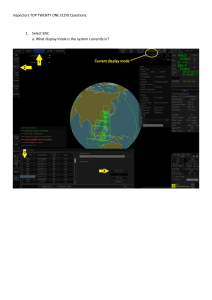

HAFFMANS INSTRUCTION MANUAL IN-LINE O2 GEHALTEMETER TYPE OGM W W W.HAFFMANS.NL OGM serial number: from Control Unit OGM-11001 OGM-31001 P30101 P50501 OGM from software version: V3.01-01 Read this instruction manual carefully before using the instrument. Haffmans BV is not responsible for any damage caused by the owner’s failure to follow the instructions given in this manual. Haffmans BV is not responsible for print or translation errors in this edition of the manual. The specifications and design of this product are subject of change without notice. All rights reserved. No part of this publication may be reproduced or distributed in any form or by any means, or stored in a database or retrieval system, without the prior written permission of Haffmans BV. Art. No. Release date Version : : : 112.364 01 November 2014 V01.05-01 HAFFMANS OGM Contents 1. Technical specifications ............................................................................................... 7 2. Introduction ................................................................................................................. 11 2.1 Intended use ..................................................................................................... 11 3. Safety ........................................................................................................................... 13 3.1 Symbols ........................................................................................................... 13 3.2 Precautionary measures and safety instructions.......................................... 13 4. General product information ...................................................................................... 15 4.1 Control unit ....................................................................................................... 15 4.2 Sensor .............................................................................................................. 15 4.3 Coating holder ................................................................................................. 16 4.4 Operation ......................................................................................................... 16 4.5 O2 -measurement ............................................................................................. 17 5. Installation ................................................................................................................... 19 5.1 Contents of the delivery .................................................................................. 19 5.2 Assembly of the OGM ...................................................................................... 20 5.3 Preparation and starting up ............................................................................ 21 5.4 Main measuring screen ................................................................................... 21 5.5 Using for the first time .................................................................................... 22 6. Operation ..................................................................................................................... 31 6.1 Operation OGM ................................................................................................ 31 6.2 Local and Remote control ............................................................................... 33 6.3 Logbook ........................................................................................................... 33 7. Calibration ................................................................................................................... 35 7.1 Calibration of the temperature sensor ........................................................... 35 7.2 Calibration of the O2 sensor(s) ....................................................................... 35 7.3 Calibrating analogue outputs ......................................................................... 41 8. Cleaning and maintenance ......................................................................................... 43 8.1 Daily maintenance ........................................................................................... 43 9. Faults and repair ......................................................................................................... 45 9.1 List of faults ..................................................................................................... 45 9.2 Alarm messages .............................................................................................. 45 9.3 Repairs and maintenance ............................................................................... 47 10. Deactivating, storage and transport .......................................................................... 49 10.1 Deactivating ..................................................................................................... 49 10.2 Storage ............................................................................................................. 49 10.3 Transport .......................................................................................................... 49 OGM Page 5 of 81 HAFFMANS OGM Appendix A: Formulas .......................................................................................................... 51 Appendix B: Software structure ........................................................................................... 53 Appendix C: Connections ..................................................................................................... 57 Appendix D: RS-protocol ...................................................................................................... 63 Appendix E: Instruction for assembly panel ....................................................................... 65 Appendix F: LHG Sensor (Option) ....................................................................................... 69 F.1 Drawing ............................................................................................................ 69 F.2 Mounting instructions ..................................................................................... 70 Appendix G: Customer service ............................................................................................ 71 Appendix H: Warranty conditions ........................................................................................ 73 Appendix I: EC Declaration of conformity .......................................................................... 75 Appendix J: Spare parts ....................................................................................................... 77 Appendix K: PROFIBUS ........................................................................................................ 81 Page 6 of 81 OGM HAFFMANS OGM 1. Technical specifications Scope of measurements O2 LHO O2 WLO O2 LHG Temperature Accuracy* : standard : [ppb w/w] : 0 tot 2000 (DO) : available : [µg/l] : 0 tot 2000 (DO) : [ppm w/w] : 0.00 tot 2.00 (DO) : [mg/l] : 0.00 tot 2.00 (DO) : [%] O2 : 0,000 to 4,180 (gas) : [%a.s.] : 0.00 to 20.0 (gas) : [ppm vol/vol] : 0 to 41800 (gas) : standard : [ppb w/w] : 0 tot 45000 (DO) : available : [mg/l] : 0.00 tot 45.00 (DO) : [µg/l] : [ppm w/w] : 0 tot 45000 (DO) : 0.00 tot 45.00 (DO) : [%] O2 : 0.00 to 100.00 (gas) : [%a.s.] : 0.00 to 500.00 (gas) : [ppm vol/vol] : 0 to 1000000 (gas) : standard : [ppm vol/vol] : 0 to 200 (gas) : available : [%] O2 : 0 to 0.02 (gas) : [% a.s.] : 0 to 0.1 (gas) : standard : [oC] : -5.0 to 40.0 : available : [oF] : 23.0 to 104.0 : [ppb] : ± Approx. (1 ppb+2% of the measured value) : ± (1 µg/l +2% of the measured value) : LHO : O2 dissolved (DO) : [µg/l] OGM : [ppm] : ± (0.001 ppm+2% of the measured value) : [mg/l] : ± (0.001 mg/l+2% of the measured value) Page 7 of 81 HAFFMANS OGM O2 in gas : [% a.s.] : ± (0.01%a.s.+2% of the measured value ) : [%] O2 : ± (0.002 %O2 +2% of the measured value ) : [ppm] : ± (20 ppm +2% of the measured value ) : [mg/l] : 0 – 45 (< 5% of the measured value from 0.1 mg/l) : [ppb] : 0 – 45.000 (< 5% of the measured value from 100 ppb) : [µg/l] : 0 – 45.000 (< 5% of the measured value from 100 µg/l) : [ppm] : 0 – 45 (< 5% of the measured value from 0.1 ppm) : [% a.s.] : 0 – 45 (< 5% of the measured value from 1.098 ppm) : [%] O2 : 0 – 45 (< 5% of the measured value from 0.230 ppm) : [ppm] : 0 – 1,000,000 (< 5 % of the measured value from 2300 ppm) : [ppm] : 0 – 200 (2 ppm.