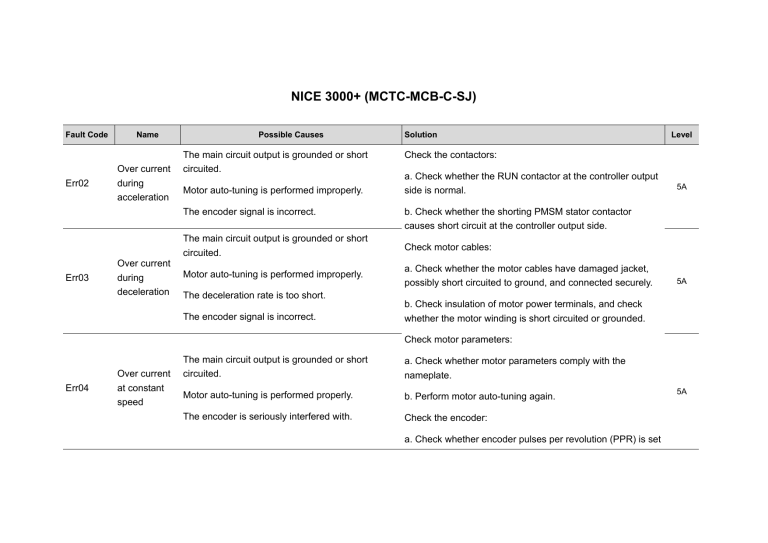

NICE 3000+ (MCTC-MCB-C-SJ) Fault Code Err02 Name Over current during acceleration Possible Causes The main circuit output is grounded or short circuited. Motor auto-tuning is performed improperly. The encoder signal is incorrect. Err03 Over current during deceleration Solution Check the contactors: a. Check whether the RUN contactor at the controller output side is normal. Check motor cables: Motor auto-tuning is performed improperly. a. Check whether the motor cables have damaged jacket, possibly short circuited to ground, and connected securely. The encoder signal is incorrect. 5A b. Check whether the shorting PMSM stator contactor causes short circuit at the controller output side. The main circuit output is grounded or short circuited. The deceleration rate is too short. Level 5A b. Check insulation of motor power terminals, and check whether the motor winding is short circuited or grounded. Check motor parameters: Err04 Over current at constant speed The main circuit output is grounded or short circuited. a. Check whether motor parameters comply with the nameplate. Motor auto-tuning is performed properly. b. Perform motor auto-tuning again. The encoder is seriously interfered with. Check the encoder: a. Check whether encoder pulses per revolution (PPR) is set 5A Fault Code Name Possible Causes Solution Level correctly. b. Check whether the encoder signal is interfered with, whether the encoder cable runs through the duct independently, whether the cable is too long, and whether the shield is grounded at one end. c. Check whether the encoder is installed reliably, whether the rotating shaft is connected to the motor shaft reliably by observing whether the encoder is stable during normal-speed running. d. Check whether the encoder wirings are correct. For asynchronous motor, perform SVC and compare the current to judge whether the encoder works properly. The input voltage is too high. Err05 Overvoltage during acceleration The regeneration power of the motor is too high. The braking resistance is too large, or the braking unit fails. The acceleration rate is too short. Err06 Overvoltage during The input voltage is too high. The braking resistance is too large, or the braking Check whether the input voltage is too high. Observe whether the bus voltage is too high (normal: 540–580 V for 380 voltage input). Check for the balance coefficient. Check whether the bus voltage rises too quickly during running. If yes, the brake resistor does not work or its model is improper: a. Check whether the cable connecting the brake resistor is damaged, whether the cooper wire touches the ground, and 5A 5A Fault Code Name deceleration Possible Causes unit fails. The deceleration rate is too short. Err07 Overvoltage at constant speed Err08 Maintenance notification period reached The input voltage is too high. The braking resistance is too large, or the braking unit fails. The elevator is not maintained within the notification period. Instantaneous power failure occurs on the input power supply. Err09 Undervoltage The input voltage is too low. The drive control board fails. Solution whether the connection is reliable. b. Check whether the resistance is proper comparing with brake resistor nameplate. c. If a braking unit is used, check whether the braking unit works properly and whether the model is proper. If the resistance of the brake resistor is proper and overvoltage occurs each time when the elevator reaches the target speed, decrease the values of F2-01 or F2-04 to reduce the curve following error and prevent overvoltage due to system overshoot. Check whether the acceleration/deceleration rate is too short when Err05 and Err06 is reported. Level 5A Power-off and maintain the elevator. Disable the maintenance notification function by setting F9-13 to 0. Contact us or our agent directly. 5A Check whether the external power voltage is too low. Check whether the power fails during running. Check whether wiring of all power input cables is secure. Contact us or our agent directly. 