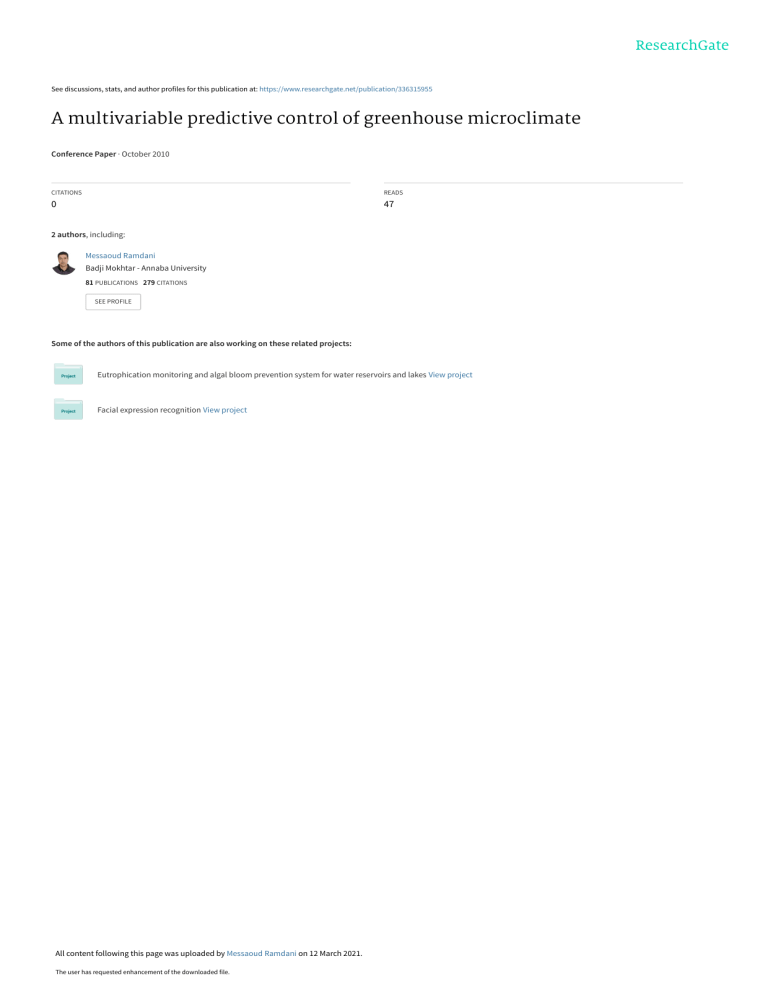

See discussions, stats, and author profiles for this publication at: https://www.researchgate.net/publication/336315955 A multivariable predictive control of greenhouse microclimate Conference Paper · October 2010 CITATIONS READS 0 47 2 authors, including: Messaoud Ramdani Badji Mokhtar - Annaba University 81 PUBLICATIONS 279 CITATIONS SEE PROFILE Some of the authors of this publication are also working on these related projects: Eutrophication monitoring and algal bloom prevention system for water reservoirs and lakes View project Facial expression recognition View project All content following this page was uploaded by Messaoud Ramdani on 12 March 2021. The user has requested enhancement of the downloaded file. A multivariable predictive control of greenhouse microclimate Mouna Boughamsa, Messaoud Ramdani Department of Electronics, Faculty of Engineering University Badji-Mokhtar of Annaba PO. Box. 12, 23000, Annaba, Algeria E-mail: [email protected] Abstract— This paper deals with the problem of modeling and control of greenhouses inside climate defined by the air temperature, humidity and CO2 concentration. The control objective aims to ensure a favourable inside microclimate for the culture growth to achieve high yield at low expense, good quality and low production cost. Achieving this goal is difficult, due to the complexity of the phenomena involved in the plant growth process and the high sensitivity to the outside weather. A multivariable predictive control based on subspace state space description is used in order to optimise the future behaviour of the greenhouse environment, concerning the set-point profile and the minimisation of the control effort energy. The simulation results show that the proposed controller provides promising performances. subspace modeling approach. Section 4 outlines the model based predictive control. Experimental results concerning the greenhouse climate control are presented in section 5. Finally, some concluding remarks as well as some possible improvments are given in section 6. Outside weather conditions wind speed air temperature air humidity CO2 concentration solar radiation greenhouse Keyword : Greenhouse climate, predictive control, Subspace identification. I. I NTRODUCTION Greenhouses are designed to provide a protected indoor microclimate in which crops can be grown under a tightly controlled climate. The greenhouse climate is one of the key factors affecting plant production, and it is influenced by many elements such as the outside weather, the actuators, and the crop itself. Fig. 1 outlines the general scheme of a greenhouse process. The automatic climate control, which is used mainly to maintain a protected environment despite fluctuations of external climate, has many advantages such as energy conservation, better productivity of plants, and reduced human intervention [3]. Many greenhouses use a conventional PID control, but this control strategy may not be suitable to garantee the desired performance due the interaction between the different variables and components in a greenhouse. Motivated by these disadvantages, recent research led to the development of strategies for further enhancement of greenhouse climate control. Optimal and predictive control have been proposed to decide about heating and ventillation and produce control actions that regulate air temperature and CO2 concentration [1], [2], [4]. Most techniques are not designed specifically in order to enable simultaneous control of air temperature