+/- 5% vdgw) : [%] O2 : 0 – 0.02 (0.0002 % O2 +/- 5% vdgw) : [% a.s.] : 0 – 0.1 (0.001 %a.s +/- 5% vdgw) : [°C] : ± 0,1°C : [°F] : ± 0,2°F : [barg] : 10.00 barg WLO : O2 dissolved (DO) O2 in gas LHG : O2 in gas : temperature Maximum pressure during use : [psi] : 145.0 psi 2 Product speed : [kg/cm ] : 10.20 kg/cm2 : [kPa] : 1000 kPa : min : [m/s] : >0 : max : [m/s] :- during measurement In pipe Page 8 of 81 OGM HAFFMANS OGM Maximum cleaning LHO/WLO : [°C] : 110 : [°F] : 230 : [°C] : 50 : [°F] : 120 : max : [m/s] : 10m/s : O2 : [s] standard : [s] : Adjustable from each 2 to 999 s or auto mode : 30s temperature LHG Speed of cleaning liquid during CIP Measuring frequency : 400 measurements / O2 sensor Memory Power Control unit: : standard : optional : 100-240V ~ 50-60Hz, 25 W : 24 V DC, 25 W Installation O2 sensor : LHO/WLO : Varivent (>DN40) of 25 mm : LHG : 25 mm Control unit: : standard : wall assembly mounted : optional : panel assembly or , pipe/ sensor assembly mounted IP class O2 sensor : standard : IP 67 : optional : IP 68 : IP 65 Control unit: Dimensions O2 sensor : Varivent : 25mm Control unit: : mm : Ø 84x175 excl. plug : mm : Ø 84 x 240 excl. plug : mm : L235 x W205 x H165 : Kg : 1.8 kg : Kg : 2.2 kg : Kg : 2.0 kg Weight O2 sensor : Varivent : 25mm Control unit: OGM Page 9 of 81 HAFFMANS OGM Max. number of O2 sensors for each control unit :2 * The accuracy from the OGM is determined at 20°C Page 10 of 81 OGM HAFFMANS OGM 2. Introduction 2.1 Intended use The OGM (O2 content gauge) is an in-line oxygen content gauge for measuring the oxygen content in gas or the dissolved oxygen content in liquids. The standard gauge consists of a control box and a sensor. A maximum of two sensors can be connected to each control box. A second sensor is available as an optional extra. The OGM must be installed in a product pipe. The connections can be: Varivent/viewing glass from DN40 or a 25 mm welding socket. The dissolved oxygen must be measured in a full, flowing product pipe. Using the sensor in a pipe that is not full or taking the measurement whilst the product is not flowing will not cause errors nor will it cause damage to the device. The use of the Varivent connection will be assumed throughout this instruction manual. If an explanation or a part of the text specifically refers to the 25 mm connection, this will be indicated by the use of an asterisk (*). OGM Page 11 of 81 HAFFMANS OGM Page 12 of 81 OGM HAFFMANS OGM 3. Safety 3.1 Symbols The symbols ‘Note!’, ‘Warning’ and ‘Danger’ used in this instruction manual have the following meanings. Note! Instructions for the correct and effective use of the instrument. Warning Incorrect or careless use may cause serious damage to the instrument. Incorrect or careless use may place the user or the surroundings in DANGER. 3.2 Precautionary measures and safety instructions Warning The use of chlorite-based or fluorine-based cleaning products is not permitted. These may cause damage to the instrument. Ensure that the pipe is not pressurized and that the instrument is disconnected from the power supply during assembly and disassembly. This will prevent electric shocks. During CIP/cleaning, the outside of the instrument may become hot. The sensor will turn itself off automatically when the inside of the sensor reaches a temperature of 65°° C. Do not touch the outside of the instrument! OGM Page 13 of 81 HAFFMANS OGM Page 14 of 81 OGM HAFFMANS OGM 4. General product information 4.1 Control unit “ENTER” button “CURSOR UP”/”SHORTCUT” button “Start” button “CURSOR DOWN”/”Sensor” button Fig 4.1: Operating panel 4.2 Sensor Coating holder Temperature sensor Fig. 4.2: Sensor varivent connection OGM Fig. 4.3: Sensor 25mm Page 15 of 81 HAFFMANS OGM 4.3 Coating holder The OGM Varivent and the 25 mm connection can both be delivered in the versions LHO and WLO. The LHO coating has a six-sided head. The WLO version has a square head. The LHG can be recognized by the six-sided head and the metal grid on the coating holder. See following images. Fig. 4.4: LHO coatingholder Fig: 4.5: WLO coatingholder Fig: 4.6: LHG coatingholder The type is also indicated on the coating holder. 4.4 Operation The instrument can be operated: a. Locally with the control unit by the buttons on the panel b. Remote with I/O or optional with Profibus For further operational instructions, please see chapter 6 Page 16 of 81 OGM HAFFMANS OGM 4.5 O2 -measurement The O2 measurement is based on measuring the luminescence of an oxygen-sensitive layer. The luminescence changes according to the oxygen partial pressure. The amount of dissolved oxygen gas in the liquid is calculated, using the measured oxygen partial pressure and temperature. The oxygen sensor optically measures the O2 level of the liquid, using the luminescence measuring principle, whereby an oxygen-sensitive layer is exposed to blue light, and, as a result, molecules in the oxygen-sensitive layer are excited. Fig. 4.7 1) Luminescence in the absence of oxygen 2) Luminescence in the presence of oxygen In the absence of oxygen, the molecules light up red. If oxygen is present, then the oxygen molecules collide with the molecules in the oxygen-sensitive layer. The molecules that collide with oxygen no longer light up. As a result of this process, a relationship is created between the oxygen concentration and both the light intensity and the speed at which the light intensity is reduced. The light intensity reduces at a higher oxygen concentration and the speed at which the intensity reduces increases as the concentration increases. The oxygen content is calculated using the time difference between the exposure to the blue light and the molecules lighting up (phase shift) and the product temperature. OGM Page 17 of 81 HAFFMANS OGM Page 18 of 81 OGM HAFFMANS OGM 5. Installation 5.1 Contents of the delivery The OGM has been calibrated, checked and tested by Haffmans BV before it was shipped, and the instrument is therefore ready for immediate use. You do not have to calibrate the instrument again before starting operations. Check whether the delivery is complete and undamaged. If the delivery is incomplete or damaged, please contact Haffmans BV or the Haffmans agency in your area immediately (also see: www.Haffmans.nl). In all correspondence, please note the OGM’s serial number, order number or invoice number (as provided by Haffmans BV). Note! Before using the instrument, please insure that the instrument is complete and no parts are missing. The delivery includes: • • • • • • • • • Control box O2 sensor Power cable Sensor communication cable I/O cable for analogue outputs Manual + certification calibration data sensor Calibration beaker, including additional o-ring 60x3 (* 20x2,5) Attachment clip for wall mounting RS-232 Cable You can also order, optionally: • • • • Sensor / Pipe mounting option. Retaining ring for connecting the sensor for the Varivent assembly CD-Rom with PC software to read out data, incl. 3m RS cable Inline pipe section with 2 varivent connections, one with inspection glass and one with retaining ring + o-ring. The following sizes are available DN40, DN50, DN65, DN80, DN100, DN125, DN150. For other spare parts and components see Appendix J. OGM Page 19 of 81 HAFFMANS OGM 5.2 Assembly of the OGM 5.2.1 Assembly control box There are three options to install te control box. 1. Wall mounting 2. Panel mounting 3. Pipe mounting For more information and instructions see appendix E. 5.2.2 Assembly sensor Assembly advice horizontal piping Always build in Varivent + 25 mm sensors horizontally. V X Fig. 5.2: Assembly advice sensors Assembly advice vertical piping Rotation / position of sensors irrelevant. Note! Page 20 of 81 Bends and stream impact do not have to be taken into account. Ensure at all times that (irrespective of the position of the sensor) the coating is fully in the product stream. If this condition is not complied with, you will always measure a faulty oxygen value. OGM HAFFMANS OGM 5.3 Preparation and starting up Depending on the version of the OGM ordered, this shall be connected as shown in Appendix C. After all cables have been connected, the power can be turned on and the OGM starts up immediately. Warning Hard materials, such as woodchips and/or grindings can damage the OGM’s measuring head. Warning First carry out a cleaning cycle after the instrument has been turned on. 5.4 Main measuring screen Three seconds after you have turned on the power, the main measuring screen appears. Depending