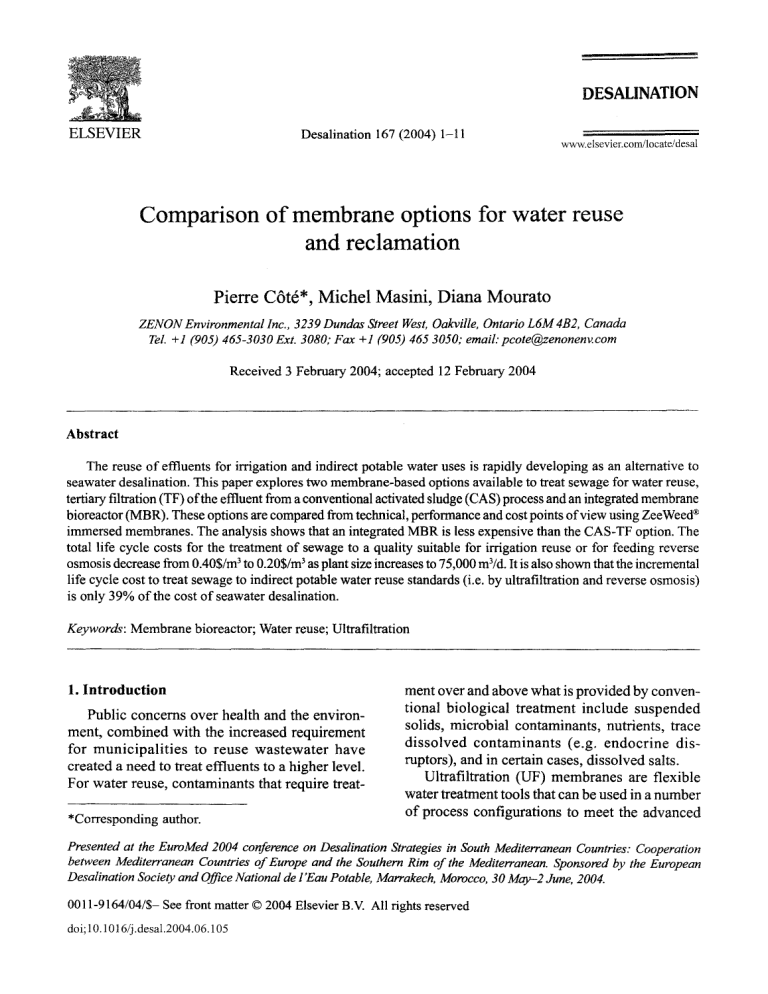

DESALINATION ELSEVIER Desalination 167 (2004) 1-11 www.elsevier.com/locate/desal Comparison of membrane options for water reuse and reclamation Pierre C6t6", Michel Masini, Diana Mourato ZENON Environmental Inc., 3239 Dundas Street West, Oakville, Ontario L6M 4B2, Canada Tel. +1 (905) 465-3030 Ext. 3080; Fax +1 (905) 465 3050; email: [email protected] Received 3 February 2004; accepted 12 February 2004 Abstract The reuse of effluents for irrigation and indirect potable water uses is rapidly developing as an alternative to seawater desalination. This paper explores two membrane-based options available to treat sewage for water reuse, tertiary filtration (TF) of the effluent from a conventional activated sludge (CAS) process and an integrated membrane bioreactor (MBR). These options are compared from technical, performance and cost points of view using ZeeWeed® immersed membranes. The analysis shows that an integrated MBR is less expensive than the CAS-TF option. The total life cycle costs for the treatment of sewage to a quality suitable for irrigation reuse or for feeding reverse osmosis decrease from 0.405/m3to 0.205/m3as plant size increases to 75,000 m3/d.It is also shown that the incremental life cycle cost to treat sewage to indirect potable water reuse standards (i.e. by ultrafiltration and reverse osmosis) is only 39% of the cost of seawater desalination. Keywords: Membrane bioreactor; Water reuse; Ultrafiltration 1. I n t r a d u c t i o n Public concerns over health and the environment, combined with the increased requirement for municipalities to reuse wastewater have created a need to treat effluents to a higher level. For water reuse, contaminants that require treat*Corresponding author. ment over and above what is provided by conventional biological treatment include suspended solids, microbial contaminants, nutrients, trace dissolved contaminants (e.g. endocrine disruptors), and in certain cases, dissolved salts. Ultrafiltration (UF) membranes are flexible water treatment tools that can be used in a number of process configurations to meet the advanced Presented at the EuroMed 2004 conference on Desalination Strategies in South Mediterranean Countries: Cooperation between Mediterranean Countries of Europe and the Southern Rim of the Mediterranean. Sponsored by the European Desalination Society and Office National de l'Eau Potable, Marrakech, Morocco, 30 May-2 June, 2004. 0011-9164/04/$- See front matter © 2004 Elsevier B.V. All rights reserved doi;lO.1016/j.desal.2004.06.105 2 P. Cttd et al./Desalination 167 (2004) 1-11 effluent treatment objectives listed above. Immersed membranes, when used by themselves, are limited to the removal of particulate and colloidal contaminants; however, they can be combined with biological or chemical treatment to remove dissolved contaminants. Furthermore, they represent the ideal pretreatment to reverse osmosis. The main objective of this paper is to compare treatment options available for water reuse from the point of view of water quality and cost. The two primary options, shown in Fig. 1, are conventional activated sludge (CAS) followed by tertiary filtration (TF) and integrated membrane bioreactor (MBR). In this paper, these options are discussed for plants ranging in size between 3,800 m3/d (1 MGD) and 76,000 m3/d (20 MGD). (a) Clarifier (b) Aeration tank Clarifier MF/UF MBR Fig. 1. Primary options to treat sewage for water reuse: (a) conventional activated sludge + tertiary membrane filtration (CAS-TF); (b) membrane bioreator (MBR). 