required. Add filler metal to the molten pool to make a small weld and then remove the flame. Repeat this procedure until all tack welds are made, making sure that the gap is kept the same and of the correct size (where a gap is required). Refer to Figure 18. The visual inspection of some different fillet weldings under an angle of 90° is featured in Figure 18. Figure 18: Visual Inspection of Fillet Welding Defects For Training Purposes Only Issue: August 2014 Page 614 of 926 Modul 7 Welding, Brazing, Soldering and Bonding PART 66 – Basic Training Cat B1 – Module 7 Butt Welding to Join Two Flanged Plates Refer to Figure 19. Butt welding is the joining of two plates. The symbol of butt welding is shown in Figure 19. Dimensions for the preparation of the weld are: bending radius R bending height h = = thickness of the sheet s thickness of the sheet + 1 mm. Welding Tack Welding to Prepare Butt Welding Refer to Figure 20. Figure 20 shows an example of a simple method of tack welding. The use of a filler rod is not necessary. Refer to Figure 21. Examples of correct and incorrect butt welding are shown in Figure 21. Figure 19: Joint of Two Flanged Plates by Butt Welding For Training Purposes Only Issue: August 2014 Page 615 of 926 Modul 7 Welding, Brazing, Soldering and Bonding PART 66 – Basic Training Cat B1 – Module 7 Figure 21: Visual Inspection of Butt Welding Figure 20: Tack Welding and Butt Welding For Training Purposes Only Issue: August 2014 Page 616 of 926 Modul 7 Welding, Brazing, Soldering and Bonding Square –Butt Welding Refer to Figure 22. PART 66 – Basic Training Cat B1 – Module 7 The common symbol used for square –butt welding and the preparation of the two workpieces for a square –butt weld are shown in Figure 22. Dimensions for the preparation of the weld are: b = 1 – 2 mm for s up 1 mm b = 2 – 3 mm for s between 1 and 4 mm. Tack Welding for Square –Butt Welding Refer to Figure 23. Figure 23 shows the correct method of tack welding for square –butt welding. Note: Before starting square butt welding make sure that the plates are supported from below on a hollow base, e.g. a U - profile. A successful weld depends on a suitable base. Refer to Figure 24. Square butt welded joints are examined visually. A presentation of correctly and incorrectly welded joints is featured in Figure 24. Leftward and Rightward Welding Leftward Welding Refer to Figure 25. Figure 22: Square - Butt Welding For Training Purposes Only In this method of welding, the welding torch should be held firmly, ensuring that the wrist is free to move. The weld is started on the right hand side of the joint, working towards the left hand side. Issue: August 2014 Page 617 of 926 Modul 7 Welding, Brazing, Soldering and Bonding PART 66 – Basic Training Cat B1 – Module 7 The welding torch is moved forward with the flame pointing in the direction of the welding, with the filler rod being held in front of the flame. The angles of the welding torch and filler rod are shown in Figure 25. The welding torch is given small sideways movements, while the filler rod is moved steadily across the weld seam. The filler rod metal is added using a backward and forward movement of the rod, allowing the flame to melt the bottom edges of the plates just ahead of the weld pool. It is important that the filler rod is not held continuously in contact with the weld pool, because the heat from the flame will not reach the bottom edges of the joint. Rightward Welding Refer to Figure 26. In this method, the welding is started on the left –hand side of the joint, working towards the right hand side. The welding torch points in the direction of the welding and moves in a straight line along the joint. The filler rod is held at an angle of 45° and is moved forward in a series of loops. Note: The differences in edge preparation, welding torch direction and filler rod movement are the main factors to be considered when comparing the leftward and rightward techniques. If the thickness of the material is more than 3 mm, leftward welding is used. Figure 23: Tack Welding for Square-Butt Welding For Training Purposes Only Issue: August 2014 Page 618 of 926 Modul 7 Welding, Brazing, Soldering and Bonding PART 66 – Basic Training Cat B1 – Module 7 Figure 25: Leftward Welding Figure 24: Visual Inspection of Square-Butt Welding For Training Purposes Only Issue: August 2014 Page 619 of 926 Modul 7 Welding, Brazing, Soldering and Bonding PART 66 – Basic Training Cat B1 – Module 7 Welding Defects Refer to Figure 27. Lack of Penetration Lack of penetration (detail a)) is the failure of the filler metal to penetrate into the joint. It is caused by incorrect edge penetration incorrect welding technique not enough de - slagging. Lack of Fusion Lack of fusion (detail b)) is the failure of the filler metal to fuse with the parent metal. It is caused by not enough heat too fast travelling incorrect welding technique. Porosity Figure 26: Rightward Welding Porosity (detail c)) is a group of small holes inside the weld metal. It is caused by gas being trapped during the welding process, due to chemicals in the metal, dampness, or cooling of the weld too quickly. Slag Inclusion Slag inclusion (detail d)) is slag or other impurities trapped in the weld. It is caused by the slag from previous weld runs not being cleaned away, or not enough cleaning and preparation of the parent metal before welding. For Training Purposes Only Issue: August 2014 Page 620 of 926 Modul 7 Welding, Brazing, Soldering and Bonding Figure 27: Welding Defects (Details a) to d)) For Training Purposes Only PART 66 – Basic Training Cat B1 – Module 7 Figure 28: Welding Defects (Details e) to i)) Issue: August 2014 Page 621 of 926 Modul 7 Welding, Brazing, Soldering and Bonding Refer to Figure 28. PART 66 – Basic Training Cat B1 – Module 7 Blowholes (detail h)) are large holes in the weld caused by Undercut Undercuts (detail e)) are grooves or slots along the edges of the weld caused by gas being trapped, due to moisture contamination of either the filler or parent metals incorrect welding technique. Excessive Penetration travelling too fast too much heat building - up incorrect welding technique. Too much penetration (detail i)) is where the weld metal comes through the root of the weld. It is caused by Overlays Overlays (detail f)) consist of metal that has flown onto the parent metal without fusing with it. The defect is caused by too much heat concentration travelling too slow incorrect edge preparation. Burn Through not enough heat contamination of the surface of the parent metal incorrect welding technique. Burn through (not shown in the Figure) is the collapse of the weld pool due to Cracking poor edge preparation too high heat concentration. Cracking (detail g)) is the formation of cracks in the welded metal or the parent metal. 7.15.4.3 It is caused by Basics of Brazing incorrect welding technique cooling rate stresses because the cooling was too fast and generated too much stresses in the material unsuitable parent metals used in the weld. Blowholes For Training Purposes Only Brazing Refer to Figure 29. Brazing is a joining process whereby a non ferrous filler metal and an alloy are heated to melting temperature (above 450°C (800°F)) and distributed between two or more close fitting parts by capillary action. At its liquid temperature, the molten filler metal interacts with a thin layer of the base metal, cooling to form an exceptionally strong, Issue: August 2014 Page 622 of 926 Modul 7 Welding, Brazing, Soldering and Bonding sealed joint due to grain structure interaction. Figure 29 shows a typical brazing application on a sheet metal body. The brazed joint becomes a sandwich of different layers, each metallurgically linked to each other. Common brazements are about 1/3 as strong as the materials they join, because the metals partially dissolve each other at the interface, and usually the grain structure and joint alloy is uncontrolled. To create high strength brazes, sometimes a brazement can be annealed, or cooled at a controlled rate, so that the joint’s grain structure and alloying is controlled. PART 66 – Basic Training Cat B1 – Module 7 Silver Brazing If silver alloy is used, brazing can be referred to as ’silver brazing’. Colloquially, the inaccurate terms ’silver soldering’ or ’hard soldering’ are used, to distinguish from the process of low temperature soldering that is done with solder having a melting point below 450°C (800°F). Silver brazing is similar to soldering but higher temperatures are used and the filler metal has a significantly different composition and higher melting point than solder. Likewise, silver brazing often requires the prior machining of parts to be joined to very close tolerances prior to joining them, to establish a joint gap distance of a few mils (thousandths of an inch) for proper capillary action during joining of parts, whereas soldering does not require gap distances that are anywhere near this small for successful joining of parts. Silver brazing works especially well for joining tubular thick –walled steel pipes, provided the proper machining is done prior to joining the steel parts. Metals usable for Brazing Metals such as aluminum can be brazed though aluminum requires more skill and special fluxes. It conducts heat much better than steel and is more prone to oxidation. Some metals, such as titanium cannot be brazed because they are insoluble with other metals, or have an oxide layer that forms too quickly at intersoluble temperatures. Brazing versus Welding Figure 29: Typical Brazing Application For Training Purposes Only Brazing is different from welding, where even higher temperatures are used, the base material melts and the filler material (if used at all) has the same composition as the base material. Given two joints with the same geometry, brazed joints are generally not as strong as welded joints. Careful matching of joint geometry to the forces acting on the Issue: August 2014 Page 623 of 926 Modul 7 Welding, Brazing, Soldering and Bonding joint, however, can often lead to very strong brazed joints. The butt joint is the weakest geometry for tensile forces. The lap joint is much stronger, as it resists through shearing action rather than tensile pull and its surface area is much larger. To get joints roughly equivalent to a weld, a general rule of thumb is to make the overlap equal to 3 times the thickness of the pieces of metal being joined. Advantages over Welding The lower temperature of brazing is less likely to distort the work piece or induce thermal stresses. Example: When large iron castings crack, it is almost always impractical to repair them with welding. In order to weld cast –iron without recracking it from thermal stress, the work piece must be hot –soaked to 871oC. When a large (more than 50 kilograms (100 lb)) casting cracks in an industrial setting, heat –soaking it for welding is almost always impractical. Often the casting only needs to be watertight, or take mild mechanical stress. The lower temperature associated with brazing vs. welding can increase joining speed and reduce fuel gas consumption. Brazing can be easier for beginners to learn than welding. For thin workpieces (e.g., sheet metal or thin –walled pipe) brazing is less likely to result in burn –through. Brazing can also be a cheap and effective technique for mass production. Components can be assembled with preformed plugs of filler material positioned at joints and then heated in a furnace or passed through heating stations on an assembly line. The heated filler then flows into the joints by capillary action. Braze –welded joints generally have smooth attractive beads that do not require additional grinding or finishing. The most common filler materials are gold in colour, but fillers that more For Training Purposes Only PART 66 – Basic Training Cat B1 – Module 7 closely match the colour of the base materials can be used if appearance is important. Possible Problems A brazing operation may cause defects in the base metal, especially if it is in stress. This can be due either to the material not being properly annealed before brazing, or to thermal expansion stress during heating. An example of this is the silver brazing of copper –nickel alloys, where even moderate stress in the base material causes intergranular penetration by molten filler material during brazing, resulting in cracking at the joint. Note: Any flux residues left after brazing must be thoroughly removed; otherwise, severe corrosion may eventually occur. Brazing Equipment Various combustible gases are used for producing the flame, e.g. acetylene, hydrogen, coal gas (illuminating gas) or propane. Acetylene gas is preferable in most circumstances because it attains a higher temperature than other gases, and is also simple to produce. The gas is burnt in a mix with oxygen. Gas Cylinders Refer to Figure 2 again. The gases mostly used in brazing, i.e. oxygen and acetylene, are sold in steel cylinders (often referred to as ’bottles’). Oxygen cylinders contain the pure gas at a pressure of 200 bar, and are painted blue for identification. Acetylene cylinders are painted yellow. Issue: August 2014 Page 624 of 926 Modul 7 Welding, Brazing, Soldering and Bonding PART 66 – Basic Training Cat B1 – Module 7 Note: The colours mentioned above are according to DIN (German standard). Other standards, e.g. the British Standard (BS), may use different colour markings. The colours are used to avoid accidentally interchanging the pressure reducer and the flexible hose. Note: If no acetylene is available, carbide may alternatively be used. Whereas oxygen can be pressurized without danger, this does not apply to acetylene. The steel cylinder used for acetylene therefore contains a porous mass filled with acetone. Acetone has the property of dissolving acetylene, which can then be compressed in the cylinder at a pressure of 15 bar. Pressure Reducer Refer to Figure 30. The high pressure in the cylinder is lowered to the actual working pressure by passing the gas through a pressure reducer (reducing valve) attached to the cylinder supply valve. When the cylinder valve is opened, oxygen flows to the valve through the first stage, which is set to a pressure of 25 – 40 bar; the cylinder pressure is indicated by the cylinder pressure gauge. Oxygen flows into the intermediate chamber until pressure builds up on the diaphragm and forces the spring back, so that the valve closes. This pressure is shown on the working pressure gauge. If the torch is opened, the pressure in the intermediate chamber drops, and spring pressure causes the valve to open until the balance is again established. For Training Purposes Only Issue: August 2014 Page 625 of 926 Modul 7 Welding, Brazing, Soldering and Bonding PART 66 – Basic Training Cat B1 – Module 7 Figure 30: Pressure Reducer For Training Purposes Only Issue: August 2014 Page 626 of 926 Modul 7 Welding, Brazing, Soldering and Bonding Welding Torch Refer to Figure 7 again. Of the various types of welding torches, the injector type, also referred to as the suction torch, is commonly used today. As shown in Figure 7, the welding torch consists of a tubular handle and an interchangeable burner insert, which is selected according to the thickness of the workpiece to be welded (interchangeable welding torch). The individual parts of the burner insert are PART 66 – Basic Training Cat B1 – Module 7 Brazing fluxes are either boiled or dispersed borax. The latter is a mixture of boiled borax, common salt and potash. It should be stored in an airtight pack. Special fluxes are needed for brazing aluminium and aluminium alloys. The most important of these are copper (including brass) filler, as well as silver and aluminium filler. Example: L - Ms 54 is a brass alloy with 54 % copper and the remainder zinc; L - Ag 12 is a silver solder with 12 % silver and the rest copper or zinc. The higher the copper content of a brass filler, the higher its strength and the working temperature. the pressure nozzle (injector nozzle) the mixing tube V the welding (burner) nozzle the tightening (collar) nut. In the mixing tube, the combustible gas is mixed with oxygen to burn at the burner nozzle in the form of a pointed flame. Gas and oxygen flow can be regulated independently by special valves. Brazing alloys for aluminium materials contain at least 72 % aluminium, with silicon, copper, tin, nickel or cadmium additives. Filler materials are mainly sold as rod, solid and hollow (flux - filled) wire, foil and granules. The torch is connected to the gas cylinders by their flexible rubber hoses. To avoid accidental confusion, the hoses are red for the combustible gas and blue for oxygen. Fluxes and Filler Materials A variety of alloys of metals, including silver, tin, zinc, copper and others are used as filler for brazing processes. There are specific brazing alloys and fluxes recommended, depending on which metals are to be joined. Flux is a substance added to the metal surface for the purpose of eliminating any oxides or similar contaminants that may have formed and thus ensuring a stronger bond between the surfaces. For Training Purposes Only Issue: August 2014 Page 627 of 926 Modul 7 Welding, Brazing, Soldering and Bonding PART 66 – Basic Training Cat B1 – Module 7 Figure 31: Welding Torch For Training Purposes Only Issue: August 2014 Page 628 of 926 Modul 7 Welding, Brazing, Soldering and Bonding Hints for Proper Brazing PART 66 – Basic Training Cat B1 – Module 7 The joint area is coated with flux and lined with the hard solder. Heating must continue until the hard solder fills the joint completely. Cooling takes place slowly, thereafter the residual flux must be removed. Workpiece Clearances In order to work properly, parts must be closely fitted and the base metals must be exceptionally clean and free of oxides for achieving the highest strengths for brazed joints. For capillary action to be effective, joint clearances of 0.002 to 0.006 inch (50 to 150 mm) are recommended. Cleaning Cleaning of surfaces can be done in several ways. Whichever way is selected, it is vitally important to remove all grease, oils, and paint. For custom jobs and part work, this can often be done with fine sand paper or steel wool. In pure brazing (not braze welding), it is vitally important to use sufficiently fine abrasive. Coarse abrasive can lead to deep scoring that interferes with capillary action and final bond strength. Residual particulates from sanding should be thoroughly cleaned from pieces. In assembly line work, a ’pickling bath’ is often used to dissolve oxides chemically. Dilute sulfuric acid is often used. Pickling is also often employed on metals like aluminum that are particularly prone to oxidation. Oxy - Acetylene Flame The brazing flame is produced at the torch itself, where acetylene and oxygen are mixed in a 1 : 1 ratio. If the oxygen - acetylene mixing ratio is in the range of 1 : 1, the white incandescent flame cone is sharply delineated; this is referred to as the ’neutral’ setting. If excess gas is present, the tapered area flickers and becomes greenish in colour. The flame then transfers free carbon to the weld seam, which becomes harder as a result. For Training Purposes Only Issue: August 2014 Page 629 of 926 Modul 7 Welding, Brazing, Soldering and Bonding 7.15.5 Bonding 7.15.5.1 Bonding of Sheet Metal Parts PART 66 – Basic Training Cat B1 – Module 7 Refer to Figure 1. More and more metal bonding completes or replaces the usual sheet metal joining procedures. Modern bonding agents also achieve high strength under normal conditions and in the future will replace many known joining procedures. Today, bonding is used for outer surfaces and cell components of aircraft, ships, cars and bridge constructions as well as roof and window constructions. Additional examples are the bonding of pipes, the bonding of friction linings on clutches and brakes of cars or the bonding of ceramic cutting in a laminar way onto turning tools and cutting tools. Bonding has special advantages when joining different materials, like steel sheet onto aluminium sheet or aluminium sheet onto glass. There are smooth surfaces, split - free seams, constant strength at the complete cross - section, insulating effect and weight reduction. Figure 1: Riveting in Comparison with Bonding For Training Purposes Only Issue: August 2014 Page 630 of 926 Modul 7 Welding, Brazing, Soldering and Bonding PART 66 – Basic Training Cat B1 – Module 7 Refer to Figure 2. The effect of the bonding agents is based on the adhesion effect between bonding agent and workpiece and cohesion of the bonding agent. The effect of the adhesion force is illustrated in the following example. Example: When moistening 2 glass plates with water and placing one upon the other, both glass plates clinch tight together by adhesion and may only be separated by displacement. High tensile forces but only low shearing forces can be transmitted. The adhesion can be improved by different pretreatments of the surfaces. The cohesion ensures the coherence of the mass particles in the same material. Among other things, cohesion depends on the temperature and determines the condition of aggregation of the substances. A strong cohesion increases the inner strength, a weak cohesion leads to joint softening. The cohesion is responsible for the viscosity of the bonding agent during processing as well as for the tenacity after hardening. The bonding areas have to be cleaned carefully, i.e. they must be free from dirt and grease so that the molecules of the bonding agent can settle down close to the material. The viscosity of the bonding agent has to be adapted to the roughness of the surfaces. The surface depressions have to be filled up with the bonding agent and another layer has to be applied as constantly as possible. As the levelling is very hard to achieve, the adhesion becomes the higher the lower the roughness of the surface is. For Training Purposes Only Issue: August 2014 Figure 2: Bonding Principle Page 631 of 926 Modul 7 Welding, Brazing, Soldering and Bonding Cold bonding agents harden by chemical reaction at room temperature (20o C). The time of hardening is 5 seconds up to several days depending on the bonding agent. Hot bonding agents harden in 5 minutes up to several hours when heated to 150o C – 250o C. Some bonding agents require a contact pressure up to 300 N/cm2 for hardening. According to the consistency a distinction can be made between Comparison of Single – Package and Double –Package Systems Single –Package System immediately applicable mixing required can be stored ready for use single - package systems double - package systems. Single – Package System Single - package systems are bonding agents mixed with a solvent. The hardening happens in the air after evaporation of the solvent, also by deoxidization, by humidity or heat. The bonding areas may only be joined when the surface of the applied glue film is dry. PART 66 – Basic Training Cat B1 – Module 7 Double –Package System – no hardener and binder must be mixed prior to bonding process can only be used shortly after mixing, this may lead to loss or waste of material short hardening time – without drying cupboards or heating regard to temperature or bonding appliances are generally pressure necessary only for joints with limited layer for larger surfaces and thicker thickness (max. 1 mm) joint layers easily workable; possibility of automation options are reduced process automation Double – Package System Double - package systems just act by mixing 2 components, bonding and hardening agent. As the hardening process starts early, the mixture has to be used within a certain period of time (pot life). Bonding Strain Refer to Figure 3. The strain of the bonding must always be considered. Tensile strains should be avoided as they unfavourably burden the joint and the tensile strength of the bonding agents is not very high. Peeling strains are extremely unfavourable because they produce tensile stresses in the glue layer. For Training Purposes Only Issue: August 2014 Page 632 of 926 Modul 7 Welding, Brazing, Soldering and Bonding PART 66 – Basic Training Cat B1 – Module 7 Cutting strains should be achieved in connection with tensile, compressive or torsional forces. The strength of the bonding joint also depends on the type of bonding agent, the size of the lap area and thickness of the layer. The thermal resistance exists up to 200o C for phenol resin, for polyamide resin up to 400o C. Bonding Preparation The surfaces of the bonding area have to be pretreated to produce a bonding joint. Dirt has to be removed by degreasing, rinsing and wiping, etc., so that the adhesion works. An active surface is only achieved by slicing additional layers until the ’core material’ is reached. This is achieved by grinding, blasting, etc. The surface should not only be roughened but a perfect wash primer should be created. The operating instructions of the bonding agent state the respective treatment of the bonding areas. The selection of the correct bonding agent is very important. If there are any doubts, make a wetting test, i.e. a drop of glue is applied to the contact surface and the spreading is watched. The larger the spreading, the larger the adhesion. The bonding joint requires a tight contact of the joint parts. Bonding agent and hardening agent are applied to rough surfaces on both sides, to plane surfaces on one side. The layer of the bonding agent should be between 25 and 100 m. Both joint parts must not be displaced until hardening. Many bonding agents require only a light pressure. Contact adhesive requires a higher pressure. The loosening of bonding joints may be performed mechanically by adhesion or cohesion fracture, by stripping or peeling. Loosening may also be done by heating (80o C to 250o C depending on the bonding agent) whereby thermoplastic bonding agents melt, duroplastic bonding agents decompose. For Training Purposes Only Issue: August 2014 Figure 3: Bonding Joints Page 633 of 926 Modul 7 Welding, Brazing, Soldering and Bonding PART 66 – Basic Training Cat B1 – Module 7 Safety Precautions The following safety regulations should always be observed when working with bonding agents: Solvents and adhesives can cause skin reactions. Skin contact, therefore, should be avoided in any way. In the case of skin contact, wash immediately with warm water and soap. When skin reaction persists, consult physician immediately. Do not carry out bonding work near flames. Do not smoke in working area. Gas masks should be worn during extensive bonding work. Always ensure proper ventilation. Solvents adhesives are easily flammable and are potentially explosive. Absolute cleanliness must be observed during every bonding process. For Training Purposes Only Issue: August 2014 Page 634 of 926 Modul 7 Aircraft, Weight and Balancing 7.16 Aircraft, Weight and Balancing 7.16.1 Introduction to Weight and Balance 7.16.1.1 Importance of Weight and Balance An aircraft is a dynamic device that requires a careful balance between all of its forces to maintain safe and efficient flight. The lift produced by the wing is concentrated at a point approx. 