5A Fault Code Err10 Name Controller overload Possible Causes Solution Level Eliminate mechanical problems: This fault is reported generally when the controller a. Check whether the brake is released, and whether the runs at the current higher than the rated value for a brake power supply is normal. b. Check whether the balance coefficient is proper. long time. The causes include: c. Check whether the guide shoes are too tight. The mechanical resistance is too large. Check the motor auto-tuning result: a. Check whether the encoder feedback signal and The balance coefficient is improper. parameter setting are correct, and whether the initial angle of The encoder feedback signal is abnormal. the encoder for the PMSM is correct. b. Check the motor parameter setting and perform motor Motor auto-tuning is not performed properly (the elevator running current is higher than the normal auto-tuning again. If this fault is reported when the slip experiment is carried on, in this case). perform the slip experiment by using the function set in F3-24. 4A FC-02 is set improperly. Err11 Motor overload The mechanical resistance is too large. The balance coefficient is improper. Err12 The power input phases are not symmetric. Power supply phase loss The drive control board fails. Restore FC-02 to the default value. Refer to the solution of Err10. 3A Check whether the three phases of power supply are balanced and whether the power voltage is normal. If not, adjust the power supply. Contact us or our agent directly. 4A Fault Code Err13 Name Possible Causes Power output The output wiring of the main circuit is loose. phase loss The motor is damaged. The ambient temperature is too high. Err14 Module overheat The fan is damaged. The air filter is clogged. Err15 Err16 Output abnormal Current control fault Braking (resistor) short occurs on the output side. The RUN contactor is abnormal. Subcodes 1, 2: The current deviation is too large. Subcode 3: The speed deviation is too large. Solution Level Check whether the motor wiring is secure. Check whether the RUN contactor on the output side is normal. Eliminate the motor fault. 4A Lower the ambient temperature. Clear the air filter. Replace the damaged fan. Check whether the installation clearance of the controller satisfies the requirement. 5A Check that wiring of the brake resistor and braking unit is correct, without short circuit. Check whether the main contactor works properly and whether there is arch or stuck problem. Contact us or our agent directly. 5A Subcodes 1, 2: a. Check whether the input voltage is low (often in temporary power supply). b. Check whether cable connection between the controller and the motor is secure. c. Check whether the RUN contactor works properly. Subcode 3: a. Check the circuit of the encoder: 5A Fault Code Name Possible Causes Solution Level Check whether encoder pulses per revolution (PPR) is set correctly. Check whether the encoder signal is interfered with, whether the encoder cable runs through the duct independently, whether the cable is too long, and whether the shield is grounded at one end. Check whether the encoder is installed reliably, whether the rotating shaft is connected to the motor shaft reliably by observing whether the encoder is stable during normal-speed running. b. Check whether the motor parameters are correct, and perform motor auto-tuning again. c. Increase the torque upper limit in F2-08. Err17 Encoder interference during motor auto-tuning Subcode 1: Reserved. Subcode 2: The SIN/COS encoder signal is abnormal. Subcode 2: a. Serious interference exists in the C, D, and Z signals of the SIN/COS encoder. Check whether the encoder c cable is laid separately from the power cables, and whether system grounding is reliable. b. Check whether the PG card is wired correctly. Subcode 3: The UVW encoder signal is abnormal. Subcode 3: a. Serious interference exists in the U, V, and W signals of the UVW encoder. Check whether the encoder c cable is laid separately from the power cables, and whether system 5A Fault Code Name Possible Causes Solution Level grounding is reliable. b. Check whether the PG card is wired correctly. Err18 Current The drive control board fails. detection fault Contact us or our agent directly. 5A Subcodes 1, 5, 6: Check the motor wiring and whether phase loss occurs on the contactor at the output side. Subcode 1: Learning the stator resistance fails. Err19 Motor auto-tuning fault Subcode 11: Subcodes 5, 6: Learning the magnetic pole position At angle-free motor auto-tuning, the power is cut off when the motor rotary displacement is too small, and this fault is fails. reported at direct running upon power-on again. To rectify the Subcode 8: Reserved. fault, perform angle-free motor auto-tuning again and make Subcode 11: Saving the angle fails at synchronous the motor runs for consecutive three revolutions. motor angle-free auto-tuning. Subcode 101: Subcodes 101, 102: Motor auto-tuning fails. Synchronous motor with-load auto-tuning