2. Design and costing models CapdetWorks©was used for the design and cost estimation of conventional activated sludge plants. CapdetWorks e is a preliminary design and costing program available from Hydromantis, Inc. (www.Hydromantis.com). WTCost e was used for the design and cost estimation of reverse osmosis plants. WTCost~ is a preliminary design and costing program for membrane process plants developed with the support of the US Bureau of Reclamation, available from [email protected]. ZeeCost © was used for the design and cost estimation of the immersed membrane systems used as tertiary filtration with the conventional activated sludge plants and for the membrane bioreactor plants. ZeeCost e is ZENON's proprietary design and costing program for ZeeWeed® immersed membrane systems. While the cost estimations with these programs allow comparing options and drawing conclusions on a relative basis, the absolute precision of the cost estimations is considered to be +25%. 3. Treatment configurations Process flow diagrams for the CAS-TF option are presented in Fig. 2. Two levels of screening are provided, a coarse screen similar to a CAS plant, and a fine screen to protect the immersed membranes from accumulation of trash and hair. For small plants (<19,000 m3/d - 5 MGD), there is no primary clarification and the thickened sludge is digested aerobically (Fig. 2a). For large plants (>19,000 m3/d- 5 MGD), a primary clarification step was added, and the thickened sludge is digested anaerobically (Fig. 2b). Process flow diagrams for the MBR option are presented in Fig. 3. The inclusion of primary clarification and aerobic or anaerobic digestion as a function of flow rate is identical to the CASTF case. Also, for all but very small plants the membranes are immersed into separate tanks from the main bioreactors. This provides more flexibility in isolating membranes for cleaning or maintenance without handling. 4. Process conditions Typical sewage concentrations were used as input to the models in order to design the biological treatment steps and estimate sludge production (Table 1). Simulations were run for average flows of 3,800 m3/d (1 MGD), 19,000 m3/d P. C6tO et al. /Desalination 167 (2004) 1-11 (a) 3 ReJect Sewage )//----~ Treated effluent ioreactor ( Coarse Screen Secondary clarifier T Sludgerecycle q Dewatering Dewatered sludge Fine screen MF/UF Excess sludge Aerobic digester (b) Reject Sewage '@-D" -V , #/t Coarse Screen Bioreactor Primary clarifier I sludge Dewatering Treated effluent Secondary clarifier Sludge recycle Fine screen MF/UF Excess sludge Anaerobic digester Fig. 2. Process flow diagram for the conventional activated sludge tertiary filtration (CAS-TF) option: (a) small plants; (b) large plants. Table 1 Raw sewage characteristics Parameter Concentration, mg/L BOD SS TKN TP 240 240 40 8 , (5 MGD), 38,000 m3/d (10 MGD) and 76,000 m3/d (20 MGD). Typical peaking factors of two times average flow were used for all plants. The process conditions used to design the plants are summarized in Table 2. For the conventional activated sludge system, typical values for North American design were selected by using most of the default values suggested by CapdetWorks. The same sludge age (SRT) was used for CAS and MBR, but hydraulic retention times and mixed liquor concentrations were significantly different. The membrane system used for the MBR is ZENON's ZeeWeed ® 500d [1]. Membranes cassettes containing 48 modules of 31.6 m 2 each were arranged into separate membrane tanks (2, 6, 8 and 12 tanks for the four flow rates simulated). The continuous mixed liquor re-circulation flow rate between the membrane tanks and the main bioreactor was set at 5 ×Qa~eto de-concentrate the membrane tank and provide for nitrification/ denitrifieation. The design was based on an average flux of 20 L/m2/h. A set of blowers for 4 P C6t~ et al./Desalination 167 (2004) 1-11 (a) Sludgerecycle Sewage I Bioreactor P ,,.,oarse ¢IF/UF Screen ~ Excesssludge Screeningsolids Dewateredsludge[ Aerobic I digester Dewatering ~ Primary cladfier (b) Sludgerecycle I' 'If .