1/3 of the way back from the leading edge. To provide stability, the center of gravity (or: that point at which all of the aircraft weight can be considered to be concentrated) is located slightly ahead of this center of lift. This location results in a force that tries to pitch the nose of the aircraft down, but this nose - down force is balanced by a tail load which pulls the nose up. Refer to Figure 1. The amount of tail load is determined by the airspeed, and it drops off when the aircraft slows down. The weight remains constant and ahead of the center of lift, so it pulls the nose down and the aircraft will automatically regain the speed it has lost. Weight and Balance Problems Whenever the center of gravity (CG) falls outside of the rather narrow limits allowed by the aircraft designer, serious control problems will result. These problems concerning the weight and balance fall into three categories: aircraft overload: – the weight of the aircraft is more than maximum – more runway is needed a lower climb angle is required – structural safety factors/limits are reduced For Training Purposes Only PART 66 – Basic Training Cat B1 – Module 7 – stalling speeds will increase – more engine power is required center of gravity is too far forward: – landing will become critical because of the nose –down tendency – stability is decreased – adverse spin characteristics – more engine power is required for steady flight center of gravity is too far aft: – airspeed is decreased – adverse stall characteristics – stability is decreased – more engine power is required. Any of these reasons can result in the loss of the aircraft and the loss of life. Aircraft Weight Definitions and Restrictions Note: All maximum and operational design weights are listed in the certification data sheet and in the flight crew operating manual of each aircraft. The structure of the aircraft is designed to safely accept certain loads. But in flight through rough air and on the impact of a hard landing, the forces due to acceleration may well overload the structure and cause it to fail. When an aircraft is designed, limits are put on its maximum weight, and restrictions are set up regarding the range within which the center of this weight is allowed to vary. A part of the certification procedure for an aircraft is to determine that its weight and balance are within the allowable limits, and this information is furnished with the aircraft as part of its operations manual. Issue: August 2014 Page 635 of 926 Modul 7 Aircraft, Weight and Balancing PART 66 – Basic Training Cat B1 – Module 7 Figure 1: Balancing Tail Load For Training Purposes Only Issue: August 2014 Page 636 of 926 Modul 7 Aircraft, Weight and Balancing PART 66 – Basic Training Cat B1 – Module 7 Maximum Design Weights Refer to Figure 2. Maximum Design Taxi Weight (MTW) The lift from the wings acting upwards together with the weight of the loaded fuselage acting downwards impose a bending moment on the wings. The designed structural strength of the wings limits the maximum weight of the fuselage because the weight of the fully loaded wings will tend to counterbalance the fuselage weight by counteracting the lifting forces. Therefore, the most critical bending would occur with no fuel in the wings and maximum load in the fuselage. This is the maximum permitted weight of the aircraft at which it may be moved, either using its engines or being pushed or towed by a tractor. Maximum Design Take - Off Weight (MTOW) This is the maximum permitted weight at the beginning of the take – off run. The performance requirements laid down for take - off are intended to ensure that a fully loaded aircraft is able to follow a safe flight path out of an airfield. The MTOW is always established for a specific set of atmospheric conditions and a specific runway length. Maximum Design Landing Weight (MDLW) This is the maximum allowable weight at which an aircraft may land. It is usually less than the maximum take - off weight, because the loads and stresses during a landing, i.e. those caused by the touch –down ’impact’ and depending on the vertical velocity, are greater than those during take –off. Maximum Design Zero - Fuel Weight (MZFW) This is the weight of the completely equipped aircraft including persons and/or cargo but without any fuel or other consumable fluids (e.g. water). This weight limit is laid down in order to avoid undue stress especially on the wing structures. Any increase in load beyond this limit must entirely consist of usable fuel and other consumables only. For Training Purposes Only Issue: August 2014 Figure 2: Wing Loads With and Without Fuel Page 637 of 926 Modul 7 Aircraft, Weight and Balancing PART 66 – Basic Training Cat B1 – Module 7 Operational Weights Refer to Figure 3. Basic Weight (BW) Basic weight (or: empty weight) is the weight of an aircraft and engine(s), with all such items of operating equipment installed which have a fixed location. It includes all optional and special equipment. Furthermore, it includes fixed ballast, unusable fuel, full reservoirs of operating fluids including oil, hydraulic fluid and other fluids required for normal operation of aircraft systems except potable water, lavatory precharge water and water intended for injection in the engines. Basic weight can only determined by weighing. Dry Operating Weight (DOW) The sum of the basic weight plus the crew, the crew’s baggage as well as catering loads make up the DOW. The weight of any aircraft spares carried on board will also be added to the DOW. Operating Weight Operating weight is DOW plus the weight of usable take –off fuel plus any engine additive such as demineralised water. Traffic Load Traffic load is the weight of passengers, baggage, cargo and mail. It may include the weight of loading equipment (as per company regulations). The traffic load is further divided into passengers and dead load. For Training Purposes Only Issue: August 2014 Page 638 of 926 Modul 7 Aircraft, Weight and Balancing PART 66 – Basic Training Cat B1 – Module 7 Figure 3: Maximum and Operational Weights For Training Purposes Only Issue: August 2014 Page 639 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Aircraft, Weight and Balancing Allowed Traffic Load This term indicates the payload availability. It is calculated by subtracting the operating weight from the regulated take off weight Refer to Figure 4. It is the responsibility of the pilot to ensure before each flight that his aircraft is properly loaded, that it does not exceed the allowable gross weight and that the center of gravity is within the allowable range. The weight of an aircraft changes during its operational life as equipment is added or removed and as repairs are made. All of these changes must be monitored and the weight and balance information used by the pilot must be kept up to date. This is the responsibility of the aviation maintenance technician. Very close track must be kept of the weight and balance of aircraft used to carry passengers or cargo. They must be reweighed periodically and have their center of gravity recomputed. The fuel tanks of some smaller aircraft are located in the wings, and the seats and baggage compartment are located directly below the wing. So it is not likely that these aircraft will be loaded in such a way that the center of gravity will fall outside of the allowable center of gravity range. Most of the larger aircraft, however, have several rows of seats, some of which are ahead of the center –of –gravity range and some behind it; and there are often both forward and aft baggage compartments. This wide range of loading possibilities requires the use of charts or other aids for the pilot to be sure that the center of gravity is within the allowable range. For Training Purposes Only Figure 4: Example of Center-of-Gravity Limits 7.16.1.2 Purpose of Weight and Balance Control Weight Control For each aircraft the manufacturer has defined an all-up weight (AUW) which must never be exceeded. Otherwise a safe take-off may no longer be ensured. Therefore it is necessary to check an aircraft’s weight regularly. Balance Control Many performance data of an aircraft, e.g. ceiling, manoeuvrability, rate of climb, speed and fuel consumption, are based on the highest possible degree of stability in flight. Issue: August 2014 Page 640 of 926 Modul 7 Aircraft, Weight and Balancing As discussed earlier, the stability is affected by the use of flight controls. Additionally, the distribution of equipment and payload influences the stability in one way or another. E.g. if heavy cargo is stowed in the tail only the aircraft, once airborne, will show the tendency of ’nose up’, i.e. the pilot will have to use the elevator to force the aircraft into a horizontal position thereby producing additional drag. This drag either causes the aircraft to slow down or requires the pilot to increase thrust in order to maintain speed which results in higher fuel consumption. Furthermore the rate of climb and the manoeuvrability will be reduced. All effects mentioned above affect the efficiency of the aircraft considerably. Therefore it is necessary to ensure that an aircraft is ’balanced’, i.e. that equipment and loads are fitted/distributed evenly on board. the playground teeter - totter (or: seesaw), which is a practical example of weight and balance. Refer to Figure 5. When a large child and a small child get on a seesaw, the large child must slide up close to the support (or: the fulcrum), to balance the small child who is farther away from the fulcrum. The distance from the fulcrum to the center of gravity of the weight is called the ’arm’ of the weight, and it may be measured in such units as feet, inches or meters. The amount of force (in this case, the weight of the child) is measured in pounds or kilograms, and is considered to be concentrated at a point called the center of gravity. The mathematical product of weight and arm is the moment of force. It is expressed in pound - feet, pound - inches or in kilogram - meters. Conclusion The primary purpose of weight and balance control is safety. The secondary purpose is to achieve utmost efficiency during flight. lmproper loading or excess weight reduce the efficiency of an aircraft in terms of ceiling, manoeuvrability, rate of climb, speed and fuel consumption. Further results may be overstressed structures and/or a considerable change in flight characteristics. Therefore periodic weighings are necessary and a balance check need to be done every time the aircraft is supposed to take off. 7.16.1.3 PART 66 – Basic Training Cat B1 – Module 7 Note: Distances and weights stated in actual manuals may be given according to international agreements either in m, cm and kg or in inches (”) and pounds (lbs) depending on the location of the manufacturer, i.e. on the country of origin of the aircraft. Similarly, liquids may be given either in liters or, alternatively, in gallons. To avoid confusion, measures used in the following will be given in inches (”) and pounds (lbs) throughout. Since a moment is a force that causes rotation, the direction (either clockwise or counter clockwise) in which the force causes the weight to rotate must be specified. Principles of Weight and Balance The actual principle involved in finding the center of gravity of an aircraft is quite simple, and it is easy to visualise when considering For Training Purposes Only Issue: August 2014 Page 641 of 926 Modul 7 Aircraft, Weight and Balancing PART 66 – Basic Training Cat B1 – Module 7 Figure 5: Example of the Distance from the Fulcrum For Training Purposes Only Issue: August 2014 Page 642 of 926 Modul 7 Aircraft, Weight and Balancing PART 66 – Basic Training Cat B1 – Module 7 To best understand the principles of weight and balance, let us consider that the board used does not have any weight of its own, and that all of the weight is concentrated at the centers of gravity of the weights themselves. Refer to Figure 6. In Figure 6 there is a board on which 2 weights are placed. The weight on the left is 25 lbs, and the one on the right is 50 lbs. There are 120” between the centers of gravity of the 2 weights. The location of the fulcrum about which the 2 weights are in balance is to be calculated. First the location of a datum (or a reference line) is to be chosen from which all measurements are made. This line can be anywhere, but for this initial explanation, it is assumed it to be located at the center of gravity of one of the weights. In this case weight A, the one on the left side, is chosen. Refer to Figure 7. To visualise the computations more clearly, a graph, such as the one shown in Figure 7, can be made. Since weight A is on the datum, its arm is zero. When any number is multiplied by zero, the product is also zero. The arm of weight B is 120”, and its moment is 120 ă 50 = 6,000 pound –inches and its direction of rotation is clockwise. For Training Purposes Only Issue: August 2014 Page 643 of 926 Modul 7 Aircraft, Weight and Balancing PART 66 – Basic Training Cat B1 – Module 7 Figure 6: Lever Problem Using Weight A as the Datum Figure 7: Chart Showing the Lever Problem of Figure 6 For Training Purposes Only Issue: August 2014 Page 644 of 926 Modul 7 Aircraft, Weight and Balancing PART 66 – Basic Training Cat B1 – Module 7 To find the balance point, the fulcrum, the total moment must be divided by the total weight. The total moment is 6,000 pound - inches, and the total weight is 75 lbs. This places the balance point 80 inches to the right of the datum. In this example, there are no counter clockwise moments and so the total moment is clockwise. Refer to Figure 8. To check the result and prove that the board is really balanced about the calculated point a graph similar to that in Figure 8 is made. Here the datum is moved from the center of gravity of weight A to the fulcrum, and all of the moments are calculated again based on this new location. Any counter clockwise moment is considered to be negative, and a moment that causes a clockwise rotation is positive. Weight A has an arm of minus 80”, and its moment is - 2,000 pound inches. The arm of weight B is plus 40”, and when this is multiplied by the weight, it gives a moment of +2,000 pound - inches. The sum of the moments is zero, which means that the board does actually balance about the fulcrum. Figure 8: Fulcrum Used as Datum For Training Purposes Only Issue: August 2014 Page 645 of 926 Modul 7 Aircraft, Weight and Balancing Refer to Figure 9. PART 66 – Basic Training Cat B1 – Module 7 rotate the board in a clockwise direction. The moment of this force is +550 pound-inches. It can easily be seen that the datum can be placed anywhere when working this same problem, using actually 2 different locations for the datum. In Figure 9, the datum is placed between the 2 weights, 30” to the right of weight A. The arm of A is now - 30”, and its moment is – 750 pound-inches. The arm of weight B is +90”, and its moment is +4,500 pound-inches. The total moment is +3,750 pound-inches and the weight is 75 lbs. So the balance point is 50” to the right of the datum, which places it in exactly the same location as previously found, i.e. 80” to the right of A. Refer to Figure 10. Some aircraft manufacturers place the datum a given distance ahead of the aircraft so all of the moments will be positive. As can be seen from the example in Figure 10, this does not change the result. The datum in this example is located 60” to the left of weight A, and the moment of A is +1,500 pound-inches. Weight B is 180” from the datum, and its moment is +9,000 pound-inches. The total moment is +10,500 pound-inches. When this is divided by the total weight of 75 lbs, the balance is found to be 140” to the right of the datum. This again is the same location as found in the previous 2 computations, i.e. 80” to the right of weight A. Refer to Figure 11. The teeter - totter explanation can be continued to find where a third weight C should be placed to balance the board. Figure 11 shows a board on which the weights D and E are placed. Since the moment of weight E is greater than that of D, there will be a net force tending to For Training Purposes Only Figure 9: Simple Lever Problem, Placing the Datum between Weight A and the Fulcrum Issue: August 2014 Page 646 of 926 Modul 7 Aircraft, Weight and Balancing Figure 10: Lever Problem Placing the Datum to the Left of the Lever For Training Purposes Only Issue: August 2014 PART 66 – Basic Training Cat B1 – Module 7 Figure 11: Balancing the Lever with a Third Weight Page 647 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Aircraft, Weight and Balancing Refer to Figure 12. The board shall be balanced by placing weight C (having 50 lbs) at the correct distance from the fulcrum. Weight C must have a moment of –550 pound –inches, because for the board to be in balance about a point, the sum of the moments about that point must be zero. Therefore the moment of C must be –550 pound –inches. Because of its weight of 50 lbs, its arm must be –11”, or: the center of weight C must be 11” to the left of the fulcrum. Figure 12 shows that the sum of the 2 negative moments is –1,800 pound –inches, and the positive moment is +1,800 pound –inches, so the board is in balance. The total weight is 480 lbs, and the balance point shall be shifted by 5”. The arm of the ballast is 170”, and the arm of the new balance point is 42.5”. Therefore: Ballast = = ((380+100)∙5)/(170-42.5) 2,400/127.5 = 18.82 Ibs By calculation it is found out that 18.82 lbs of ballast must be added at 170” away from weight A to move the balance point 5” to the right. It is necessary for an aircraft center of gravity to fall within a given range, and sometimes ballast must be added to the aircraft to move the empty –weight center of gravity into the allowable range. Again, the board can be used to see the way how this is done. Refer to Figure 13. Assuming that the board in Figure 13 is in balance at a point 37.5” from weight A, but the board should be in balance at a point 42.5” away from A. Weight B is 180” from weight A. There is a location 170” from A at which the ballast weight can be placed. The problem is to find the amount of weight which has to be added 170” away from weight A in order to move the point of balance 5” to the right. The formula to be used is: ballast = 𝑡𝑜𝑡𝑎𝑙 𝑤𝑒𝑖𝑔ℎ𝑡 ∙ 𝑑𝑖𝑠𝑡𝑎𝑛𝑐𝑒 𝑛𝑒𝑒𝑑𝑒𝑑 𝑡𝑜 𝑠ℎ𝑖𝑓𝑡 𝑏𝑎𝑙𝑎𝑛𝑐𝑒 𝑝𝑜𝑖𝑛𝑡 𝑎𝑟𝑚 𝑜𝑓 𝑏𝑎𝑙𝑙𝑎𝑠𝑡 − 𝑎𝑟𝑚 𝑜𝑓 𝑑𝑒𝑠𝑖𝑟𝑒𝑑 𝑏𝑎𝑙𝑎𝑛𝑐𝑒 𝑝𝑜𝑖𝑛𝑡 For Training Purposes Only Issue: August 2014 Page 648 of 926 Modul 7 Aircraft, Weight and Balancing PART 66 – Basic Training Cat B1 – Module 7 Figure 12: Proving the Balance Found in Figure 11 For Training Purposes Only Issue: August 2014 Page 649 of 926 Modul 7 Aircraft, Weight and Balancing PART 66 – Basic Training Cat B1 – Module 7 Figure 13: Determining the Amount of Ballast For Training Purposes Only Issue: August 2014 Page 650 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Aircraft, Weight and Balancing Refer to Figure 14. The result can be checked as shown in Figure 14. The sum of all moments about the new balance point is zero, so the correct amount of ballast has been added. Item A has a weight of 380 lbs, and it is located at an arm of - 42.5”. This gives a moment of - 16,150 pound-inches. Item B has a weight of 100 lbs and an arm of +137.5”, giving a moment of +13,750 poundinches. The ballast weighs 18.82 lbs and is located at +127.5, and so the moment is +2,400 pound-inches. The total positive moment is +16,150 pound-inches and the total negative moment is - 16,150 pound-inches. The sum of the moments about the new balance point is zero, so the ballast weight is correct. 7.16.1.4 Terms Used in Weight and Balance In any branch of technology, there are certain technical terms which the technician must be familiar with before he can really understand the subject. The following terms and definitions are commonly used in weight and balance. Aerobatic Category Aircraft Such an aircraft is certificated and approved for flight without restrictions other than those shown to be necessary as a result of a flight test. Arm Figure 14: Proving the Amount of Ballast Determined in Figure 13 For Training Purposes Only The arm is the horizontal distance from the location of an item of equipment from the reference datum. The length of the arm is given or measured in m, cm or inches. It is preceded by the plus (+) or minus (–) sign except for a location which is exactly on the datum plane. The plus sign indicates a distance aft of the reference datum, the minus sign indicates a distance forward of the datum plane. Issue: August 2014 Page 651 of 926 Modul 7 Aircraft, Weight and Balancing PART 66 – Basic Training Cat B1 – Module 7 In the aircraft’s specification the arm of each item is usually inserted in parentheses immediately behind its designation or weight, e.g. ’seat (+23)’. When such information is not given, it must be obtained by actual measurement. The location of the CG is normally specified as being a given distance from the datum. Balance Point They are the maximum forward and aft location allowable for the center of gravity. These limits are established by the designer of the aircraft and are approved by the Federal Aviation Administration. They are furnished to the aviation maintenance technician and to the pilot, and it is the responsibility of the pilot to see that these limits are never exceeded in flight. A balance point is the point about which a body balances and the point about which the algebraic sum of all of the moments is zero. The balance point and the center of gravity are physically the same point, but the location of the center of gravity is normally measured from the datum, while the location of the balance point is measured from one of the weighing points. Center – of – Gravity Limits Center – of – Gravity Range Ballast This is the weight that is installed in an aircraft for the purpose of bringing the center of gravity into the desired range. Permanent ballast must not be removed without changing the aircraft empty weight center of gravity as recorded in the aircraft weight and balance records. Temporary ballast may be added, removed or moved within the aircraft to bring the center of gravity into the desired range for a specific flight condition. Center of Gravity Theoretically, the center of gravity (CG) is the point through which the total mass of an aircraft is said to act. It is also the point at which the forward-acting moments and the aft-acting moments are exactly equal in magnitude. An aircraft being suspended (or supported) at this point will be balanced, i.e. it will not have any tendency to rotate or to move in either a ’nose up’ or ’nose down’ attitude. For Training Purposes Only The distance between the forward and the aft center of gravity limits of an aircraft. An aircraft is forbidden to be operated if its center of gravity does not fall within this range. Datum The datum (or: reference datum) is an imaginary vertical plane at right angles to the longitudinal axis of an aircraft. It is chosen at random and used to take all horizontal measurements for balance purposes. During this procedure the aircraft is fixed in straight level flight attitude. For each type of aircraft all locations of equipment, tanks, baggage compartments, seats, engines, propellers etc. are listed in the aircraft specification (or in type certificate data sheets) together with their distances from the reference datum. Issue: August 2014 Page 652 of 926 Modul 7 Aircraft, Weight and Balancing There is no fixed rule for the location of the datum. In most cases it is located at the nose of the aircraft or in another predominant point of the aircraft structure itself. The manufacturer has the choice of locating the datum at a position where it is most convenient for measurement, locating equipment and weight and balance computations. Once the datum plane is selected it must be properly identified in order not to leave any doubt about the exact location. PART 66 – Basic Training Cat B1 – Module 7 Levelling Means The method specified by the aircraft designer by which the technician can determine that the aircraft is properly levelled for weighing. This information is included in the aircraft specifications or in the type certificate data sheets. Moment The moment is the turning effect about a fulcrum caused by the lever arm and the weight of an item. The value of the moment is the mathematical product of the weight and the length of the arm. Delta The Greek letter ∆ (delta) is used in weight and balance computations to indicate a change in values. For example, ∆ CG indicates a change in the center of gravity. The moment of an item about the reference datum is obtained by multiplying the actual weight of the item (or the load, fuel etc.) by its horizontal distance from the datum plane. Empty –Weight Center – of – Gravity Range Refer to Figure 15. This range defines the most forward and most rearward empty weight center of gravity locations that will not allow the center of gravity of a legally loaded aircraft to fall outside of the loaded center of gravity range. Whether the value found is preceded by a plus or a minus sign depends on whether the moment is the result of a weight having been removed or added and on its location in relation to the datum plane. The value of any weight added to the aircraft on either side of the reference datum is preceded by a ’+’, the value of any weight removed is preceded by a’ –’. Fulcrum A fulcrum is the support about which a lever rotates. Fuel Load ’Fuel load’ means the expendable part of the fuel carried in an aircraft. It includes only the usable fuel, not the fuel in the lines or that part of the fuel which remains in the tank sumps. For Training Purposes Only Example: A weight of 20 lbs located at a distance of 30” from the reference datum has a moment of 20 lbs ă 30” = 600 pound-inches. The arm of a weight ahead of the datum is negative (–) and that behind the datum is positive (+). When the signs of the arm and the weight are alike, both either plus or minus, the moment will be positive. But if the signs are different, the moment will be negative. Issue: August 2014 Page 653 of 926 Modul 7 Aircraft, Weight and Balancing Moments found to have a ’+’ always create a ’nose up’ effect, moments with a minus sign always produce a ’nose down’ tendency. PART 66 – Basic Training Cat B1 – Module 7 Net Weight Net weight is the scale reading less the tare weight. Normal Category Aircraft Such an aircraft is certificated and approved for non - aerobatic flight operations. Payload ’Payload’ is that portion of the useful load of an aircraft from which any type of revenue may be derived. It includes passengers and baggage/cargo. For military aircraft, payload includes weapons, cameras and e.g. ECM pods (chaffs, jammer etc.). Standard Weights For general weight and balance purposes the following weights are considered as standard: gasoline: 6.0 lbs per gallon turbine fuel: 6.7 lbs per gallon lubricating oil: 7.5 lbs per gallon water: 8.35 lbs per gallon crew and