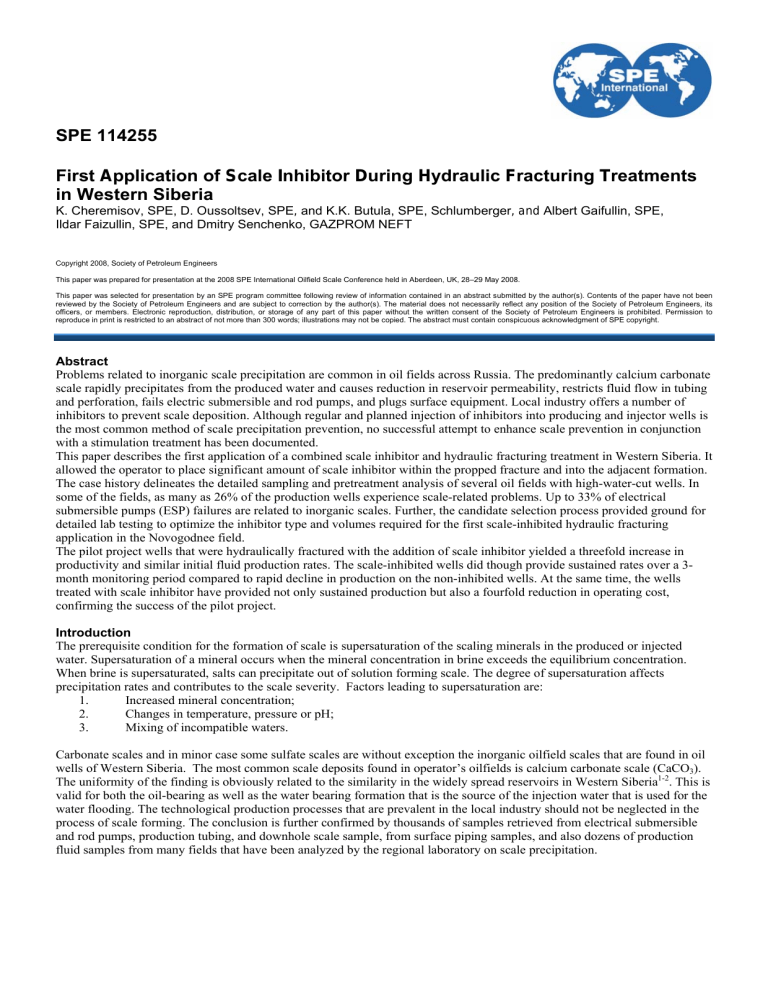

SPE 114255 First Application of Scale Inhibitor During Hydraulic Fracturing Treatments in Western Siberia K. Cheremisov, SPE, D. Oussoltsev, SPE, and K.K. Butula, SPE, Schlumberger, and Albert Gaifullin, SPE, Ildar Faizullin, SPE, and Dmitry Senchenko, GAZPROM NEFT Copyright 2008, Society of Petroleum Engineers This paper was prepared for presentation at the 2008 SPE International Oilfield Scale Conference held in Aberdeen, UK, 28–29 May 2008. This paper was selected for presentation by an SPE program committee following review of information contained in an abstract submitted by the author(s). Contents of the paper have not been reviewed by the Society of Petroleum Engineers and are subject to correction by the author(s). The material does not necessarily reflect any position of the Society of Petroleum Engineers, its officers, or members. Electronic reproduction, distribution, or storage of any part of this paper without the written consent of the Society of Petroleum Engineers is prohibited. Permission to reproduce in print is restricted to an abstract of not more than 300 words; illustrations may not be copied. The abstract must contain conspicuous acknowledgment of SPE copyright. Abstract Problems related to inorganic scale precipitation are common in oil fields across Russia. The predominantly calcium carbonate scale rapidly precipitates from the produced water and causes reduction in reservoir permeability, restricts fluid flow in tubing and perforation, fails electric submersible and rod pumps, and plugs surface equipment. Local industry offers a number of inhibitors to prevent scale deposition. Although regular and planned injection of inhibitors into producing and injector wells is the most common method of scale precipitation prevention, no successful attempt to enhance scale prevention in conjunction with a stimulation treatment has been documented. This paper describes the first application of a combined scale inhibitor and hydraulic fracturing treatment in Western Siberia. It allowed the operator to place significant amount of scale inhibitor within the propped fracture and into the adjacent formation. The case history delineates the detailed sampling and pretreatment analysis of several oil fields with high-water-cut wells. In some of the fields, as many as 26% of the production wells experience scale-related problems. Up to 33% of electrical submersible pumps (ESP) failures are related to inorganic scales. Further, the candidate selection process provided ground for detailed lab testing to optimize the inhibitor type and volumes required for the first scale-inhibited hydraulic fracturing application in the Novogodnee field. The pilot project wells that were hydraulically fractured with the addition of scale inhibitor yielded a threefold increase in productivity and similar initial fluid production rates. The scale-inhibited wells did though provide sustained rates over a 3month monitoring period compared to rapid decline in production on the non-inhibited wells. At the same time, the wells treated with scale inhibitor have provided not only sustained production but also a fourfold reduction in operating cost, confirming the success of the pilot project. Introduction The prerequisite condition for the formation of scale is supersaturation of the scaling minerals in the produced or injected water. Supersaturation of a mineral occurs when the mineral concentration in brine exceeds the equilibrium concentration. When brine is supersaturated, salts can precipitate out of solution forming scale. The degree of supersaturation affects precipitation rates and contributes to the scale severity. Factors leading to supersaturation are: 1. Increased mineral concentration; 2. Changes in temperature, pressure or pH; 3. Mixing of incompatible waters. Carbonate scales and in minor case some sulfate scales are without exception the inorganic oilfield scales that are found