// Sewage _ ~ Treated effluent Bioreactor I Coarse Screen ~ MFAJF Excesssludge Screeningsolids Dewateredsludge 1~ Treated effluent Dewatering[ -[Anaerobic [ "1 digester | ~ , Fig. 3. Process flow diagramfor the membranebioreactoroption(MBR): (a) smallplants; (b) large plants. Table 2 Designprocess conditionsfor the sewagetreatmentplants Unit process Parameter Coarse screen Primary clarifier Fine screen Bioreactor Size, mm Loadingrate, rn/h Size, mm HRT, h MLSS, g/L SRT, d Loadingrate, m/h Averageflux, L/m2/h DischargeTSS, g/L Secondaryclarifier ZeeWeed®filtration Gravity thickener Sludgedigestion HRT, d Smallplants (<19,000m3/d) CAS-TF MBR 10 10 No No 2 2 23 6.5 3 10 15 15 1.4 No 22 20 60 60 Aerobic Anaerobic 15 15 Largeplants (>19,000 m3/d) CAS-TF MBR 10 10 1.7 1.7 2 2 12 3.6 3 10 15 15 1.4 No 22 20 60 60 Aerobic Anaerobic 35 35 P. Crtd et al. / Desalination 167 (2004) 1-11 membrane scouring was provided independently from the biological process blowers and was sized to provide an average of 0.26 m3/h/m2 of membrane surface area. The membrane system used for the CAS tertiary filtration is ZENON's ZeeWeed®1000 [2]. Membrane cassettes containing 48 modules of 37 m 2each were arranged into separate membrane tanks (2, 6, 8 and 12 tanks for the four flow rates simulated). The ZeeWeed® 1000 is operated as a dead-end filtration system with backpulses and de-concentration every 20 min. It was assumed that the backwash reject water was returned to the head of the plant. The design was based on an average flux of 22 L/mVh. The scouring aeration for the ZeeWeed ® 1000 is an average of 0.02 mVh/m2 of membrane surface area, applied only during the backwashing sequence. Energy consumption for each of the two membranes systems included suction pumps assuming an average trans-membrane pressure of 35 kPa, and scouring aeration as described above. 5. Treatment efficiency comparison In this section, an analysis of the major differences between the two processes, conventional activated sludge - - tertiary filtration (CASTF) and membrane bioreactor (MBR) is presented for key water quality parameters. 5.1. Suspended solids/Silt Density Index For both the CAS-TF and the MBR, the ultrafiltration membrane allows reducing suspended solids to below detection limit [3]. The membrane step also provides a physical barrier against upsets of the biological process that results from a poorly settle-able sludge. The barrier effect is reflected in the Silt Density Index (SDI) parameter, which is typically below 3 [4]. Key challenges to maintain treated water quality over time include preventing against re-growth on the permeate side of the membrane and maintaining a high level of membrane integrity. The first challenge is met by 5 using pre-chlorination (TF only) or chlorine and/ or acid in the backpulse water (both TF and MBR). The second challenge is met by conducting regular bubble-point integrity tests and repairing defects as needed. 