times out. Check that encoder wiring is correct, or replace the PG card and perform motor auto-tuning again. Subcode 102: 5A Fault Code Name Possible Causes Solution Level Motor auto-tuning times out in operation panel control mode. Check that encoder wiring is correct, or replace the PG card and perform motor auto-tuning again. Subcode 1:The encoder signal is not detected during synchronous motor no-load auto-tuning. Subcode 2: Reserved. Subcode 3: The phase sequence of the motor is incorrect. Err20 Speed feedback incorrect Subcode 4: Z signal cannot be detected during synchronous motor auto-tuning. Subcode 5: The cables of the SIN/COS encoder break. Subcode 1, 4, 5, 7: a. Check whether the encoder signal circuit is normal. b. Check whether the PG card is normal. Subcode 3: Exchange any two phases of the motor UVW cables. Subcode 9: a. The angle of the synchronous motor is abnormal. Perform motor auto-tuning again. Subcode 8: Reserved b. The speed loop proportional gain is small or integral time is large. Increase the proportional gain or decrease the integral time properly. Subcode 9: The speed deviation is too large. Subcode 12: Subcode 10, 11: Reserved. a. Check whether the brake has been released. Subcode 12: The encoder AB signals are lost at startup. b. Check whether AB signal cables of the encoder break. Subcode 7: The cables of the UVW encoder break. c. If the motor cannot be started at the slip experiment, 5A Fault Code Name Possible Causes Solution Subcode 13: The encoder AB signals are lost during running. perform the slip experiment by using the function set in F3-24. Subcodes 14–18: Reserved. Subcode 13: Subcode 19: The signals of the SIN/COS encoder are seriously interfered with during running. AB signals of the encoder become loss suddenly. Check whether encoder wiring is correct, whether strong interference exists, or the motor is stuck due to sudden power failure of the brake during running. Subcode 55: The signals of the SIN/COS encoder are seriously interfered with or CD signals are incorrect during motor auto-tuning. Level Subcode 19: The encoder analog signals are seriously interfered with during motor running, or encoder signals are in poor contact. You need to check the encoder circuit. Subcode 55: The encoder analog signals are seriously interfered with during motor auto-tuning, or encoder CD signals are in wrong sequence. Subcode 101: The leveling signal is stuck. Err22 Leveling signal abnormal Subcodes 101, 102: Subcode 102: The leveling signal is lost. Check whether the leveling and door zone sensors work Subcode 103: The leveling position deviation is too properly. large in elevator auto-running state. Check the installation verticality and depth of the leveling 1A Fault Code Name Possible Causes Solution Level plates. Check the leveling signal input points of the MCB. Subcode 103: Check whether the steel rope slips. Err23 Motor short circuit to ground Short circuit to ground exists on the motor side. Check whether short circuit to ground exists on the motor side. 5A Subcode 101: Err24 RTC clock fault Subcode 101: The RTC clock information of the MCB is abnormal. Replace the clock battery. 3B Replace the MCB. Err25 Storage data abnormal Subcodes 101, 102: Subcodes 101, 102: The storage data of the MCB is abnormal. Contact us or our agent directly. Err26 Earthquake signal Subcode 101: The earthquake signal is active and Subcode 101: Check that the earthquake signal is consistent the duration exceeds 2s. with the parameter setting (NC, NO) of the MCB. 4A 3B Fault Code Name Possible Causes Solution Level Subcode 101: Err29 Shorting PMSM stator contactor feedback abnormal Subcode 101: Feedback of the shorting PMSM stator contactor is abnormal. Check that the signal feature (NO, NC) of the feedback contact on the contactor is correct. Check that the contactor and corresponding feedback contact act correctly. 