passengers: 170.0 lbs per person. Note: EASA - OPS, JAR - OPS1 and FAR 135, which cover commercial air transport operators, have added a few more standard weights, e.g. for adults, children, checked –in and hand luggage. Figure 15: Moment about a Reference Datum For Training Purposes Only Issue: August 2014 Page 654 of 926 Modul 7 Aircraft, Weight and Balancing PART 66 – Basic Training Cat B1 – Module 7 Station Utility Category Aircraft A ’station’ is a location in an aircraft which is identified by a number denoting its distance in inches from the datum. Such an aircraft is certificated and approved for limited aerobatic operations. Weighing Points Tare This is the weight of all items such as chocks or blocks that are used to hold the aircraft on the scales while it is being weighed. The tare must be subtracted from the scale reading to find the net weight of the aircraft. There are specified points on an aircraft where the scales are placed for weighing the aircraft. Unusable Fuel That portion of the fuel in an aircraft fuel system that will not flow to the carburettor or fuel metering system in normal flight attitudes. The amount and location of this fuel is specified in the specification sheets or in the type certificate data sheets. Undrainable Oil That portion of the oil in an aircraft lubricating system that will not drain out when the drain plug is removed or when the drain valve is opened with the aircraft in its normal ground attitude. Useful Load It includes the weight of the pilot, co - pilot, passengers, baggage, usable fuel and drainable oil. It is actually the empty weight of the aircraft subtracted from the maximum allowable gross take off weight. For Training Purposes Only Issue: August 2014 Page 655 of 926 Modul 7 Aircraft, Weight and Balancing 7.16.2 Weight and Balance Procedures 7.16.2.1 Weighing Procedure PART 66 – Basic Training Cat B1 – Module 7 specified in the type certificate data sheet, is deducted from the weight of the aircraft as weighed. Note: Not all aircraft are weighed to the same procedure. Therefore the manufacturer’s maintenance publication must always be consulted! The oil tanks or sumps of the aircraft should be filled to the ’full’ mark or drained (whatever is prescribed in the aircraft documentation). Since the amount of oil is quite small compared with the amount of fuel carried on board, it is not necessary to calculate the weight change of the oil caused by temperature changes. Preparation Refer to Figure 1. Because of the large surface area of an aircraft, it is possible for it to accumulate enough dirt to give an inaccurate result. When the aircraft is prepared for weighing, it should be washed and all accumulation of dirt and debris should be removed from the inside. lf it is required but impractical to drain, the oil tanks should be properly filled and the weight recorded according to the manufacturer’s details. On many aircraft the position of flight controls and the cabin layout (cabin configuration) are also essential to be checked prior to weighing and the results noted in the aircraft specification or information data base of the maintenance organisation. The equipment list should be checked to be sure that all of the required aircraft equipment is actually installed, and that there is nothing installed that is not on the equipment list. Loose equipment (e.g. oxygen masks, emergency equipment) should be stowed in the correct place (compartments, hatches). The hydraulic reservoir should be full, and if the aircraft is equipped with an anti - icing system, the anti - icer fluid tank should also be full. The fuel tanks should be drained, and only the unusable fuel should be in the aircraft when it is weighed. This unusable fuel is part of the aircraft empty weight. If it is impractical to drain the fuel tanks, they may be filled completely. The temperature of the fuel is taken when the aircraft is weighed, and a correction is applied to compute the actual weight of the fuel on board. This total fuel weight minus the weight of the usable fuel, as For Training Purposes Only Issue: August 2014 Page 656 of 926 Modul 7 Aircraft, Weight and Balancing PART 66 – Basic Training Cat B1 – Module 7 Weighing Equipment There are two types of equipment that may be used to weigh an aircraft: platform scales electronic load cells. Platform Scales Refer to Figure 2. Platform scales are normally used for smaller aircraft. The aircraft are lifted off the floor with jacks and are lowered onto platform scales with a scale under each wheel. These scales are specially built with low beams so they will fit under the wing of low wing aircraft. Chocks are used on the scale platform to prevent the aircraft from rolling, as the brakes must be released to prevent an uneven application of force to the platform. The weight of the chocks is called the ’tare weight’, and it must be subtracted from the scale reading to get the net weight of the aircraft. Figure 1: Aircraft Weighing Configuration For Training Purposes Only Issue: August 2014 Page 657 of 926 Modul 7 Aircraft, Weight and Balancing PART 66 – Basic Training Cat B1 – Module 7 Refer to Figure 3. The aircraft is levelled according to the levelling instructions in the type certificate data sheet. The level of some aircraft is determined by placing a spirit level across two screws on the side of the fuselage, while others are levelled by dropping a plumb bob from a specified screw, usually located in the cabin door frame. Longitudinal level is the most important condition, but the aircraft should be laterally levelled as well. If the aircraft is weighed on the jacks, it may be levelled by adjusting the extension of the jacks. But if it rests on its landing gear on the scales, fine adjustment of the level may be made by changing the amount of inflation of the tyres or of the shock struts. Note: It is extremely important when jacking or weighing an aircraft that thr recommendations of the aircraft manufacturer (AMM Chapter 08) befollowed indetail, as the procedures required for each aircraft differ. When the aircraft is on the scales and is level, plumb bobs may be dropped from the datum and from the weighing points so that lines may be chalked on the floor from which accurate measurements can be made to determine the center of gravity. Figure 2: Platform Scales Electronic Load Cells Electronic load cells are used to weigh larger aircraft. Such aircraft are weighed by placing load cells between the jack and the jack pad on the aircraft. These load cells are strain - gauge capsules whose resistance changes proportionally to the amount of load that is imposed on them. An electronic bridge circuit converts this change in resistance into a readout. For Training Purposes Only The aircraft make and model together with its serial number are written down as well as the location of the datum as found in the aircraft documentation. Issue: August 2014 Page 658 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Aircraft, Weight and Balancing Recording of Data Refer to Figures 4 and 5. A weighing form is useful to systematically collect and record all information required to obtain the empty weight CG. Figure 3: Levelling an Aircraft For Training Purposes Only Figure 4: Typical Weighing Form Issue: August 2014 Page 659 of 926 Modul 7 Aircraft, Weight and Balancing PART 66 – Basic Training Cat B1 – Module 7 Figure 5: Weighing Form (Example) For Training Purposes Only Issue: August 2014 Page 660 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Aircraft, Weight and Balancing Any unusual weighing conditions are to be recorded, e.g. whether or not any fuel or oil were on board during weighing. The amount of fuel and its temperature should be recorded, as well as the amount of oil. The location of the weighing points should be specified in inches or mm forward or aft of the datum. The scale reading is taken and recorded for both the left and right main weighing points and for the nose or tail point. The weight of any tare used to hold the aircraft on the scales is subtracted from the scale reading to get the net weight at each of the three weighing points. The distance between the datum and the weighing points as measured along the floor is recorded in the column ’arm’. If the weighing point is ahead of the datum, the arm is negative, if it is behind the datum, the arm is positive. The moments to be calculated are the products of the arms (in mm or inches) times the net weights (in kg or pounds). The moments are expressed as pound-inches or mm-kg. Finally, the total moment, i.e. the sum of the moments, is divided by the total weight (i.e. the sum of the scale readings) to obtain the arm of the CG. Note: If the aircraft was not weighed empty, the weights and moments of any additional fluids and/or equipment must be calculated separately, recorded and subtracted from the ’as - weighed’ values to get the empty weight CG of the aircraft. The weighing form is completed by stating the maximum allowable gross weight as found in the type certificate data sheet. The difference between the maximum allowable gross weight and the empty weight is the useful load. The information is made valid by the technician signing the weighing form and including his certificate number and the date the aircraft was weighed. 7.16.2.2 Finding the Center of Gravity Locating the Balance Point It is convenient to calculate the position of the balance point by using the center line of the main wheels as datum. After the balance point has been located, it is easy to relate this position to the original datum. Refer to Figure 6. The ’as - weighed’ weight, arms and moments of the fuel are recorded in the lower chart. Since theses weights are to be subtracted from the weight of the aircraft, they are negative; and if their arm is negative, the moment will be positive. But if the arm is positive, the moment will be negative. The algebraic sum of the moments is recorded in the bottom line of the ’moments’ column. The total net weight is the sum of the three scale readings less the tare weight. The total moment divided by the total weight is the arm of the center of gravity. For Training Purposes Only A chart is made and since the main wheels are used as the datum, their arm and their moment will both be zero. The weight and arm of the nose wheel are recorded. The balance point is found by dividing the total moment by the total weight. In our illustration, the balance point is found to be 14.54 inches ahead of the center line of the main wheels. Issue: August 2014 Page 661 of 926 Modul 7 Aircraft, Weight and Balancing PART 66 – Basic Training Cat B1 – Module 7 Locating the Center of Gravity Aircraft with Nose Wheel (Tricycle Landing Gear) Datum ahead of the Main Wheels Refer to Figure 7. If the datum is located ahead of the main wheels, the distance of the center of gravity from the datum may be found by subtracting the distance between the main wheels and the balance point from the distance between the datum and the main wheels. The formula to be used is: CG = distance (datum to mains) – distance (mains to balance point) Datum behind the Main Wheels Figure 6: Finding the Balance Point of an Aircraft from the Weighing Points For Training Purposes Only Issue: August 2014 Page 662 of 926 Modul 7 Aircraft, Weight and Balancing PART 66 – Basic Training Cat B1 – Module 7 The formula to be used is: CG = distance (datum to mains) distance (mains to balance point). Aircraft with Tail Wheel Datum ahead of the Main Wheels Figure 7: Datum Ahead of the Main Wheels Refer to Figure 8. If the datum is located behind the main wheels, the distance of the center of gravity from the datum is found by adding the distance between the main wheels and the balance point to the distance between the datum and the main wheels. For Training Purposes Only Figure 8: Datum behind the Main Wheels in an Aircraft with Nose Wheel Issue: August 2014 Page 663 of 926 Modul 7 Aircraft, Weight and Balancing PART 66 – Basic Training Cat B1 – Module 7 Refer to Figure 9. If the aircraft has a tail wheel, the balance point is behind the main wheels, and if the datum is located ahead of the main wheels, the distance of the CG can be found by adding the distance between the balance point and the center - line of the main wheels to the distance from the datum to the main wheels. The formula to be used is: CG = distance (datum to mains) distance (mains to balance point). Datum behind the Main Wheels Figure 9: Datum Ahead of the CG (Tail Wheel Aircraft) For Training Purposes Only Issue: August 2014 Page 664 of 926 Modul 7 Aircraft, Weight and Balancing PART 66 – Basic Training Cat B1 – Module 7 Refer to Figure 10. If the datum is located behind the main wheels of a tail –wheel aircraft, the distance of the CG from the datum is found by subtracting the distance between the main wheels and the balance point from the distance between the main wheels and the datum. The formula to be used is: CG = distance (datum to mains) – distance (mains to balance point). Figure 10: Datum behind the CG (Tailwheel Aircraft) For Training Purposes Only Issue: August 2014 Page 665 of 926 Modul 7 Aircraft, Weight and Balancing 7.16.2.3 Center –of –Gravity Range PART 66 – Basic Training Cat B1 – Module 7 If the aircraft can be made to fall outside the loaded CG range, it must be placarded to prevent the pilot from loading the aircraft improperly. In extreme cases, fixed ballast may be installed in the aircraft to prevent it from falling outside of the empty-weight CG range. Refer to Figure 11. When an aircraft is designed, the engineers determine the most forward and the most rearward location for the center of gravity that will allow the aircraft to have all of the required flight characteristics. These locations are measured as percentages of the mean aerodynamic chord (MAC), or in engineering terms, in % MAC (detail a)). In order for this information to be usable to the technician, it is given to him in terms of inches from the datum (detail b)). Empty –Weight Center –of –Gravity Range Some smaller aircraft, whose fuel tanks are located in the wing and whose two seats are side by side with a small baggage compartment immediately behind the seats, have such a limited movement of the center of gravity that the manufacturer includes an empty weight CG range in the specification sheets. Refer to Figure 12. Figure 12 shows that the empty weight center of gravity range is inside the loaded center of gravity range. If the empty weight CG of the aircraft falls within the empty weight CG range, the aircraft cannot be legally loaded in such a way that it’s center of gravity in flight will fall outside the loaded CG range. If the empty weight CG does not fall within the allowable empty – weight range, the technician must calculate an adverse loaded center of gravity condition. Figure 11: Center-of-Gravity Range For Training Purposes Only Issue: August 2014 Page 666 of 926 Modul 7 Aircraft, Weight and Balancing PART 66 – Basic Training Cat B1 – Module 7 gravity range. But on their type certificate data sheets they have a center of gravity graph, such as the one shown in Figure 13, usually including the figures on which the graph is based. Up to a gross weight of 5,150 lbs, the forward CG limit is +128” and the aft limit is +139.2”. At a gross weight of 6,725 lbs, the forward limit is +134.2” with the aft limit still being +139.2”. The forward limit moves back in a straight line between these two values. Note: At a gross weight of 6,400 lbs the forward limit is +133.0” and the aft limit is +139.2”. Center of Gravity in Aircraft with Landing Gear Retracted Refer to Figure 14. When the landing gear is retracted there is a moment change of +857 pound-inches (due to the change of the relevant arms). If the center of gravity at 6,400 lbs is +135 inches with the landing gear down, a moment of +857 pound-inches must be added when the landing gear is retracted. Figure 12: Operational Center of Gravity When the total weight (still 6,400 lbs) is divided to get the new moment, it can be seen that the CG has moved rearwards to +135.134”. Loaded Center –of –Gravity Range Refer to Figure 13 again. Center of Gravity in Aircraft with Landing Gear Extended Refer to Figure 13. Large aircraft having several rows of seats and with both forward and aft baggage compartments do not have an empty weight center of For Training Purposes Only The aircraft shown in Figure 13 has a ramp weight of 6,819 lbs and a gross maximum take off and landing weight of 6,725 lbs. This means that the aircraft can be loaded with 15.7 gallons of fuel above the maximum take off and landing weight. This is only 7.8 gallons per engine which will be used by the time the aircraft taxies to the take off position. Issue: August 2014 Page 667 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Aircraft, Weight and Balancing Figure 14: Center-of-Gravity Change when the Landing Gear is retracted 7.16.2.4 Shifting the Center of Gravity Permanent Ballast Refer to Figure 15. Figure 13: Center-of-Gravity Graph for Aircraft with Landing Gear Extended For Training Purposes Only If an aircraft has been altered in such a way that its center of gravity is outside of its allowable range, it may be brought back into range by adding permanent ballast. If ballast is needed, it should be installed with an arm as long as possible so the required weight will be minimum. The aircraft structure to which the ballast is attached must be strong enough to support the weight under all flight conditions. Ballast is normally painted red and marked ’Permanent Ballast – Do Not Remove.’ Issue: August 2014 Page 668 of 926 Modul 7 Aircraft, Weight and Balancing PART 66 – Basic Training Cat B1 – Module 7 Figure 15 shows an example of a small two seater aircraft after its engine has been changed. This moved the center of gravity to a position 2” ahead of the forward empty weight CG limit. In order to bring the center of gravity back within limits, a bar of lead may be attached to the tailpost. To determine the amount of lead needed, the out of range moment is divided by the arm of the ballast from the desired CG position: ballast weight = total weight ∙ distance out of limits 𝑑𝑖𝑠𝑡𝑎𝑛𝑐𝑒 𝑏𝑒𝑡𝑤𝑒𝑒𝑛 𝑏𝑎𝑙𝑙𝑎𝑠𝑡 𝑎𝑛𝑑 𝑑𝑒𝑠𝑖𝑟𝑒𝑑 𝑏𝑎𝑙𝑎𝑛𝑐𝑒 𝑝𝑜𝑖𝑛𝑡 In order to move the center of gravity from +22” to +24”, a weight of 11.1 lbs must be installed at the tailpost. Figure 15: Calculation of Additional Permanent Ballast For Training Purposes Only Issue: August 2014 Page 669 of 926 Modul 7 Aircraft, Weight and Balancing PART 66 – Basic Training Cat B1 – Module 7 Temporary Ballast Refer to Figure 16. For certain flight conditions, it may be necessary to carry temporary ballast to keep the aircraft within the allowable CG limits. Some tandem seat trainers must be flown solo from the rear seat because, with one occupant in the front seat and a full tank of fuel ahead of the front seat, the center of gravity will be ahead of the forward limit. If a pilot wants to fly solo from the front seat, he must carry enough ballast in the baggage compartment behind the rear seat to bring the loaded CG into range. The formula used is the same as was used to find the amount of permanent ballast required. Example: The center of gravity shall be moved 2” rearwards. The loaded weight of the aircraft is 1.045 lbs and the loaded center of gravity is +10”. The center of the baggage compartment is 36” behind the forward CG limit. By calculation, it is found out that a weight of 58 lbs must be carried in the baggage compartment for solo flight from the front seat. This ballast must be clearly marked, stating that it is to be carried in the aircraft only when the aircraft is being flown solo from the front seat. Note: As a practical consideration, it must be assured that the baggage compartment is structurally strong enough to carry this amount of weight. Figure 16: Calculation of Temporary Ballast For Training Purposes Only Issue: August 2014 Page 670 of 926 Modul 7 Aircraft, Weight and Balancing PART 66 – Basic Training Cat B1 – Module 7 Shifting Weight Refer to Figure 17. Large aircraft having several rows of seats and more than one baggage compartment may be kept in balance without adding ballast, by shifting some of the weight that is carried. For example, in Figure 17, there is a large aircraft with a baggage compartment at station 26 and one at station 246. Note: Stations (or: station lines) are vertical reference lines which are used to locate main assemblies and parts of the structure. Station numbers indicate the distance in inches from a line of origin, the datum. This line of origin is designated as ’station 0’. The question is to find out how much weight is to be shifted to get the center of gravity moving 1.5” rearwards. The ratio of the weight shifted to the total weight of the aircraft is proportional to the ratio of the required change of the center of gravity to the distance the weight is shifted: weight shifted required change of center of gravity = total weight distance Using the above formula, it can be found out that by shifting 55.9 lbs of baggage from the front to the rear baggage compartment, the CG is moved 1.5” rearwards. Figure 17: Moving the Operational Center of Gravity by Shifting Weight For Training Purposes Only Issue: August 2014 Page 671 of 926 Modul 7 Aircraft, Weight and Balancing PART 66 – Basic Training Cat B1 – Module 7 an The radio that is to be installed has a (positive) weight of +9 lbs at a positive arm of +49”. One of the most important weight and balance problems is to find the new empty weight and empty weight CG after an alteration (i.e. a permanent removal or installation) was carried out to the aircraft. The anti - collision beacon has a weight of +4 lbs at an arm of +127”. The sum of the positive moments is +107,209 pound–inches. The negative moments are - 1,816 pound–inches. This gives a total moment of +105,393 pound–inches. Normally, if the weights of the item(s) installed or removed from the aircraft are known and the location of the alteration is known, a new empty weight and empty weight CG can be calculated without having to re weigh the aircraft. The new total weight is 2,009 lbs. When the total moment is divided by the total weight, the new empty weight CG is found to be 52.46” aft of the datum. 7.16.2.5 Weight and Alteration Balance Changes after Refer to Figure 18. Example: An alteration is to be carried out as follows: removal of an old radio from the instrument panel along with its power supply that is mounted in the baggage compartment installation of a smaller radio in the instrument panel; this new radio does not require a separate power supply installation of an anti collision beacon on top of the vertical stabiliser. Figure 18, detail b), shows the chart to compute the change in the empty weight and in the empty weight CG. The empty weight of the aircraft is 2,024 lbs, the arm of its empty weight CG is +52.5”. The radio that is removed from the instrument panel has a (negative) weight of –16 lbs at an arm of +49”. The power supply weight is also negative, –12 lbs, at an arm of +86”. For Training Purposes Only Issue: August 2014 Page 672 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Aircraft, Weight and Balancing 7.16.2.6 Checklist for Aircraft Weighing Preparations Thoughtful preparation saves time and reduces mistakes. First of all, assemble all necessary equipment, e.g. – Scales – hoisting equipment – jacks – levelling equipment – applicable aircraft specifications (e.g. type certificate data sheet) – applicable weight and balance computation forms. lf possible, the aircraft should be weighed in a closed building where air movements cannot cause incorrect scale readings. Consult the aircraft manufacturer’s instructions to determine whether the aircraft should be weighed with full fuel tanks or with the fuel drained. Consult the aircraft manufacturer’s instructions to determine whether the aircraft should be weight with full oil tanks/sumps or with the oil drained. When draining the engine oil from the oil tanks, the system should be drained with all drain valves open. Under these conditions the amount of oil remaining in the oil tanks, pipes and in the engine is termed ’residual oil’ which is included in the empty weight. Inspection of Aircraft Figure 18: Weight and Balance Changes Resulting from an Alteration For Training Purposes Only Issue: August 2014 lnspect the aircraft to ensure that all items and equipment included in the certified empty weight are securely fitted in their correct location. Remove all items which are not regularly carried in flight. Replace all inspection panels, oil and fuel tank caps, cowlings, doors, emergency exits, etc. Page 673 of 926 Modul 7 Aircraft, Weight and Balancing Inspection of Weighing Equipment PART 66 – Basic Training Cat B1 – Module 7 Calculation Properly calibrate the scales to ’zero’ (check last calibration date). Use the weighing scales in accordance with the manufacturer’s instructions. Some aircraft are not weighed by placing the wheels on the scales but with the scales being placed either at the jacking points or at special weighing points. Fix the aircraft by using chocks. Care must be taken to level the aircraft properly, especially about the longitudinal axis. Gross Weight and Center of Gravity Gross weight and CG location of the loaded aircraft is obtained by first determining the empty weight and the empty weight center of gravity location. When these data are known the effect of fuel, crew, passengers, cargo and expendable weight can be computed by adding all the weights and moments of these additional items and recalculating the center of gravity for the loaded aircraft. The empty weight CG is found by the following calculations: Weighing Refer to Figure 19. After the aircraft has been placed on the scales and levelled, fix plumb bobs at the reference datum, at the main weighing points and at the tail or nose weighing point in such a way that the tips of the plumb bobs touch the floor. Mark the contact points on the floor with chalk. If desired a chalk line may be drawn connecting the marks. This will give a clear pattern of the weighing points’ distances to the reference datum. Record the weights indicated at each of the scales and take the necessary measurements while the aircraft is levelled. A standard weighing form is to be used for recording. When all weight and measurement values have been recorded the aircraft may be removed from the scales. Weigh the tare (e.g. the chocks) and deduct its weight from the scale reading at each respective weighing point where tare was involved. For Training Purposes Only First the moments have to be calculated by using the formula: net weight - arm. Issue: August 2014 Page 674 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Aircraft, Weight and Balancing Loaded Aircraft Calculations The CG location is found by calculating the total moments using the following formula: Moment = net weight ∙ arm. Weighing point Left main wheel Right main wheel Nose wheel Total Net weight (pounds) 617 614 152 1,383.0 ∙ ∙ ∙ Arm (inches) 68” 68” –26” = = = Moment (pound inches) 41,956.0 41,752.0 –3,952.0 79,756.0 Then calculate the center of gravity by dividing the sum of the moments by the total weights involved: 𝑐𝑒𝑛𝑡𝑒𝑟 𝑜𝑓 𝑔𝑟𝑎𝑣𝑖𝑡𝑦 = 𝑡𝑜𝑡𝑎𝑙 𝑚𝑜𝑚𝑒𝑛𝑡 79,756.0 = 𝑡𝑜𝑡𝑎𝑙 𝑤𝑒𝑖𝑔ℎ𝑡 1,383.0 Consequently the center of gravity as weighed is 57.67” from the datum. Since the aircraft was weighed with the oil tank full it is necessary to subtract the weight and arm of oil to obtain the empty weight and the empty weight center of gravity (EWCG). These values will be recorded in rows eight (8) and nine (9) of the form (see overleaf): Figure 19: Weighing Procedure (Example) For Training Purposes Only Issue: August 2014 Page 675 of 926 Modul 7 Aircraft, Weight and Balancing Weight point Net weight (pounds) Aircraft total as weighed 1,383.0 ∙ Minus oil, 8 gallons at 7.5 lbs per gallon –60.0 Total ∙ Arm (inches) = 79,756.0 –30.00 = 1,800.0 1,383.0 the CG limits, provided standard loading and seating arrangements are used. Moment (pound inches) 57.67 PART 66 – Basic Training Cat B1 – Module 7 Refer to Figure 20. 