in oil wells of Western Siberia. The most common scale deposits found in operator’s oilfields is calcium carbonate scale (CaCO3). The uniformity of the finding is obviously related to the similarity in the widely spread reservoirs in Western Siberia1-2. This is valid for both the oil-bearing as well as the water bearing formation that is the source of the injection water that is used for the water flooding. The technological production processes that are prevalent in the local industry should not be neglected in the process of scale forming. The conclusion is further confirmed by thousands of samples retrieved from electrical submersible and rod pumps, production tubing, and downhole scale sample, from surface piping samples, and also dozens of production fluid samples from many fields that have been analyzed by the regional laboratory on scale precipitation. 2 SPE 114255 In this paper data pertinent to the fields of Sutorminskoe, Muravlenkovskoe, Novogodnee and Meretoyakhinskoe oilfields will be represented (Table 1, Figure 1 and Figure 2) to justify the scale prevention pilot work performed on the Novogodnee field. Based on operator’s production department, only in the first quarter 2007 more then 350 wells have shown problems related to scale deposits. Oilfield Producing wells Scale problems % Muravlenkovskoe 399 104 26.1 Novogodnee 47 10 21.3 Sugmutskoe 345 58 16.8 Sutorminskoe 1055 156 14.8 Vingapurovskoe 538 28 5.2 Table 1: 2007 Scale related ESP failures for various operators’ oilfields The reasons for ESP failures have been categorized within six major categories: • Solids, including proppant and proppant particles, formation material, cement particles and rust; • Production rate decrease causing insufficient hydrostatic head leading to EPS pump overheating and failure; • Critical parts failure relating to installation mechanical damage; • Inorganic scale build up in rotor-stator area; • Cable damage, mainly during installation or resulting from acid treatments; • And others – relating to unidentified causes of pump failure. Graphically the reasons of failure are split as in figure below: ESP failure 15% 9% 21% Solids Produciton Rate Decrease Critical Parts Failure Inorganic Scales Other Cable Damage 33% 9% Figure 1: Reasons of ESP failure 13% Figure 2: Muravlenkovskoe field scale occurrence Even in cases where the abrupt failure of the ESP is not the prime cause of the production stop the cumulative effect of gradual scale build-up on production can not be neglected. A simple model can be created to evaluate the gradual loss of production rate in low scale build up environments. Figure 3 shows the production decline plot for actual and pseudosteady state calculated data overlay for a typical well in the Muravlenkovskoe field. The modeling was done using in house analytical software. Figure 4 shows cumulative production plot for actual and modeling data. Based on modeling data, because of scales related problems the well annual production is reduced for 3400 tons of oil. SPE 114255 3 10000 8000 25 Actual data & No Scale Prevention Model-based data 20 Oil, tons Oil, tons/day Cumulative production Production decline 30 15 6000 4000 10 2000 5 40 60 80 100 120 140 160 180 200 220 240 260 280 300 320 340 360 Days Actual data Modeling data 0 1 20 40 60 80 100 120 140 160 180 200 220 240 260 280 300 320 340 360 Days Figure 3: Well A - production decline, Muravlenkovskoe field Figure 4: Well A - cumulative production The above example does not include any downtime in production from well being shut-in, downtime caused by waiting on workover rig or on pump replacement and the resulting deferred oil and reduced cash flow. Nor does it include losses in productivity that may occur during the workover cycle. These direct and indirect and indeed very realistic expenses are to be taken into account by the operator when the well is shut down because of scaling. Therefore scale deposition prevention can provide