and humidity concentration in the greenhouses. However, humidity control has a great effect on crop growth and production. In this paper, we investigate the use of a constrained multivariable predictive control of the microclimate of a greenhouse. The rest of this paper is organized as follows : Section 2 describes briefly the analytic greenhouse model to simulate the greenhouse. Section 3 provides an overview of the crops energy (temperature) CO2 CO2 concentration vapor (air humdity) ventilation heating CO2 enrichment vapor injection control Fig. 1. Scheme of greenhouse climate model. II. T HE GREENHOUSE MODEL The dynamic behaviour of the greenhouse-climate is a combination of physical processes involving enery trasfer (radiation and heat) and mass transfer (water vapour fluxes and CO2 concentration) taking place in the greenhouse and from the greenhouse to the outside air, Fig. 1. These processes depend on the outside climate conditions, structure of the greenhouse, type and state of the crop and on actuating control signals, such as ventillation and heating and CO2 injection to influence photosynthesis and cooling by evaporation for humidity enrichment and decreasing the air temperature. The greenhouse climate model describes the dynamic behaviour of the state variables by the use of differential equations for the air temperature, humidity and CO2 cencentrations. The model can be written by deriving the appropriate energy and mass balances, for the inside temperature, Ta (◦ C), humidity, Ha (g/m3 ) and CO2 concentration (g/m3 ). Based on the first principle, the evolution of the temperature of the greenhouse can be described by the following differential equation : III. S UBSPACE IDENTIFICATION METHODS dTa Vg ρCp = Qr + Qh + Qs − Qc − Qv − Qtr Sg dt (1) where Vg is teh volume of the greenhouse (m3 ), Sg is the soil surface (m2 ), ρ is the air density (kg/m3 ), Cp is the specific heat of the air (Jkg −1 K −1 ), Qr is the energy contribution by solar radiation (W ), Qh is energy supplied by the heating system (W ), Qs and Qc are the heat exchanges by convection and conduction between the soil surface, cover and the greenhouse air (W ), Qv is the heat lost by ventilation and infiltration (W ), Qtr is the flux of the latent heat due to crop transpiration. The effect of ventillation and filtration is given by : Qv = ρCp φvent (Ta − Te ) Sg (2) where φvent is the ventillation rate (m3 /s), which depends on the specific vent type, opening angle and wind speed, Te is the external air temperature. The heat fluxes due to crop transpiration can be deduced from the crop canopy transpiration and from the inside air saturation deficit. The heat exchanged by conduction and convection between the cover, soil and internal greenhouse air, depends on the difference between the air temperature and their surface temperature. Qc = ha−e (Ta − Te ) (3) Qs = hs−a (Ts − Ta ) (4) where ha−e is the heat transmission coefficient by convection and conduction, (W m−2 K −1 ) and hs−a is the heat transmission coefficient throught the greenhouse soil, (W m−2 K −1 ). The energy coming from the solar radiation can be expessed as Qrad = crad Se , where crad is the heat load coefficient. The humidity differential equation is given by : dHa (5) = ΦC,AI − ΦAI,AE − Φcond dt where Ccap,h (m) is mass capacity of the greenhouse air. The water vapour exchange throught the ventillation system is influenced by the ventillation flux and the difference between inside and outside air humidities : Ccap,h ΦAI,AE = φvent (Ha − He ) (6) The crop