5.2. Microbes Microbial pathogens are particles that are rejected by the membranes, like suspended solids. Parasites and bacteria are much larger than the pore size of UF/MF membranes and are rejected by a sieving mechanism. Viruses may be smaller than the membrane pore size but are normally totally rejected because they are associated with suspended solids. As pointed out above, membrane integrity must be maintained over time. 5.3. Chemical oxygen demand~synthetic organic chemicals The MBR process, when compared to CAS, 1) runs at a higher MLSS concentration, 2) has a longer and better controlled SRT, and 3) is less susceptible to upsets; this leads to the development of a more diversified biomass and results in better biodegradation of soluble organic compounds [5]. Therefore, in general, the MBR is a better solution than CAS-TF to remove COD and SOCs. 5.4. Nutrients The MBR process, because it works at a high MLSS concentration and it eliminates the loss of slow growing nitrifiers to the clarifier weir, has demonstrated superior performance for nitrification, even at very low temperature [6]. One issue is to make sure that the retum sludge from the membrane tank, which may have a high DO concentmtion, does not impact denitrification; technical solutions exist to deal with this issue and it has been showed that total nitrogen (TN) concentrations smaller than 10 and 3 mg/L can be achieved in cold and warm water, respectively [7,8]. In general, the CAS-TF process is unable to achieve the same level of TN removal because the CAS 6 P C6t~ et al./Desalination 167 (2004) 1-11 and the TF processes do not work synergistically. Both the MBR and CAS-TF processes can achieve very high removal of total phosphorus, either biologically [9] or chemically [7] through complete removal of the phosphorus associated with suspended solids (either bacteria or colloidal inorganic particles). Effluent levels of 0.2 mg/L (biologically) or 0.1 mg/L (chemically) can be achieved consistently. to 9.5 h in large plants; for large plants, the addition of the primary clarifiers is not compensated by the reduction of the biological tanks HRT, and the total HRT increases with flow rate as a result of using anaerobic digester. Overall, the MBR plants HRT is 75% (small plants) to 50% (large plants) smaller than those of the CAS-TF plants. Fig. 5 shows the total surface area occupied by the plant as a function of flow rate. The total surface area was estimated based on the total process tanks footprint (proportional to flow rate) and the area required for roads, parking, laboratory, etc. (not directly proportional to flow rate). The land required for an MBR plant is about half of that required for a CAS-TF plant. 6. Plant size comparison MBR plants are much smaller than CAS-TF plants. This is shown by comparing the total hydraulic retention time (HRT) in Fig. 4 and the total plant surface area in Fig. 5. The total HRT (the volume of all tanks divided by the average flow rate) for the CAS-TF plants is 28 h in small plants, decreasing to 20 h for the larger plants; HRT decreases with flow rate as the net impact of adding primary clarifiers and reducing the biological tanks HRT in larger plants is positive regardless of anaerobic digester. For MBR plants, the total HRT increases from 7.5 h in small plants 7. Capital costs The total capital costs are presented in Fig. 6 for 3 plants, CAS, CAS-TF and MBR, including the following components for all unit processes shown in Figs. 2 and 3: • Direct costs (equipment for all unit processes, mobilization, site preparation, site electrical, 30 25 l ~ i v a t e d Sludge- TertiaryFiltration I 20 Ill 10 MembraneBioreaetor 0 10,000 20,000 30,000 40,000 50,000 Flow rate (m3/d) Fig. 4. Hydraulic retention time. 60,000 70,000 80,000 P C6td et al./Desalination 167 (2004) 1-11 7 1.8 T ! 