significant positive impact on the field economics. The assessment of scaling and scale type is the first step in the scale prevention process. The following paragraphs will deal with these steps. Scale Characterization It was important to qualify the scale type and the possibility of scale occurrence. Qualitative analysis of scale deposits was performed by: • Analysis of retrieved samples from tubing; • Analysis of retrieved samples from failed ESP. The tendency of scale precipitation was based on: • Analysis of retrieved produced water samples; • Analysis of retrieved injection water samples; And the prediction was done either based on Stiff-Davis3-4 method or based on an internal reservoir stimulation software program that includes a wellbore model, a reservoir model and a chemical reaction model. Based on the complete information about the reservoir, wellbore and fluid properties the chemical model predicts the nature and extent of scaling. The model predicts phase equilibrium using thermodynamic principles and geochemical databases. Input data such as elemental concentration analysis, temperature, pressure and gas-phase compositions are required to predict the effect of perturbations such as changes in temperature and pressure or mixing of incompatible waters. Samples of inorganic scale deposits collected from tubing (Novogodnee oilfields, Meretoyakhinskoe oilfield) and broken ESP (Sugmutskoe oilfield, Muravlenkovskoe oilfield) were showing 95% occurrence of calcium carbonate (CaCO3) (Figure 5). Figure 5: Scale sample from retrieved tubing -well Meretoyakhinskoe-X 4 SPE 114255 Figure 6: Scale sample from retrieved ESP - well Sutorminskoe-XXXX As a first step in evaluation of the scales samples were taken from failed ESP (Figure 6) run in different fields. A total of 19 samples were analyzed. The internal laboratory was requested to perform X-Ray diffraction (XRD) analysis to define the scale composition. The procedure prior to any analysis consisted of cleaning of samples in xylene and methanol to remove any remaining oil. The solvent was carefully decanted, to ensure collection of all of the particles, and the samples placed in a drying oven until dried to a constant weight. Once cleaned the scale samples were all very similar in appearance. A typical sample is shown in Figure 7 below: Figure 7: Scale sample from retrieved ESP - well Sugmutskoe-XXXX The results of the XRD analysis show that all but one of the scale samples are composed almost entirely of calcium carbonate (CaCO3). The only exception to this is the sample collected from well in the Muravlenkovskoe field, which was found to be largely composed of quartz (SiO2) with only a small trace of calcium carbonate. This sample was also found to include approximately 10% metal fragments, which were removed prior to the XRD analysis. SPE 114255 5 Table 2: Results of X-Ray diffraction analysis of retrieved samples Scaling Prediction Stiff-Davis method was used to predict the tendency of oilfield waters to deposit scale. The water samples from several field have been (Table 3 and Table 4) sampled and have shown that the producing well have tendency toward calcium carbonate deposition (Table 5 and Figure 8). PARAMETER pH Bromide Hydrocarbonate Carbonate Barium Iron Potassium Calcium Magnesium Sodium Strontium Density at 18.50C Sulfate Chloride VALUE UNITS 8.21 3.96 493 <0.3 0.74 0.031 12 16 1.6 820 3.3 0.998 60.8 1020 - Table 3: Formation water analysis mg/L mg/L HCO3 mg/L CO3 mg/L mg/L mg/L mg/L mg/L mg/L mg/L g/cm3 mg/L mg/L PARAMETER pH Bromide Hydrocarbonate Carbonate Barium Iron Potassium Calcium Magnesium Sodium Strontium Density at 18.50C Sulfate Chloride VALUE UNITS 7.55 25.1 661 <0.3 13 3.4 39 140 13 3800 33 1.005 22.7 5980 mg/L mg/L HCO3 mg/L CO3 mg/L mg/L mg/L mg/L mg/L mg/L mg/L g/cm3 mg/L mg/L Table 4: Injection water analysis 6 SPE 114255 Table 5: Self-scaling (% of injection water is equal to 0): A Scaling Tendency Muravlenkovskoe, Well 817. 