81,556.0 By using the above formula again, the EWCG is found as being 61.64” from the datum. Critical Balance Points An aircraft has certain fixed points, fore and aft, beyond which the center of gravity should not be permitted at any time during flight. A check should be made to ensure that the CG will not shift out of limits when crew, passengers, cargo and expendable weights are added or removed. If the limits are exceeded and the aircraft is flown in this condition it may lead to insufficient stability with resulting difficulty in controlling the aircraft. Adverse loading checks are a deliberate attempt to load an aircraft in a manner that will create the most critical balance condition and still remain in the designed CG limits of the aircraft. It should be noted that when the EWCG falls within the EWCG range it is unnecessary to perform a forward or rearward weight and balance check. Usually, it is impossible to load the aircraft to exceed For Training Purposes Only Issue: August 2014 Page 676 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Aircraft, Weight and Balancing 7.16.2.7 Weight and Balance of Helicopters Refer to Figure 21. A helicopter can be compared to a pendulum, the point of suspension being where the main rotor hub intersects the mast and the pendulum weight being the helicopter. If the pendulum weight is allowed to stop, it will come to rest directly below the suspension point. Example: If the center of gravity (CG) of a helicopter is aft of the hub/mast intersection, the helicopter will be tail down in flight. The pilot can correct this condition by moving the cyclic control stick forward. If the required movement of the control stick is great enough, the pilot will have used all available control, thus limiting manoeuvrability and forward speed. The same principles also apply to lateral CG positions in that a movement of the CG either to the left or right requires lateral compensating cyclic inputs. Since such loss of manoeuvrability is unsafe, care must always be taken to keep the helicopter’s CG within specified limits. Figure 20: Center-of-Gravity Calculations For Training Purposes Only Issue: August 2014 Page 677 of 926 Modul 7 Aircraft, Weight and Balancing PART 66 – Basic Training Cat B1 – Module 7 Figure 21: Fuselage Station Diagram (Example) For Training Purposes Only Issue: August 2014 Page 678 of 926 Modul 7 Aircraft, Weight and Balancing PART 66 – Basic Training Cat B1 – Module 7 Reference Lines Refer to Figure 22. Figure 22: Reference Lines (Example) For Training Purposes Only Issue: August 2014 Page 679 of 926 Modul 7 Aircraft, Weight and Balancing The reference lines used to identify the location of structural parts and the positions of e.g. the center of gravity of a helicopter are defined as follows: Fuselage Station Lines Fuselage station (FS) lines are vertical reference lines which are used to locate main assemblies and parts of the structure. FS numbers indicate the distance in inches from a line of origin which is located approx. 7.60 inches (approx. 19.3 cm) aft of the most forward nose contour. This line of origin is designated as ’station 0’. Boom Station Lines Boom station (BS) lines are reference lines perpendicular to the centerline of the tailboom. BS numbers indicate the distance in inches from a line of origin which is located approx. 59.5 inches (approx. 151.1 cm) forward of boom station 59.5. Boom Extension Station Lines Boom extension station (BES) lines are reference lines same as the boom station lines, except that the BES number indicates the distance in inches from a line of origin approx. 17.37 inches (approx. 44.1 cm) forward of the most forward surface of the boom structure. BES lines terminate at BES 59.5. Water Lines PART 66 – Basic Training Cat B1 – Module 7 Buttock Lines Buttock lines (BL) are vertical reference lines used to locate main assemblies and parts of the structure by a number. The BL number indicates the distance in inches on each side of the helicopter center line which is designated as BL 0. Fin Station Lines Fin station lines are reference lines perpendicular to the centerline of the fin. Fin stations indicate the distance in inches from a line of origin approx. 5.0 inches (approx. 12.7 cm) above the tail rotor gearbox fitting. Weight –and –Balance Calculations Refer to Figure 23. Thorough calculations must be made prior to flight to ensure that the limits are not exceeded. These calculations are done in the same way as those for fixed –wing aircraft except that an additional calculation is made for the lateral (left/right) position of the CG. For the preflight calculations the record of the last weighing is used and those positions are neglected which do not apply for this certain flight. Additionally, the results are to be cross –checked against the appropriate tables for the limits of weight, arms and moments laid down in the helicopter manual. Water lines (WL) are horizontal reference lines (viewed from the side or front of the helicopter) used to locate main assemblies and parts of the structure by a number. The WL number indicates the distance in inches from a line of origin located below the lower skin contour. This line of origin is designated as ’WL 0’. For Training Purposes Only Issue: August 2014 Page 680 of 926 Modul 7 Aircraft, Weight and Balancing PART 66 – Basic Training Cat B1 – Module 7 Example: The calculation laid down in the record shown in Figure 23 is as follows: The helicopter is weighed and the results ’Scale’ and ’Tare’ are entered in the record for each weighing point (in this case 4) to find the net weight. Both CGs are calculated by using the appropriate formulas. Remember: Moment = weight times arm. CG = total of moments divided by total weight. Results: longitudinal CG = 173.4 inch lateral CG = 0.577 (rounded 0.58) inch. The weight (green) and the arms of the CGs (red and yellow) are entered in the ’As weighed’ row and the relevant moments are calculated. Weights and arms of fluids and equipment are entered in the record and the individual moments calculated (for both lateral and longitudinal CGs). For calculating the CGs in ’weight empty’ configuration the sums of all moments is divided by the total of the weight to find the position of the CGs (= total arms (blue)). Now the most forward and the most aft positions of the longitudinal CG (so-called CG limits) are found by entering those weights, with their arms, which occupy the most forward or aft locations. Again, the total arms are found by dividing the sums of the moments by the sums of the weights. For the preflight calculation, all positions (weights) occupied are entered in the table. Finally, the results are checked against the appropriate tables of limits laid down in the relevant manual. Refer to Figure 24. Figure 23: Actual Weighing Record (Example) For Training Purposes Only Issue: August 2014 Page 681 of 926 Modul 7 Aircraft, Weight and Balancing PART 66 – Basic Training Cat B1 – Module 7 Refer to Figure 25. Figure 25: Forward Ballast Location (Example) If necessary, moving the CG is accomplished by adding ballast with defined weights in prescribed locations. Figure 24: Center-of-Gravity versus Gross-Weight Chart (Example) In many cases, the CG limits are shown in a graph, too. These graphs are similar to that shown in Figure 24. For Training Purposes Only Issue: August 2014 Page 682 of 926 Modul 7 Aircraft, Weight and Balancing 7.16.2.8 PART 66 – Basic Training Cat B1 – Module 7 Loading and Weight Distribution Small Aircraft It is the responsibility of the aviation technician to ensure that the aircraft weight and balance information is correct and updated. Whenever equipment is added or removed, or a repair or alteration is made that could affect either the empty weight of the aircraft or its empty weight CG, this must be recorded in the weight and balance information. All of the old computations must be clearly marked so the pilot can easily see that they have been superseded. Refer to Figures 26 and 27. The flight manual of each aircraft normally has a weight and balance loading graph and a moment envelope such as those shown in Figures 26 and 27. Note: Rather than using moments, Figure 26 shows a moment index. This is the moment divided by an appropriate reduction factor (in this case 1,000) to get a figure that is convenient to use. Refer to Figure 28. Before each flight where the weight and balance may be critical, the pilot should compete a form similar to the one in Figure 28. A typical loading problem may be to determine whether or not an aircraft is within its ’legally loaded’ envelope when it carries 4 standard weight occupants (170 lbs each), full fuel, full oil and 80 lbs of baggage. Example: The empty weight of the aircraft and its moment index are recorded as shown in Figure 28. Refer to Figure 26 again. For Training Purposes Only Issue: August 2014 Page 683 of 926 Modul 7 Aircraft, Weight and Balancing PART 66 – Basic Training Cat B1 – Module 7 Figure 26: Loading Graph for Determining the Moment Index For Training Purposes Only Issue: August 2014 Page 684 of 926 Modul 7 Aircraft, Weight and Balancing PART 66 – Basic Training Cat B1 – Module 7 Figure 27: Loaded Moment Envelope For Training Purposes Only Issue: August 2014 Page 685 of 926 Modul 7 Aircraft, Weight and Balancing PART 66 – Basic Training Cat B1 – Module 7 The 40 gallons of fuel weigh 240 lbs. The fuel has a moment index of +11.5. The total weight is 2,355 lbs, and the total moment index is +106.6. Refer to Figure 27 again. To determine whether or not the aircraft is loaded so that its CG falls within the allowable range, the results must be transferred to the graph in Figure 27. Then a horizontal line is drawn through the 2,355 –pound weight line and a vertical line through the 106.6 poundinch/1,000 moment index line. These two lines should intersect within the envelope. The actual intersection is within the envelope, near the rearward CG limit. As stated in Figure 27, this aircraft is approved for both the normal and the utility categories. In the normal category the allowable gross weight is 2,400 lbs and the most rearward center of gravity is 45.83” aft of the datum (moment divided by weight). In the utility category, the maximum gross weight is only 2,050 lbs and the most rearward center of gravity is 40.85” aft of the datum. Figure 28: Finding the Total Moment Index of a Loaded Aircraft There are two gallons of oil on board, and since oil weighs 7.5 lbs per gallon 15 lbs are located on the vertical scale of Figure 26. The graph is continued horizontally to the oil curve. A vertical line then followed from the intersection down shows –0.3 on the moment index scale. There are to be two occupants (or: a weight of 340 lbs) in the front seats. The moment index for this is +12. Loading of Commercial Aircraft Operators of aircraft which are commercially operated must compile a passenger and cargo manifest for each flight. This allows the pilot to know his exact take off weight and whether or not his aircraft is loaded within the allowable center of gravity limits. The rear seat also carries 340 lbs. Its moment index is +24.5. The operator is given the choice of using either the actual weight of the passengers and crew or of using standard weights for the occupants and the baggage. The baggage (80 lbs) has a moment index of +7.3. Refer to Figures 29 and 30. For Training Purposes Only Issue: August 2014 Page 686 of 926 Modul 7 Aircraft, Weight and Balancing PART 66 – Basic Training Cat B1 – Module 7 Figure 29: Passenger and Cargo Manifest For Training Purposes Only Issue: August 2014 Page 687 of 926 Modul 7 Aircraft, Weight and Balancing PART 66 – Basic Training Cat B1 – Module 7 Figure 30: Moment Indexes for Occupants For Training Purposes Only Issue: August 2014 Page 688 of 926 Modul 7 Aircraft, Weight and Balancing A typical passenger and cargo manifest is shown in Figure 29, in which the actual weights of the passengers and the related moment indexes as found in Figure 30 are entered. Refer to Figure 31. PART 66 – Basic Training Cat B1 – Module 7 Furthermore, the fuel weight and moment indexes shown in Figure 31 are entered as well as the weight and moment indexes of the crew, the oil and the empty aircraft. The total weight and moment index is the sum of these individual values. The maximum allowable weight for this flight is 10,000 lbs. Refer to Figure 32. For each weight, the table in Figure 32 provides the minimum and maximum moment indexes which indicate the allowable forward and aft CG limits. For example, in order to find the forward and aft limits for a loaded weight of 9,435 lbs, it must be interpolated between the values for 9,400 and 9,450 lbs. The table states that the difference in the minimum index for each 100 lbs is 89.8 index numbers. Because the actual weight is 35 lbs (or: 35 % of 100 lbs) above 9,400 lbs, 35% of 89.8 index numbers are to be added to get the correct minimum index number of 8,467.9. The maximum index interpolation requires 102.8 index numbers for each 100 lbs. 35 % of this is 36.0, so the maximum index for 9,435 lbs is 9,694.5. Both the loaded weight and loaded moment index are within the allowable limits. Figure 31: Moment Indexes for Fuel For Training Purposes Only Issue: August 2014 Page 689 of 926 Modul 7 Aircraft, Weight and Balancing PART 66 – Basic Training Cat B1 – Module 7 Figure 32: Chart for Determining the Center of Gravity for any Specific Weight For Training Purposes Only Issue: August 2014 Page 690 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Aircraft Handling and Storage 7.17 Aircraft Handling and Storage 7.17.1.2 7.17.1 Airfield Safety Regulations 7.17.1.1 Characteristics of an Airfield Whereas the traffic of taxiing aircraft is radio-coordinated by the control group (tower) of the airfield, the rest of the ground traffic (cars, bicycles, pedestrians) has to observe the following rules in order to ensure an utmost degree of safety: An airfield is a very large hazard area where serious and minor accidents frequently occur. Accidents never happen without a reason. All personnel working at an airfield should fully be aware of this fact and be vigilant of the appropriate health and safety procedures. These procedures are laid down to protect the health of individuals and the serviceability of the various plants, machines and other installations that make up the airfield environment. The following special characteristics of airfields are to be considered: several large multi - purpose buildings close to each other mixed traffic of both taxiing aircraft and vehicles servicing and maintenance work on aircraft great variety, number and location of personnel and vehicles to perform servicing and maintenance ambulances, fire - fighting vehicles and the wreck crane need have easy, free and safe access to each point of accident or crash passage across the flight line possible in all directions. These characteristics present potential hazards to health and safety and necessitate the development of a comprehensive set of ground safety regulations. For Training Purposes Only Issue: August 2014 Airfield Traffic Every user of the airport has to observe the general traffic regulations. For walking or driving on the airfield, special permission is required, the issue of which is limited to a certain group of persons and vehicles. Walking and driving on the runway are only permitted when air traffic control (tower) issues permission. The maximum speed of the apron is usually limited to 30 km/h. This speed limit does not apply to fire - fighting and rescue vehicles or ambulances in operation. Taxiing aircraft always have the right of way. For all other vehicles the sequence to get the right of way is as follows: 1. fire-fighting vehicles, ambulances, rescue vehicles, police vehicles when the optical or acoustic warning has been switched on 2. sweeping machines in operation 3. other vehicles with identification lights switched on. During night or during gloomy weather the headlights must be turned on and dipped. Smoking and use of open fire – even within vehicles – are strictly prohibited at the airfield. The safety lines around parked aircraft and the safety distances to taxiing aircraft must strictly be observed. Vehicles operating at the flight line on a regular basis should have special markings (e.g. safety colours or flags) and be provided with safety equipment. Page 691 of 926 Modul 7 Aircraft Handling and Storage 7.17.1.3 PART 66 – Basic Training Cat B1 – Module 7 Aircraft Noise Refer to Figure 1. The noise produced by a running engine can impair hearing. Noise levels exceeding 85 decibels (dB) are particularly dangerous and can cause irreparable damage to hearing. When engines are running the following danger zones exist: the air intake zone(s): with strong suction in front of the engine air intake duct(s) the turbine rotation zones: to both sides of the aircraft; indicated by red markers on the left and right sides of the fuselage the exhaust zone(s): high temperatures and high-speed exhaust gases behind the engine jet pipes. Figure 1: Aircraft Danger Areas (Examples) For Training Purposes Only Issue: August 2014 Page 692 of 926 Modul 7 Aircraft Handling and Storage PART 66 – Basic Training Cat B1 – Module 7 Refer to Figure 2. For rotary –wing aircraft the following regulations apply: The engine and intake/exhaust duct regulations are the same as for fixed-wing aircraft. Main rotor disc: – Do not enter the rotor disc without permission of the pilot and marshaller. – Always approach the aircraft in full view of the pilot. – Do not enter the rotor disc area on startup/shutdown due to danger of blade sailing. Tail rotor disc: Be aware of the tail rotor disc. At high speeds you can become attracted by the rotor disc and can be drawn towards it. Refer to Figure 1 again. Figure 1 shows the minimum safety distances for a medium –size fighter aircraft during ground engine operation. For other types of aircraft the distances may vary considerably. In the example shown in Figure 1 the minimum safety distance in front of the air intakes is 6 m (during start up) or 4 m with the engines at idle. Personnel working within the danger zone while the engines are running must be familiar with these safety distances. Similarly, they must be familiar with the dangers associated with loose articles which could be drawn into the intake ducts. When the engines are running, the turbine rotation zones on both sides of the fuselage must be avoided. They are indicated by red markers. Figure 2: Rotary--Wing Aircraft Danger Areas (Example) For Training Purposes Only Issue: August 2014 Page 693 of 926 Modul 7 Aircraft Handling and Storage The technician in charge of the ground engine operation is to ensure that all danger zones around the aircraft are cleared from both personnel and ground equipment before the engines are started. Beware of jet engines: always keep out of blast and suction areas! Note: The a. m. list is only a fraction of the dangers on the flight line. Aircraft Tie - down Procedure Aircraft shall be tied down in accordance with the aircraft maintenance manual. The main regulations to be followed are: Refer to Figure 2 again. Figure 2 shows the minimum safety distances for a typical rotary wing aircraft during ground engine operation. 7.17.1.4 Flight Line Safety It is the responsibility of all aircraft personnel to prevent accidents. To reduce the risk of accidents, a list of safety precautions to be observed when working in or around the aircraft is published in local working orders or in aircraft maintenance manuals. These precautions have to be observed by everybody. All personnel are to obey the following general safety precautions: Overall pockets should have velcro or button down flaps to prevent articles from falling out which could cause cockpit controls to jam or an electrical short circuit. Workshoes or boots are to have soft soles to protect the aircraft finish (paintwork) and fittings. They should be resistant against oil, fuel or grease. During aircraft servicing, warning notices are to be positioned around the aircraft informing personnel of a particular hazard, e.g. ’aircraft armed’ or ’arming’, ’radiation hazard’ etc. When aircraft engines are being run on the ground several danger zones exist which are to be cleared from personnel and equipment before start-up. For Training Purposes Only PART 66 – Basic Training Cat B1 – Module 7 Main and nose landing gears need be secured by the prescribed means. The battery main switch need be switched OFF. Doors, cargo doors, inspection panels, etc. are to be closed Air intakes and pitot head openings are to be protected by the appropriate covers and blanking plugs. The down-cables need have enough slack in order to prevent excessive tension on wings or mooring fittings in case of a single - sided pressure loss of the tyres or the landing gear struts. Ground locks are to be fitted. Foreign Object Damage The presence of foreign objects in and around aircraft is and will always be a hazard. Therefore great care and awareness must be adhered to by all personnel. The following list states some sources of possible foreign object damage (FOD): Issue: August 2014 Sand, dust, mud and loose stones which can be sucked into the aircraft engine or picked up in the slip stream and propelled with a force strong enough to injure personnel or cause damage to other aircraft and equipment in the vicinity. Tools left in the aircraft by careless personnel which could block controls or components and cause loss of lives and aircraft Page 694 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Aircraft Handling and Storage Use of rags and cotton waste to blank off open pipe work. Some of the material could inadvertently be left in the pipe causing a blockage which may lead to a failure of an essential system. Replenishing systems with incorrect or contaminated fluids which could perish the seals resulting in a system failure. Incorrect stowage of ground support equipment, such as maintenance stands and trolleys, left in the incorrect area without their parking brakes being applied. Methods of Preventing FOD Foreign object damage can be minimised by all personnel being fully aware of their individual responsibilities and by observing the following basic safety rules: Check the number of tools before commencing a job at or in the aircraft and check again on completion. Any discrepancy must be reported. It is essential that any foreign object, i.e. nuts, bolts, washers etc. must be removed from the aircraft immediately after use or when it has fallen down. Never consider an item as being ’too small to cause trouble’, it can (and will)! Fit correct dust and blanking caps to components and open pipe work, e.g. fuel or hydraulic pipelines. Do not use adhesive tape, since static charging occurs when removing it Check for foreign objects prior to closing any access doors and panels Never use fluid from an open container (it may be contaminated) without carrying out a full fluid hygiene test If a fault is observed, do not ignore it! Whatever trade it concerns, report it to the respective trade supervisor. For Training Purposes Only 7.17.1.5 Engine Safety Refer to Figure 1 again. Aircraft engines in operation are hazardous to persons and objects in their vicinity. In the area around the air inlet the engine will ’suck’ the air and any objects close to the inlet into the engine. They develop thrust which results in heavy movement of the air behind the engine outlet. They produce noise which is dangerous to human ears. For these reasons, so –called ’danger areas’ must be established around each engine in operation, whether in idle or at high rpm, whether at the test stand or at the runway. Personal injury and equipment damage may occur when known danger areas are entered. Note: The size of the danger areas and the safety distances may vary depending on the type of aircraft. The dimensions given in this Lesson are to be looked at as examples. If no other values are given (e.g. in the maintenance manual) they should be taken as minimum sizes and distances. Thrust Danger Areas Idle Thrust Danger Areas Refer to Figure 3. Issue: August 2014 Page 695 of 926 Modul 7 Aircraft Handling and Storage PART 66 – Basic Training Cat B1 – Module 7 Figure 3: Thrust Danger Areas with Engine in Idle For Training Purposes Only Issue: August 2014 Page 696 of 926 Modul 7 Aircraft Handling and Storage PART 66 – Basic Training Cat B1 – Module 7 An engine in operation at idle has the following dangerous areas around it. The forward area is dangerous due to suction caused by the engine air intake. The main danger area is directly behind the fan cowl in the fan air discharge area. The fan air mixes with the exhaust gases and causes strong wind conditions at each side and aft of the engine. The danger areas at idle rpm extend to 55 m (180 feet). The speed of the air at idle thrust decreases from approx. 180 knots to approx. 17 knots (and less) depending on the distance from the fan air discharge. At each side of the engine, there is an area that is safe to enter when a person needs to approach the engine. Take - Off Thrust Danger Areas Refer to Figure 4. An engine at take - off power has larger danger areas around it than at idle. The forward area is dangerous due to suction caused by the engine air intake. The danger area has doubled in size from idle setting. Danger areas at take - off power increase to 155 m (500 feet). Take off thrust hazards change from a speed of approx. 180 knots to approx. 