transpiration is driven by the difference in water vapour pressure between the ambient air and the sub-stomatal cavity, which is assumed to be saturated with respect to water vapour. The canopy transiration is described by ΦC,AI = ccanopy,h cm,h (cres,h Hstoma (Ta ) − Ha ) (7) where cres,h is a parameter, which reflects the stomatal resistance to the humidity transpiration and cm,h is a mass transfer coefficient constant. The ccanopy,h represents the canopy humidity range. When the outside temperature is much lower than inside air temperature, the condensation process takes place. This process can be described by Φcond = ccond,h (Hroof (Te ) − Ha ) (8) The subspace identification methods refer to a class of algorithms based on the approximation of subspaces generated by the row spaces of block Hankel matrices of the input/output data, to calculate a discrete-time state space model of the following form : xk+1 = Axk + Buk + wk yk = Cxk + Duk + vk Q S wi δij ≥ 0 = E wjT vjT vi ST R (9) (10) where x, u, and y are the process states, inputs and outputs, respectively, while A is the system (state transition) matrix, B is the input matrix, C is the output matrix and D is the direct input to output matrix. w is called the process noise and v is called the measurement noise. The matrices Q, S and R are the covariance matrices of the noise sequences w and v. E denotes the expected value operator and δij the Kronecker delta. The subscript index k denotes a discrete time system. Related to equation (9), it is assumed that the system is asymptotically stable, the pair (A, C) is observable and the pair (A, B) is controllable. There are now many different versions of subspace algorithms, and they have reached a certain level of maturity. All subspace methods consist of three main steps : first estimating the predictable subspace for multiple future steps, then extracting state variables from this subspace and finally fitting the estimated states to a state-subspace model by applying the least squares method. The subspace identification algorithm considered in this study is the standard Subspace State-Space System IDentification (N4SID) algorithm. First, the measured data are arranged to form block Hankel matrices Yf , Yp , Uf , and Up , where the subscripts "f" and "p" denote the future and past, respectively. The Hankel matrices can be arranged to form a linear regression equation : Up (11) Y f = R U p R Yp R U f Y p Uf which can be solved in a least squeres sense. By excluding the linear combination of the Uf , the matrix of predicted outputs can be written as : Up (12) Ŷf = RUp RYp Yp It can be shown [7] that the input-state-output relations can be expressed as Yf = ΓXf + RUf Uf + Ef (13) where Γ is the extended observability matrix. Xf is a matrix of state sequences stored as row vectors, and Ef is a noise term. By excluding Uf , the matrix of predicted outputs can be defined. Ŷf = ΓX̂f (14) where X̂f presents the predicted states, which are up to now known. By performing the singular value decomposition (SVD) of (12), deleting small singular values, and comparing to (14) gives Ŷf = U SV T ≈ U1 S1 V1T = ΓX̂f 1/2 Γ = U1 S1 , X̂f = Γ+ Ŷf , (15) (16) where+ denotes the Moore-Penrose pseudoinverse. Once the matrix of states is given by (16), the state space model matrices can be found by solving a simple set of overdetermined equations in a least squares sense A B X̂k+1 X̂k = + vk (17) C D Yk Uk with vk as residual matrix. In addition, the Kalman gain K can then, if desired, be computed from A, C, and the covariance