100 Mg/l 80 60 CaCO3 BaSO4 40 20 0 0 10 20 30 40 50 % of Injected Water in Formation Water Figure 8: Scaling tendency for formation and injection water mixture (from 0 to 50%): The widely spreading scaling problem prompted the operator to search for urgent measures of remediation, prevention and removal. The following will describe the concentrated engineering effort related to the scale prevention pilot project on the Novogodnee field. Case History The work described in the paper reflects an example of a typical oilfield in Western Siberia – a brownfield that is under aggressive production targets and the production is based mainly on ESP, where formations are hydraulic fractured to effectively connect the lateral and vertical flow discontinuity and increase productivity. The field, like others has been placed for many years on an intensive water injection program to maintain reservoir pressure. A high water cut is associated with the complex flow pattern of the injection water through the reservoir. The additional uncertainty of the injection water flow is linked to the water injection above the rock parting pressure and the thermal fracturing caused by continuous water injection. About 4 years ago the operator started to face inorganic scale related problems. At present time both chemical and mechanical solutions to remove scales are widely used. A lot of effort and large funds are being spent to develop scale prevention system, including continuous dosage of scale inhibitor either on surface or downhole, periodical inhibition by scale inhibitor squeeze treatment or inhibition of water flooding and producing wells. This is common practice in the Russian oilfields and has been extensively documented. Novogodnee Field The field is located in the Western Siberian basin. The main Jurassic reservoir (JV-1) has an average permeability of 10 mD and a net pay of 7 to 10 m. The light crude has a viscosity of 0.3 cp, a high GOR of 540 m3/m3 and a bubble point of 308 bar. The wells are naturally flowing because of the higher reservoir pressure and high GOR, and this is more then exception after SPE 114255 7 the hydraulic fracture completion. Producer and injector wells, drilled in the Novogodnee oilfield are typically “S”-shaped with a similar well design. A 393 mm (15 ½”) diameter conductor hole is drilled vertically to 360 m TVD and a 324mm (12 ¾”) diameter casing is set. The 295 mm (11 5/8”) surface hole is kicked off at about 400 m or as required for trajectory optimization with build rates at 3 to 4º/30m. The inclined section is maintained to 1500 m TVD. A 245 mm (9 5/8”) intermediate casing is run to a measured depth of approximately 170 m. Finally, a 216mm (8 ½”) production hole is drilled till planned TD (about 3000 m TVD) and cased with 178 mm (7”) casing at ~3300 m MD. After perforating and hydraulic fracturing the producing zone, a 89 mm (3.5”) tubing string is run with a packer set above the reservoir. Methodology for the pilot project Oilfield scales can be removed by mechanical means or by chemical treatments using acids and other solvents. The method of scale removal is selected based on the type of scale formed and where it is deposited. Mechanical methods are effective against thick scales formed in tubulars, but cannot access scales formed in formation or proppant pack. Mechanical methods are often more expensive since they require workover rigs or coiled tubing units. Chemical treatments can be applied but will prove only somewhat effective in dissolution of sulfate scales and scales deposited deep in the formation or proppant pack. Scale build up restricts the flow path of the formation fluids to surface, hence production will suffer until the scales are removed. Therefore, prevention of scale deposition is the best strategy in dealing with scale problems. Scale prevention can be accomplished by using scale inhibitors6-8. The common oilfield scale inhibitors used by the industry are phosphorous