on the number of sensors connected, the following measuring screens will appear (after the control box has received the calibration data, shown by the INIT message on the bottom of the display): Fig. 5.4: One sensor connected Fig 5.5: Two sensors connected In advance, you have to set in the menu configuration sensor settings, how many sensors are connected and if these apply to gas or liquid, see chapter 5.5.2. “sensor settings”. The control unit then has to be restarted. Sensor 1 is set standard to ON and sensor 2 to OFF. When you start up the instrument for the first time, the main measuring screen shall appear, see fig. 5.3. When two sensors are connected/turned on, the measuring screen for two sensors (see fig. 5.4) appears as main screen, and you can scroll with the ↓ button to the measuring screen of sensor 1 or sensor 2. If one sensor is turned on, only the measuring screen of that sensor appears and you cannot scroll down. If two sensors are connected and one or both do not give measurment values, then a dotted line will be displayed and the status notification changes (see fig. 5.3). The top line states the real time and the control mode (remote/local). In the bottom of the screen a line – XXXXXXXX – is activated, which can show an alarm/message, if applicable. If there are OGM Page 21 of 81 HAFFMANS OGM multiple alarms, these will scroll into this line consecutively for 3 seconds. The bottom line shows the status of the O2 measurements. Possible modes: INIT/MEASURE/STANDBY/CALIBRATION Immediately after starting up the instrument, INIT appears at the bottom of the screen. This means that the control unit is loading the calibration values of the sensors. This will take approx. 30 seconds after the sensor has been switched on. When in standby mode, no O2 measurements are conducted and lines appear at the O2 value. The temperature of that sensor is indicated permanently. The calibration mode is activated when the measuring cell is calibrated. You cannot measure when this is ongoing. To receive a quick information update, go to the SHORTCUT menu with the ↑ button, to view additional measuring values, charts and alarms. Enter-button: If you press the enter-button for 3 seconds in the measuring screen, you will access the main menu screen. 5.5 Using for the first time Before starting operations with the OGM, the manufacturer’s default setting can be changed to your preferential settings. The OGM has two operator levels: - Operator level (A) - Supervisor level (B) Appendix B “Software Structure” describes the access of both levels to the various screens. 5.5.1 User level To access the supervisor level, please follow the following steps. 1. Push the “Enter” button in the main measuring screen and hold this for three seconds. The main menu appears. 2. Select “User” with the cursor buttons and confirm the selection by pressing “Enter”. The password menu appears. 3. Select “Password” with the cursor buttons and confirm the selection by pressing “Enter”. 4. Enter the right password with the cursor buttons in [6848] and confirm this with “Enter”. 5. A message with “Correct Input” or “Incorrect Input” appears after the code has been entered and confirmed. 6. Then select the icon with the cursor buttons and confirm with “Enter”. 7. All screens in the Operator and Supervisor level are now visible. 8. If you forget to log off, or if no buttons are used during 30 minutes in the Supervisor level, the software automatically switches back to the Operator level. This time cannot be adjusted. Page 22 of 81 OGM HAFFMANS OGM 5.5.2 Configuration If wanted, the configuration of the OGM can be adjusted. To access the configuration menu, please follow the following steps. 1. Push the “Enter” button in the main measuring screen and hold this for three seconds. The main menu appears. 2. Select “Configuration” with the cursor buttons and confirm the selection by pressing “Enter”. The configuration menu appears. 3. The following settings can be adjusted in this menu. Units The units used in the OGM for the O2 values and temperature can be selected optionally. 1. Select the submenu “Units” in the configuration menu with the cursor buttons and confirm with “Enter”. 2. Then select sensor 1 or 2 or the temperature and confirm with “Enter”. 3. With the arrow buttons, the following units can be selected. For Gas : %; %a.s; ppm (vol/vol) O2 Temperature : °C, °F For liquids (DO) O2 : Temperature : ppb; ppm (w/w) ; mg/l; µg/l °C, °F The units ppb; ppm; mg/l and µg/l are all oxygen values dissolved in liquid (DO). 4. You can return to the menu with “Enter”. 5. Then select the icon to return to the “Configuration” menu Info This screen shows the software version and serial number present on the OGM. Date You can alter the date with the scroll buttons. By pressing “Enter” you can enter the date. By pressing “Enter” again, you can enter the month and the year. Close with “Enter” to return to the “Configuration” menu. Time You can alter the time with the scroll buttons. You can set the hours with “Enter”. By pressing “Enter” again, you can enter the minutes and seconds. Close with “Enter” to return to the “Configuration” menu. OGM Page 23 of 81 HAFFMANS OGM Language With the scroll buttons, you can choose Dutch, German, English, French and Spanish; select a language by pressing “Enter”, you are then returned to the configuration menu. Sensor settings In the “Sensor Settings” menu, you can indicate for each sensor whether or not this is connected, and whether these are to be used for liquids or gas. The sample time can also be set for each sensor. Apart from entering the sample time, the sensors can also be set in auto mode. If the auto mode is chosen, the sample time is chosen automatically. This shall start standard with a sample time of 2 seconds. If the measured value deviates by more than 10% after this time, the sample time remains 2 seconds. If the sample time deviates by less than 5%, this will be doubled to 4, 8 15 etc. to a maximum of 60 seconds. So if in the next measurement: Deviation < 5%, the sample time shall be, resp. 2 4 8 15 30 60 seconds. Deviation > 10%, the sample time shall be, resp. 60 30 15 8 4 2 seconds. The following lists the setting options: Item Setting options Default setting O2 sensor 1 OFF, ON ON O2 sensor 2 OFF, ON OFF Item range default Unit Sample time (sensor 1) AUTO, 2 … 999 30 s Sample time (sensor 2) AUTO, 2 … 999 30 s Gas application: The O2 sensor selectively measures the partial oxygen pressure. Gas application: The oxygen value is expressed standard at atmospheric pressure. The partial oxygen pressure is directly proportional to the gas pressure. To attain the proper O2 result at atmospheric pressure, of a gas measured under pressure, the measured O2 value has to be compensated. Example: Patm during calibration: 1013 mBar O2 measured at 1.033 Bara (20 cm H2O) = 1,0 % O2 at Patm= 0.981 % Liquid application: If the O2 sensor is used in liquid, this is fully pressure independent. The settings can be set/altered as follows: 1. Select “Sensor Settings” in the “Configuration” menu and press “Enter” once. The menu “Sensor Settings” appears. Page 24 of 81 OGM HAFFMANS OGM 2. 3. 4. 5. Select the desired item in this menu with the cursor buttons and confirm with “Enter”. The desired settings can then be chosen with the cursor buttons. Use the “Enter” button to return to the menu “Sensor Settings”. Then use the cursor buttons to select the icon, and return to the “Configuration” menu by pressing the “Enter” button. Automatic switch-off on temperature. This function is described as “auto stop temp”. The function of this parameter is to automatically stop the O2 measurement on reaching this temperature and is typically used to prevent ageing of the O2 coating during cleaning, without offering a remote signal. If the temperature again drops below this set value with a hysteresis of 1 °C , the sensor shall automatically resume measuring. This function applies to both sensors. Item Range Default setting Auto stop temp 0°C….90°C 50°C Analogue outputs The analogue outputs can be set as desired. A maximum of two analogue outputs can be set. After selecting “Analogue Outputs”, the attendant setting of the unit automatically appears (after confirmation). Depending on the units set under “Units”. The range is also adapted if the unit is altered. The following lists the settings and the default settings. Item Setting options Default setting Configure output 1 O2 sensor1, O2 sensor2, Temp.sensor1, Temp.sensor2 O2 sensor 1 Configure output 2 O2 sensor1, O2 sensor2, Temp.sensor1, Temp.sensor2 Temp. sensor 1 Item Setting options Default setting Levels Standby Min, Max, Freeze Freeze Item Range Default Unit Minimum value ( if O2 sensor) 0 …. 