matrix of vk . Fig. 2. The basic principle of model-based predictive control. IV. M ODEL PREDICTIVE CONTROL Model predictive control (MPC) is a powerfull methodology for controlling industrial processes. Since its emergence more than two decades ago, the technique has been considerably developed. MPC, is perhaps, the most general way of posing the control problem in the time domain and applicable to linear and nonlinear systems, especially when the reference trajectories are known. The MPC consist of four basic elements ; (i) a model, which describes the process, (ii) a goal, defined by an objective function, (iii) optional constraints on the system and control variables, and (iv) an optimization procedure. The model describes the dynamic behaviour of the system and may be black-box, gray-box or white-box model. The objective function depends on the predicted future system inputs and output. In general, the difference between system outputs and a reference trajectory is used in combination with a cost term on the control effort. A special case is the quadratic form (18), mostly referred to as generalized predictive control (GPC), which can be solved analytically for linear systems without constraints. With constraints, the optimization problem is a convex Quadratic Programming (QP) problem, which can be efficiently be solved numerically. The quadratic form is given by : J= Hp X i=1 2 kr (k + i) − ŷ (k + i)kPi + Hc X 2 ku (k + i − 1)kQi i=1 (18) where Pi and Qi are positive definite weight matrices. In linear model based predictive control, a linear model is used to predict the output ŷ as a function of the control signal sequence û (k, · · · , k + Hp ), with Hp the prediction horizon. The objective function given by (18), is minimized for a given reference trajectory. The signal u may change over the control horizon Hc (Hc ≤ Hp ) and remains constant between Hc and Hp . Given a linear model in state-space description : x (k + 1) = Ax (k) + Bu (k) y (k) = Cx (k) (19) the constrained linear model based predictive control can be obtained by solving the quadratic program 1 T T ∆ũ H∆ũ + c ∆ũ (20) min ∆ũ 2 with : H = 2 RuT P Ru + Q T T T c = 2 Ru P (Rx Ax (k) − r̃) (21) and satisfaying the constraints on u, ∆u, and y : Λ∆ũ ≤ ω (22) with I∆u −I∆u Λ = I Hp m , −I Hp m Ru −Ru ω= umax − Iu u (k − 1) −umin − Iu u (k − 1) ∆umax −∆umin y max −Rx Ax(k) y min −Rx Ax(k) (23) I Hp m is a (Hp m × Hp m) unity matrix. The matrices Rx , Ru , Iu and I∆u are defined : C CA (24) Rx = .. . CAHp −1 CB 0 ··· 0 CAB CB ··· 0 Ru = .. .. . . .. .. . . CAHp −1 B CAHp −2 B · · · CAHp −Hc B (25) V. S IMULATION R ESULTS For a reliable simulation of a greenhouse climate process, the nonlinear model described in section II is used as a virtual system to generate the data. However, it is not very easy to select either the input or the output variables for the process. In this work, the air tempeature Ta (◦ C), and the humidity 20.957 49.103 C= 11.947 9.1409 0 0 0 D= 0 0 0 4.3965 1.1767 13.664 6.4769 This paper shows that the constrained multivariable predictive control can be applied successfully to control the greenhouse climate. The control signals are computed in order to optimize the future behaviour of the greenhouse environment, concerning the set-point accuracy and the minimization of the energy. The use of subspace identification methods has proved to be a valuable tool in the estimation of LTI state-space model for the greenhouse. This model is asymptotically stable and it can be used for control. Our future work will be directed toward the use of the local model network approach in order to improve the performace of the predictive controller. R EFERENCES [1] I. Islovish, P. O. Gutman and I. Seginer, A nonlinear optimal greenhouse control problem with heating and ventillation, Optimal Control Applications and Methods, vol. 17, pp. 157-169, 1996. Ta (°C) Ha (g/m3) 15 time (h) 20 −5 25 5 10 15 time (h) 20 25 15 10 50 1.6 2 Ventilation (m3/m2.h) 20 CO2 injection (g/m .h) 55 45 40 35 30 1.4 1.2 1 25 5 10 15 20 time (h) 25 Fig. 3. 