5A Check the coil circuit of the shorting PMSM stator contactor. Subcodes 101, 102: Check whether the leveling signal cables are connected reliably and whether the signal copper wires may touch the In the normal-speed running or re-leveling running ground or be short circuited with other signal cables. mode, the running time is larger than the smaller of Check whether the distance between two floors is too large F9-02 and (FA-38 + 10), but the leveling signal has or the re-leveling time set in F3-21 is too short, causing over no change. long re-leveling running time. Subcodes 101, 102: Err30 Elevator position abnormal 4A Check whether signal loss exists in the encoder circuits. Err33 Elevator speed abnormal Subcode 101: The detected running speed during normal-speed running exceeds the limit. Subcode 102: The speed exceeds the limit during inspection or shaft auto-tuning. Subcode 103: The speed exceeds the limit in Subcode 101: Check whether the parameter setting and wiring of the encoder are correct. Check the setting of motor nameplate parameters. Perform 5A Fault Code Name Possible Causes Solution shorting stator braking mode. motor auto-tuning again. Subcode 104: The speed exceeds the limit during emergency running. Subcode 102: Attempt to decrease the inspection speed or perform motor auto-tuning again. Level Subcode 103: Check whether the shorting PMSM stator Subcode 105: The emergency running time protection function is enabled (set in Bit8 of F6-45), function is enabled. and the running time exceeds 50s, causing the Subcodes 104, 105: timeout fault. Check whether the emergency power capacity meets the requirements. Check whether the emergency running speed is set properly. Err34 Err35 Logic fault Shaft auto-tuning data abnormal Logic of the MCB is abnormal. Contact us or our agent directly to replace the MCB. Subcode 101: When shaft auto-tuning is started, the elevator is not at the bottom floor or the down slow-down switch is invalid, Handling at inspection-speed commissioning: Subcode 102: The system is not in the inspection state (inspection switch not turned on) when shaft auto-tuning is performed. Err35 (subcode 103) is reported at each power-on because shaft auto-tuning is not performed before inspection-speed commissioning. This fault does not affect inspection-speed commissioning and you can hide the fault directly on the operation panel. Subcode 103: It is judged upon power-on that shaft Handling at normal-speed commissioning and running: auto-tuning is not performed. Subcode 101: Check that the down slow-down switch is Subcodes 104, 113, 114: In distance control mode, valid, and that F4-01 (Current floor) is set to the bottom floor 5A 4C Fault Code Name Possible Causes Solution it is judged at running startup that shaft auto-tuning number. is not performed. Subcode 102: Check that the inspection switch is turned to Subcode 105: The elevator running direction and inspection state. the pulse change are inconsistent. Subcodes 103, 104, 113, 114: Perform shat auto-tuning Subcodes 106, 107, 109: The plate pulse length again. sensed at up/down leveling is abnormal. Subcode 105: Check whether the elevator running direction Subcodes 108, 110: No leveling signal is received is consistent with the pulse change in F4-03: F4-03 increases within 45s continuous running. in up direction and decreases in down direction. If not, change the value of F2-10 to ensure consistency. Subcodes 111, 115: The stored floor height is smaller than 50 cm. Subcode 106, 107, 109: Subcode 112: The floor when auto-tuning is completed is not the top floor. Check that NO/NC state of the leveling sensor is set correctly. Check whether the leveling plates are inserted properly and whether there is strong power interference if the leveling sensor signal blinks. Check whether the leveling plate is too long for the asynchronous motor. Subcodes 108, 110: Check whether wiring of the leveling sensor is correct. Level Fault Code Name Possible Causes Solution Level Check whether the floor distance is too large, causing running time-out. Increase the speed set in F3-11 and perform shaft auto-tuning again to ensure that learning the floors can be completed within 45s. Subcodes 111, 115: Enable the super short floor function if the floor distance is less than 50 cm. If the floor distance is normal, check installation of the leveling plate for this floor and check the sensor. Subcode 112: Check whether the setting of F6-00 (Top floor of the elevator) is smaller than the actual condition. Subcode 101: The feedback of the RUN contactor is active, but the contactor has no output. Err36 RUN contactor feedback abnormal Subcode 102: The controller outputs the RUN signal but receives no RUN feedback. Subcode 103: The startup current of the asynchronous motor is too small. Subcode 104: When both feedback signals of the RUN contactor are enabled, their states are inconsistent. Subcodes 101, 102, 104: Check whether the feedback contact of the contactor acts properly. Check the signal feature (NO, NC) of the feedback contact. Subcode 103: Check whether the output cables UVW of the controller are connected properly. Check whether the control circuit of the RUN contactor coil is normal. 