45000 0 Maximum value (if O2 sensor) 0 …. 45000 2000 ppb; ppm; mg/l; ug/l; %as; % ppb; ppm; mg/l; ug/l; %as; % Minimum value (if Temp.sensor) - 10 … 150 -5 Maximum value (if temperature sensor) - 10 … 150 OGM °C °F 110 °C °F Page 25 of 81 HAFFMANS OGM The settings can be set/altered as follows: 1. Select “Analogue Output” in the “Configuration” menu and press the “Enter” button once. The menu “Analogue Outputs” appears. 2. In this menu, select the option “Limits” with the cursor buttons and confirm with “Enter”. 3. Then use the cursor buttons to select the setting concerned and alter these settings where required. 4. Use the “Enter” button to return to the “Analogue Outputs” menu. 5. Use the cursor buttons to select the icon and use the “Enter” button to return to the “Configuration” menu. mA Values output 1 and 2 The mA values of output 1 and 2 are controlled as follows: Status Off Init Standby Measure Calibrate Autostop O2 signaal No signal 4mA Adjustable (Min, Max, freeze) Measurement value = mA 20mA Adjustable (Min, Max, freeze) Temperatuur signaal No signal 4mA Measurement value = mA Measurement value = mA Measurement value = mA Measurement value = mA Setting = “Min”: ‘The mA values of output 1 and 2 go to 4mA in status Standby or Autostop Setting = “Max”: ‘The mA values of output 1 and 2 go to 20mA in status Standby or Autostop Setting = “Freeze”: The mA values of output 1 and 2 keep the actual measurement value in status Standby or Autostop In case of an alarm output 1 and 2 will be controlled as shown in chapter 9.2 (Alarm messages) Note! Page 26 of 81 The settings for output 1 and 2 determine the measured values for the Analog outputs. See I/O connector 5: Pin 7+8 in appendix C. OGM HAFFMANS OGM Alarm settings As soon as the electronics discovers an alarm, this is indicated with a flashing backlight on the display. The lower part of the display shows which alarm was discovered. In the “Alarm” menu, the alarm levels concerning the measured values can be set as desired. The settings apply to sensor 1 and sensor 2. If only one sensor is connected, the other settings will not be visible. The following list the settings options and the default settings. Range Item Default unit O2 alarm 0 …. 45000 500 ppb; ppm; mg/l; ug/l; %as; % O2 extra 0 …. 45000 1000 ppb; ppm; mg/l; ug/l; %as; % Temperature low - 10 … 150 20 °C °F Temperature high - 10 … 150 20 °C °F The settings can be implemented as follows: 1. Select “Alarm Settings” in the “Configuration” menu and press the “Enter” button once. The menu “Alarm Settings” appears. 2. Select the desired item in this menu with the cursor buttons and confirm with “Enter”. 3. Then select the setting concerned with the cursor buttons. 4. Use the “Enter” button to return to the “Alarm Settings” menu. 5. Use the cursor buttons to select the icon and use the “Enter” button to return to the “Configuration” menu. Alarm outputs The following four alarm outputs are available: A1: General alarm A2: O2 alarm A3: O2 extra alarm sensor 1 A4: O2 extra alarm sensor 2 An O2 alarm can be set for each O2 measurement in two ways: - high – high/high, if an O2 level should not be exceeded, where two levels can be set, e.g. high as alarm and high/high to intervene in the process. - low – high, if the O2 level has to be within a range, typically applied for yeast activation. OGM Page 27 of 81 HAFFMANS OGM Conditions alarm type: Sensor 1 O2 high > O2 extra O2 high > O2 extra Sensor 2 O2 high > O2 extra O2 high > O2 extra Type of alarm High - high/high low - high Digital outputs A1, A2, A3 A1, A2, A3 High - high/high Low - High A1, A2, A4 A1, A2, A4 General alarm (A1): - All defects - All error messages - Temperature alarms of sensor 1 and/or sensor 2 - O2 alarms of sensor 1 and/or sensor 2 Digital output A1 (Normally Close contact (NC)) will only go to zero if the alarm is present during two measurements. The alarm can be reset with ACK/RESET ALARM in the shortcut menu. This maintains these digital outputs on high (and shall remain high as long as the alarm is on). The switching conditions of alarm outputs A2, A3 and A4 can easily be found in the following information. Sensor Alarm A1 A2 A3 A4 1 Temp < > min/max x . . . 1 High-high/high: O2 > O2 high x x . . 1 High-high/high: O2 > O2 extra x x x . 1 Low-high: O2 > O2 high x x . . 1 Low-high: x . x . O2 > O2 extra 1 Sensor fault / defect x . . . 2 Temp < > min/max x . . . 2 High-high/high: O2 > O2 high x x . . 2 High-high/high: O2 > O2 extra x x . x 2 Low-high: O2 > O2 high x x . . 2 Low-high: O2 > O2 extra x . . X x . . . 2 Page 28 of 81 Sensor fault / defect OGM HAFFMANS OGM High – high/high alarm (O2 extra > O2 high) O2 extra O2 high Measured value t [min] A3 extra alarm output A2 alarm output A1 Alarm on fail-save 2 2 Ack/reset Alarm OGM 2 2 Ack/reset Alarm Ack/reset Alarm Page 29 of 81 HAFFMANS OGM Low – high alarm (O2 extra <O2 high) O2 High low (O2 extra) Measured value t [min] A3 extra output A2 alarm output A1 Alarm on fail-save 2 2 Ack/reset Alarm 2 2 Ack/reset Alarm For a list of the physical connections of the I/O see appendix C. All digital outputs have been executed as normally closed (NC). The alarms go to zero if the alarm is present during two measurements. Ack/reset Alarm: The alarm can be reset with ACK/RESET ALARM in the shortcut menu. This maintains these digital outputs on high (and shall remain high as long as the alarm is on). In other words, the alarm relay shall fall out. Also, the backlight on the screen shall stop flashing. As long as the alarm condition is present, this message shall remain on the alarm line on the screen. This message shall disappear if the alarm condition is no longer present or if the measurement is discontinued. Page 30 of 81 OGM HAFFMANS OGM 6. Operation The instructions in this chapter have to be performed before using the OGM for the first time. This chapter also describes the instructions for daily use and operation. 6.1 Operation OGM 6.1.1 Main measuring screen After the control box has been started up, the main measuring screen appears automatically after 3 seconds. Depending on the number of connected sensors, a measuring screen can be chosen: Measuring screen sensor 1. Measuring screen sensor 2. Measuring screen sensor 1+2. With the cursor buttons “sensor”, you can chose these screens. For further explanation, see chapter 5.3. 6.1.2 Starting the measurement. When the “Start” button is activated, the OGM shall start the measurement, and the red LED on the start button shall light up. The measuring frequency during the measurement depends on the sample time set during configuration, see chapter 5.5.2. “sensor settings”. In the following, a survey of the start button function: One sensor connected: Start button is to start/stop the measurement Two sensors connected: Measuring screen sensor 1: Start button is to start/stop measurement sensor 1 Measuring screen sensor 2: Start button is to start/stop measurement sensor 2 Measuring screen sensor 1+2: Start button is to start/stop measurement sensor 1+2 Note! The red LED will light up if one or both sensor measurements are conducted. The last 400 measurements of each sensor are stored in the memory. If the memory is full, the oldest measurement is overwritten by the latest. OGM Page 31 of 81 HAFFMANS OGM 6.1.3 Shortcut With the - button, you can switch to a shortcut menu. With this menu, you can switch directly to the measuring values, trend lines and sensor-specific values. See the following overview below. With the cursor buttons, you can choose the screens you want. To confirm a selection , please press “Enter”. Fig. 6.1: Survey shortcut menu. 6.1.4 Main menu To alter various settings, please go to the main menu. To access the main menu, press the ENTER button for 3 seconds. The screen as seen in fig. 6.2 appears. Fig. 6.2: Main menu Page 32 of 81 OGM HAFFMANS OGM 6.2 Local and Remote control Before using the OGM, all desired parameters have to be set locally on the control unit. You can then choose whether to operate the sensor locally or remote. If you choose remote, the control unit can no longer be operated locally (start/stop). For remote control, you can choose between: - RS 232 (protocol delivered on request) - Profibus 6.3 Logbook You can choose the logbook screen from the main menu. This screen shows various values, statistics and charts. For a comprehensive overview of the screens in the logbook, see appendix B “Software structure”. A short overwiew of these screens is given below. Measuring values This menu shows the measuring values of sensors 1 or 2 separately. No more than 400 measurements are stored in the memory. For each measuring value, the O2 value, temperature, date and time is stored. If the memory is full, the oldest measurement is replaced by the latest. Trending A chart can be shown for the measured oxygen values as well as for the temperature. The values shown are always the measurements for the last 30 minutes. Depends on the unit chosen in “Units”. O2 (0,5 % / DIV) Depends on the max. value chosen in analogue outputs. 