0.2 ~IJ o~0 T - - - - 10,000 20,000 30,000 40,000 50,000 60,000 70,000 80,000 Flow rate (m3/d) Fig. 5. Total plant surface area. (a) (b) 2,000- 1,200. ~ 1,50O r. 1,000 g00 "~ 1,000 g 600 50o ,.,41--CA8 .'O..MBR ,,,at-CAS.TI7 40(I 200 0 10,00O 20,0O0 30,000 40,000 50,000 60,000 70,000 80,00O Flow rate, m3/d 0 CAS MBR CAS-TF Fig. 6. Total capital costs: (a) total capital costs; (b) capital costs breakdown (38,000 mVd). yard piping, instrumentation and control, laboratory and administration buildings) Indirect costs (legal fees, engineering design, inspection, contingency and miscellaneous) Land cost The capital costs of CAS plants are shown as a reference in Fig. 6a. For all plant sizes considered, MBR plants are less expensive than CAS plants. This is because the savings associated with eliminating secondary clarifiers, reducing the size of the aeration tanks and reducing footprint are larger than the added costs for the membrane system and the fine screen. The capital costs of CAS-TF plants are higher that the costs of CAS or MBR plants. The cost of a tertiary filtration membrane system is basically added to that of a CAS plant, without eliminating anything. The breakdown of capital costs between direct, indirect and land costs is shown in Fig. 6b for a 8 P cot~ et al./Desalination 167 (2004) 1-11 38,000 mVd (10 MGD) plant size. Direct costs represent about 2/3 of total capital costs. The cost of land, which represents 13.6% and 12.1% for the CAS and CAS-TF plants, shrinks to 7.3% for the MBR plants; this fraction is indeed sensitive to land unit cost ($150/m 2 in this case). For labor, it was assumed that the use of membranes did not reduce labor requirement for the conventional part of the plant; however, there is evidence that a fully automate MBR plant requires less labor than a CAS plant. For materials, a membrane life of 8 years was assumed. For energy, a relatively high unit cost of $0.10/kWh was used. 8. Operation and maintenance costs The total operation and maintenance (O&M) costs are presented in Fig. 7 for the 3 plants CAS, CAS-TF and MBR, including the following components for all unit processes shown in Figs. 1 and 2: • Labour • Materials (renewal of equipment, membrane replacement) • Energy • Chemicals (membrane cleaning) O&M costs of the plants including membranes (MBR and CAS-TF) are higher than the CAS plant by 20-30% for all flows (Fig. 7a). The O&M cost of a MBR plant is slightly higher than the CASTF plant because the MBR membranes system requires a higher scouring aeration rate and the membrane replacement cost is higher. Fig. 7b shows that all four categories of O&M costs are higher for the MBR system. However, these were based on conservative assumptions. 9. Total life cycle costs The total life cycle costs presented in Fig. 8 were generated using a PV factor of 14.32 (20 years, 6% interest rate and 2.5% inflation rate). They vary from $0.45/m 3 for small plants to $0.20/m 3 for large plants. Total life cycle costs are smallest for the CAS plants, followed by MBR and CAS-TF plant. The premium for a membranefiltered wastewater over CAS is 5-20% and increases with plant size. 10. Water reuse vs. desalination In this section, the cost of water reuse is compared to the cost of seawater desalination. To produce water of equivalent quality, a reverse osmosis (RO) step was added to the process flow diagrams shown in Fig. 2. For this case, RO is needed to remove dissolved organics carbon and residual nutrients such a nitrate. For desalination, (b) (a) 0.30................................................................................... ~ 0.20, ~ 0 1 '5 o 0.10 ~O -.