compounds or polymers such as organo-phosphonates, polyacrylamide and polyacrylate. These inhibitors minimize scale deposition by disrupting scale nucleation process and/or scale crystal growth and adherence by adsorbing onto the scale species at the active growth sites and thus blocking their growth. Injector rows Area of Scale Prevention Pilot Project Figure 9: Novogodnee Field To effectively prevent scale formation over a long period of time, an inhibitor must have the character of being retained in the formation or the proppant pack and released slowly. The common scale inhibitors in use are retained in the formation by either adsorbing to the pore walls or precipitating in the pore space. As the formation water is produced, the inhibitor desorbs or dissolves slowly into the produced water, and if the inhibitor concentration stays above a certain threshold level, it will provide the protection against scaling. This threshold is commonly called minimum inhibitor concentration (MIC) and for a given inhibitor can be in the range between 5 to 10 ppm. The scale inhibition method described in this paper essentially consists of a scale inhibitor added to a conventional fracture treatment5 thereby eliminating a separate inhibitor squeeze treatment. As the inhibitor is mixed into the fracturing fluid during the treatment the inhibitor is well mixed and dispersed throughout the entire fracture. In addition to the benefit of this unique scale inhibitor placement the propped fracture itself helps control scale by reducing the pressure drawdown at a given production rate and hence the propensity for scaling resulting in longer and better productivity of the well. Although the precipitation of the applied scale inhibitor occurs fairly quickly, an extended shut-in period is not necessary to facilitate precipitation. However a 12 hours shut-in period was performed after the scale-fracturing treatment to ensure success on this pilot project. 8 SPE 114255 The volume of scale inhibitor used was pre-selected based on laboratory testing to provide effective protection of the well against carbonate scale. The targeted protection time is commonly six or more months, if possible. The scale inhibitor volume was estimated based on the predicted water production rate and assumed inhibitor return concentration for a sox month period. To establish the duration of the scale protection method, the required volumes for forthcoming treatments and the requirements of re-inhibition, post-treatment scale inhibitor returns monitoring is critical for the success of all scale inhibition treatments. It requires a commitment of resources for periodic water sample collection and analysis. Monitoring of the scale inhibitor returns in produced water was based on quantitative determination of water soluble polyacrylates. The method requires several basic steps: 1. Suppression of ions in the aqueous system with 1N HCl acid; 2. Adsorption and concentration of the suppressed ions onto a silica-gel adsorbent; 3. Desorption of the adsorbed ions from the sorbent with eluant; 4. Formation of a red colored complex at addition of potassium thiocyanate; 5. Measurement of the transmission on the spectrophotometer at wave length of 480 nanometers. A results must be taken as ppm from calibration graph. To compare the effectiveness of the scale-frac treatment post frac production from three offset wells data was reviewed. All wells were producing from Jurassic formation – JV1-1 (Figure 10). Water flooding system is used for reservoir pressure maintenance (Figure 11). As result of water break through both wells have extremely high water cut (up to 98%). The only method of increasing production economically is by hydraulic fracturing, which provide significant liquid production increase whereby decreasing water cut to 90-95% (in average oil production increase is about 35 to 40 tons of oil/day/). The main reason of scaling is mixing of incompatible formation and injection