5 extra: O2 extra alarm value extra max. O2 extra alarm value max. 0 OGM 0 Time (1,0 min. / DIV) 30 Page 33 of 81 HAFFMANS OGM Operational hours This menu shows the hours when the sensor is operational. This distinguishes between measuring hours and standby hours. Extremes This menu stores the extreme values of the oxygen and the temperatures. Calibration The last three calibration data of the O2 sensor are stored. The last calibration data of the sensor are stored in the memory of the control unit. If a “Restore” is input in the sensor, the last calibration data of the sensor are restored. This option is no longer functional (i.e. the calibration data are incorrect) if a sensor or control unit is exchanged between two calibrations. Alarms In this menu, no more than 50 alarms are shown, with the date and time. The user cannot adapt this menu. If the memory is full, the oldest alarm is replaced by the latest. Reset All stored measurements can be deleted, using reset. Page 34 of 81 OGM HAFFMANS OGM 7. Calibration 7.1 Calibration of the temperature sensor The temperature sensor is an accurate NTC with precise tolerances, and therefore does not need to be calibrated. 7.2 Calibration of the O2 sensor(s) Because the oxygen sensor is only subject to very minor ageing due to light exposures, regular calibration is not necessary. Research has shown that the LHO coating, after 1 million times light exposure (i.e. 1 million O2 measurements), the O2 deviation from the zero point is only 5 ppb, and no deviation is found with higher O2levels. There is a light pulse counter integrated in the software, which counts the number of light exposures. If there have been 1 million light exposures, the warning “calibrate or replace O2 sensor” and the sensor has to be recalibrated or replaced. As a reminder, the display continuously shows a warning symbol. O2 After succesful calibration, the light pulse counter is reset and the warning symbol disappears. The complete light pulse counter is not reset. If a complete new coating holder is installed, this is reset (after selection). In the following, three primary options to calibrate the oxygen sensor are addressed: 1. Calibration-free This method is recommended if no calibration gases are available. The oxygen sensor is replaced with a pre-calibrated oxygen sensor, delivered with certificate. 2. One-point calibration LHO: 0-point calibration accurately in the lower oxygen level and less accurately in higher oxygen level. LHG: 0-point calibration accurately in the lower oxygen level and less accurately in higher oxygen levels. WLO: air-calibration accurately in the higher oxygen level and less accurately in lower oxygen levels. 3. Calibration with two gases. This method is recommended to guarantee the specified accuracy for the entire oxygen measuring scope. 7.2.1 Calibration frequency Recalibration is recommended after 1 million exposures. When using the standard sample time (1 measurement / 30 seconds), the sensor has to be calibrated once a year, assuming the sensor has then been operational 24/7. If a quicker sample time is required, the sensor will reach 1 million exposures soon, and calibration is then necessary. OGM Page 35 of 81 HAFFMANS OGM 7.2.2 Calibration-free The “Calibration free” method is applicable when changing the O2 sensor and the new O2 sensor has a calibration certificate. For the “calibration free” calibration, the calibration data for the zero point and the high calibration point can be manually entered into the software. Procedure 1. Press the “Enter” button in the main measuring menu longer than 3 seconds. The main menu appears. 2. Now use the cursor buttons to select “Calibration” and confirm with “Enter”. (Please note: the calibration menu is a level B supervisor level!) 3. Then select the sensor you want to calibrate and confirm with “Enter”. (“Latest calibrations” shows when the last calibration was executed). 4. Then select “Manual Calibration” and finish with “Enter”. (The “Light pulse counter” shows how many light pulses the coating had between two intervals. The “Total light pulse counter” shows how many light pulses the coating had from when it was first operational. The other data are the current measured values of the oxygen sensor). 5. Now select consecutively the atmospheric pressure, the phase angles, the temperatures and the oxygen concentrations, recorded on the certificate supplied by Haffmans BV. Enter the numbers, using the cursor buttons, use the “Enter” button to go to the next number. After the last number, press the “Enter” button to go to the next item on the menu. 6. After entering the calibration data for replaced coating, select “Yes” on the line “Replace coating”. 7. Then select “store calibration” and the calibration values are stored in the O2 sensor. With the icon you will return to the previous menu. Please note! Page 36 of 81 If you return to the previous menu without selecting “store calibration”, the old calibration data are maintained. OGM HAFFMANS OGM 7.2.3 One-point calibration LHO & LHG –sensor For most calibrations, the low oxygen level is usually sufficient to recalibrate the zero point. To do so, follow the instructions in chapter 7.2.4 “Calibration with two gases”. It is not necessary to enter the atmospheric air pressure and the high calibration point again. Therefore, skip points 7, 9 and 10. WLO –sensor For most applications in high oxygen measuring level, it is usually sufficient to recalibrate the high calibration point in the air. To do so, follow the instructions in chapter 7.2.4 “Calibration with two gases”. It is not necessary to enter the low calibration point again. Therefore, skip points 8 and 10. 7.2.4 Calibration with two gases Additional requirements: Barometer with accuracy of one mbar. For the WLO sensor, a relative air humidity measurement with an accuracy of 1% RV is necessary when calibrating with a high oxygen level calibration point with liquid gas. When calibrating, the zero point and a high calibration point can be calibrated with a certified oxygen concentration. The calibration gases have to be dry gases. The following lists the gases for the different sensor types: Sensor type LHO 0-point N2 class 5.0, CO2 class 5.0 LHG N2 class 5.0, CO2 class <0.5 ppm O2 ! CO2 class 5.0 O2 class < 0.5 ppm O2 ! Or use class 6.0 N2 or CO2 N2 class 5,0, CO2 class 5,0 WLO High point Gas mixture O2 concentration 1 - 4% Accuracy 1% Gas mixture O2 concentration 100 – 200 ppm Accuracy 1% Air (with 20,95 % O2) Table 7.1: list of gases for calibration The OGM has to be dry when calibrating with gas. Flush the OGM for approx. 15 min. with N2 or CO2 or oil-free compressed air. During calibration, the unit % or %a.s. has to be used for the LHO and WLO coating. For the LHG coating, always use the unit PPM (gas)! Because the oxygen sensor measures the partial oxygen pressure, the oxygen level measured in gas during calibration depends on the current air pressure. By manually entering the current air pressure in the parameter “P-atm” in the calibration menu, when showing the oxygen level in the gas unit, %O2 and % a.s. are taken into account. Note! OGM For an accurate calibration, the calibration gas and the OGM have to acclimatize for 4 hours in the same room. Page 37 of 81 HAFFMANS OGM Procedure 1. Place the OGM in the calibration beaker intended for that purpose. 2. Press the “Enter” button in the main measuring menu longer than 3 seconds. The main menu appears. 3. Now select “Calibration” with the cursor buttons and close with “Enter”. (Please note: the calibration menu is a level B supervisor level!) 