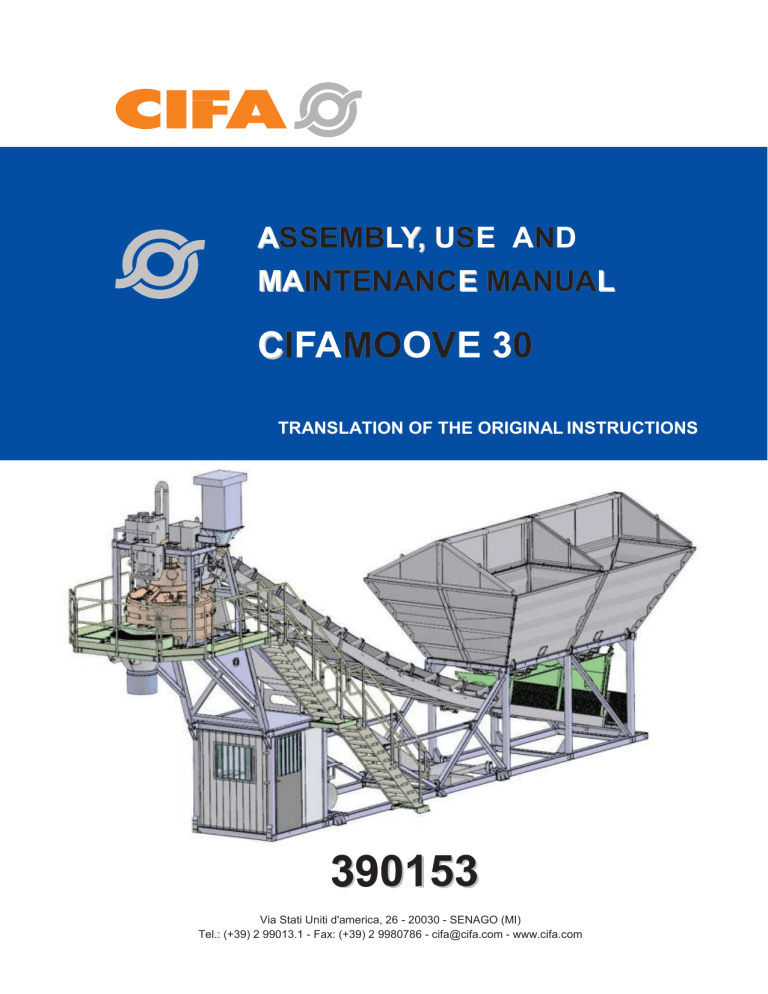

ASSEMBLY, USE AND MAINTENANCE MANUAL CIFA AMOOVE 30 TRANSLATION OF THE ORIGINAL INSTRUCTIONS 390 153 Via Stati Uniti d'america, 26 - 20030 - SENAGO (MI) Tel.: (+39) 2 99013.1 - Fax: (+39) 2 9980786 - [email protected] - www.cifa.com Page intentionally left blank CIIFA AMO OOVE 30 US SE AND MAINTENANCE MA AN U AL WARNING: READ AND MAKE SURE YOU UNDERSTAND THIS MANUAL BEFORE USING THE MACHINE. WARNING: KEEP THIS MANUAL INSIDE THE MACHINE. TRANSLATION OF THE ORIGINAL INSTRUCTIONS Review Date of latest review Edition 0 05/2013 ENGLISH Creation date 05/2013 User and Maintenance Manual CIFAMOOVE 30 PA 4 PREFACE Dear Customer, Thank you for choosing us. We are delighted to have you as a customer and we are sure you will be fully satisfied with this machine. All parts of this machine, which is the result of research and decades of experience, have been built using extremely reliable commercial materials and components that make it a high performance machine with low maintenance and operating costs. Finally, remember that we are happy to provide our technical services and proven experience now and in the future. IMPORTANT To avoid damaging the machine or its smooth operation, and to ensure proper life of the components is recommended to use ORIGINAL PARTS. 4 User and Maintenance Manual PA CIFAMOOVE 30 5 IN N D EX 1 INTRODUCTION ............................................................................................................................... SECT.1:2 1.1 GENERAL LETTER AT DELIVERY............................................................................................... SECT.1:2 1.2 USE OF THIS MANUAL ................................................................................................................ SECT.1:3 1.2.1 GENERAL INFORMATION ......................................................................................................... SECT.1:3 1.2.2 PURPOSE OF THIS MANUAL ................................................................................................... SECT.1:3 1.2.3 PRESERVATION OF THE MANUAL .......................................................................................... SECT.1:4 1.2.4 HOW TO UPDATE THE MANUAL.............................................................................................. SECT.1:4 1.2.5 CONSULTING THE MANUAL ................................................................................................... SECT.1:4 1.3 SYMBOLS ..................................................................................................................................... SECT.1:5 1.4 WARRANTY................................................................................................................................... SECT.1:6 1.5 PLANT IDENTIFICATION .............................................................................................................. SECT.1:7 2 DESCRIPTION .................................................................................................................................. SECT.2:2 2.1 DESCRIPTION OF THE CIFAMOOVE 30 PLANT ........................................................................ SECT.2:2 2.1.1 ACCESSORIES AND COMPLETION......................................................................................... SECT.2:3 2.2 INTENDED USE OF THE MACHINE............................................................................................. SECT.2:5 2.3 REASONABLY FORESEEABLE MISUSES.................................................................................. SECT.2:7 2.4 TECHNICAL DATA ........................................................................................................................ SECT.2:8 2.5 OVERALL DIMENSIONS .............................................................................................................. SECT.2:9 2.6 FLOW DIAGRAM........................................................................................................................... SECT.2:10 2.7 DESCRIPTION OF MAIN UNITS ................................................................................................... SECT.2:11 2.7.1 DESCRIPTION OF AGGREGATES BATCHING UNIT............................................................... SECT.2:11 2.7.2 DESCRIPTION OF MIXING UNIT............................................................................................... SECT.2:13 2.7.3 DISCHARGE HOPPER............................................................................................................... SECT.2:16 2.7.4 PNEUMATIC SYSTEM................................................................................................................ SECT.2:17 