17 knots depending on the distance from the fan air discharge. There are no safe areas around an engine in operation at take - off power. For Training Purposes Only Issue: August 2014 Page 697 of 926 Modul 7 Aircraft Handling and Storage PART 66 – Basic Training Cat B1 – Module 7 Figure 3: Thrust Danger Areas with Engine in Idle For Training Purposes Only Issue: August 2014 Page 698 of 926 Modul 7 Aircraft Handling and Storage PART 66 – Basic Training Cat B1 – Module 7 Acoustic Danger Areas Safety precautions are necessary to prevent injury to people from noise caused by operating aircraft engines. The noise caused by engines and propellers may exceed 85 decibels (dB (A)). A person’s hearing can be permanently damaged by the high intensity of noise during engine operation. Ear protection must be used in areas near to engines that are operated. Ear protection must be worn. Do not stay in this area for more than one hour at a time! Area Y extends to 740 m (2,400 feet) at take –off thrust. In this area, the noise is less dangerous but ear protection must be worn. Engine at Ground Idle Refer to Figure 5. Dangerous noise areas for engines operating at ground idle are as follows: Area X extends to 24 m (75 feet). In this area the noise can cause permanent ear damage when being exposed to for one hour or more. Ear protection must be worn. Do not stay in this area for more than 1 hour (h) at a time! Area Y extends to 95 m (300 feet). In this area, the noise is less dangerous but ear protection must be worn. Engines Producing Take - Off Thrust Dangerous noise areas for engines operating at take –off thrust are: V Area X extends to 31 m (100 feet). In this area the noise can cause permanent ear damage when exposed to for 1 h or more. For Training Purposes Only Issue: August 2014 Page 699 of 926 Modul 7 Aircraft Handling and Storage PART 66 – Basic Training Cat B1 – Module 7 Propeller Danger Zones Refer to Figure 6. For aircraft with propellers and engines operating, the following danger areas have to be established: air intake zones: strong suction forward of the propellers propeller rotation zones: left and right of the propellers in the rotation plane exhaust zones: high temperatures and high air velocity behind the engines. Figure 5: Acoustic Danger Areas (Example) For Training Purposes Only Issue: August 2014 Page 700 of 926 Modul 7 Aircraft Handling and Storage PART 66 – Basic Training Cat B1 – Module 7 Figure 6 : Dangerous Engine and Propeller Areas For Training Purposes Only Issue: August 2014 Page 701 of 926 Modul 7 Aircraft Handling and Storage 7.17.1.6 Danger Zones during Aircraft Refuelling Refer to Figure 7. PART 66 – Basic Training Cat B1 – Module 7 When an aircraft is refuelled, fuel vapour emerges through the vent pipe. When mixed with air, this fuel vapour produces explosive mixtures in certain areas (danger zones) around the aircraft. The size of the danger zones depends on the fuel type and the refuelling rate. When using normal fuel (Jet - A) and a refuelling rate between 600 l/min and 1,200 l/min, the danger zone extends around the vent pipe up to a radius of 2 m. With decreasing refuelling rates, the dimensions of the danger zone are reduced. The danger zones are increased when another fuel with a lower ignition point is used (e.g. Jet A - 1 or Jet B). Refer to Figure 8. When refuelling the aircraft in aircraft shelters, areas with an explosion hazard extend up to a radius of 3 m. In vertical direction, they extend from the ground up to the level of the ventilation openings. Air movement (wind/ventilation) of more than 1 m/s within the aircraft shelter during refuelling eliminates the explosion hazard due to sufficient dilution of the explosive mixtures. The air movement must be maintained during the whole refuelling process, from the ground up to the level of the ventilation openings. Figure 7: Danger Zones when Refuelling Outdoors For Training Purposes Only Issue: August 2014 Page 702 of 926 Modul 7 Aircraft Handling and Storage PART 66 – Basic Training Cat B1 – Module 7 Safety Precautions The following safety precautions are to be observed when working on the fuel system: Only equipment which does not cause sparks and does not reach a higher temperature than 80 % of the fuel ignition temperature may be used in the danger zones In general, ground support and test equipment does not comply with the requirements for the danger zones. Therefore, the radius of a danger zone is to be looked at as a safety radius. Figure 8: Danger Zones when Refuelling Indoors For Training Purposes Only Issue: August 2014 Page 703 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Aircraft Handling and Storage 7.17.2 Ground Handling and Storage of Aircraft 7.17.2.2 7.17.2.1 Introduction Generally, aircraft movement on the ground can be accomplished in two ways: The tasks required to be carried out on an aircraft between flights, apart from routine maintenance, cover a variety of subjects. Special ground equipment is often required to make possible that these tasks are carried out satisfactorily. When handling light aircraft this equipment may be of a very basic nature, but when dealing with large transport aircraft more sophisticated equipment may be necessary. Preparations for the reception of an aircraft should be made in advance of its arrival. The positioning of an aircraft in the reception area should be arranged in such a way that access paths to the aircraft are available for all replenishing vehicles and for the loading and unloading of passengers and/or cargo. All equipment likely to be required for the servicing of an aircraft should be readily available and should be in a fully serviceable condition. Movement of Aircraft on the Ground The aircraft moves on its own. The aircraft is pushed or towed by hand or by a tug. Aircraft Moving on its Own When an aircraft manoeuvres by using its own engine(s) and own steering controls, it is said to taxi. In this situation, the pilot is to follow the instructions given by the control personnel in charge. These instructions are either given by controllers in the tower via radio communications or by a so called marshaller via hand signals. Note: The first method will not be discussed here. Marshalling When an aircraft has to be moved into a hangar in order to allow servicing operations or maintenance to be carried out, it should be positioned so as to avoid obstructing access to other working space or necessitating disturbance before the work has been completed. The location of all necessary facilities such as weighing platforms, electric and pneumatic power sources, lighting and the necessity for providing docks or platforms must also be considered to enable the work to be carried out properly. For Training Purposes Only Refer to Figure 1. Issue: August 2014 Page 704 of 926 Modul 7 Aircraft Handling and Storage PART 66 – Basic Training Cat B1 – Module 7 Figure 1: Aircraft Marshalling Marshalling is a term used to guide aircraft while they are on the ground or on the flight line. The marshaller directs the aircraft into and from their parking space e.g. at the gate. Signalling is done either with the hands or (more common) with marshalling wands or bats, which can be illuminated by night. Refer to Figures 2 to 5. Figure 2: Marshalling Signals (I) For Training Purposes Only Issue: August 2014 Page 705 of 926 Modul 7 Aircraft Handling and Storage Figure 4: Marshalling Signals (III) Figure 3: Marshalling Signals (II) For Training Purposes Only PART 66 – Basic Training Cat B1 – Module 7 Issue: August 2014 Page 706 of 926 Modul 7 Aircraft Handling and Storage PART 66 – Basic Training Cat B1 – Module 7 Note: Figures 2 to 5 show the most important signals for fixed wing aircraft. It is also the marshaller’s duty to check for any items that may be hanging from the aircraft and that all ground personnel stays clear of the aircraft before it is moved. Aircraft Moved by Hand or Tug Light Aircraft Great care should be exercised when man-handling light aircraft, particularly those constructed of wood and fabric. When handling an aircraft having a nose-wheel landing gear, a steering arm should be fitted to the nose-wheel to guide the aircraft. Force should only be applied to such parts of the structure which are designed to accept it. Force should never be applied to trailing edges of wings or control surfaces, to streamlined wires, or to areas which are marked to prohibit the application of force. An engine should always be regarded as ’live’, therefore a propeller must not be used to push or to pull the aircraft. When an aircraft having a steerable nose-wheel connected to the rudder pedals is moved, care must be taken not to exceed the turning limits, which are normally marked on the nose wheel leg. For this type of aircraft it is also important that the rudder controls are not locked during towing operations. igure 5: Marshalling Signals for Helicopters For Training Purposes Only When handling an aircraft fitted with a tail skid instead of a tail wheel, it is customary to raise the tail by lifting on the tailplane struts near to the fuselage fittings, so that the aircraft is balanced at the main Issue: August 2014 Page 707 of 926 Modul 7 Aircraft Handling and Storage PART 66 – Basic Training Cat B1 – Module 7 wheels. The aircraft may then be pushed backwards as required. On some aircraft it may also be advisable to place the propeller in a horizontal position to prevent it from striking the ground when the tail is lifted. When towing a light aircraft by means of a tractor, the correct tow – bar should be connected between the towing attachment at the base of the nose wheel leg and the tractor. A person familiar with the aircraft’s brake system should be seated in the cockpit/cabin to operate the brakes in an emergency; the brakes should normally not be applied unless the aircraft is stationary. Once the tow-bar is connected, the brakes and, where fitted, the rudder lock, may be released and the aircraft towed forwards at safe speed, depending on the conditions of the environment (ground surface, weather etc.). Large Aircraft Refer to Figure 6. Large multi - engined aircraft are usually moved by towing them with a tow-bar attached to the nose wheel leg. A special tug may be required to provide sufficient tractive effort. The tow-bar is fitted with a shear-pin or bolt, which will shear at a predetermined load to prevent the application of excessive force to the nose landing gear. The center of gravity (CG) of the aircraft must be determined before towing to ensure that there is sufficient weight on the nose wheel. Adverse fuel distribution and a ’non standard’ condition of the aircraft (e.g. when an engine has been removed) could affect the CG position. The maximum forward and aft limits of the CG are generally specified in the relevant maintenance manual. Ballast may sometimes be required to achieve a safe CG position, but the maximum towing weight must not be exceeded. For Training Purposes Only Figure 6: Aircraft Towing with Tow-Bar Before towing is commenced the landing gear ground locks should be installed. The steering mechanism should be disconnected or disabled (if applicable). The nose wheel shock absorber should be checked for normal extension. In addition, the brake pressure should be checked and, if necessary, built up to the minimum safe pressure. If it is necessary to turn the nose wheel over a wider angle than that allowed by the prescribed steering limits, the nose wheel is usually freed by removing the apex pin from the torque links, thus allowing the nose wheel to move completely free. When towing the aircraft, 2 qualified pilots or suitably trained and authorised members of the towing crew should be seated in the cockpit to operate the brakes and/or any other aircraft system which may be required. Issue: August 2014 Page 708 of 926 Modul 7 Aircraft Handling and Storage PART 66 – Basic Training Cat B1 – Module 7 These persons should be in telephone communication with the outside ground crew and with the tractor driver. The ground crew should be located at the wing tips and the tail to guide the aircraft when passing any obstructions. One person should be in overall control of the operation. The aircraft’s brakes should be released before the tractor moves off. The towing speed should be kept at a safe speed. The radii of turns should be kept as large as possible to minimise tyre scrubbing and twisting loads on the main landing gear legs. Care should be taken not to exceed any towing force limits which may be specified for various nose wheel steering angles in the relevant Maintenance Manual. Before stopping, the aircraft should be towed for a short distance in a straight line in order to remove any stresses imposed by turning. Once stationary the aircraft brakes may be re - applied, the tractor and tow-bar may be removed and the nose wheel steering links refitted and locked. Refer to Figure 7. Figure 7: Tow-Bar with Flat-Tyre Dolly For Training Purposes Only Issue: August 2014 Page 709 of 926 Modul 7 Aircraft Handling and Storage PART 66 – Basic Training Cat B1 – Module 7 In an emergency it may be necessary to move an aircraft from the runway with one or more deflated tyres. Provided that there is one sound tyre on an axle the aircraft may be towed to the maintenance area, but sharp turns should be avoided. The towing speed should be kept to an absolute minimum and brakes should be applied very carefully. If an axle is not supported by a sound tyre the aircraft may only be moved the shortest distance necessary to clear the active runway. There the wheels with deflated tyres must be removed and serviceable components fitted before towing is continued. After any tyre failure the associated wheel must be inspected. It may also be necessary to inspect the wheels and tyres which have not failed if the aircraft has landed or been towed with a deflated tyre. Refer to Figure 8. Most disadvantages of tugs with tow-bars can be avoided by using towbarless aircraft tractors. By means of the pick up device, which is located in the tractor’s center, the aircraft is seized on its nose gear tyres and pulled onto the platform. In simple terms it can be said that the aircraft is ’hitched up’ and a backlash-free link is established between tractor and aircraft. This direct and backlash-free link ensures that the combination consisting of towbarless tractor and aircraft can easily achieve speeds of up to 30 km/h. By using part of the aircraft weight (up to 45 tons) as an additional load, there is no need for ballasting the tug. For Training Purposes Only Issue: August 2014 Page 710 of 926 Modul 7 Aircraft Handling and Storage PART 66 – Basic Training Cat B1 – Module 7 Figure 8: Towing with Towbarless Tractor For Training Purposes Only Issue: August 2014 Page 711 of 926 Modul 7 Aircraft Handling and Storage 7.17.2.3 Parking and Picketing Parking between Flights When an aircraft is out of service and not parked in a hangar it should be secured against inadvertent movement and protected against adverse weather conditions. The necessary actions which are recommended in the relevant maintenance manual depend on the type of aircraft, the length of time it will be out of service and the prevailing or forecast weather conditions. Between flights it is usually sufficient to apply the parking brakes, lock the control surfaces and chock the wheels. If strong wind blows (or is expected) light aircraft need be headed into the wind. Light aircraft without wheel brakes need be headed into the wind and their wheels need be chocked in front and at rear. Flight controls of many aircraft are locked by movement of a lever in the cockpit/ cabin, which is connected to locking pins at convenient positions in the control runs or at the control surfaces. When this type of lock is not fitted, locking attachments may have to be fitted to the control column and rudder pedals. It is a better method to fit external control surface locks, which prevent the movement of these surfaces and thus prevent strain on the control system. All external locks need have suitable streamers attached to visually indicate that the locks are fitted. PART 66 – Basic Training Cat B1 – Module 7 openings, such as static vents, engine intakes and cooling air intakes, need be blanked to prevent the ingress of dirt, birds, insects and precipitation, and all fittings, such as pitot heads and incidence indicators, need be covered. When severe weather is expected it is recommended that cockpit/cabin covers and wheel covers are also fitted. Blanks and covers for all these components are specially designed for the particular aircraft. If they are not visible they are to be fitted with streamers to ensure that they will not be left in such a position when the aircraft is prepared for service. Light Aircraft Light aircraft normally need be tied down when parked over night or longer. They are fitted with picketing rings (or positions for the attachment of picketing rings are provided) at the wings and the tail and/or adjacent to the main landing gear legs. The aircraft need to be parked in such a way that they head into the wind. Parking over Night They need be secured from the picketing points to suitable anchorage points on the ground (e.g. heavy concrete blocks). Cable or nylon rope of adequate strength should be used if possible. If rope made from natural fibres is used, sufficient slack must be left to allow for shrinkage in damp conditions. Additional picketing of the landing gear legs may be recommended in strong wind conditions and, if so, care should be taken not to damage any pipelines or equipment attached to the legs or wheels. Precautions Large Aircraft If an aircraft has to be parked in the open over night or for longer periods additional precautions need be taken against the effects of adverse weather. The landing gear ground locks need be fitted, all Large aircraft only require picketing in very strong wind conditions. The aircraft need be headed into wind, the parking brakes need be applied (unless preloaded main wheel chocks are recommended) and For Training Purposes Only Issue: August 2014 Page 712 of 926 Modul 7 Aircraft Handling and Storage cables going from the aircraft picketing points to prepared anchorages could be attached. In some cases the picketing cables are special components and include a tension meter which is used when a preload to the cable is applied. Helicopters PART 66 – Basic Training Cat B1 – Module 7 Folding the main rotor blades depends on the method how they are attached to the rotor head and on the position of each blade. The procedure for a particular helicopter should, therefore, be obtained from the relevant maintenance manual. In the ’folded’ position the blade tips are generally secured by means of support cradles, which are attached to the tail cone structure. When helicopters are parked in normal conditions only air intake, exhaust and pitot blanks need to be fitted. In gusty or heavy weather it should be ensured that the collective lever is in the ’min pitch’ condition. Refer to Figure 9. The main rotor blades should have tip socks fitted and tethered to the aircraft. The tail rotor gust lock need be fitted to prevent the blades from moving (flapping). Under no circumstances should the main rotor blades or tail pylon be folded in winds exceeding 6 knots. In bad weather it is preferable to park helicopters in the hangar when not required for immediate flying tasks. On many helicopters the main rotor blades are tethered by aligning one blade along the tail cone, locking the collective pitch lever in fine pitch and applying the tip covers to each blade and then pulling them against the damper stops. Each blade may then be lashed to its respective picketing point, but care must be taken not to pull the blades down excessively. The tail rotor is generally tethered by fitting the blade covers and securing them to the associated picketing points or tail skid. For Training Purposes Only Issue: August 2014 Figure 9 Rotor Blades Tethered for Heavy Weather Page 713 of 926 Modul 7 Aircraft Handling and Storage 7.17.2.4 PART 66 – Basic Training Cat B1 – Module 7 Jacking An aircraft may have to be jacked up for various reasons, e.g. for servicing, weighing, changing wheels and retraction tests. Care is necessary to avoid damaging the aircraft during the jacking operation. Jacking points are usually provided at the wings and the fuselage to enable the whole aircraft to be lifted and individual wheels to be changed at the nose and main landing gear. Refer to Figure 10 and 11 Some aircraft require a jacking pad to be fitted to each jacking point and adapters to be fitted to the jacks, while in other cases special stirrups or beams may be required to lift individual axles. Because of the position of the jacking points the center of gravity (CG) of some aircraft may, although satisfactory for flight, fall behind the main jacking points and thus will be unsatisfactory for jacking purposes. In these cases it may be necessary to add ballast forward of the main jacking points to bring the center of gravity within the limits specified in the relevant maintenance manual. In addition each jacking or steadying point may have a load limit which, if exceeded, could result in structural damage. To avoid exceeding the limiting load at the jacking points it is sometimes necessary to fit hydraulic or electrical load cells to the jacks, while ballast may have to be used to avoid exceeding the loading limit at a steadying point. Microswitches fitted to the landing gear legs and operated by the extension or contraction of the shock absorbers are used to arm or disarm various electrical circuits on the aircraft. When the aircraft is jacked up these circuits will operate as they do during flight. But this may not be desirable. Therefore these circuits should be isolated by tripping the appropriate circuit breakers or by removing the associated fuses, as necessary. For Training Purposes Only As a safety precaution light aircraft should normally be jacked inside a hangar. Large aircraft may be jacked in the open provided that they are headed into the wind and that the surface is level and strong enough to support the weight of the aircraft at the jacking points. A maximum safe wind speed for jacking is generally specified in the relevant maintenance manual. A ’bottle’ jack and an adapter or special fittings may often be used when raising a single undercarriage or part of a bogie beam for the purpose of changing a wheel. The remaining wheels should be chocked in front and at rear to prevent the aircraft from moving. It may also be specified that a tail support is located at the rear fuselage jacking point when a nose landing gear has to be raised. The jack should be raised so that the unserviceable wheel is lifted a few inches above the ground. Before lowering an aircraft to the ground, all ground equipment, work stands, supports, etc., should be removed from the aircraft structure to prevent inadvertent damage. The wheels should also be rotated by hand to check that the brakes are free. The jacks should be lowered slowly and simultaneously by opening their pressure release valves. To guard against failure of a jack the locking nuts on the jack rams should be unscrewed while the jacks are lowered and kept 50 mm (2 inches) below the jack heads. When the aircraft rests on its wheels the jacks should be fully lowered and the pressure release valves should be closed. Chocks should then be placed in position, the jacks, jacking pads and adapters should be removed from the aircraft and any electrical circuits being disarmed as a safety measure should be reinstated. Issue: August 2014 Page 714 of 926 Modul 7 Aircraft Handling and Storage PART 66 – Basic Training Cat B1 – Module 7 Figure 11: Example of Aircraft Jacking Figure 10: Aircraft Jacks and Trestles For Training Purposes Only Issue: August 2014 Page 715 of 926 Modul 7 Aircraft Handling and Storage 7.17.3 Aircraft Servicing 7.17.3.1 Ground Servicing Equipment PART 66 – Basic Training Cat B1 – Module 7 Tools and Instruments Chocks Aircraft chocks are needed to hold the aircraft stationary and safe when parked or during servicing. They are necessary because the aircraft’s braking systems are not always applied. Ladders and Steps Refer to Figure 1. Ladders and steps are used to gain access to aircraft servicing points. They range from simple steps to large hydraulically operated mobile aircraft entry steps. There are also several elevating and extending ladders with working platforms in use. Figure 1: Ladders and Steps For Training Purposes Only Issue: August 2014 Page 716 of 926 Modul 7 Aircraft Handling and Storage Vacuum Cleaners For removing dust and small foreign objects from areas of aircraft structures not easily being accessible vacuum cleaners are essential. Various vacuum cleaners are available, from small hand-held cleaners to large wheeled equipment that need a towing vehicle to move it around the servicing area. Gas Cylinders When using gas cylinders to replenish aircraft systems and components there are different types of trolley to move the cylinders. Normally gas cylinders are mounted on a 4-wheel trolley which is capable of carrying 4 cylinders connected by suitable high-pressure pipes to a single outlet. These trolleys are heavy and require a tractor or several men to move them. Lighter 2-wheel trolleys are available to carry 2 cylinders or even a single cylinder. The lighter trolleys are more convenient for use by an unassisted man. Whatever the type of trolley, suitable valves are fitted to control the gas flow with pressure gauges indicating both total and delivery pressures. PART 66 – Basic Training Cat B1 – Module 7 engine lubrication aircraft hydraulics windscreen de-icing aircraft de-icing. Note: Aircraft de-icing is usually done by de-icing trucks or stationary de-icing equipment) It is therefore very important that all cans for replenishing are clearly marked to identify the fluids they contain. Mobile Refrigeration Units Aircraft cooling systems only operate when the aircraft engines are running. If the aircraft is standing in direct hot sunshine it quickly becomes very hot inside. This reduces the servicing personnel’s efficiency and may be detrimental to various aircraft equipment. To protect aircraft equipment and personnel the aircraft interior can be kept at an acceptable temperature by using specially constructed mobile refrigeration units. These air cooling units vary in size, depending on the aircraft type to be serviced. Ground Power Units Fluid Replenishment Cans Refer Figure 2. To enable aircraft fluid systems to be replenished from sealed, dustand dirt-free containers a series of replenishment units have been developed. These are called ’fluid replenishment cans’ (so –called ’risbridger’). These cans are manually pressurised to deliver fluid through hoses and hand-controlled delivery guns to aircraft tanks in positions that are not easily accessible. A ground power unit (GPU) is used for starting aircraft engines and providing electrical power during servicing. Incorporated is an electric generator which can be an AC or DC unit or a combined AC/DC unit. This is driven by a gasoline or diesel engine or by an electric motor driven from the hangar’s mains supply or a power distribution point in the servicing area. Such replenishment units are used for fluids in a variety of aircraft systems such as: For Training Purposes Only Issue: August 2014 Page 717 of 926 Modul 7 Aircraft Handling and Storage PART 66 – Basic Training Cat B1 – Module 7 drain the aircraft hydraulic system filter the aircraft system hydraulic fluid fill