water. Well XXX2-Y1 Treated with scale inhibitor Well XXX0-Y1 No scale inhibitor Zone treated Figure 10: Electric logs of the off-set wells treated and untreated with scale inhibitor SPE 114255 9 Well XXX2-Y1 Treated with scale inhibitor Well XXX1-Y1 Treated with scale inhibitor Injector lines Well XXX0-Y1 No scale inhibitor Figure 11: Map showing the location of the offset wells Prediction of calcium carbonate deposition was performed using scale prediction method based on determination of solubility index using Stiff-Davis equation. Calcium carbonate precipitation is caused by a shift toward carbonate in the carbonate-bicarbonate-carbon dioxide equilibrium. At negative equilibrium, the precipitate goes back into solution and calcium carbonate deposit does not occur. As equilibrium is positive, the brine is supersaturated and precipitation occurs. All of the wells show tendency toward calcium carbonate deposition LABORATORY REPORT Novogodnee Field, well XXX0 pad Y1 Prediction of Calcium Carbonate Deposition Ca++ Mg++ Na+ Fe++ CATIONS mg/L 200.00 48.84 9926.96 0.40 meq/L 9.98 4.02 431.80 0.01 Ion Concentration mg/L Na 9926.96 Ca 200.00 Mg 48.84 830.00 Cl 2.00 SO4 0 CO3 1220.00 HCO3 Total Ionic Strength SI = pH - pCa - pAlk - K = 2.66 ClSO4-HCO3- ANIONS mg/L 830.00 2.00 1220.00 BHT degC 85 Ionic Strength 0.2184 0.0100 0.0040 0.0116 0.0000 0.0000 0.0098 0.2538 pH 7.92 meq/L 23.41 0.04 19.99 pCa 2.302 "Stiff-Davis" equation indicates that this water has a Stability Index of A positive index indicates a tendency toward calcium carbonate deposition pAlk 1.699 2.66 Table 6: Scale prediction analysis for well Novogodnee-XXX0 The first fracture treatment on well XXX0-Y1, Novogodnee oilfield was performed in May 2007 using water based crosslinked borate frac fluid with a gel loading of 4.8 kg/m3. Initial post frac fluid rate was as high as 450 m3/day and an incremental oil rate of 62 ton/day. After 13 days of production the well was shut down due to scale precipitation in tubing, casing, perforation and proppant pack. Workover operations, including matrix acidizing and drilling, lasted 62 days. After that the well was producing for 11 days, and was shut down for the second time due to scale build up (Figure 12). After three workover operations the nearby injector well have been augmented with a scale inhibition injector pump after which further scale caused shutdowns were omitted and the production stabilized at 280 m3/day and a productivity index (PI) of 2.3 m3/day/atm was calculated based on measured rate and drawdown. 10 SPE 114255 Post frac Production - well XXX0-Y1, Novogodnee oilfield 6 Total liquid production, m3/day 500 5 400 4 300 3 Qliq PI 200 2 100 0 23-May 12-Jun 1 0 2-Jul 22-Jul 11-Aug 31-Aug 20-Sep 10-Oct 30-Oct 19-Nov 9-Dec 29-Dec 18-Jan Date Figure 12: Post Frac production – well XXX0-Y1, Novogodnee oilfield The most difficult parameter to take into consideration is the loss due to production decline of a producing, hydraulically fractured wells because of scale deposits in proppant pack. The scale deposits are decreasing the permeability of formation and proppant pack, by precipitation in pore space. This permeability decrease results in significant reduction of production. The response of the well Novogodnee XXX0-Y1 with the increasing PI after the scale inhibition injection has started on the near by injector wells can not uniquely explained, as it can be explained by proppant pack clean up after initial three workover operations, or even because of the reservoir pressure increase, related to the increased number of injector put on line. At the time of the initial occurrence of scaling problems on well XXX0-Y1, it was decided to treat the off-set wells with scale inhibitor that is incorporated into the hydraulic fracturing treatment. Before the treatment, the same scale precipitation prediction has been performed on the off-set wells to well XXX0-Y1. The laboratory analysis of the formation waters