4. Then select the sensor you want to calibrate and confirm with “Enter”. (“Latest calibrations” shows when the last calibration was executed) 5. Then select “O2 auto” and confirm with “Enter”. (The “Light pulse counter” shows how many light pulses the coating had between two intervals. The “Total light pulse counter” shows how many light pulses the coating had from when it was first operational. The other data are the current measured values of the oxygen sensor). 6. The software automatically recognizes which coating is present on the sensor. (LHO, LHG or WLO) 7. Then enter the current air pressure. To do so, use a barometer that is accurate to one millibar. Page 38 of 81 OGM HAFFMANS OGM 8. Then flush out the calibration beaker with the right type of gas, see table 7.1.Then let the gas flow for 15 minutes with a maximum speed of 30 l/h. Now, press “Enter”, so the cursor is at value 0.00%. Press enter again, to store the calibration values of the zero point. The calibration value is now stored in the memory. If no stable value is reached, the message: ”O2 unstable values” appears. 9. Then calibrate the high calibration point. Connect the right type of calibration gas to the calibration beaker and let this flow for 15 minutes, with a maximum flow of 30l/h. Press “Enter” again and enter the oxygen level of the calibration gas, and again close with “Enter”. The calibration value is now stored in the memory. If no stable value is reached, the message :”O2 unstable values” appears. For the WLO-sensor, the relative humidity has to be taken into account. This value has to entered in “RV-act”. The outside air or dry compressed air contains 20.95% oxygen. 10. Then indicate whether or not you have replaced the coating. If you enter “Yes”, the “Total light pulse counter” is set to zero. 11. If you have a new coating holder with new coating constants, select the menu “Constants”. The coating holder constants screen appears. Enter the new constants and then return to the calibration menu. OGM Page 39 of 81 HAFFMANS OGM 12. Now select “Store calibration” and the data are stored permanently in the sensor Then use the icon to return to the calibration menu. Note! If you return to the previous menu without selecting “store calibration”, the old calibration data are maintained. Checking calibration data. If you want to check the OGM for its calibration point with calibration gases, you can also use the calibration menu. Connect the gases to the calibration beaker and enter the right Patm in the calibration menu. The right oxygen value is then calculated in “Actual O2 value”. Please note! Page 40 of 81 When checking, do not use “store calibration” OGM HAFFMANS OGM 7.3 Calibrating analogue outputs The analogue outputs of the OGM control unit can be calibrated. These values then match the values entered in Analogue Outputs. The analogue outputs are calibrated standard at 4mA and 20mA. Procedure 1. Press the “Enter” button in the main measuring menu longer than 3 seconds. The main menu appears. 2. Now select “Calibration” with the cursor buttons and close with “Enter”. (Please note: the calibration menu is a level B level!) 3. Then select “Analogue outputs” with the cursor buttons and close with “Enter”. 4. Now select “Calibration analogue outputs” with the cursor buttons and close with “Enter”. 5. The analogue outputs can now be calibrated in this screen for the right mA-controls. Please connect an mA-meter (or multimeter) to the output concerned to measure the current in the output. See appendix C for connections of the analogue outputs. 6. By selecting the “MIN. mA-value”, the connected analogue output is controlled. With the cursor buttons you can increase or decrease the value set. Increasing /decreasing the count value shall run concurrently with increasing/decreasing the current. This calibrates the output. 7. By selecting the “Max. mA-value”, the connected analogue output is controlled. With the cursor buttons you can increase or decrease the value set. Increasing /decreasing the count value shall run concurrently with increasing/decreasing the current. increasing/decreasing the current. This calibrates the output. 8. After calibrating the outputs, select “Store calibration” to store the data in the OGM memory. Then use the icon to return to the previous menu. Note! OGM If you return to the previous menu without selecting “store calibration”, the old calibration data are maintained. Page 41 of 81 HAFFMANS OGM Page 42 of 81 OGM HAFFMANS OGM 8. Cleaning and maintenance 8.1 Daily maintenance 8.1.1 Inspection • • • 8.1.2 Ensure that the instrument is free of dirt and dust. Check that plugs and cables are properly connected. Blind off connectors not in use. Cleaning • • The LHG version can not be cleaned in the pipes with regular CIP. Only clean with a cloth, and water if necessary. LHO + WLO versions Regular CIP of the process pipes with appropriate cleaning agents. Agent - Alkali cleaning based on NaOH of KOH (≤95°C, ≤5% NaOH or KOH) - Acidic cleaning based on HNO3 of H3PO4 (≤60°C, ≤3% HNO3 or H3PO4) • Current 0 - 10 m/s Clean the sensor or the control unit on the outside just with water (possibly with a detergent). Warning Never direct a powerful jet of water at the control panel or at other instruments. Warning Never use tools to clean the coating. Touching the coating can cause serious damage to the instrument OGM Page 43 of 81 HAFFMANS OGM Page 44 of 81 OGM HAFFMANS OGM 9. Faults and repair 9.1 List of faults Problem Cause Solution Nothing is displayed on the screen when a button is pressed. The power is not connected. The power is in the safemode (too hot). Connect the power. The O2 value seems to be wrong. Defective temperature sensor. The message “O2 sensor is not responding” appears on the measuring screen Oxygen sensor not connected. Oxygen sensor defective. 9.2 Alarm messages ID Error message Cause Wait 10 minutes and connect the power again. Check whether a realistic temperature value is indicated. Check O2 sensor with calibration gases and possibly recalibrate. Connect oxygen sensor. Contact Haffmans BV. Solution mA Output 20mA 01 S1 – Temp sensor not found NTC defective Install new NTC, contact Haffmans BV 02 S1 – Temp sensor short circuit NTC short-circuit Install new NTC, contact Haffmans BV No sensor connected, Sensor defective, Break in communication cable, Thermal disconnection sensor (T>65°C) No sensor connected 20mA Check connection Reset OGM Let the sensor cool down 03 S1 – O2 comm error 04 S1 – Not found 05 S1 – Temperature high Temp. Value > set “temp high” value 06 S1 – Temperature low Temp. Value < set “temp low” value 07 S1 – O2 high alarm O2 value > set “O2 high" alarm Check the process, alter the alarm “O2 high” 08 S1 – O2 extra alarm O2 value > set “O2 high” alarm Check the process, alter the alarm “O2 extra” 09 S1 – Calibration expired O2 The coating reached 1 million light pulses. The sensor has to be recalibrated. OGM 20mA Connect sensor Check the process Alter the alarm “temp high” level Check the process Alter the alarm “temp low” level 20mA Actual measurement value Actual measurement value Actual measurement value Actual measurement value Actual measurement value Page 45 of 81 HAFFMANS OGM ID Error message Cause Solution 10 S2 – Temp sensor not found NTC defective Install new NTC, contact Haffmans BV 11 S2 – Temp sensor short circuit NTC short-circuit Install new NTC, contact Haffmans BV 20mA Check connection Reset OGM Let the sensor cool down 20mA No sensor connected, Sensor defective, Break in communication cable, Thermal disconnection sensor (T>65°C) No sensor connected mA Output 20mA 12 S2 – O2 comm error 13 S2 – Not found 14 S2 – Temperature high Temp. Value > set “temp high” value 15 S2 – Temperature low Temp. Value < set “temp low” value 16 S2 – O2 high alarm O2 value > set “O2 high" alarm Check the process, alter the alarm “O2 high” 17 S2 – O2 extra alarm O2 value > set “O2 high” alarm Check the process, alter the alarm “O2 extra” 18 S2 – Calibration expired The coating reached 1 million light pulses. The sensor has to be recalibrated. 