the aircraft system with clean micronically filtered hydraulic fluid check performance of aircraft systems check the hydraulic system for internal and external leaks. The hydraulic power unit and its components are mounted on a metal base with 4 wheels. It may be self-propelled or provided with a tow bar for towing by hand or vehicle. Figure 2: Example Electrical Ground Power Unit Hydraulic Power Units Refer Figure 3. Hydraulic power units are used when it is impracticable to run the aircraft engines, e.g. when the aircraft is on jacks undergoing landing gear functional checks or when adjustment is being carried out on powered flight controls. These tasks could take considerable time and several operations of the system. Some hydraulic power units have limited operations, while others can be used to perform all the system tests. For example, one particular test unit can perform the following functions: For Training Purposes Only Issue: August 2014 Figure 3: Example Hydraulic Power Unit Page 718 of 926 Modul 7 Aircraft Handling and Storage Consumable Materials PART 66 – Basic Training Cat B1 – Module 7 Note: Compressed gas is a consumable product but compressed gas cylinders are not. One of the most important tasks in servicing is the ’first line servicing’ of an aircraft. A lot of time is spent on ’pre flight’, turnround flight’ and ’post flight’ servicing which include, among other things, adjustment of the fuel load to meet operational requirements and to ensure that oil and coolant levels are correct. They must be controlled and accounted for while in use and when empty. Oil tanks may be replenished from an oil replenishment trolley or from replenishment cans. The coolant medium is known as glycol and, before being mixed with water and tested, it is stored in 45-gallon drums. After mixing it is then dispensed to replenishment trolleys or cans. Typical Consumables Refer to Figure 4. In aircraft servicing the term ’consumable materials’ refers to a wide range of materials which are actually consumed in use or which are of low value and not worth repairing in case they are faulty/broken. The term ’expendable items’ is also used to identify the same range which may cover: hydraulic fluid engine lubricating oil liquid oxygen compressed gas greases cleaning materials aircraft general spares, i.e. nuts, bolts, washers, rivets, etc. de-icing fluid. For Training Purposes Only Issue: August 2014 Figure 4: Typical Consumables Page 719 of 926 Modul 7 Aircraft Handling and Storage 7.17.3.2 PART 66 – Basic Training Cat B1 – Module 7 Static charge can be built up by fluid flowing through a pipe or hose as during refuelling. Thus, when refuelling or defuelling, care must be taken to prevent the existence of static electricity and the resulting danger of a spark. Aircraft Fuelling and Defuelling Note: Aircraft fuelling, refuelling and defuelling is a regular service task. Even if not directly involved, all maintenance personnel must be aware of the procedures and safety precautions required during fuelling in order to avoid accidents and injuries. Aviation fuel is stored underground and pumped through pipes to suitable filling installations near the servicing area known as hydrants. The fuel may also be transferred from the underground store to refuelling vehicles or ground tankers. The vehicles carry their own pressure and suction fuel systems, which are not only used to refuel the aircraft but to defuel it as well. On emergency airfields, the fuel may be stored in 45-gallon drums, barrels or jerrycans. Refer to Figure 5. Static electricity can be prevented by: earthing the ground tanker through a conducting chain, earthing spike or strap ensuring that the hose end fittings are electrically bonded and that the nozzle is connected to the aircraft fuel tank by the bonding clip or plug ensuring that the conducting tail or nose wheel of the aircraft is in contact with the ground (or the aircraft is earthed in the case of non - conductive tyres being fitted). Static EIectricity Note: Before discussing refuelling and de-duelling operations it is necessary to mention the effect of static electricity. Static electricity is generated as a result of friction. A good example of this phenomenon can be demonstrated by a person passing a comb through his hair several times. lf the hair is dry the person will discover that the hairs tend to stand up as the comb approaches. Furthermore, the comb will also now be able to ’pick up’ small pieces of paper. As a result of the friction between the comb and the hair both have become electrically charged, one positively and the other negatively. lf these charges were great enough a spark would have jumped between the two. For Training Purposes Only Issue: August 2014 Page 720 of 926 Modul 7 Aircraft Handling and Storage PART 66 – Basic Training Cat B1 – Module 7 Figure 5: Bonding for Fuelling For Training Purposes Only Issue: August 2014 Page 721 of 926 Modul 7 Aircraft Handling and Storage PART 66 – Basic Training Cat B1 – Module 7 Refuelling There are 2 methods of aircraft refuelling: gravity refuelling pressure refuelling. Gravity Refuelling Refer to Figure 6. When gravity refuelling is necessary the aircraft fuel tanks are filled through ports in the top of the tank(s), either by nozzle and hose from ground tankers or from small capacity fuel containers. All fuel should be delivered through a streamline or equivalent standard filter. Auxiliary fuelling equipment, such as hand pumps and funnels, are to be used for one grade of fuel only. This method is also known as ’open line’ refuelling. Figure 6: Gravity Refuelling For Training Purposes Only Issue: August 2014 Page 722 of 926 Modul 7 Aircraft Handling and Storage PART 66 – Basic Training Cat B1 – Module 7 Pressure Refuelling Handling the Hose When pressure refuelling is possible the fuel tanks are fed with fuel under pressure through connections fitted under the wing or at some other point easily accessible from the ground. The precise procedure for pressure refuelling a particular type of aircraft is detailed in the relevant maintenance manual. Hose lines and all fuelling equipment must be kept absolutely clean. Care must be taken when handling the hose: The pressure refueller (ground tanker or bowser) meets the requirements of modern aircraft in which the fuel supply lines radiate from a single refuelling connection, or a small number of connections, to the numerous fuel tanks on board. Pressure refuelling is a more rapid means of filling the aircraft’s tanks than open - line refuelling. The pressure refueller is capable of pumping fuel into the aircraft at a high rate of delivery and is primarily used for refuelling turbine engine aircraft; it is, however, also capable of handling gasoline. Refer to Figure 7. The coupling operation is made by offering up the hose unit to the aircraft unit so that the bayonet slots engage with the bayonet lugs of the hose unit and then pressing the handlever or handwheel forward while, at the same time, rotating it clockwise until fully engaged. The spring - loaded valve of the aircraft unit is pushed open by the hose unit valve when the latter is operated by the valve handle. A device to firmly interlock both units is active until the valve is returned to the ’closed’ position. To disconnect the coupling the valve handle is pushed toward the mouth of the hose unit and the coupling rotated anti-clockwise. Then the sealing cap of the aircraft coupling unit is refitted. For Training Purposes Only It must not be dragged along the ground, nor against the edges of the main wings or propeller blades. lt must never be dropped to the ground after use but lowered carefully. Dust caps must be fitted to the hose delivery nozzles and also to the filters of the refuelling system when it is not in use. The bowser operator must stand by to control the pumping motors and cocks, as these must be operated after the nozzle cock has been turned ON and before the cock is turned OFF to avoid damage from an extensive pressure build up in the hose. The meters of the pressure refueller indicate the rates of fuel flow to the hoses. A slight retardation of flow shows that the first tank of the aircraft is full and that a pressure refuelling valve has closed. The indications for the various tanks will occur in quick succession until all tanks are full and the valves are closed when refuelling an aircraft having tanks of similar capacity. At this point the pressure indicated on the tanker gauge rises to the tanker relief pressure setting and the flow indicated on the meter slows down to zero. Usually a means of indicating each tank being full is provided: normally an indicator light will extinguish for each filled tank. The tanker operator makes all the preparations necessary for refuelling but it is the airman’s job to connect the hose unit to the aircraft. Issue: August 2014 Page 723 of 926 Modul 7 Aircraft Handling and Storage The Coupling Unit Refer to Figure 7 again. PART 66 – Basic Training Cat B1 – Module 7 Bonding cables are provided to the end of which a grounding plug is fixed for insertion into the aircraft’s grounding socket; a crocodile clip may also be provided for attachment to a suitable part of the aircraft if a grounding socket is not available. Between the hose and the inlet ot the coupling unit a conical strainer is located. Although all hose coupling units are similar in their general operation there are differences in design between one type and another. For example, some coupling units have a locking lever which is used to lock the valve either in the ’open’ or ’shut’ position. Usually this lever is brought into the ’unlock’ position until the coupling unit is engaged and then it is moved back to the ’lock’ position. When disconnecting the coupling unit the procedure is reversed. Therefore it is important to know how to use the coupling unit(s) in service at the airfield before operation. DefueIIing Defuelling is necessary when a fuel tank is to be removed for servicing or when the aircraft is undergoing repairs/modifications, or when the aircraft has crashed. lt may also be necessary to defuel an aircraft to conform to its all-up weight (AUW) for the specific task intended. With an aircraft fitted with pressure fuelling equipment the fuel system can be defuelled into the ground tanker by connecting the hose from the inlet side of the tanker pumps to the aircraft defuelling point. Aircraft with gravity systems have drain valves and/or drain plugs at the bottom of each tank though, exceptionally, there may be central defuelling point or collector box, in which case the aircraft booster pumps can be used to increase the rate of flow. Figure 7: Pressure Refuelling For Training Purposes Only Issue: August 2014 Page 724 of 926 Modul 7 Aircraft Handling and Storage After defuelling, all defuelling and drain points must be closed, sealed and locked. Without specific instructions to do so a fuel system should never be drained by disconnecting a fuel pipeline. The safety precautions to be taken for defuelling an aircraft are as important as those tor fuelling. Safety Precautions for Refuelling and Defuelling General Since aviation fuels must be volatile in order to facilitate starting and improve combustion, vapours are always a hazard to be considered. Therefore it is necessary to maintain the strictest precautions whenever handling aviation fuels. Take care, and remember the following general regulations for maintaining health: Always remember to wear protective clothing and try to avoid spillage onto your clothing and skin. Spilt fuel can burn and dry up the skin by dissolving out the natural oils, which results in cracks and infection, the most common infection being dermatitis. Always apply a barrier cream to your hands before commencing the refuelling operation and wash your skin with soap and warm water if any spillage occurs. Always re - apply a skin cream to put back the natural oils. Never eat, drink or smoke until you have washed your hands after using petroleum products. The following technical safety regulations are to be applied whenever fuel is handled: Only use the correct grade of fuel. For Training Purposes Only Issue: August 2014 PART 66 – Basic Training Cat B1 – Module 7 The area in which fuelling operations are being carried out is classified as a ’dangerous area’. The bounds of the area extend 8 m vertically and 16 m horizontally from the extremities of the aircraft being fuelled. During fuelling operations the risk of fire is great due to the large quantities of fuel vapour driven off into the atmosphere. All servicing trolleys, GPUs, airconditioning units should be positioned upwind of the refuel operation. There is also a considerable risk of static electricity, either from any charges accumulated on the aircraft or generated by friction during pressure refuelling. Ensure that both aircraft and bowser are earthed. Tools should be of a non - sparking material, such as aluminium, copper, brass or bronze. Non - sparking footwear, e.g. rubber, cork or pure leather is to be worn. Extreme care is to be taken to avoid fuel being deposited on the ground in the area of an aircraft, either during fuelling operations or as a result of fuel tank venting. Do not smoke or carry cigarette lighters or matches on your person Simultaneous fuelling operations and the loading/off - loading of nuclear weapons is not permitted. When it is necessary to fuel an aircraft fitted with a nuclear weapon, no other servicing is to be undertaken during the fuelling operation. All quality control checks on the fuel contained in the refueller are to be completed before the refueller hoses are connected to the aircraft. ln the case of hydrant fuelling, the fuel quality control checks are to be carried out immediately after fuel has commenced to flow through the dispensers. When fuelling aircraft from 45-gallon drums a check for water content is to be made by using the approved water detector and all transfers of fuel into an aircraft are to be made through the approved micro filter or filter separator. Page 725 of 926 Modul 7 Aircraft Handling and Storage Where auxiliary power plants are being used as the source of aircraft electrical power, they are to be started before the filler caps are removed or fuelling connections made. Should the auxiliary power plant stop for any reason during fuelling operations it is not to be re - started as long as the fuelling operation is in progress. No switches, circuitbreakers or electrical contact are to be operated either open or closed whilst refuelling (refuel panel excepted). Safety before Fuelling Refer to Figure 8. Extreme care must be taken to prevent fuelling hoses from resting on, or being pulled across, de –icer boots or leading edges of the main wings. Wing mats are always to be used. The following safety precautions must be observed before a fuelling operations commences: PART 66 – Basic Training Cat B1 – Module 7 The refuelling vehicle is to be bonded to the aircraft by connecting the refueller bonding cable to the aircraft servicing earth bolt. lf no earth bolt is fitted the bonding cable is to be connected to an unpainted metal part of the aircraft structure at a point approved by the Engineering Officer. When fuelling by the open line hose method the refueller hose and coupling (or nozzle, as appropriate) is to be bonded to the designated point on the aircraft by means of the bonding assembly provided before the aircraft tank filler cap is removed. The bonding assembly is to be removed after the cap has been replaced. ln addition to the bonding requirements the aircraft is to be earthed in accordance with current regulations when external electrical power is supplied to the aircraft. Where it is necessary to fuel aircraft in hangars provision is to be made for ready access for fire fighting vehicles and a quick and unobstructed removal of aircraft and equipment from the area Fire extinguishers of the approved type are to be readily available. The tanker driver will ensure that the grade markings displayed on the refueller are appropriate to the grade of fuel contained within the refueller. The airman is to ensure that this is the correct grade for the aircraft to be refuelled and that the markings on the bowser and required fuel type for the aircraft are identical. The refuelling vehicle is to be positioned in such a way that it can be removed quickly in case of an emergency, i.e. nose directed away from the aircraft. The aircraft is to be earthed to the ground. The refuelling vehicle is to be bonded to the ground by means of the trailing bonding strop fitted to its chassis. For Training Purposes Only Issue: August 2014 Page 726 of 926 Modul 7 Aircraft Handling and Storage PART 66 – Basic Training Cat B1 – Module 7 Safety during Fuelling The following safety precautions are to be taken during fuelling operations: Aircraft are not to be fuelled with running engines unless specific instructions to the contrary are issued by the Command Engineering Staff. Electrical loads other than those essential for the fuelling operation are not to be switched on except in an emergency. Radio sets and radar equipment installed in aircraft are not to transmit. Where aircraft are being fuelled with essential electrical sources switched on a competent tradesman is to be positioned at or in the aircraft to cut the main source of power quickly in an emergency. The refueller or hydrant dispenser operator is to remain at the refueller pumping compartment or hydrant dispenser head, being prepared to stop the fuel transfer in an emergency. The refueller hose and coupling or nozzle is never to be left unattended during fuelling operations Any spillage or leakage detected is to be investigated and remedied immediately. ln the event of a serious leak or spill, pumping and servicing operations are to be stopped and the refuelling vehicle pushed or towed from the affected area. All spilt fuel is to be neutralised and the area rendered vapour free before fuelling or other aircraft servicing operations are continued. Liquid oxygen systems are not to be replenished or exhausted Figure 8: Bonding Connections For Training Purposes Only Issue: August 2014 Page 727 of 926 Modul 7 Aircraft Handling and Storage PART 66 – Basic Training Cat B1 – Module 7 Operations after Fuelling The following operations are to be carried out after fuelling: remove refuelling hoses fit tank caps disconnect refueller bonding assemblies stow hoses in refueller enter details of fuel state in the appropriate aircraft record and sign against the entry. Note: The order in which aircraft fuel tanks are filled or emptied is governed by the type of aircraft. Therefore it is essential to consult the relevant maintenance manual before refuelling or defuelling is started. Summary Although the afore-mentioned defines the general safety procedures for the fuelling of aircraft it does not override any existing special to aircraft type regulations. Remember that all precautions taken in the manufacture and transportation of fuel are wasted unless the utmost care and attention is given to its handling at the aircraft. Aircraft refuelling is a highly specialised service and you carry a major responsibility when employed in this task. For Training Purposes Only Issue: August 2014 Page 728 of 926 Modul 7 Aircraft Handling and Storage 7.17.4 Definitions Aircraft De-Icing Note: This Lesson is provided for training purposes only. When actually working on any system/unit/equipment described here (or similar type), refer to the relevant original manufacturer‘s manual/documentation. 7.17.4.1 PART 66 – Basic Training Cat B1 – Module 7 Introduction The Role of De-Icing/Anti-Icing in Aviation Even small amounts of snow and ice on airframes and airfoils can significantly degrade the lifting properties and control of an aircraft. This poses a great safety risk, especially during the take off and climb out portions of a flight. Therefore, it is necessary that ice and snow are prevented from accumulating (anti-icing) or are removed (deicing) from aircraft as close to the departure time as possible. Refer to Figure 1. De-icing and anti-icing procedures have the same aim, i.e. to make equipment (aircraft) and road conditions safe for travel. These two processes use essentially the same materials which are applied to the same locations with the same equipment. The two processes differ in the time of application, amount of application and in some monitoring measures which help determine the time and amount of application. Snow and ice build up prevention and removal from airfields (runways, taxiways and roadways) are also essential for flight safety. Actual or predicted weather conditions are the trigger for anti-icing and de-icing activities. Aircraft and airfield anti-icing and de-icing operations often involve the use of chemical agents, which can be a significant source of water pollution. As part of the overall pollution prevention strategy, a number of changes in anti-icing and de-icing agents and procedures have been made or are expected in the near future. These changes are aimed at minimising the environmental impact of anti-icing and de-icing operations without jeopardising aircraft safety. Figure 1: Aircraft De-Icing For Training Purposes Only Issue: August 2014 Page 729 of 926 Modul 7 Aircraft Handling and Storage De-Icing De-icing involves spreading or spraying a liquid/solid de-icing agent on already formed ice and collected snow. This application lowers the freezing point of the snow/ice so that it becomes a liquid rather than remaining a solid. Anti-Icing Anti-icing involves spraying or spreading a liquid/solid de-icing agent directly on the pavement or aircraft before snow or ice is present, thus lowering the freezing point at which snow/ice bond to the pavement. 7.17.4.2 Types of De-Icing and Anti-Icing Agents Aircraft De-Icing/Anti-Icing Agents Aircraft de-icing/anti-icing agents are glycol based. Two separate and independent standards, military and commercial, are used to designate aircraft de-icing/anti-icing agents. The military specification covering these agents is ’Anti-icing and De-icing Defrosting Fluids’, MIL –A –8243D, which specifies two classifications: Military Type I – De-icing/anti-icing fluids that are propylene glycol based Military Type II – De-icing/anti-icing fluids that are ethylene glycol based (three parts ethylene glycol to one part propylene glycol). Propylene glycol based fluids are the only aircraft de-icing/anti-icing agents approved for purchase and use by Air Force activities. For Training Purposes Only PART 66 – Basic Training Cat B1 – Module 7 These military ’Type’ designations should not be confused with the commercial Society of Automotive Engineers (SAE) ’Type’ designations pertaining to aircraft de-icing/anti-icing fluids. The SAE designations, which meet Aerospace Material Specifications (AMS), classify aircraft de-icing/anti-icing agents based on their viscosity or ’holdover’ properties. The SAE designations do not distinguish between ethylene glycol or propylene glycol based agents. The chemical makeup of these agents is not a factor in the SAE designation, as is the case with the military designation. SAE Type I fluids (AMS 1424) are of low viscosity and are used primarily for de-icing aircraft. SAE Type II fluids (AMS 1428) are of higher viscosity and are used primarily as aircraft anti-icing agents. SAE Type II anti-icing agents are applied prior to icing conditions to prevent ice formation on the aircraft and must adhere to the aircraft longer than de –icing agents. Aircraft anti –icing requires a smaller volume of chemical, but requires specialised training and different application equipment than de-icing agents. Additionally, application of anti-icing agents on military aircraft may require special training or procedures due to their unique coatings as compared to commercial aircraft. Airfield De-Icing/Anti-Icing Agents A greater variety of de-icing/anti-icing agents are available for use at airfields than for aircraft. These agents include: Issue: August 2014 Glycols Urea alcohol and other new formulations, such as: sodium format Page 730 of 926 Modul 7 Aircraft Handling and Storage PART 66 – Basic Training Cat B1 – Module 7 Remote De –Icing sodium acetate and potassium acetate. Refer to Figure 2. 7.17.4.3 De-Icing/Anti-Icing Procedures ’Clean Aircraft’ Concept Aircraft must be free of ice and snow before take off because a build up on the wings and control surfaces causes the aerodynamic properties to deteriorate. This means that the aircraft needs a longer take –off roll, for instance, which in turn delays lift off and may even result in an abandoned take off. For aircraft with tail mounted engines, there is also the risk of ice sheets falling off the wings during take off and being ingested by an engine and causing damage. Consequently, all aircraft de-icing operations comply by a standardclean aircraft concept, for example (ISO 11076). This standard stipulates that an aircraft can take off only when it is completely free of frost, ice, snow and slush (de-icing) and adequately protected against the formation of new ice (anti-icing). Clear Ice in the Summer The official de-icing season at a typical Europe airport lasts from the beginning of October until the end of April. However, de-icing may also be necessary in the summer. For instance, when an aircraft lands after a long flight, the local air temperature may be +15oC, whereas the remaining fuel in the tanks has a temperature below – 30oC. If it rains during the aircraft’s turnaround time, the absorption of heat by the cold fuel can lead to the rapid formation of a sheet of clear ice on the wing surface. For Training Purposes Only Figure 2: Remote De-Icing with Closed Cabin De-Icing Trucks At a most modern airport, most aircraft (roughly 95 %) are de-iced just before take off with their engines running at special de-icing areas at the heads of the runways. Each de-icing area is provided with several mobile de-icing vehicles. Issue: August 2014 Page 731 of 926 Modul 7 Aircraft Handling and Storage PART 66 – Basic Training Cat B1 – Module 7 Reasons for the high percentage of remote de-icing operation include the strict environmental regulations for used de-icing fluids. under wing de-icing, or when de-icing aircraft outside the actual deicing season. As much of the sprayed de-icing fluid as possible is collected at the remote areas. It is regenerated in the airport’s recycling facility to produce new de-icing fluid. For example, propeller aircraft such as the Fokker 50 and the Dash 8, which have no propeller brakes, and general aviation propeller planes are de-iced on the apron. In these cases, de-icing is performed by special apron de –icing vehicles at the aircraft’s parking position. Apron De-Icing Engine and Propeller De-Icing Refer to Figure 3. These procedures use hot air. Accumulations of ice or snow on turbine blades or propellers result in vibrations during engine operation and may even cause damage to engines. One - Step and Two - Step Procedures One - Step Procedure The thin type de-icing fluid has a very short hold - over time, and is used at sub - zero temperatures both for de-icing and for protection against the formation of new ice. Because only one application of type I fluid is necessary, it is called ’one - step procedure’. Two - Step Procedure Figure 3: Apron De-Icing with Open Basket De-Icing Truck FB In some cases aircraft are de-iced on the apron. However, this happens only when it is not possible to de-ice the aircraft with running engines at the remote areas, for special de-icing procedures such as For Training Purposes Only However, if there is any form of precipitation (fog, mist, snowfall), then the two - step procedure is required. The first step involves de-icing the aircraft with type I de-icing fluid to remove all frost, ice, snow or slush. Type II de-icing fluid is then sprayed on the cleaned surfaces to protect the aircraft against the formation of new ice before take - off. Type II fluid forms a heavy film on horizontal surfaces, and consequently has a longer hold - over time than the thin type I fluid. Issue: August 2014 Page 732 of 926 Modul 7 Aircraft Handling and Storage PART 66 – Basic Training Cat B1 – Module 7 For example, type I has a very short hold –over time during snowfall at temperatures below 0° C. Type II has a much longer hold –over time under the same weather conditions. For the prevention of ice formation the de-icing fluid is sprayed onto the aircraft’s outside surfaces without being mixed with water, i.e. with a concentration of 100 %. If take off is delayed beyond the hold - over time, then the de-icing procedure must be repeated to protect the aircraft against the formation of new ice. In this case, the old de-icing fluid already sprayed onto the aircraft is ’washed off’ and replaced by fresh deicing fluid. The hold - over time then begins again. There are various types of de-icing vehicles. This Chapter describes two different types, which are: de-icer trucks towable de-icers. The de-icing fluid protects the aircraft only during the time on the ground. During take off, the de-icing fluid flows off the aircraft. On board technologies protect aircraft against ice formation while airborne. 