20 5 10 15 20 time (h) 30 30 25 25 15 10 15 20 time (h) 25 20 15 10 0 0 20 40 60 time (h) 80 −5 100 120 10 100 8 80 60 40 20 0 10 5 5 0 25 Data sequences of the process. 20 VI. C ONCLUSIONS 10 25 In Fig. 4 are presented the process reponses to setpoint changes (tracking case). It can be observed that the system responds well. The constraints of the controls are defined by the boundaries of the domain of the control variables, heating [0 · · · 150 (W/m2 )], air ventilation [2 · · · 100 (m3 /(m2 · h))] and CO2 enrichment [0 · · · 10 (g/(m2 · h)]. The states of the greenhouse climate process are constrained to prevent stress of the plants. The temperature should always be above 16◦ C and if possible not higher than 35◦ C. View publication stats 0 Heat (W/m2) −0.24666 −0.08253 0.6043 0.45966 5 0 10 CO2 injection (g/m2h) 0.01747 0.00547 −0.04574 −0.02855 data model 10 20 Ta (°C) −0.06526 −0.01797 B= 0.18028 0.096702 data model 30 Ventilation (m3/m2) 40 Heat (W/m2) Ha (g/m2 ) inside the greenhouse are selected as ouputs. The heating Q (W/m2 ), the ventillation LR (W m3 /(m2 ·h)) and the CO2 (g/(m2 · h)) enrichment are selected as inputs. Instead of using Pseudo-random binary sequences, multi-level (m-level) sequences allow the user to highlight nonlinear system behaviour while manipulating the harmonic content of the signal. So, the control signals correspond to m-level uniformly distributed random sequences. Their amplitudes and frequencies were chosen so as to adequately excite the system, without deviating too much from the operating point and therefore enabling the identification of a suitable linear model. All data signals are stored at a sampling time rate of 3 min. In Fig. 3 are presented the data sequences of the process. The identified model is : 0.82096 −0.18947 −0.00076 0.16485 −0.05124 0.94452 −0.00682 0.05162 A= 0.30709 0.83751 0.95905 −0.43743 0.14914 0.37314 −0.00421 0.71948 0 50 100 time (h) 150 200 0 50 100 time (h) 150 200 0 50 100 time (h) 150 200 6 4 2 0 −2 Fig. 4. System response to setpoint changes and control signals for tracking setpoints. [2] I. Islovish, I. Seginer, P. O. Gutman and M. Borshchevsky, Sub-optimal CO2 enrichment of greenhouses, Journal of Agriculture Engineering Research, pp. 117, 136,1995. [3] A. Sriraman, and r. V. Moyorga, A fuzzy inference sytem approach for greenhouse climate control, Environ. Informatics Archioves, vol. 2, pp. 699-710, 2004. [4] M. Y. El. Ghoumari, H. J. Tantau, and J. Serrano, Nonlinear constrained MPC : real time implementation of greenhouses air temperature, Comput. Elect. Agric., vol. 49, pp. 345-356, 2005. [5] F. Fourati, and M. Chtourou, A greenhouse control with feedforward and recurrent neural networks, Simulation Modeling Pract. and Theory, vol. 15, pp. 1016-1028, 2007. [6] F. Lafont, and J. F. Balmat, Optimized fuzzy control of a greenhouse, Fuzzy Sets and Syst., vol. 128, pp. 47-59, 2002. [7] Van Overschee, P. and De Moor, B., Subspace identification for linear systems : Theory, implementation, Applications. Kluwer Academic, Dordrecht, 1996.