19 S1 – Init error 20 S2 – Init error Not all calibration data have been entered correctly. Not all calibration data have been entered correctly. Connect the sensor to the control unit and reset the control unit. Connect the sensor to the control unit and reset the control unit. 23 I/O communication failed Electronics defective. Contact Haffmans BV 20mA Compare the measured temperature with the temp. set at “auto stop temp.” and, if required, increase this. Adjustable Compare the measured temperature with the temp. set at “auto stop temp.” and, if required, increase this. Adjustable 24 25 O2 S1 – Auto Stop Active S2 – Auto Stop Active Page 46 of 81 One temp. > then the temperature set at parameter “auto stop temp” is measured, switching on the auto stop function of the O2 measurement. One temp. > then the temperature set at parameter “auto stop temp” is measured, switching on the auto stop function of the O2 measurement. Connect sensor Check the process Alter the alarm “temp high” level Check the process Alter the alarm “temp low” level 20mA Actual measurement value Actual measurement value Actual measurement value Actual measurement value Actual measurement value 20mA 20mA OGM HAFFMANS OGM 9.3 Repairs and maintenance When assembling and disassembling, make sure that there is no power on the instrument, In such a manner that there is no risk of electric shocks. Warning To prevent damage, first read the instructions as described in this manual Replacing the coating holder: If the coating is defective or damaged, a new coating holder of the same type has to be placed on the sensor. Instructions for replacing the coating holder: 1. Take the sensor from the pipe and place it on a flat straight surface so it cannot roll from the workplace onto the ground. 2. Screw the coating holder from the measuring head with a wrench/ring spanner size 14. See fig. 9.1. You can only use a spanner for the WLO version. The 25mm coating holders have a wrench size 10. Fig. 9.1: Unscrewing the coating holder Light 3. Remove glue and dirt residue from the screw thread around the light conductor Please note! Do not damage the light conductor See fig. 9.2. Screw thread Fig. 9.2: Light conductor OGM Page 47 of 81 HAFFMANS OGM 4. Then take the new coating holder and assemble the large O-ring around the flange See fig. 9.3. Fig. 9.3: New coating holder 5. Now apply a drop of Loctite 572 on the inside of the screw thread of the coating holder. to prevent the coating holder from possibly shaking loose. Prevent excess glue from blocking the path of the light. Add Loctite 572. Fig. 9.4: Apply the coating holder screw with a drop of loctite 6. Then screw the coating holder back on the sensor and calibrate it. Warning Page 48 of 81 Never unscrew the temperature sensor. If you unscrew the temperature sensor, you forfeit your warranty right. OGM HAFFMANS OGM 10. Deactivating, storage and transport 10.1 Deactivating If the OGM is no longer used, the components must be sent to an appropriate waste disposal organization or the entire unit can be returned to Haffmans BV. The materials from which the main components are made are given below: - 10.2 Control unit Sensor : ABS casing, various prints. : Stainless steel, oxygen print, POM Storage The instrument must be stored in a dry location and be protected against mechanical and/or chemical damage. The calibration beaker has to be installed to protect the coating. 10.3 Transport When the OGM is sent, the display of the control unit has to be protected against direct mechanical shocks. The O2 sensor also has to be provided with the calibration beaker, to protect the O2 coating. We advise keeping Haffmans’ packaging materials for reuse, if the OGM has to be sent someplace. OGM Page 49 of 81 HAFFMANS OGM Page 50 of 81 OGM HAFFMANS OGM Appendix A: Formulas Conversion O2 units The OGM can be set for various oxygen units, where the following conversions can be conducted in the instrument: %O2 = % air saturation ⋅ 20,95 100 With Tm : Temperature in ° C patm : Atmospheric air pressure during the oxygen calibration in bar ( ) cT = 48,998 - 1,335 ⋅ Tm + 0,02755 ⋅ Tm2 - 0,000322 ⋅ Tm3 + 0,000001598 ⋅ Tm4 temperature correction mg %air saturation 0,2095 32 = p atm ⋅ ⋅ ⋅ cT ⋅ l 1013 100 22,414 mg l µg mg = ⋅ 1000 = ppb l l ppm = OGM Page 51 of 81 HAFFMANS OGM Page 52 of 81 OGM HAFFMANS OGM Appendix B: Software structure Starting screen Automatic After 3 sec. Button ↓ Button ↓ Button ↓ Sensor 2 Sensor 1 Sensor 1 & 2 Measuring screen ↓ button → Button Main menu Measuring values Sensor 1 O2 trend chart Sensor 1 Details values Sensor 1 Shortcut Measuring values Sensor 2 O2 trend chart Sensor 2 Details values Sensor 2 OGM Page 53 of 81 HAFFMANS OGM A = Operator level B = Supervisor level User A Units B Info Configuration A A Sensor settings Main menu B Analogue outputs B Limits B Calibration analogue outputs B Alarm settings B Auto Calibration sensor 1 B Calibrations B Calibration sensor 1 B Regular calibration sensor 1 Calibration sensor 2 B Auto Calibration sensor 2 B Regular calibration sensor 2 Page 54 of 81 OGM HAFFMANS OGM Measuring values sensor 1 A Measuring values A Measuring values sensor 2 A Trending A O2 chart s1 Display A Company A Temp chart s1 Display A O2 chart s2 Display A Extremes A Temp chart s2 Display A Calibrations A History1 Sensor1 A Logbook A History2 Sensor1 A Alarms A Reset B History3 Sensor1 A History1 Sensor2 A History2 Sensor2 A History3 Sensor2 A OGM Page 55 of 81 HAFFMANS OGM Page 56 of 81 OGM HAFFMANS OGM Appendix C: Connections Connector: M/S Power supply A RS-communication / Profibus communication B Sensor communication 1 C Sensor communication 2 D I/O communication Tabel 1 M 1. 2. 3. OGM Mains 230Vac Mains supply Mains supply Protective earth 3-way L1 L2 PE Female (code 1) Brown Blue Yellow-green M Page 57 of 81 HAFFMANS OGM S 1. 2. 3. Supply 24Vdc External supply External supply Protective earth 3-way +24V GND PE Male (code 2) Red Black Yellow-green A 1. 2. 3. 4. 5. 6. Communication Common Supply, 24Vdc COM-1, RS232 COM-1, RS232 COM-1, RS232 Supply, 12Vdc 6-way GND +24V Txd-1 Rxd-1 Gnd-1 +12V Male (code 1) White Brown Green Yellow Grey Pink B 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 0. Sensor 1 Common Supply, 24Vdc COM-2, RS232 COM-2, RS232 COM-2, RS232 Temp. input-1* Temp. ground Supply, 12Vdc COM-2, RS485 COM-2, RS485 Shielding 10-way GND +24V Rxd-2 Txd-2 Gnd-2 NTC-1 NTC-com +12V B (D+) A (D-) Ground Male (code 2) White Brown Green Yellow Grey Pink Blue Red Black Violet Casing S A B * In use for OGM only (not available at OptHaze-i) Page 58 of 81 OGM HAFFMANS OGM C 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 0. Sensor 2 Common Supply, 24Vdc COM-3, RS232 COM-3, RS232 COM-3, RS232 Temp. input-2* Temp. ground Supply, 12Vdc COM-2, RS485 COM-2, RS485 Shielding 10-way GND +24V Rxd-3 Txd-3 Gnd-3 NTC-2 NTC-com +12V B (D+) A (D-) Ground Male (code 2) White Brown Green Yellow Grey Pink Blue Red Black Violet Casing C * In use for OGM only (not available at OptHaze-i) D 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 0. PLC I/O Common - PLC * DON’T USE ** Sensor 1 on/off Sensor 2 on/off Set product ID1• Set product ID2• Spare input Spare input GND for inputs An. output-1 + An. output-1 – An. output-2 + An. output-2 – Alarm output-1 Alarm output-2 Alarm output-3 Alarm output-4 Input value + Input value – Shielding 19-way GND +24V Input-24V Input-24V Input-24V Input-24V An-input An-input Gnd-IO Out-20mA Out-gnd Out-20mA Out-gnd Outp-24V Outp-24V Outp-24V Outp-24V Inp-20mA Inp-20mA Ground Male (code 2) White Brown Green Yellow Grey Pink Blue Red Black Violet Grey-pink Red-blue White-green Brown-green White-yellow Brown-yellow White-grey Brown-grey White-pink Casing D * Use as GND (reference) to PLC and/or for alarm relays ** DON’T USE to/for supply (reference for inputs only) • Use for OptHaze-i only (not available at OGM) OGM Page 59 of 81 HAFFMANS OGM Example connection I/O: Page 60 of 81 OGM HAFFMANS OGM OGM Page 61 of 81 HAFFMANS OGM Page 62 of 81 OGM HAFFMANS OGM Appendix D: RS-protocol Setting Baudrate Databit Parity Stopbit Hardware control 57600 8 No 1 No Note: Select used com-port in the Haffmans programm OGM Page 63 of 81 HAFFMANS OGM Page 64 of 81 OGM HAFFMANS OGM Appendix E: Instruction for assembly panel There are three options to install the control box. 1. Wall mounting The control unit can be mounted against a flat internal or external wall using the mounting bracket, on a pipe using the optional pipe mounting bracket The maximum distance between the control unit and the sensor is 15 meters. Wall mounting (4x) Fig. 5.1: Wall mounting 2. Panel Assembly To assemble the control unit in a switch box, use the panel assembly set. This set is optional available and contains the following parts: - OGM Switchbox bracket Seal Cylindrical screw M5X40 (2 pieces) Cutting template Page 65 of 81 HAFFMANS OGM A hole has to be cut in the panel door. Use the included cutting template to define the dimensions of the hole. Stick the seal at the backside of the control unit. The control unit can now be mounted in