and the precipitation prediction confirmed both off-set wells XXX1-Y1 and XXX2-Y1 are prone to calcite scale precipitation (Table 7 and Table 8). SPE 114255 11 Prediction of Calcium Carbonate Deposition Novogodnee WELL XXX1 PAD ClSO4-HCO3- mg/L 15500 10 397 Ionic Strength 0.2134 0.0280 0.0060 0.2170 0.0002 0.0000 0.0032 meq/L 437.20 0.21 6.50 Ca++ Mg++ 1.86 = pH - pCa - pAlk - K = 7.4 XXX2 meq/L 600 29.94 Cl- pAlk Stiff-Davis" equation indicates that this water has a Stability Index of positive index indicates a tendency toward calcium carbonate deposition mg/L meq/L 18000 507.71 61 5.02 SO4-- 0 0.00 477.56 HCO3- 427 7.00 Fe++ 0.20 0.01 Concentration mg/L Ionic Strength BHT degC Na 10979 0.2415 93 Ca 600 0.0300 Mg 61 0.0050 Cl 18000 0.2520 SO4 0 0.0000 CO3 0 0.0000 427 0.0034 SI = pH - pCa - pAlk - K = 2.187 Y1 10979 Total Ionic Strength 1.855 PAD ANIONS mg/L HCO3 pCa WELL Na+ Ion BHT degC 93 0.4678 pH Novogodnee CATIONS ANIONS meq/L 27.94 6.03 421.93 0.01 Concentration mg/L 9700 560 73 15500 10 0 397 otal Ionic Strength FIELD Y1 CATIONS mg/L 560 73 9700 0.20 Prediction of Calcium Carbonate Deposition 0.5320 pH 7.4 1.92 pCa pAlk 1.825 2.155 "Stiff-Davis" equation indicates that this water has a Stability Index of A positive index indicates a tendency toward calcium carbonate deposition A negative index indicates a corrosive condition but no deposition 1.86 Table 7: Scale prediction well Novogodnee-XXX1 1.92 Table 8: Scale prediction well Novogodnee-XXX2 The hydraulic fracture treatment on well XXX1-Y1 was performed in August 2007. Scale inhibitor was added during the pad stage and all proppant stages in concentration 15 l/m3. Post frac incremental oil rate averaged 40 tons of oil per day and total liquid production rate averaged 450 m3/day. Figure 13 shows the post-frac liquid production rate and calculated PI for the first five months after treatment showing no significant production decline (PI > 3.0 m3/day/atm). Post frac Production - well XXX1-Y1 Novogodnee oilfield 10 600 Total liquid production, m3/day 9 500 8 7 400 6 5 300 Qliq PI 4 200 3 2 100 1 0 1-Jul 0 21-Jul 10-Aug 30-Aug 19-Sep 9-Oct 29-Oct 18-Nov 8-Dec 28-Dec 17-Jan Date Figure 13: Post Frac production – well XXX1-Y1, Novogodnee oilfield, treated with scale inhibitor Subsequent fracturing treatment with scale inhibitors was performed on well XXX2-Y1, Novogodnee oilfield in August 2007. The same approach to scale inhibitor volume estimation was used for this treatment as well and the inhibitor was added on pad stage and all proppant stages in concentration of 15 l/m3. Because of a premature screen-out only 60% of the designed amount of scale inhibitor was placed into formation and proppant pack. Post frac incremental oil rate averaged 29 tons of oil per day and total liquid production rate averaged 420 m3/day. Figure 14 presents the liquid production rate and 12 SPE 114255 calculated PI for the first five months after treatment, showing no significant production decline (PI > 4.0 m3/day/atm) that would indicate scaling. Post frac Production - well XXX2-Y1 Novogodnee oilfield 10 Total liquid production, m3/day 600 9 500 8 7 400 6 5 300 Qliq PI 4 200 3 2 100 1 0 0 1-Jul 21-Jul 10-Aug 30-Aug 19-Sep 9-Oct 29-Oct 18-Nov 8-Dec 28-Dec 17-Jan Date Figure 14: Post Frac production – well XXX2-Y1, Novogodnee oilfield, treated with scale inhibitor The inhibitor return monitoring process started on both wells immediately after the production commenced. In agreed time intervals produced water samples from both well were collected, and send to the local client support laboratory. The samples were analyzed to determine the inhibitor concentration. In practice, it was noticed that the measured inhibitor return concentration were reduced relatively quickly to low but stable concentration levels. Figure 15 and Figure 16 show the results of the scale inhibitors return concentration monitored for well XXX1-Y1 and XXX2-Y1, showing continuous presence of scale inhibitors