2.8 DESCRIPTION OF CONTROL PANEL ......................................................................................... SECT.2:18 2.8.1 CONTROL PANEL...................................................................................................................... SECT.2:18 2.8.2 AUTOMATIC OPERATION ......................................................................................................... SECT.2:19 2.9 LOCATION OF CONTROL EQUIPMENT ...................................................................................... SECT.2:20 2.10 LOCATION OF SAFETY EQUIPMENT ....................................................................................... SECT.2:21 2.10.1 SAFETY DEVICES AND LIMIT SWITCH ................................................................................ SECT.2:21 2.10.2 FIXED AND MOVEABLE GUARDS. ........................................................................................ SECT.2:21 2.11 LOCATION OF SAFETY SIGNS .................................................................................................. SECT.2:22 2.12 SCHEME FOR NOISE EMISSIONS ........................................................................................... SECT.2:24 2.12.1 MAIN COMPONENT NOISE EMISSIONS TABLE ................................................................... SECT.2:24 2.13 AIR EMISSIONS DIAGRAM ........................................................................................................ SECT.2:24 5 User and Maintenance Manual PA CIFAMOOVE 30 3 SAFETY REGULATIONS ................................................................................................................. SECT.3:2 3.1 TERMINOLOGY AND DEFINITIONS ........................................................................................... SECT.3:2 3.2 DPI - INDIVIDUAL PROTECTIVE DEVICES ................................................................................. SECT.3:4 3.3 GENERAL WARNINGS ................................................................................................................. SECT.3:5 3.3.1 PREREQUISITES FOR EMPLOYEES RESPONSIBLE FOR PLANT ASSEMBLY, USE AND MAINTENANCE............................................................................................. SECT.3:5 3.3.2 PROTECTION AGAINST NOISE................................................................................................ SECT.3:6 3.3.3 RULES OF CONDUCT ............................................................................................................... SECT.3:7 3.3.4 WARNING - EXTINGUISHER .................................................................................................... SECT.3:8 3.3.5 LIGHTING - RECOMMENDATIONS.......................................................................................... SECT.3:8 3.4 INFORMATION FOR GENERAL USE .......................................................................................... SECT.3:9 3.5 MAINTENANCE INFORMATION.................................................................................................. SECT.3:10 3.6 INFORMATIONS FOR WELDING OPERATIONS (EXTRAORDINARY MAINTENANCE)........ SECT.3:12 3.7 INFORMATION ON USE OF LUBRICANTS ................................................................................ SECT.3:12 3.7.1 WARNING: RISKS RELATED TO USE OF LUBRICANT, TOXIC OR IRRITANT EFFECTS, SLIPPING, FIRE. ............................................................................................................... SECT.3:12 3.8 INFORMATION OF THE USE OF ADDITIVES.............................................................................. SECT.3:13 3.9 FALL PROTECTION WARNINGS ................................................................................................ SECT.3:13 3.10 INFORMATION ON TRANSPORT AND ASSEMBLY ................................................................ SECT.3:14 3.10.1 LIFTING EQUIPMENT ............................................................................................................. SECT.3:14 3.10.2 DISTRIBUTION OF LOADS ................................................................................................... SECT.3:14 3.10.3 MANUAL MOVEMENT OF LOADS.......................................................................................... SECT.3:15 4 TRANSPORT .................................................................................................................................. SECT.4:2 4.1 INFORMATION .............................................................................................................................. SECT.4:2 4.2 OVERALL DIMENSIONS DURING TRANSPORT ........................................................................ SECT.4:3 4.3 LIFTING.......................................................................................................................................... SECT.4:4 4.4 TRANSPORT ................................................................................................................................. SECT.4:4 ASSEMBLY 5 ASSEMBLY ................................................................................................................. SECT.5:2 5.1 ASSEMBLY PERSONNEL............................................................................................................. SECT.5:2 5.2OPTIMAL ASSEMBLY CONDITIONS ............................................................................................ SECT.5:3 5.2.1 ARRIVAL OF MATERIAL AT WORKSITE .................................................................................. SECT.5:3 5.2.2 WHAT TO PREPARE BEFORE INSTALLATION ....................................................................... SECT.5:3 5.3 LIST OF EQUIPMENT NECESSARY FOR ASSEMBLY ............................................................... SECT.5:4 5.4 BOLT TIGHTENING TABLE .......................................................................................................... SECT.5:6 5.5 LIFTING AND POSITIONING THE CIFAMOOVE 30 .................................................................... SECT.5:7 5.5.1 AGGREGATES UNIT POSITIONING ......................................................................................... SECT.5:7 5.5.2 MIXER UNIT POSITIONING ....................................................................................................... SECT.5:8 5.5.3 SUPPORT BRACKET POSITIONING ........................................................................................ SECT.5:9 5.5.4 FASTENING THE AGGREGATES AND MIXER UNITS ON THE FOUNDATION ..................... SECT.5:10 6 6 User and Maintenance Manual PA CIFAMOOVE 30 7 5.5.5 LANDING ASSEMBLY................................................................................................................ SECT.5:11 5.5.6 MIXER PORTAL POSITIONING ................................................................................................. SECT.5:12 5.5.7 LADDER AND LANDING COMPLETION .................................................................................. SECT.5:13 5.5.8 EXTRACTOR BELT POSITIONING ........................................................................................... SECT.5:14 5.5.9 AGGREGATE GATE POSITIONING .......................................................................................... SECT.5:19 5.5.10 MIXER DEDUSTING FILTER ASSEMBLY ............................................................................... SECT.5:23 5.5.11 DIRT RECOVERY CHUTE ASSEMBLY ................................................................................... SECT.5:24 5.6 ELECTRICAL CONNECTIONS ..................................................................................................... SECT.5:25 5.7 RAMP CONTAINMENT BULKHEAD ASSEMBLY (OPTIONAL) .................................................. SECT.5:26 6 START-UP........................................................................................................................................ SECT.6:2 6.1 START-UP .................................................................................................................................... SECT.6:2 6.2 CALIBRATIONS AND CONTROLS............................................................................................... SECT.6:3 6.3 CALIBRATING SCALES ............................................................................................................... SECT.6:4 6.4 START-UP...................................................................................................................................... SECT.6:4 7 USE OF THE PLANT ....................................................................................................................... SECT.7:2 7.1 LOADING MATERIALS IN THE PLANT ...................................................................................... SECT.7:2 7.2 AUTOMATIC CYCLE START-UP................................................................................................... SECT.7:3 7.2.1 FLOW CHART SEQUENCE ....................................................................................................... SECT.7:3 8 MAINTENANCE ............................................................................................................................... SECT.8:2 8.1 INTRODUCTION ........................................................................................................................... SECT.8:2 8.2 ORDINARY PLANT MAINTENANCE ............................................................................................ SECT.8:3 8.2.1 MAINTENANCE ON ELECTRIC PLANTS ................................................................................ SECT.8:3 8.2.2 EXTRAORDINARY PLANT MAINTENANCE ........................................................................... SECT.8:3 8.3 MAINTENANCE OF MAIN UNITS ................................................................................................. SECT.8:4 8.4 INSTRUCTIONS FOR ORDINARY AND EXTRAORDINARY MAINTENANCE ........................... SECT.8:8 8.4.1 SAFETY DEVICES...................................................................................................................... SECT.8:8 8.4.2 MIXER ......................................................................................................................................... SECT.8:8 8.4.3 CONCRETE DISCHARGING HOPPER...................................................................................... SECT.8:11 8.4.4BUTTERFLY VALVES VFS - CEMENT BATCH FEEDER AND VFF - CEMENT SILOS............ SECT.8:11 8.4.5 PNEUMATIC PLANT .................................................................................................................. SECT.8:12 8.4.6ELECTRICAL SYSTEM ............................................................................................................... SECT.8:13 8.5 LUBRICATION ............................................................................................................................... SECT.8:14 8.6 TROUBLESHOOTING .................................................................................................................. SECT.8:14 8.6.1 BELT ........................................................................................................................................... SECT.8:15 8.6.2 OLEODINAMIC PLANT .............................................................................................................. SECT.8:15 8.6.3 CEMENT BUTTERFLY VALVES ................................................................................................ SECT.8:16 7 User and Maintenance Manual PA CIFAMOOVE 30 9 DISASSEMBLING THE PLANT ..................................................................................................... SECT.9:2 9.1 GENERAL INSTRUCTIONS .......................................................................................................... SECT.9:2 9.2 OPERATIONS PRIOR TO DISASSEMBLY ................................................................................... SECT.9:2 9.3 DISASSEMBLY SEQUENCE......................................................................................................... SECT.9:2 9.4 TRASPORT.................................................................................................................................... SECT.9:3 9.5 DISPOSAL ..................................................................................................................................... SECT.9:3 10 SPARE PARTS AND AFTER SALES ............................................................................................ SECT.10:2 10.1 PROCEDURES FOR MAKING REQUESTS .............................................................................. SECT.10:2 8 8 User and Maintenance Manual CIFAMOOVE 30 PA Sect.1:1 Use and Maintenance Manual CIFAMOOVE 30 Chapter 1 INTRODUCTION Sect.1:1 User and Maintenance Manual CIFAMOOVE 30 PA Sect.1:2 1 INTRODUCTION 1.1 GENERAL LETTER AT DELIVERY This Use and Maintenance Manual, drafted in accordance with the Machines Directive 89/392 EEC, aims at collating the instructions for staff operating site machinery for transporting and distributing concrete. Given that these instructions apply to various types and models of machines, there may be slight differences in the technical descriptions of the various parts compared to the type of machine you own. This manual is intended to assist users of site machines so that they are used correctly to avoid personal injury and damage to property. Observance of the rules contained here is essential for operating responsibly and safely. In all cases, the Italian version of the manual is to be regarded as the reference version. For all the components of the machine system, consult the specific manuals. Since it is humanly impossible to foresee all the situations which may arise when working on site, the user retains full responsibility, essential for observing the aim of “Safety and Health” according to the criteria of the EEC directive and all current laws. This page is for certifying that on receiving the machine the Use Manual has been delivered by the manufacturer and that the operator assumes the responsibility of studying it and applying it step by step. For constant enhancements this manual is updated periodically. This document contains proprietary information. All rights reserved. No part of this document may be photocopied, reproduced or translated into another language without prior written consent from CIFA S.p.A. Sect.1:2 Introduction PA User and Maintenance Manual CIFAMOOVE 30 Sect.1:3 1.2 USE OF THIS MANUAL 1.2.1 GENERAL INFORMATION This user and maintenance manual must be read carefully and stored in a safe location as it contains essential information for the machine’s proper use. The machine has been built in compliance with the EU directives regarding the free circulation of industrial products throughout the European Community. It therefore comes complete with all the documentation required by these directives. ATTENTION This manual is to be considered an integral part of the machine and must be treated like any other component of the machine itself. This instruction manual is intended to be used by the following figures: - The personnel involved in the transportation, loading and unloading operations - The machine’s operators and installers - The personnel responsible for the machine’s maintenance The illustrations shown in this manual are not binding. All the technical information contained herein is the exclusive property of CIFA Spa and is to be considered confidential. It is therefore forbidden to reproduce and/or distribute this manual, whether in whole or in part, without the manufacturer’s written authorization. 1.2.2 PURPOSE OF THIS MANUAL The purpose of this manual is to provide the user with a general knowledge of the machine and the maintenance instructions deemed necessary for its proper functionality. This manual must be considered an integral part of the machine and must be preserved for the entire duration of the machine’s service life. The manual must even accompany the machine in the event that it is to be sold to a third party. ATTENTION THE INSTRUCTIONS CONTAINED IN THIS MANUAL MUST ALWAYS BE SCRUPULOUSLY RESPECTED! THIS MANUAL MUST BE READ AND FULLY UNDERSTOOD BEFORE ATTEMPTING TO USE THE MACHINE AND/OR PERFORM ANY OPERATIONS UPON IT. Chapter 2, entitled “SAFETY”, contains important and detailed information and warnings regarding safety issues, and must therefore be read with particular care. The same information will be referenced, in concise form, for the operational situations in which the described risks are present. Introduction Sect.1:3 PA User and Maintenance Manual CIFAMOOVE 30 Sect.1:4 1.2.3 PRESERVATION OF THE MANUAL This manual is to be considered an integral part of the machine and must always accompany the machine in the event that it is to be transferred or resold. The manual must be stored in a dry and easily accessible location for quick reference throughout the machine’s service life. If the manual is damaged or lost, immediately request a copy from the manufacturer. 1.2.4 HOW TO UPDATE THE MANUAL It is recommended to keep this manual constantly up to date by integrating it with any eventual amendments, additions or modifications which may be issued by the manufacturer. In the case of minor changes, the new pages will be sent out and the user will be required to integrate them within the manual by replacing the relative pages in the chapters and/or sections concerned. In the case of significant changes to the machine, a new revision of the manual will be sent out to replace the existing version, which in turn must be rendered unusable. 1.2.5 CONSULTING THE MANUAL The manual is divided into consecutively numbered chapters and sections. The fastest way to retrieve the desired information is to consult the table of contents. The required information may also be sought by examining the titles of the individual chapters and sections, as these constitute key references for easy consultation. ATTENTION It is strongly recommended to contact the CIFA S.p.A. Support Service or your local agent/dealer in the event that any problems should arise regarding the comprehension/interpretation of any portion of this manual: the relative addresses, telephone numbers and fax numbers are listed on the cover and title page of this manual. IMPORTANT Be sure to have the machine’s model and serial number on hand when contacting the technical support service. Annexed manuals: In order to integrate and complete this manual, the Machine’s