7.17.4.4 Types of De-Icing Vehicles Refer to Figure 4. De-icing and ice-protection vehicles are special types of ground support equipment. They are movable and towable. They can have their own drive assemblies and their own power supply. The vehicles are designed to remove ice which has formed on aircraft surfaces or to prevent the formation of ice. It is also possible to use this equipment for the cleaning of aircraft surfaces. For de-icing, a mixture of water and de-icing fluid is sprayed over the appropriate surfaces. The mixture ratio of the water and the de-icing fluid spray can be varied by operating the relevant valves. To increase the effect of the mixture it is possible to heat up the water to a temperature of approximately 85oC. Figure 4: Aircraft De-Icing Truck Applications For Training Purposes Only Issue: August 2014 Page 733 of 926 Modul 7 Aircraft Handling and Storage PART 66 – Basic Training Cat B1 – Module 7 De-Icer Trucks Description Refer to Figure 5. The de-icer truck shown in Figure 5, made from the manufacturer Vestergaard, is a self –contained unit designed to heat and spray deicing fluid, apply anti –icing fluid, and wash aircraft. The concept of this de-icing truck is to provide the operator with the shortest spray distance and largest operating range. The long reaching telescopic spray boom enables fast and effective operation while minimising fluid consumption. The concept enables minimum truck positioning and maintains a safe distance from the aircraft. Fluid Economy Product development continuously generates numerous features that save fluid and minimise environmental impact. Proportional Fluid Mix The Freeze Point + System provides optimal blend according to actual weather conditions, thereby saving significant amount of fluid. The system ensures very accurate mix, fast reaction times and has a surveillance safety system. Heating Systems The highly efficient heater and the ’hot at nozzle system’ economically and effectively provide hot fluid to the nozzle at all times. The heating system ensures hot fluid (90 ° C) available immediately after refilling. The hot at nozzle system circulates hot fluid in external fluid lines ensuring maximum de-icing efficiency immediately when opening the nozzle. Figure 5: Typical Aircraft De-Icer Truck For Training Purposes Only Issue: August 2014 Page 734 of 926 Modul 7 Aircraft Handling and Storage Low Flow Fluid Application Thickened fluid can be applied in a uniform layer at a low flow rate maintaining fluid properties. PART 66 – Basic Training Cat B1 – Module 7 The operator’s cabin easily holds two persons. It is ergonomically designed to provide operator comfort for extended periods of operation. Together with the unit stability it provides the operator with unsurpassed working conditions and an excellent view. Nozzle Unit Forced Air System A highly efficient snow removal procedure is provided by the manoeuvrable nozzle and the shortest available blow distance. The nozzle unit manoeuvrability allows backwards spraying towards the operator, enabling wing de-icing from the trailing edge of the wing without spraying towards flaps, rudders etc. Safety antennas are placed on the boom to avoid damage to aircraft. Diaphragm Pumps Advantages To minimise fluid degradation the fluid system is equipped with diaphragm pumps. Manpower Efficiency The de-icer can be easily switched from two man to one man operation and back allowing maximum manpower flexibility. In one man operation mode all chassis movements are controlled from the operator’s cabin. When de-icing with aircraft engines running, the one man operation ensures that the operator keeps a safe distance from the engine blast. Main Lifting Boom The main lifting boom operates vertically above the center line of the unit. The concept provides an unmatched stability even in the most harsh working conditions and positions. The boom extends to a maximum length of 15 m and provides a vertical nozzle reach of 23 m. For Training Purposes Only Major advantages are: Minimum glycol consumption Closed cabin for optimal working conditions One –man operation mode for ultimate flexibility Ideal for remote de-icing with running aircraft engines Data transmission system for organizing dispatch and collecting de-icing data. Dimension Issue: August 2014 Maximum ground to eye level: Maximum ground to nozzle height: Minimum ground to nozzle height: Minimum operational height: Minimum height (cabin folded) Overall width: Overall length: b (depending on tank size) 15.5 m 23 m 1.5 m 5.2 m 4.1 m 2.5 m 10.3 –11.7 m. Page 735 of 926 Modul 7 Aircraft Handling and Storage PART 66 – Basic Training Cat B1 – Module 7 Tank Capacity Total tank capacity: Total unit weight: (depending on tank size) 8,000 or 11,500 liter 30,000 – 36,000 kg. Towable De-Icer Small Flexible De-Icer Unit Refer to Figure 6. Description The de-icer shown in Figure 6 is designed to service aircraft from a movable platform with a maximum lifting height of 6.3 m. It is a self-contained unit that can spray type I de-icing fluid onto an aircraft. It can also be used to wash aircraft surfaces. The de-icer can be mounted on various movable platforms by utilising a simple fork lift. Dimensions Overall length: Overall width: Overall height: Maximum lifting height: 4.3 m 2.0 m 2.5 m 6.3 m. Tank capacity Tank 1 1,450 liter Tank 2 550 liter. For Training Purposes Only Figure 6: Towable De-Icer Issue: August 2014 Page 736 of 926 Modul 7 Aircraft Handling and Storage 7.17.4.5 PART 66 – Basic Training Cat B1 – Module 7 Ice-Control Nozzle General Refer to Figures 7 and 8. Ice – control nozzles have been specifically designed to apply water, glycol or water/glycol based ice – control fluids to aircraft exterior surfaces at fluid temperatures up to 210oF (99oC). The proper use of de-icing agents aids ground support professionals in the removal of ice from aircraft fuselage, landing gear and wing surfaces. The proper use of anti-icing agents aids ground support professionals in their efforts to prevent ice and snow from adhering to the wings of aircraft. This may extend holdover times and help make air travel in cold weather conditions less hazardous. These nozzles are only part of a complete ice – control system. Suitability of a particular nozzle for applying de-icing or anti –icing fluids must be determined by the end user of the nozzle. Figure 7: Ice-Control Nozzle of a De-Icing System For Training Purposes Only Issue: August 2014 Page 737 of 926 Modul 7 Aircraft Handling and Storage PART 66 – Basic Training Cat B1 – Module 7 Ice – Control Nozzle Valved Model Valved ice –control nozzles have: automatic pressure control for optimum reach slide type valve with heat resistant seat: the valve controls the flow through the nozzle while minimising turbulences that cause shear and degradation of anti-icing fluids pattern control: the nozzle has a ’toothless’ bumper to reduce turbulences. It can be easily adjusted for any desired spray pattern from a straight stream to a wide spray positionpistol grip: the pistol grip and flow control handle are insulated to protect the operator from the high temperatures generated by fluids passing through the nozzle. Ice –Control Nozzle Electric Remote Model Electric remotely controlled ice – control nozzles have: automatic pressure control for optimum reach. pattern control: the pattern adjustment is operated electrically. The nozzle has a ’toothless’ bumper to reduce turbulences. It can be easily adjusted for any desired spray pattern from a straight stream to a wide spray position sealed electric motor with easy to use manual override. flush: easily flushable while flowing to clear trapped debris. swivel connecting coupling for ease of installation. Figure 8: Applications of Ice-Control Nozzles For Training Purposes Only Issue: August 2014 Page 738 of 926 Modul 7 Aircraft Handling and Storage Nozzle Controls Flow Control Lever Type Flow Control On models that use a ball – type valve handle, the nozzle is shut – off when the handle is fully forward. The valve handle has six detent flow positions. These detent positions allow the nozzle operator to regulate the fluid flow of the nozzle depending on the need or what can be safely and effectively handled. PART 66 – Basic Training Cat B1 – Module 7 Electric pattern control: On models that use an electric pattern control, a continuously variable pattern from narrow to wide is available by operating the electric actuator according to the directions supplied with the actuator control panel. Extending the shaper outwards, as seen from behind the nozzle, moves the shaper to the straight stream position. Retracting the shaper inwards will result in an increasingly wider pattern. The actuator ’free wheels’ at each end of its stroke make limit switches unnecessary. A manual override lever on the electric actuator, when depressed, allows the manual override knob to be turned. Turning the knob counter –clockwise, as seen from the operating position behind the nozzle, extends the shaper towards the ’STRAIGHT STREAM’ position. Turning the knob clockwise retracts the shaper towards the ’WIDE SPRAY’ position Electric Remote Nozzles On models with electric remote control of the shaper there is no built in flow control. Flow control must be provided for elsewhere in the system. Pattern and Flush Control An electric remote nozzle has finger pinch points. Keep fingers away from the nozzle when using electric points. Pattern Control Manual pattern control: On models that use a twist type pattern control, a continuously variable pattern from narrow to wide is available. Turning the shaper clockwise, as seen from the operating position behind the nozzle, moves the shaper to the straight stream position. Turning the shaper counter –clockwise will result in an increasingly wider pattern. An indicator band on the nozzle barrel shows the position of the shaper by progressively uncovering symbols for ’FLUSHING’, ’WIDE SPRAY’ and ’STRAIGHT STREAM’. For Training Purposes Only Flush control Debris may get caught inside the nozzle. This trapped material will cause poor stream quality, shortened reach and reduced flow. To remove this trapped debris, the nozzle can be flushed as follows: Issue: August 2014 Valved nozzle flushing While still operating, turn the shaper counter –clockwise past the wide spray position (increased resistance to turning will be felt on the shaper as the nozzle goes into flush). This will open the nozzle allowing debris to pass through. Page 739 of 926 PART 66 – Basic Training Cat B1 – Module 7 Modul 7 Aircraft Handling and Storage Rotate the shaper clockwise out of the flushing position to continue normal operation. During flushing, the nozzle will lose much of its reaction force and reach as the pressure drops. The nozzle operator must be prepared for an increase in reaction, reach and pressure when returning the nozzle from the flushing position to normal operation to retain control of the nozzle and stream. Operating the nozzle in the flushing position will lead to an increased volume of fluid flowing out. Operate only when necessary in the flushing position and only for a short amount of time to prevent fluid waste. Electric remote flushing While still operating, retract the shaper backwards past the wide spray position (as viewed from behind the nozzle) until it reaches its stop. This will open the nozzle allowing debris to pass through. When the debris has been flushed out, extend the shaper outwards until it is out of flush as determined by the markings on the barrel and the force of the stream to continue normal operation. Flushing may also be accomplished in the manual override mode of operation by moving past the wide spray position. During flush, the nozzle will lose much of its reaction force and reach as the pressure drops. Hot ice – control fluids are capable of causing burns. Direct stream always away from personnel when flushing as hot fluid may splash to the ground directly under the nozzle. Note: If flushing does not remove the debris completely disconnect the nozzle for cleaning. Before disconnecting release the pressure and drain the nozzle. 7.17.4.6 Other Aircraft De-Icing Methods Physical/Mechanical Methods Brooms and ropes have been used to remove large accumulations of snow from aircraft, and are still used by some airlines prior to de-icing to reduce the quantity of aircraft de-icing fluids (ADF) necessary to clean the aircraft. Wing blankets have also been used to cover aircraft wings during snowstorms which also helps reducing ADF usage. De-Icing Boots Refer to Figure 9. Boot de-icing (Figure 9, detail a)) works by inflating a rubber boot located on the leading edge of an aircraft wing. When inflated, the boot causes ice to crack and become dislodged from the surface. Passing air then blows the ice away. This method of de-icing is primarily used on the leading wing edges of propeller-driven aircraft. Operating the nozzle in the flushing position will lead to an increased volume of fluid flowing out. Operate only when necessary in the flushing position and only for a short amount of time to prevent fluid waste. For Training Purposes Only Issue: August 2014 Page 740 of 926 Modul 7 Aircraft Handling and Storage PART 66 – Basic Training Cat B1 – Module 7 Figure 9: Typical De-Icing Methods For Training Purposes Only Issue: August 2014 Page 741 of 926 Modul 7 Aircraft Handling and Storage Infra-Red Heaters Refer to Figure 9 again. Infra-red de-icing systems (Figure 9, detail b)) have been developed to de - ice small aircraft. This system uses a natural - gas - fired radiant heater located inside a drive - through hangar. PART 66 – Basic Training Cat B1 – Module 7 that minimise spray losses. A variety of aircraft can sequentially go through the de - icing process using the same gantry. The precise control of the de - icing application and close proximity of the spray nozzles to the aircraft help reduce the volume of de - icing fluid needed to adequately de - ice the aircraft. Hot Air Blast De-Icing The system has one - tenth the cost of chemical de-icing. However, the technology requires a drive - through building large enough to contain the aircraft and must be located adjacent to active runways. Follow - up chemical de-icing or anti - icing is usually required to provide anti-icing protection and prevent the re - freezing of water in the aircraft’s moving parts. Hot air blast de-icing systems use heated compressed air to blow off snow and ice from aircraft wings. Air blast de - icing may be followed by conventional de - icing/anti-icing or accompanied by a fine spray of glycol de - icing fluid to prevent new ice formation. Resistive Heating Refer to Figure 10. Another method of de-icing involves the use of electrical resistive heating to remove ice from the vital surfaces of an aircraft. By applying resistive heating energy to heating mats located near the skin of an aircraft, ice is melted at the contact surface of the aircraft, and the ice is then easily dislodged. Typically, the pilot decides when to apply current, and an electronic control unit distributes power to the heating mats. This method of de-icing is typically used on the wings, propellers, and air intakes of small to medium size aircraft. The hybrid de - icing system (HDS) is a unique aircraft ground de icing system that dramatically reduces glycol usage. It is an environmentally friendly, fast, high - performance, innovative solution for any de-icing condition. Hybrid De-Icing System (HDS) HDS utilises a jet of air to remove snow and ice from the aircraft supplemented, when required, with a jet of glycol. Coaxial Nozzle Computerised Gantry Refer to Figure 9 again. HDS utilises both forced air and heated glycol premix to de-ice the aircraft. A computer – controlled gantry (Figure 9, detail c)) is similar to a drive - through car wash. Each aircraft going through this process is assigned a preset series of spray instructions depending on aircraft characteristics. The gantry is equipped with high - efficiency nozzles For some de-icing conditions though, the ’air only’ mode (no glycol) is sufficient to remove the snow built up. Air from a high - speed centrifugal compressor and hot premix from a high - pressure pump are independently delivered to a unique coaxial nozzle. The coaxial For Training Purposes Only Issue: August 2014 Page 742 of 926 Modul 7 Aircraft Handling and Storage PART 66 – Basic Training Cat B1 – Module 7 nozzle emits a high velocity premix jet that is within an equally high velocity air jet producing an effective jetting system that both sweeps away and melts the frozen precipitation. The premix jet within an air jet delivered by the hybrid coaxial nozzle yields an efficient and cost effective de-icing system. The premix jet can be instantly turned ’on’ or ’off’ or adjusted to 9 or 20 gpm flow rates. This on demand adjustment to specific de-icing conditions and the simultaneous application of air and premix are the basis for the efficiency and cost effectiveness of this one – step de-icing system. Covered Storage A final less obvious physical solution to aircraft de-/anti-icing is covered aircraft storage. This concept is extensively used for fighter planes by the Air Force, and it works well for small aircraft. It is not generally a feasible alternative for commercial passenger aircraft or large jets. Figure 10: Hybrid De-Icing System (HDS) For Training Purposes Only Issue: August 2014 Page 743 of 926 Modul 7 Disassembly, Inspection, Repair and Assembly Techniques PART 66 – Basic Training Cat B1 – Module 7 7.18 Disassembly, Inspection, Repair and Assembly Techniques the impact, resulting in structure deformation, drawn rivets or bolt holes. 7.18.1 Inspection Techniques If misalignment or twisting of the aircraft structure is suspected, alignment and/or levelling checks must be carried out. 7.18.1.1 Types of Defects Damage Categories General After cleaning and investigating the damage and surrounding area, the damage must be classified into one of the following categories, also taking into account the location of the damage. Refer to Figure 1 und 2 The term ’damage’ includes any and every type of permanent deformation or alteration to any cross - section of a structural component. Deformation or alteration to the cross - section of a structural component results from many causes, which can be generally categorised into four main groups as shown in Figure 1. Allowable damage (or: permissible damage) is defined as damage which is slight or of little significance, and is unlikely to be of sufficient severity to propagate further damage in the immediate vicinity. Examine the type and extent of the damage. To determine the damage category: remove all unwanted material from the surface of the damaged component, cut out all broken, bent, heated or badly damaged areas of the component, remove all Loose rivets. In all forms of damage, particularly where shock has been sustained, secondary damage is likely to exist. Therefore, a close examination of the structure surrounding the initial damage must be made. Damage caused by transmission offorce may be Located some distance from For Training Purposes Only The damage must be classified either as ’Allowable Damage’ or as damage which requires a repair. Allowable (Permissible) Damage Examination of Damage Repairable Damage Note: ’Allowable’ does not mean that a repair is unnecessary. Example: Scratches and burring are included in this category, and it is necessary to remove rough and sharp edges and smooth out the damage. In addition, any damage to surface coatings and/or protective treatment must be repaired using an approved procedure. Issue: August 2014 Page 744 of 926 Modul 7 Disassembly, Inspection, Repair and Assembly Techniques PART 66 – Basic Training Cat B1 – Module 7 Figure 1: Types of Defects For Training Purposes Only Issue: August 2014 Page 745 of 926 Modul 7 Disassembly, Inspection, Repair and Assembly Techniques PART 66 – Basic Training Cat B1 – Module 7 No Allowable Damage Damage which exceeds the ’Allowable Damage’ limits can be repaired by cutting out the damaged area of a structural component and inserting or attaching a reinforcing piece. These specific repairs are to be found in each chapter of the structural repair manual (SRM). No Repairable Damage No repairable damage is defined as damage to structural components which cannot be repaired and where replacement of the complete component is recommended because a repair is not practical or economical. Figure 2: Types of Defects For Training Purposes Only Issue: August 2014 Page 746 of 926 Modul 7 Disassembly, Inspection, Repair and Assembly Techniques 7.18.1.2 PART 66 – Basic Training Cat B1 – Module 7 Visual Inspection General Remarks Refer to Figure 3 . The most fundamental method of inspecting aircraft structures and components is through visual inspection. This method is irreplaceable in certain circumstances and limited in others. In any case, nothing can be inspected visually unless it is uncovered and made visible. The basic tools required to conduct a visual inspection include a good light, a mirror, and some form of magnifying glass. Flashlights are typically used to give spot - type illumination to the inspection area. Some flashlights have flexible extensions that allow you to illuminate inaccessible areas. Before the inspection area is cleaned the surface must be checked for indications of cracks, because in many cases the indication of a discontinuity/flaw is shown in the form of oil or dirt which has exited. Figure 3: Visual Inspection For Training Purposes Only Issue: August 2014 Page 747 of 926 Modul 7 Disassembly, Inspection, Repair and Assembly Techniques Inspection Tools Rigid Endoscopes Optical instruments can be used to assist in the inspection by magnifying such discontinuities/flaws which are too small to be seen by eye. Refer to Figure 4. Visual inspection aids being used for material testing are: flashlights/torches magnifying instruments – low - power magnifiers (2x - 6x magnification) used on large surface areas – high - power magnifiers (8x - 10x magnification) can be used for more careful inspection of small, local areas – microscopes with varying magnifying power can be used to examine local areas on critical parts – endoscopes (or: borescopes) with optical lenses can be used to view inside of components and other restricted areas (e.g. engines). PART 66 – Basic Training Cat B1 – Module 7 Endoscopes can be supplied with optical systems which provide direct, right-angled, rear and fore oblique directions of view to examine internal areas. They are available with different magnification powers and adjustable focus controls. Some endoscopes have an adapter on their eyepiece which permits the image of the inspection area to be recorded on photographic film, on video or to be viewed with a TV system. Endoscopes An endoscope is an optical device similar in principle to a telescope in that it enlarges objects like a magnifying glass. However, an endoscope has a small lens mounted on a shaft with a built - in light source that illuminates the area being inspected. Endoscopes are typically used to inspect the inside of engines using e.g. the spark plug hole for access. This optical device allows inspection without disassembly. For Training Purposes Only Issue: August 2014 Page 748 of 926 Modul 7 Disassembly, Inspection, Repair and Assembly Techniques PART 66 – Basic Training Cat B1 – Module 7 Flexible Endoscopes Refer to Figure 5. Flexible endoscopes are armoured plastic tubes which can be manipulated into different curves and angles to permit access to areas which cannot be reached with rigid endoscopes. At each end of the endoscopes there is a lens system which is connected by two bundles of glass fibres. The outer bundle of glass fibres transmits light to the inspection area, while the inner bundle transmits the image of the inspection area to the lens in the eyepiece. Flexible endoscopes can have replacement lenses which permit a change of the angle or of the field of view. Some endoscopes have a knob near the eyepiece which controls a steerable tip (’distal end’). Figure 4: Rigid Endoscope For Training Purposes Only Issue: August 2014 Page 749 of 926 Modul 7 Disassembly, Inspection, Repair and Assembly Techniques PART 66 – Basic Training Cat B1 – Module 7 Video Scope Refer to Figure 5. Another endoscope used for inspecting inaccessible locations is the video endoscope. The video scope is similar to a fiberoptic scope, except that the image is recorded by a tiny light – sensitive chip in the end of the probe and transmitted electronically to a video monitor. The video scope provides a high quality image of the area being viewed and can easily be adapted to video recording equipment for inspection records and review. Figure 5: Flexible Endoscope For Training Purposes Only Figure 6: Video Imaging System Issue: August 2014 Page 750 of 926 Modul 7 Disassembly, Inspection, Repair and Assembly Techniques Black Light Black light is a part of the ultraviolet light spectrum. Petroleum based products and certain other materials fluoresce under black light. This characteristic can be used for: penetrating inspection procedures magnetic particle inspection procedures visual detection of leaks (oil and fuel). Note: Glass fibres absorb ultraviolet light to a high extent. Special light conductors (fluid conductors) must be used when using endoscopes together with ultraviolet light! Although the black light is not dangerous, you must take some precautions when you use the high – pressure mercury lamps which usually supply the black light source: do not look directly at the black light source do not use the lamp if the filter is damaged or not installed do not let your skin be exposed to black light longer than necessary do not put on photochromatic spectacles (a certain type of sun glasses) when you do inspections with a black light source do not use black light near flammable gases. The black light sources have temperatures which are higher than the ignition point of most fuel vapours. 