5A Fault Code Name Possible Causes Solution Level Subcode 101: Subcode 101: The output of the brake contactor is Check whether the brake contactor opens and closes inconsistent with the feedback. properly. Subcode 102: When both feedback signals of the Check that the signal feature (NO, NC) of the feedback brake contactor are enabled, their states are contact on the brake contactor is set correctly. inconsistent. Check whether the feedback circuit of the brake contactor is Subcode 103: The output of the brake contactor is normal. inconsistent with the brake travel switch 1 feedback. Subcode 102: Err37 Brake contactor feedback abnormal Subcode 104: When both feedback signals of brake travel switch 1 are enabled, their states are inconsistent. Subcode 105: The brake contactor feedback is valid before the brake contactor opens. a. Check whether the signal feature (NO, NC) of the multi-way contacts is set correctly. b. Check whether the states of the multi-way feedback contacts are consistent. Subcode 103, 105: Subcode 106: The output of the brake contactor is a. Check whether the signal feature (NO, NC) of the brake inconsistent with the brake travel switch 2 travel switch 1/2 feedback is set correctly. feedback. b. Check whether the circuit of the brake travel switch 1/2 Subcode 107: When both feedback signal of brake feedback is normal. travel switch 2 are enabled, their states are inconsistent. Subcode 104, 107: a. Check whether the signal feature (NO, NC) of the brake 5A Fault Code Name Possible Causes Solution Level travel switch 1/2 feedback is set correctly. b. Check whether the states of the multi-way feedback contacts are consistent. Subcode 105: Check whether the feedback contact of the brake contactor mal-functions. Subcode 101: The pulses in F4-03 does not change within the time threshold in of F1-13. Err38 Encoder signal abnormal Check whether the brake works properly. F4-03 increases in down direction. Subcodes 102, 103: Subcode 103: Check whether parameter setting and wiring of the encoder are correct. Subcode 104: The SVC is used in distance control mode. Motor overheat Check whether the encoder is used correctly. Subcode 102: F4-03 decreases in up direction. Err39 Subcode 101: Subcode 101: The motor overheat relay input remains valid for a certain time. 5A Subcode 104: Set F0-00 (Control mode) to 1 (Closed-loop vector control) in distance control mode. Subcode 101: Check whether the parameter setting (NO, NC) is correct. 3A Fault Code Name Possible Causes Solution Level Check whether the thermal protection relay socket is normal. Check whether the motor is used properly and whether it is damaged. Improve cooling conditions of the motor. Err40 Reserved - - - Subcode 101: Check the safety circuit switches and their states. Err41 Safety circuit Subcode 101: The safety circuit signal becomes disconnected OFF. Check whether the external power supply is normal. 5A Check whether the safety circuit contactor acts properly. Confirm the signal feature (NO, NC) of the feedback contact of the safety circuit contactor. Subcodes 101, 102: Err42 Door lock Check whether the hall door lock and the car door lock are in disconnected Subcodes 101, 102: The door lock circuit feedback good contact. during is invalid during the elevator running. running Check whether the door lock contactor acts properly. Check the signal feature (NO, NC) of the feedback contact 5A Fault Code Name Possible Causes Solution Level on the door lock contactor. Check whether the external power supply is normal. Subcode 101: Check the signal feature (NO, NC) of the up limit switch. Err43 Up limit signal Subcode 101: The up limit switch acts when the abnormal elevator is running in the up direction. Check whether the up limit switch is in good contact. 4C Check whether the limit switch is installed at a relatively low position and acts even when the elevator arrives at the terminal floor normally. Subcode 101: Err44 Down limit signal abnormal Err45 Slow-down switch abnormal Check the signal feature (NO, NC) of the down limit switch. Subcode 101: The down limit switch acts when the Check whether the down limit switch is in good contact. elevator is running in the down direction. Check whether the limit switch is installed at a relatively high position and thus acts even when the elevator arrives at the terminal floor normally. Subcode 101: The down slow-down distance is insufficient during shaft auto-tuning. Subcode 102: The up slow-down distance is 4C Subcodes 101 to 103: Check whether the up slow-down switch and the down slow-down switch are in good contact. 