~. CAS 0,05..... ~ MBR................................................. ,It 8 © , ,ooo Flow rate(m3/d) CAS MBR Fig. 7. Operation and maintenancecosts: (a) total O&M costs; (b) O&M cost breakdown(38,000 m3/d). CAS-TF P. Ctt6 et al. / Desalination 167 (2004) 1-11 0.50~ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 Antiscalant Ca) 0,4~ o,o, o.35 Secondaryeffluentfrom conventionalactivatedsludge o.3o o 0.2~ ~ 0.15 "'*- ¢~ OdO- - - ..,+..~.~ ..,~CA~-TF , 0.0(~ 0 MF/UF i , , 10,000 20,000 30,000 40,000 :50,000 60,000 70,000 80,000 F l o w rat~ (mVd) Fig. 8. Total life cycle costs. 09) Open seawater Antiscalant ~ •1 Multimedia ~ filtration ~ RO FeC13 it was assumed that surface seawater (TDS of 35,000 mg/L) was pretreated by coagulation and multi-media filtration prior to reverse osmosis. The process flow diagrams are shown in Fig. 9 and the conditions used for the two processes are compared in Table 3. The total costs estimated for producing RO water from secondary effluent and from seawater are compared in Table 4 for 38,000 m3/d (10 MGD) plants. The costs in column A do not include the cost associated with conventional activated sludge as it was assume that sewage would be treated to that level for discharge; for simplicity, the cost for tertiary filtration estimated above were used as pretreatment cost for RO. It was assumed that the concentrate from both plants could be disposed of at no cost. The capital costs for a plant producing water from seawater are about 50% higher than the costs Fig. 9. Process flow diagrams for comparison of water reuse and seawater desalination: (a) Water reuse; (b) Seawater desalination. of a plant reusing secondary sewage. Both the pretreatment costs and RO cost are higher. In the case of pretreatment, this is due to the difference in recovery (75% for secondary effluent; 50% for seawater), which results in a larger seawater system. The capital cost for the seawater RO process is higher than for the secondary effluent RO as it is operating at a much higher pressure, lower permeate flux, lower recovery, and must be made of materials that resist corrosion in seawater. Similarly, the O&M costs for producing RO water from seawater are about 3 times higher than the cost of reusing secondary sewage. The higher pretreatment costs are due to chemicals, con- Table 3 Design process conditions for the reverse osmosis plants Unit process Coagulation Pretreamaent Anti-scalant addition Reverse osmosis Parameter FeC13dose, mg/L Dose, mg/L Stages, number Recovery, % Flux, L/m2/h Feed pressure, bar (psi) Water reuse No MBR or CAS-TF effluent 2 2 75 20 13.6 (200) Desalination 5 Multimedia filtration 5 2 50 13 68 (1000) 10 P. C6td et al. /Desalination 167 (2004) 1-11 Table 4 Costs of producing water from secondary effluent and from seawater for a 38,000 m3/d (10 MGD) plant Component A: from CAS B: from effÊuent seawater Capital costs, $/ma/d Pretreatment 161 RO 321 Total 482 Total life cycle costs, $/m3 Capital 0.07 O&M 0.21 Total 0.28 Ratio (B/A) 238 492 730 1.48 1.53 1.51 0.10 0.60 0.70 1.51 2.86 2.50 tinuous dosage o f a coagulant and higher dosage o f anti-scalant. The higher RO costs are due primarily to energy (the operating pressure is five times higher and the feed flow is 1.5 times higher), but also to membrane replacement. The total life cycle costs for producing RO water from secondary effluent and seawater are 0.285/m 3 and 0.705/m 3, respectively, a ratio of 2.55. The data presented in Table 4 are in agreement with seawater RO cost data presented by Glueckstern and Priel [10], if one takes into account the cost o f electricity used in each study (0.045S/kWh used by Glueckstern and Priel, 0.10S/kWh used in this study). 