the panel door. Use the switchbox bracket to clamp the control unit to the inner side of the panel door. To fit the door and the control unit together, use the cylindrical screws to strain the switchbox bracket. The result will look like fig. E.1. Fig. E.1: Control unit panel assembly 3. Pipe mounting Using the pipe clamp set the control box can be mounted on a vertical or horizontal pipe. This set is available as an option and includes the following components: - Pipe clamp with hinge Clamping strip 2x Cylindrical screw with nut (4 pieces) The wall mounting support which is included as standard must be screwed to the pipe clamp using the four cylindrical screws with nuts. This can be done in two ways depending on the choice of mounting on a horizontal or vertical pipe. The pipe clamp can be mounted on the pipe using 2 clamping strips. The hinge mounted on the pipe clamp is used to tilt the control box. Page 66 of 81 OGM HAFFMANS OGM Mounting on vertical pipe hinge Fig. E.3: Control box vertical pipe mounting (with hinge) Mounting on horizontal pipe 4x cylindrical screw Fig. E.4: control box horizontal pipe mounting (without hinge) OGM Page 67 of 81 HAFFMANS OGM Page 68 of 81 OGM HAFFMANS OGM Appendix F: Ultrapure Sensor including high pressure reducing set (Optional) F.1 Drawing Pos. Description 01 Welding socket 12mm 02 Ball Valve 03 Double nipple 04 Pressure reducing valve 05 Coupling 06 Steel hose 07 Needle Valve 08 Flowcel 25mm 09 O2 sensor 10 Cable for O2 sensor 11 Power supply cable 12 OGM Control panel OGM Page 69 of 81 HAFFMANS OGM 13 Profibus cable (option) F.2 Mounting instructions 1. 2. 3. 4. Weld the welding socket (pos. 1) on the pipe Turn the ball valve and the pressure reducing valve (pos 02, 03, 04 en 05) in the welding socket (pos 01), Attention: use Teflon tape. Turn the hose (pos. 06) in the pressure reducing valve (pos 04 and 05) and on the needle valve (pos 07). Attention: always use two wrenches for fastening and loosening: wrench 12 on the turning part and an adjustable wrench on the housing. Adjust the flow, with the reducing and needle valve, at a maximum of 30 l/h Page 70 of 81 OGM HAFFMANS OGM Appendix G: Customer Service Warning Repairs to the instrument’s electronics may only be performed by a Haffmans BV electrician. The fault list includes instructions for solving small problems. If you are not able to solve a problem, contact Haffmans BV, your local representative or your agent. Always state the name of the instrument, the article number, the serial number and the Haffmans BV order or invoice number. If you have any questions concerning the control or operation of your OGM, please contact Haffmans BV, your local representative or your agent. HAFFMANS BV Marinus Dammeweg 30 5928 PW Venlo The Netherlands PO Box 3150 NL-5902 RD Venlo The Netherlands T F E I OGM +31 (0)77-3232300 +31 (0)77-3232323 [email protected] www.haffmans.nl Page 71 of 81 HAFFMANS OGM Page 72 of 81 OGM HAFFMANS OGM Appendix H: Warranty conditions The Haffmans BV warranty has precedence over all rights that the purchaser has towards his supplier based on a sales contract between the purchaser and the supplier or based on the law. Haffmans BV guarantees that, under normal use, the instrument requires no maintenance and is free of material and manufacturing faults. This warranty is applicable for a period of 12 months from the date of the invoice. Necessary recalibration and/or standard maintenance is not covered by this warranty. The warranty is not applicable to fuses or an instrument or component which has been incorrectly used, which has been adapted or which has been exposed to abnormal working conditions and abnormal treatment. If a fault is observed during the warranty period, then this must be reported in writing. The instrument, together with the written description of the problem, must be returned to Haffmans BV or to a Haffmans BV representative or agent. The faulty components will be repaired or replaced free of charge provided that the fault has not been caused by: • • • • • Using the instrument in a way that deviates from the instructions given in the instruction manual. A modification to the instrument. Overdue maintenance. Repairs by a third party that has not received authorization from Haffmans BV. Abnormal work conditions or environmental conditions. The purchaser will be charged for the labour costs for disassembly and assembly relating to the repair, as well as for the transport costs for returning the instrument to the purchaser. Haffmans BV accepts no liability for possible transport damage. OGM Page 73 of 81 HAFFMANS OGM Page 74 of 81 OGM HAFFMANS OGM Appendix I: EC Declaration of conformity OGM Page 75 of 81 HAFFMANS OGM Page 76 of 81 OGM HAFFMANS OGM Appendix J: Spare parts If you order spare parts, we kindly request you to include all the information given below. • • • • Serial number of the OGM Position number Description. Article number. Pos. Description Art. No. O-ring 60x3 for varivent 109.065 O-ring 20x2.5 for 25mm sensor 112.157 Spare parts Accessories & Repair parts OGM Coating holder set Varivent LHO 112.021 Coating holder set Varivent WLO 112.122 Coating holder set 25mm LHO 112.135 Coating holder set 25mm WLO 112.136 Coating holder set 25mm LHG 112.518 Control unit OGM wide range (100 – 240Vac) version 2 112.354 Control unit OGM wide range (100 – 240Vac) with Profibus version 2 112.356 Control unit OGM 24V version 2 112.355 Control unit OGM 24V with Profibus version 2 112.357 Mounting bracket assembly Controller unit AUCI/OGM 119.005 Mounting set for pipe AUCI 119.006 O2 sensor OGM/Vari/LHO IP67 112.024 O2 sensor OGM/25mm/LHO IP67 112.032 O2 sensor OGM/Vari/WLO IP67 112.026 O2 sensor OGM/25mm/WLO IP67 112.034 O2 sensor OGM/Vari/LHO IP68 112.305 O2 sensor OGM/25mm/LHO IP68 112.307 O2 sensor OGM/Vari/WLO IP68 112.306 O2 sensor OGM/25mm/WLO IP68 112.308 Calibration beaker set varivent, 2 spare o-rings and varivent clamp 112.010 Calibration beaker set 25mm with 2 spare o-rings 112.031 Page 77 of 81 HAFFMANS OGM Page 78 of 81 Connector for wide range power supply 3p female 119.121 Connector for 24V DC power supply 3p male 119.122 Power supply cable wide range (100-240Vac) 5m, IP 67 119.132 Power supply cable wide range (100-240Vac) 15m, IP 67 119.133 Power supply cable wide range (100-240Vac) 40m, IP 67 119.134 Power supply cable 24V dc 5m, IP 67 119.136 Power supply cable 24V dc 15m, IP 67 119.137 Power supply cable 24V dc 40m, IP 67 119.138 Sensor communication cable 5m, IP 67 2x ODU 10-way 112.332 Sensor communication cable 10m, IP 67 2x ODU 10-way 112.333 Sensor communication cable 15m, IP 67 2x ODU 10-way 112.334 Sensor communication cable 5m with swivel, IP 67 2x ODU 10-way 112.335 Sensor communication cable 10m with swivel, IP 67 2x ODU 10-way 112.336 Sensor communication cable 15m with swivel, IP 67 2x ODU 10-way 112.337 Sensor communication cable 5m, IP 67 ODU 10-way – BINDER 8-way 112.901 Sensor communication cable 10m, IP 67 ODU 10-way – BINDER 8-way 112.902 Sensor communication cable 15m, IP 67 ODU 10-way – BINDER 8-way 112.903 Sensor comm. cable 5m with swivel, IP 67 ODU 10w - BINDER 8w 112.904 Sensor comm. cable 10m with swivel, IP 67 ODU 10w - BINDER 8w 112.905 Sensor comm.15m with swivel, IP 67 ODU 10w - BINDER 8w 112.906 Sensor communication cable 5m, IP 68 ODU 10-way – BINDER 8-way 112.911 Sensor communication cable 10m, IP 68 ODU 10-way – BINDER 8-way 112.912 Sensor communication cable 15m, IP 68 ODU 10-way – BINDER 8-way 112.913 Sensor comm. cable 5m with swivel, IP 68 ODU 10w - BINDER 8w 112.914 Sensor comm. cable 10m with swivel, IP 68 ODU 10w - BINDER 8w 112.915 Sensor comm.15m with swivel, IP 68 ODU 10w - BINDER 8w 112.916 Convertor BINDER 8p male – ODU 10p male 112.371 Convertor BINDER 8p female – ODU 10p male 112.374 Loose connector I/O 19p 109.130 I/O cable 5m, IP 67 109.141 I/O cable 15m, IP 67 109.142 I/O cable 40m, IP 67 109.143 Communication cable RS232 5m 119.163 OGM HAFFMANS OGM OGM Communication cable RS232 15m 119.164 Profibusset OGM 112.361 CD-Rom, PC software for reading data, incl. RS-232 cable By request 25mm/Varivent adapter, with cover pin set 112.231 25mm/Orbisphere adapter, with cover pin set 112.233 25mm/DN 25 Varivent adapter with cover pin set 112.234 Cover pin set 112.209 LHG set 25mm measuring unit 112.509 Page 79 of 81 HAFFMANS OGM Page 80 of 81 OGM HAFFMANS OGM Appendix K: PROFIBUS Information on connecting the controlbox to a Profibus system can be found in the manual of the Profibus add on. OGM Page 81 of 81