4B Fault Code Name Possible Causes insufficient during shaft auto-tuning. Subcode 103: The slow-down switch is stuck or abnormal during normal running. Solution Level Check the signal feature (NO, NC) of the up slow-down switch and the down slow-down switch. Ensure that the obtained slow-down distance satisfies the slow-down requirement at the elevator speed. Subcode 101: The leveling signal is inactive during re-leveling. Subcode 101: Check whether the leveling signal is normal. Subcode 102: The re-leveling running speed exceeds 0.1 m/s. Err46 Re-leveling abnormal Subcode 103: At startup of normal-speed running, the re-leveling state is valid and there is shorting door lock circuit feedback.. Subcode 102: Check whether the encoder is used properly. Subcodes 103, 104: Check whether the signal of the leveling sensor is normal. 2B Check the signal feature (NO, NC) of the feedback contact Subcode 104: During re-leveling, no shorting door on the shorting door lock circuit contactor, and check the lock circuit feedback or door lock signal is received relay and wiring of the SCB-A board. 2s after shorting door lock circuit output. Err47 Subcode 101: During re-leveling or pre-open Shorting door running, the shorting door lock circuit contactor outputs for continuous 2s, but the feedback is lock circuit invalid and the door lock is disconnected. contactor abnormal Subcode 102: During re-leveling or pre-open running, the shorting door lock circuit contactor has Subcodes 101, 102: Check the signal feature (NO, NC) of the feedback contact on the shorting door lock circuit contactor. Check whether the shorting door lock circuit contactor acts properly. 2B Fault Code Name Possible Causes Solution no output, but the feedback is valid for continuous 2s. Subcode 103: Check whether the leveling and re-leveling signals are normal. Subcode 103: During re-leveling or pre-open running, the output time of the shorting door lock circuit contactor is larger than 15s. Check whether the re-leveling speed is set too low. Level Subcode 101: Err48 Err49 Door open fault Door close fault Subcode 101: The consecutive times that the door Check whether the door machine system works properly. does not open to the limit reaches the setting in Check whether the CTB output is normal. Fb-09. Check whether the door open limit signal and door lock signal are normal. Subcode 101: The consecutive times that the door Subcode 101: does not open to the limit reaches the setting in Check whether the door machine system works properly. Fb-09. Check whether the CTB output is normal. 5A 5A Check whether the door close limit signal and door lock signal are normal. Err50 Consecutive Subcode 101: loss of leveling signal Leveling signal stuck is detected for three Subcodes 101, 102: 5A Check whether the leveling and door zone sensors work Fault Code Name Possible Causes Solution consecutive times. properly. Subcode 102: Check the installation verticality and depth of the leveling plates. Leveling signal loss is detected for three consecutive times. Level Check the leveling signal input points of the MCB. Check whether the steel rope slips. Handling at inspection-speed commissioning: This fault does not affect inspection-speed commissioning and you can hide the fault directly on the operation panel. Handling at normal-speed commissioning and running: Err51 CAN Subcode 101: Feedback data of CANBUS communicatio communication with the CTB remains incorrect. n abnormal Subcode 101: Check the communication cable connection. 1A Check the power supply of the CTB. Check whether the 24 V power supply of the controller is normal. Check whether there is strong-power interference on communication. Err52 HCB Subcode 101: Feedback data of Modbus communicatio Handling at inspection-speed commissioning: 1A Fault Code Name n abnormal Possible Causes communication with the HCB remains incorrect. Solution Level This fault does not affect inspection-speed commissioning and you can hide the fault directly on the operation panel. Handling at normal-speed commissioning and running: Subcode 101: Check the communication cable connection. Check whether the 24 V power supply of the controller is normal. Check whether the HCB addresses are repeated. Check whether there is strong-power interference on communication. Subcode 101: The door lock feedback signal remains active 3s after door open output. Err53 Door lock fault Subcode 101: Check whether