for five months after the treatment. Inhibitor Concentration (PPM) Scale inhibitors m onitoring - w ell XXX1-Y1, Novogodnee oilfield 1.4 1.2 1 0.8 0.6 0.4 0.2 0 22-Aug 11-Sep 1-Oct 21-Oct 10-Nov 30-Nov 20-Dec 9-Jan Date Figure 15: Scale inhibitors monitoring - well XXX1-Y1, Novogodnee oilfield SPE 114255 13 Inhibitor Concentration (PPM) Scale inhibitors monitoring - well XXX2-Y1, Novogodnee oilfield 24.0 22.0 20.0 18.0 16.0 14.0 12.0 10.0 8.0 6.0 4.0 2.0 0.0 9-Aug 29-Aug 18-Sep 8-Oct 28-Oct 17-Nov 7-Dec 27-Dec 16-Jan Date Figure 16: Scale inhibitors monitoring - well XXX2-Y1, Novogodnee oilfield Although the MIC reached low values relatively quickly after production started, both off-set well have produced without interruption for more then five months, reducing the operating expenditures to a quarter of the cost of the non-treated well. Conclusions The success of the pilot project can be defined through the following conclusions: - Production related problems related to scale deposition in the production system were confirmed; - The analysis of current scale deposits confirmed that in majority of the cases calcium carbonate scale is formed; - Scale prevention technology such as combining scale inhibitor deposition in the propped fracture greatly improves the production life of the well; - Significant operating costs can be saved with a minimal investments and upgrade of a hydraulic fracture treatment to a scale and fracture treatment. Acknowledgements The authors wish to thank Gazprom Neft and Schlumberger for the permission to publish this paper. Nomenclature PI TD MD BHT TVD GOR Qliq MIC = Productivity Index, m3/day/atm = Total depth, m = Measured depth, m = Bottom hole temperature, °C = True vertical depth, m = Gas oil ratio, m3/m3 = Liquid production rate, m3/day = Minimum Inhibitor Concentration, ppm Subscripts liq = liquid 14 SPE 114255 References 1.A.I. Voloshin et al “Scaling Problems in Western Siberia”, paper SPE80407 presented at the SPE 5th International Symposium on Oilfield Scale , Aberdeen UK, 29-30 January 2003 2.V.V. Rsgulin et al.: ’The Problem of Scaling and Ways to Solve it in the Oilfields of Rosneft Oil Co” paper SPE104354 presented at the 2006 SPE Russian Oil and Gas Technical Conference Moscow, 3-6 October 2006 3.Stiff H.A. and Davis L.E.: “A Method for Predicting the Tendency of Oil Field Water to Deposit Calcium Sulfate” paper SPE 00130 presented at the Fall Meeting of the Petroleum Branch of Oklahoma City, Okla. Oct. 3-5 1951. 4.Stiff H.A. and Davis L.E.: : “A Method for Predicting the Tendency of Oil Field Water to Deposit Calcium Carbonate” paper SPE 952213 presented at the Houston meeting, Okla. Oct. 1-3 1952. 5.Cowan T.L., Delgado E.E., Lange G.V. and Gordon J. E.: “Successful Application of a Scale Inhibitor in Borate Fracture Fluids: A Field Study”, ”, paper SPE 59542 presented at the 2000 SPE Permian Basin Oil and Gas Recovery Conference held in Midland, TX, 21–23 March. 6.Tomson M. B., Fu G., Watson M. A. and Kan A. T..: “Mechanisms Of Mineral Scale Inhibition”, paper SPE 74656 presented at the 2002 SPE Oilfield Scale Symposium held in Aberdeen, United Kingdom, 30–31 January. 7.Powell R. J., Fischer A. R., Gdanski R.D., McCabe M.A., and Pelley S. D.: “Encapsulated Scale Inhibitor for Use in Fracturing Treatments,” paper SPE 30700 presented at the 1995 SPE Annual Technical Conference and Exhibition, Dallas, TX, 22-25 October. 8.Maschio L., Cherian B., Lungwitz B., Tyndall M., Garcia M., Longwell J.:” Optimization of a Scale Treatment in the Uinta Basin – A Case History”, paper SPE 107993 presented at the 2007 SPE Rocky Mountain Oil & Gas, Denver, Colorado, U.S.A., 16–18 April 2007 Conversion Factors atm bar bar °C cp m m3 MPa md g kgPA tons × × × × × × × × × × × × 1.013250 1.450377 1.0 (1.8×°C)+32 1.0 3.28 6.28981 1.0 9.869 2.205 8.33 9.071847 E + 05 E + 01 E + 05 E + 03 E + 00 E + 00 E + 06 E - 16 E - 03 E - 03 E + 06 = Pa = psi = Pa =°F =Pa⋅s =ft =bbl =Pa =m2 =lbm =PPA =g