7.18.1.3 Treatment of Corrosion Regardless of the type of corrosion or the metal involved, corrosion treatment requires three basic steps: For Training Purposes Only PART 66 – Basic Training Cat B1 – Module 7 remove as much of the corrosion as possible neutralise any residual material restore the protective surface film. Corrosion Removal As previously discussed, the first step in corrosion control must be cleaning the surface. After the surface is completely clean and it is determined that corrosion does exist, the damage must be carefully assessed and a decision must be made as to what action should be taken. All corrosion products must be removed as soon as they are discovered, because corrosion continues as long as the deposits remain on the surface. Corrosion under a paint film cannot be thoroughly inspected without first removing all of the paint. However, before using an unfamiliar paint remover, first test it on a piece of metal similar to that of the structure to be worked on. One thing to keep in mind is never use a caustic paint remover. Prior to applying a paint remover, all areas not to be stripped should be masked with heavy aluminium foil to keep the stripper from accidently coming into contact with these areas. Water –rinsable paint remover having a syrupy consistency is usually best for aircraft surfaces. This type of remover is applied with a brush by daubing it on the surface rather than brushing it on. The surface is to be covered with a heavy coating of remover and it is allowed to stand until the paint swells and wrinkles up. This breaks the bond between the finish and the metal. It may be necessary to re - apply the remover. If so, scrape the old paint away with a plastic or aluminium scraper and apply the second coat of remover. This allows the active chemicals to get to the lower layers of finish. Issue: August 2014 Page 751 of 926 Modul 7 Disassembly, Inspection, Repair and Assembly Techniques PART 66 – Basic Training Cat B1 – Module 7 Refer to Figure 7 When stripping large areas, spread a sheet of polyethylene plastic over the wet paint remover to slow its drying time. After all of the finish has swelled up and broken away from the surface, it should be rinsed off with hot water or with live steam. A stiff nylon bristle brush may be required around rivet heads and along seams to get all of the stubborn paint that adheres to these places. Many solvents used in paint removers attack rubber and synthetic rubber products. Therefore, tyres, hoses and seals must be protected from contact with paint removers. Most paint removers are usually highly toxic; therefore, special care must be exercised to avoid contact with the skin and eyes. If paint remover is spilled or splashed on your skin, flush the area with water immediately. If any gets into your eyes, flood them with water and get to a doctor as soon as possible. Treatment of Aluminium Alloys Refer to Figure 8. In general, corrosion of aluminium can be more effectively treated on the aircraft than corrosion occurring on other structural materials. Treatment includes the mechanical removal of as much of the corrosion as practicable, the neutralisation of residual materials by chemical means and, finally, the restoration of the permanent surface coating. Mechanical Corrosion Removal After the paint is removed from a corroded area, all traces of corrosion must be removed from the surface. Very mild corrosion may be removed by using a neutral household abrasive cleaner, such as Bon –Ami, but it is to be ensured that the abrasive does not contain chlorine. Nylon scrubbers, such as ’Scotch Brite’ pads, can also be used to remove mild corrosion. More severe corrosion can be removed by brushing with aluminium wool or an aluminium wire brush. Figure 7: Surface Preparation for Surface Refinishing For Training Purposes Only Issue: August 2014 Page 752 of 926 Modul 7 Disassembly, Inspection, Repair and Assembly Techniques PART 66 – Basic Training Cat B1 – Module 7 Note: Under no circumstances should a steel wire brush or steel wool be used since traces of the steel can become embedded in the aluminium and lead to severe corrosion. Figure 8: Typical Corrosion Removal and Treatment for Aluminium Alloys For Training Purposes Only Issue: August 2014 Page 753 of 926 Modul 7 Disassembly, Inspection, Repair and Assembly Techniques PART 66 – Basic Training Cat B1 – Module 7 Refer to Figure 9. Figure 9: Abrasives for Corrosion Removal For Training Purposes Only Issue: August 2014 Page 754 of 926 Modul 7 Disassembly, Inspection, Repair and Assembly Techniques PART 66 – Basic Training Cat B1 – Module 7 Blasting the surface with glass beads smaller than 500 mesh can be used to remove corrosion from pits. After using abrasives or brushing, the metal is to be examined with a 5 - to - 10 - power magnifying glass to ensure that all traces of the corrosion have been removed. distinctive, but also provides additional protection from impact damage and corrosion. Severely corroded aluminium alloys must be given more drastic treatment to remove all corrosion. In these situations rotary files or power grinders using rubber wheels impregnated with aluminium oxide are used to grind out corrosion damage. However, when using either of these tools it has to be ensured that the minimum amount of material is removed by constantly checking the workpiece. Pure aluminium is considered to be non – corrosive. However, this is not altogether true because aluminium readily combines with oxygen to form an oxide film. This film is so dense that it excludes air from the metal’s surface thereby preventing additional corrosion from forming. The disadvantage of using pure aluminium is that it is not strong enough for aircraft structural components and, therefore, must be alloyed with other metals. After an examination with a 5 - or - 10 - power magnifying glass shows no trace of corrosion remaining, approx. 1/1,000 of a millimeter more material is to be removed to ensure that the ends of the intergranular cracks have been reached. Then the area is to be made smooth by sanding with 280 – grit, then 400 – grit, abrasive paper and cleaned with solvent or an emulsion cleaner and the surface is to be neutralised with an inhibitor (e.g. Alodine). As discussed earlier, once aluminium is alloyed, the alloying agent creates the possibility of dissimilar metal corrosion. However, aluminium alloys can be protected from corrosion and at the same time made attractive in appearance by coating them with a layer of pure aluminium. This is known as cladding. Chemical Neutralisation After removing all corrosion, treat the surface with a 5 – % chromic acid solution to neutralise any remaining corrosion salts. After the acid has been on the surface for at least 5 min, it should be washed off with water and allowed to dry. Alodine treatment will also neutralise corrosion, as well as form a protective film on the metal’s surface (application of Alodine treatment will be discussed later). Protective Coating Protective coating is performed by a bare aluminium finish to save weight or by a painted finish. Paint is not only attractive and For Training Purposes Only Cladding In the manufacture of clad aluminium, pure aluminium is rolled onto the surface of an aluminium alloy and accounts for 5 % to 10 % of the total sheet thickness. The cladding material is anodic as compared to the core material and any corrosion that takes place attacks the cladding rather than the core. Surface Oxide Film The characteristic of aluminium cladding to form an oxide film on its surface is of real value in protecting aluminium from corrosion. However, in areas where cladding is not practical, metallurgists have found other ways of forming films on metal surfaces that are hard, decorative, waterproof and airtight. Furthermore, these films typically have the added benefit of acting as a base for paint finishes to adhere Issue: August 2014 Page 755 of 926 Modul 7 Disassembly, Inspection, Repair and Assembly Techniques PART 66 – Basic Training Cat B1 – Module 7 to. The process of applying an oxide film is performed in the factories by an electrolytic process known as ’anodising’. break in the film of rinse water indicates the presence of wax, grease or oil on the surface and further cleaning must be done. The anodising process is an electrolytic treatment in which a part is bathed in a lead vat containing a solution of chromic acid and water. This process forms an oxide film on the part that protects the alloy from further corrosion. While the surface is still wet, brush or spray on a liberal coating of the chemical, allow it to stand for 2 min to 5 min, then rinse it off. If the surface is not kept wet while the chemical is working, streaks may appear and the film will not adequately protect the metal. After the oxide film has formed, the part is washed in hot water and air – dried. Aluminium treated by this process is not appreciably affected with regard to its tensile strength, its weight or its dimensions. The anodic film on aluminium alloy is normally a light gray colour, varying to a darker gray for some of the alloys. However, some aluminium alloy parts, such as fluid line fittings, are dyed for identification. Note: For large areas, treatment should be carried out in stages, i.e. only treat an area that can be kept wet throughout the treatment. After the chemical has had its full working time, flush it from the surface with a spray of fresh water. If a swab or a brush is used, exercise care not to damage the film. The surface is ready to paint after the Alodine solution dries. A satisfactory application produces a uniform yellowish – brown iridescent film or an invisible film, depending on the chemical used. If a powder appears on the surface after the material is dried, it is an indication of poor rinsing or failure to keep the surface wet during the time the chemical was working. If the powder shows up, the part must be retreated. In addition to preventing corrosion, the anodic film produced by the anodising process also acts as an electrical insulator. Therefore, the film must be removed before any electrical connection can be made. Bonding straps are often connected directly to an aluminium alloy part and for this attachment, the anodised film must be removed by sanding or scraping. When small parts are fabricated in the field or when the protective anodising film has been damaged or removed, the part can have a protective film applied through chemical rather than an electrolytic process. This process is known as ’alodising’ and uses a chemical that is available under several proprietary names, such as Alodine 1201. Prior to alodising a component, all traces of corrosion must be removed. The surface should then be cleaned with a metal cleaner until it supports an unbroken water film. In this water break test, any For Training Purposes Only Rags and sponges used in the application of conversion coating chemicals must be kept wet or thoroughly washed out before they are discarded. Rags drying with the chemical in them constitute a fire hazard. Organic Film One of the most universally used corrosion control devices for metal surfaces is a good coat of paint. Paint adherence is not a problem on porous surfaces, but on smooth surfaces, such as those found on aluminium, the surface must be prepared in order for the paint to have a rough surface to which it can adhere. Issue: August 2014 Page 756 of 926 Modul 7 Disassembly, Inspection, Repair and Assembly Techniques An aluminium surface is typically roughened with a mild chromic acid etch or by the formation of an oxide film through anodising or alodising. The surface can also be mechanically roughened by carefully sanding it with 400 – grit sandpaper. When sandpaper is used, it is absolutely imperative that every bit of sanding dust be removed with a damp rag before the primer is applied. Shop rags or hand towels obtained from a commercial service do not normally make good rags for washing surfaces prior to painting. These rags, though clean, frequently contain silicone or other surface contaminants that are incompatible with finishing materials. After removing dust and contaminants, perform a final cleaning of the surface with aliphatic naphtha (thinners) or an approved prep solvent. Zinc Chromate Primer Zinc chromate primer has been used for years with lacquer and enamel. It is an inhibiting primer, meaning that the film is slightly porous and water can enter it causing chromate ions to be released and held on the surface of the metal. This ionised surface prevents electrolytic action and inhibits the formation of corrosion. Zinc chromate conforms to specification MIL - P - 8585 A and can have either a yellow –green or a dark green colour. It is thinned with Toluol or some of the proprietary reducers made especially for zinc chromate. Prior to applying zinc chromate, the surface to be painted is cleaned of all fingerprints and traces of oil. Then a thin, wet coat of zinc chromate is applied with a spray gun. Because zinc chromate is toxic, an appropriate filter mask or respirator is always to be used when spraying zinc chromate or other paint products. The synthetic resin base of a zinc chromate primer provides a good bond between the finish and the metal. It also has the property of being dope – proof, which means aircraft dope does not cause it to For Training Purposes Only PART 66 – Basic Training Cat B1 – Module 7 lift. When a repair is made or a part is fabricated, zinc chromate is often applied to stop corrosion before it ever gets a chance to start. Wash Primer A wash primer is used in aircraft factories for priming new aircraft before they are painted. This 2 – part primer consists of a resin and an alcohol – phosphoric acid catalyst. The material is mixed and allowed to stand for a short time. It is then sprayed onto the surface with a very light tack coat, followed by a full – bodied wet coat. Epoxy Primer Epoxy primers are one of the most popular primers for use under polyurethane finishes because they provide maximum corrosion protection. A typical epoxy primer consists of 2 component materials that produce a tough, dope – proof sandwich coat between the finish and the surface. Epoxy primers can be used on aluminium, magnesium or steel. For maximum corrosion protection, they can be applied over a wash primer. The new finishes that are available for aircraft use give beauty and protection far greater than the older, more familiar materials. However, the critical nature of their mixing and application makes it imperative that the manufacturer’s instructions be followed in detail. Most finishing materials are classified as ’systems’ and as such, each has a specific set of recommended materials with which it is compatible. Treatment of Ferrous Metals As with other materials, ferrous metal structures and components require some form of protection from corrosive agents to maintain their strength. However, because of their different chemical Issue: August 2014 Page 757 of 926 Modul 7 Disassembly, Inspection, Repair and Assembly Techniques composition, ferrous materials must be treated differently to achieve the same results. PART 66 – Basic Training Cat B1 – Module 7 immediately, new damage rapidly sets in. Zinc chromate primer is used to protect most freshly cleaned steel surfaces. Mechanical Corrosion Removal Unlike aluminium, the oxide film that forms on ferrous metals is porous and attracts moisture. Therefore, if any trace of iron oxide remains on an iron alloy, it continues to convert the metal into corrosion. The most effective method of removing rust is by mechanical means. Abrasive paper and wire brushes can be used, but the most thorough means of removing all corrosion from unplated steel parts is by abrasive blasting. Abrasive blasting is typically done using sand, aluminium oxide or glass beads. If a part has been plated, either with cadmium or with chromium, exercise care to protect the plating, since it is usually impossible to restore it in the field. Highly stressed steel parts, such as those used in landing gear and engines, must be cleaned with extreme care. If corrosion is found on these parts, it should be eliminated immediately by removing the absolute minimum amount of material. A fine stone, fine abrasive paper or even pumice typically works well. Wire brushes should not be used since they cause minute scratches which can produce stress concentrations that potentially weaken a part. If abrasive blasting is used, it must be done with caution, using a very fine – grit abrasive or glass beads. Refer to Figure 10. After all corrosion has been removed, any rough edges caused by pitting must be feathered with a fine stone or with 400 – grit abrasive paper. The surface should then be primed as soon as possible. A dry, clean surface is an ideal setting for corrosion and if not protected For Training Purposes Only Issue: August 2014 Figure 10: Corrosion Removal Page 758 of 926 Modul 7 Disassembly, Inspection, Repair and Assembly Techniques Surface Treatment PART 66 – Basic Training Cat B1 – Module 7 corrosion can take place once the initial film has formed. This type of protection is known as sacrificial corrosion. A number of options exist for treating ferrous metal surfaces. These options include plating, galvanising, painting and metal spraying. Nickel or Chrome – Plating One way to protect ferrous metals from corrosion is through chrome – plating. This plating process produces an airtight coating over the surface that excludes moisture from the base metal. Galvanising Steel parts such as firewalls are typically treated with a coating of zinc in a process called ’galvanising’. The protection afforded by this process is similar to that provided by cadmium plating in that when penetrated, the zinc corrodes and forms an airtight oxide film. Steel is galvanised by passing it through vats of molten zinc and then rolling it smooth through a series of rollers. There are two types of chrome – plating used in aircraft construction: Metal Spraying decorative chrome hard chrome. Decorative chrome is used primarily for its appearance and surface protection, while hard chrome is used to form a wear – resistant surface on piston rods, cylinder walls and other parts which are subject to abrasion. Parts to be plated with hard chrome are normally ground undersize and plated back to their proper dimension. Engine cylinder walls are often plated with a porous chrome, whose surface has thousands of tiny cracks which hold oil to aid in lubrication. Cadmium Plating Almost all steel aircraft hardware is cadmium – plated. This soft, silvery – gray metal is electroplated onto the steel to a minimum thickness of 0.13 mm. It provides an attractive finish as well as protection against corrosion. When the cadmium plating on a part is scratched through to the steel, galvanic action takes place and the cadmium corrodes. The oxides which form on the surface of the cadmium are similar to those which form on aluminium in that they are dense, airtight and watertight. This means that no further For Training Purposes Only Aircraft engine cylinders are sometimes protected from corrosion by spraying molten aluminium on their surface. To accomplish this process, a steel cylinder barrel is sand – blasted absolutely clean, then aluminium wire is fed into an acetylene flame where the wire is melted and blown onto the surface by high – pressure compressed air. Corrosion protection afforded by this treatment is sacrificial corrosion, similar to that provided by cadmium and zinc coating. Organic Coatings The most common organic coating used to protect ferrous metals is paint. However, like aluminium, the surface must be properly prepared to ensure a good bond. Dry abrasive blasting typically removes all of the surface oxides and roughens the surface enough to provide a good bond for the paint. However, parts which have been cadmium – plated must normally have their surface etched with a 5 – % solution of chromic acid before the primer adheres. Issue: August 2014 Page 759 of 926 Modul 7 Disassembly, Inspection, Repair and Assembly Techniques PART 66 – Basic Training Cat B1 – Module 7 After surface preparation, a thin, wet coat of zinc chromate primer is sprayed on and allowed to dry. The final finish can usually be applied after approx. an hour. contaminants in engine compartments, carbon deposits build up on engine cases and become baked on. These contaminants are removed through a process called ’decarbonisation’. Treatment of Magnesium Alloys A decarbonising unit consists of a heated tank and a decarbonising agent, either water soluble or hydrocarbon based. Parts are immersed in the heated liquid which loosens the accumulated carbon. Complete removal, however, sometimes requires brushing, scraping or grit blasting. Magnesium parts must not be placed in the decarbonising tank with steel parts and metallic cleaning materials, such as brushes or abrasives, are not to be used. Magnesium is one of the most active metals used in aircraft construction. However, because of its excellent weight – to – strength ratio, designers accept its corrosiveness. Magnesium alloys do not naturally form a protective film on their surfaces the way aluminium does, so special care must be taken so that the chemical or electrolytic film applied during the manufacturing process is not destroyed. Mechanical Removal of Corrosion When magnesium corrodes, the corrosion products occupy more space than the metal. Therefore, magnesium corrosion typically raises paint or, if it forms between lap joints, it swells the joints. When corrosion is found on a magnesium structure, all traces must be removed and the surface treated to inhibit further corrosion. Since magnesium is anodic to almost all of the commonly used aircraft structural metals, corrosion should not be removed with metallic tools. Any metallic tool can leave contaminants embedded in the metal that cause further damage. Therefore, stiff non –metallic bristle brushes or nylon scrubbers are used to remove corrosion. If corrosion exists in the form of deep pits the corrosion must be cut out with sharp carbide –tipped cutting tools or scrapers. If abrasive blasting is used to remove corrosion from magnesium, only glass beads are used which have been used for nothing but magnesium. Many engine parts are made of magnesium and these parts require special cleaning procedures. Because of the high temperatures and For Training Purposes Only Surface Treatment After all of the corrosion has been removed, a chromic acid pickling solution is applied. A satisfactory substitute for this solution may be made by adding approx. 60 drops of sulphuric acid to 5 liters of a 10 – % chromic acid solution. This is applied with rags to the surface and allowed to stand for approx. 10 min to 15 min, then the part is rinsed thoroughly with hot water. A treatment which forms a more protective film is a dichromate conversion treatment. This solution is applied to the metal and allowed to stand until a golden brown oxide film forms uniformly on the surface. Once this occurs, the surface is rinsed with cold water and dried with compressed air. The oxide film is extremely soft when it is wet and it must be protected from excessive wiping or touching until it dries and hardens. This film is continuous and protects the magnesium surface from corrosion by excluding all electrolyte from its surface. Like aluminium alloys, magnesium can also have a film deposited on its surface by electrolytic methods. Anodising magnesium produces a Issue: August 2014 Page 760 of 926 Modul 7 Disassembly, Inspection, Repair and Assembly Techniques hard, surface oxide film which serves as a good base for further protection by a coat of paint. Magnesium is such an active metal and magnesium skins are usually so thin that it is absolutely essential that only the proper solutions and proper procedures be used for corrosion treatment. Rather than mixing your own pickling and conversion coating solutions, prepared chemicals are used meeting the appropriate military (MIL) specifications. Note: The manufacturer’s recommendation is to be followed in detail. PART 66 – Basic Training Cat B1 – Module 7 hydrocarbons, as an engine operates. If the oil remains in the engine for any length of time, these contaminants can form powerful corrosives that attack the internal parts of the engine. Therefore, engines that are to be stored must first be preserved. When preparing an engine for storage, the engine must be drained of oil and refilled with a suitable preservative. Some manufacturers require that the engine be run for a short period to heat the preservative oil and coat all internal surfaces. When the engine is stopped, the spark plugs are removed and the propeller is rotated until a cylinder is at bottom center. The cylinder is then sprayed with preservative oil. Corrosion Prevention As stated earlier, the best way to prevent the formation of corrosion is to eliminate one or more of its basic requirements. This is typically done by removing the electrode potential difference within the metal or preventing the introduction of an electrolyte. Dissimilar Metal Insulation When all cylinders are coated, desiccant plugs are installed in the spark plug holes to absorb any moisture. It is important not to move the propeller after applying the preservative oil, since the pistons will break the preservative seal and allow corrosion to form. In addition to the engine, the propeller should be wiped with an oily cloth. This leaves a protective film on the propeller’s surface which inhibits the formation of corrosion. Refer to Figure 11. It is often necessary for different metals to be held in contact with each other. When this is the case, dissimilar metal or galvanic corrosion can take place. In order to minimise this danger, the areas to be joined are sprayed with two coats of zinc chromate primer and a strip of pressure –sensi