the door lock circuit is normal. Subcode 102: The states of the door lock multi-way Check whether the feedback contact of the door lock feedback contacts are inconsistent 3s after door contactor acts properly. open output. Check whether the system receives the door open limit Subcode 103: Reserved. signal when the door lock signal is valid. Subcode 104: The higher-voltage and low-voltage door lock signals are inconsistent. Subcode 102: Check whether when the hall door lock signal and the car 5A Fault Code Name Possible Causes Solution Level door lock signal are detected separately, the detected states of the hall door locks and car door lock are inconsistent. Subcode 104: When the higher-voltage and low-voltage door lock signals are detected at the same time, the time when the MCB receives the two signals has a deviation of above 1.5s. This causes system protection. This subcode is reset at power-off and power-on again. Err54 Overcurrent at inspection startup Subcode 101: reserved Subcode 102: Subcode 102: Reduce the load 5A The current at startup for inspection exceeds 120% Change Bit1 of FC-00 to 1 to cancel the startup current of the rated current. detection function. Err55 Stop at another landing floor Subcode 101: During automatic running of the elevator, the door open limit is not received within the time threshold in Fb-06. Subcode 101: Check the door open limit signal at the present floor. 1A Err57 Serial peripheral interface Subcodes 101, 102: The SPI communication is abnormal. No correct data is received with 2s of DSP communication. Subcodes 101, 102: Check the wiring between the control board and the drive board. 5A Fault Code Name Possible Causes (SPI) Subcode 103: The MCB does not match the AC communicatio drive. n abnormal Err58 Solution Level Subcode 103: Contact us or our agent directly. Subcodes 101, 102: Subcode 101: The up slow-down switch and down Check whether the signal feature (NO, NC) of the slow-down Shaft position slow-down switch are disconnected switches and limit switches are consistent with the parameter simultaneously. switches setting of the MCB. abnormal Subcode 102: The up limit feedback and down limit Check whether malfunction of the slow-down switches and feedback are disconnected simultaneously. limit switches exists. 4B Subcode 101: Subcode 101: Err62 Analog input cable broken Check whether F5-36 is set correctly. The current car load (F8-05) is smaller than the car Check whether the analog input cable of the CTB or MCB is no-load load (F8-06) and the deviation is larger connected incorrectly or broken. than the threshold. Adjust the load cell switch function. 1A Check the level switch and brake Err65 UCMP fault Unintended car movement protection It can be canceled by set below parameters according FA-05. 1. FA‐05=16.00 F05.0* L**.** 1A Fault Code Name Possible Causes Solution Level Set A1‐08 bi7=1; 2. FA‐05=20.04 F05.0* L**.** Set FJ‐00=01320, then set FJ‐02 bit12=1; 3. FA‐05=20.04 F05.5* L**.** Set FJ‐00=01320, then set FJ‐02 bit12=1. It only mandatory in China and can be canceled by set below parameters according FA-05. Err66 Brake force test failed 1. FA‐05=16.00 F05.0* L**.** except 16.00 F05.02 L**.** Set A1‐08 bi6=1; set F2‐38=30. In the normal mode, the brake force test failed 2. FA‐05=16.00 F05.02 L**.** Set A1‐10 bit13=1, then set A1‐08 bi6=1; set F2‐38=30. 1A 3. FA‐05=20.04 F05.0* L**.** Set FJ‐00=01320, then set FJ‐03 bit3=1; set F2‐38=30 4. FA‐05=20.04 F05.5* L**.** Set FJ‐00=01320, then set FJ‐03 bit3=1; set F2‐33=30 Err80 Shaft protection (Only for Russia) Subcode 101: Landing door lock open when cabinet not at the floor. When lift in normal mode, as long as one landing door lock is not closed monitored by landing display board, E80 will happen. Subcode 101: All landing door lock connect to JP2:2,3 (JP1:3, 4 if HCB-D2 or HCB-Y1 board) of landing display boards. Only in inspection mode, after all landing door locks closed except current floor where car is, E80 will reset automatically. 1A Fault Code Err81 Name Safety window open (Only for Russia) Possible Causes Solution Level Subcode 101: Subcode 101: Car top safety window switch open Only in inspection mode, recover the switch which connect to CCB-A: JP22 or CCB-B: JP37. It isn't detected in fire phase 2. Fault Err41 is not recorded in the elevator stop state. Fault Err42 is reset automatically when the door lock circuit is shorted or 1s after the fault occurs in the door zone. If faults Err51, Err52, and E57 persist, they are recorded once every one hour. 1A