11. Conclusions Two membrane options to reuse water were presented, conventional activated sludge followed by tertiary filtration (CAS-TF) and integrated membrane bioreactor (MBR). Both treatment trains provide equivalent effluent quality from the point of view of suspended solids and Silt Density Index and are suitable to feed a reverse osmosis (RO) polishing step. However, the MBR is superior for the removal of organic contaminants and nutrients (nitrogen and phosphorus) because the membranes work in synergy with the bioreactor. Overall, the hydraulic retention time of the MBR-based plants is 75% (plants <20,000 ma/d) to 50% (plants >20,000 m3/d) smaller than those of the CAS-TF-based plants. The land required for an MBR plant is about half o f that required for a CAS-TF plant. The capital costs o f MBR-based plants are lower than CAS-TF-based plants, but their O&M costs are slightly higher. Overall, total life cycle costs o f the two membrane options are comparable, and are 5-20% higher than conventional activated sludge plants, the difference increasing with size. The costs to treat sewage to indirect potable reuse standards are only a fraction of the costs to desalinate seawater. When total life cycle costs are considered, the cost o f treating secondary effluent by membrane filtration and RO is 0.285/m 3, as compared to 0.705/m 3for seawater desalination for a capacity of 38,000 m3/d (10 MGD). References [1] I. Crossley, S. Pedersen and A. Janson, ZENON introduces new reinforced hollow fiber membrane system, Proc. AWWA Membrane Technology Conference and Exhibition, Atlanta, GA, March 25, 2003. [2] P. C6t6, J. Cadera, N. Adams and U. Mende, A new immersed membrane for water filtration, Proc. IWA 2nd World Water Congress, Berlin, Germany, October 15-18, 2001. [3] D. Thompson, C. Schneider and M. Murphy, Immersed membrane bioreactors for water reuse: summary of 5 years experience, Proc. 25th Annual Hawaii WaterEnvironmentAssociationConference, Honolulu, Hawaii, January 29-31, 2003. [4] P. C6t6, J. Cobum and M. Eid, Use ofultrafiltration for water reuse and desalination, Proc. IDA World Congress on Desalinationand WaterReuse, Bahrain, October 26-31, 2001. [5] P. C6t6, H. Buisson, C. Pound and G Arakaki, Immersed membrane activate d sludge for the reuse of municipal wastewater, Desalination, 113 (1997) 189-196. [6] MBR for Municipal Wastewater Treatment: Pilot Plant Research Beverwijk, STOWA Report, 2002. P. C6td et al. / Desalination 167 (2004) 1-11 [7] D. Mourato, D. Thompson, C. Schneider, N. Wright, M. Devol and S. Rogers, Upgrade of a sequential batch reactor into a ZcnoGem® membrane bioreactor, Proc. WEFTEC Conference, New Orleans, LA, October 1999. [8] D. Thompson, C. Schneider, G~ Chomic and R. Gasset, Application of a membrane bioreactor for municipal wastewater re-use in the Florida Keys, Proc. Florida Water Resources Conference, Jacksonville, FL, April 9, 2001. [9] R. Gnirss, B. Lesjean, H. Buisson, C. Adam and M. Kraume, Enhanced biological phosphorus removal 11 (EBPR) in membrane bioreactors (MBR), Proc. AWWA Membrane Technology Conference and Exhibition, Atlanta, GA, March 2-5, 2003. P. [101 Glueckstem and M. Priel, Comparative cost of UF vs. conventional pretreatment for SWRO systems, presented at 5th Israel Desalination Society Conference, Haifa, Israel, December 2002. [11] P. C6t6, State-of-the-art techniques in reserve osmosis, nanofiltration and electrodialysis, International Report #9 presented at IWSA 20th World Congress, Durban, South Africa, September 9-15, 1995.