SPARE PARTS manual has been provided as an annex. Sect.1:4 Introduction User and Maintenance Manual CIFAMOOVE 30 PA Sect.1:5 1.3 SYMBOLS Specific instructions are provided whenever the situations described in this manual involve issues regarding personal safety or the machine’s proper functionality and use. These instructions are indicated and highlighted using SPECIAL SYMBOLS. The three special symbols (or safety symbols) used in this manual are always accompanied by keywords, which classify them based on the danger level of the situation in question. The symbols are associated with appropriate messages, which describe the potential risks, as well as the considerations and conduct to be adopted. Wherever appropriate, these messages also highlight any prohibitions to be observed and/or provide appropriate instructions in order to eliminate the risks in question. In certain cases the messages may also be accompanied by illustrations. The special symbols (or safety symbols) are listed below in order of importance: Indicates that it is necessary to consult specific manuals Indicates the instructions to be followed in order to avoid the risk of ATTENTION personal injury; provides information regarding potential hazards and how to avoid them, and suggests proper conduct. Indicates situations that could pose potential risks for the machine WARNING and/or the product being processed and/or the environment. Indicates useful information for consulting the manual and for the IMPORTANT machine’s proper functionality. Pay close attention to the special symbols while reading the manual and take note of the explanations for the situations indicated by the PROHIBITED symbols themselves. Introduction Sect.1:5 User and Maintenance Manual CIFAMOOVE 30 PA Sect.1:6 1.4 WARRANTY Warranty falls if by using the plant the instructions given by this handbook are not properly followed and if original spare parts are not used. (Warranty does not include wear and consumable parts: e.g. Skip lifting cables, wearing plates inside the mixing unit, internal coating of discharging hopper, wheels of loading bucket, etc…) Anyway sales conditions have always main validity. Any claim under guarantee must be sent to Cifa Spa, by writing, immediately after the verification of defect, giving the plant serial number (which is stamped on the CE plate – see § 1.5). Cifa Spa only can decide if a defect should be solved by Cifa Service or by third parties. Sect.1:6 Introduction User and Maintenance Manual CIFAMOOVE 30 PA Sect.1:7 1.5 PLANT IDENTIFICATION Manufacturer: CIFA S.p.A. Address: Via Stati Uniti d’America, 26 - 20030 Senago – MI - Italy For a proper identification of the batching plant, refer to Plant identification CE plate with following data: Type/model of plant Production no. Year of construction Moreover, reference to component (mixing unit, electric engine) plates can be given which indicate serial number of each machine. Introduction Sect.1:7 User and Maintenance Manual CIFAMOOVE 30 Page intentionally left blank Sect.1:8 Introduction PA Sect.1:8 User and Maintenance Manual CIFAMOOVE 30 PA Sect.2:1 Use and Maintenance Manual CIFAMOOVE 30 Chapter 2 DESCRIPTION OF PLANT Sect.2:1 PA User and Maintenance Manual CIFAMOOVE 30 Sect.2:2 2 DESCRIPTION 2.1 DESCRIPTION OF THE CIFAMOOVE 30 PLANT The CIFA CIFAMOOVE plant is a compact, pre-assembled, easily road transported and easy installation, quick activation plant for the production of ready-mix concrete. This plant has been designed for road transport in a single module. Further transport vehicles are required for optional accessories only. CIFAMOOVE is essentially composed of two main units: • Aggregates batching unit which involves the storage dosing and weighing system of batched aggregates and the conveyor belt for transferring aggregates into the mixer. Aggregate storage Conveyor belt Weighint system Sect.2:2 Plant description User and Maintenance Manual CIFAMOOVE 30 • PA Sect.2:3 Mixing unit, composed of a mixer, or concrete, water and additive dispensing components, a filter, a support structure complete with a ladder and working surfaces. The support frame also houses the control cabin. Cement Batcher Mixer dedusting Water batcher Mixer Aggregates Batcher Access ladders Inspection platform Support structure Control cabin 2.1.1 Accessories and completion The CIFAMOOVE plant is integrated with the following units (supplied upon request), which together form a concrete mixing plant: • Storage and concrete batching unit, composed of one or more concrete silos, dosing augers and any necessary extensions. • Accessories: vibrators, filters, butterfly valves, level indicators, probes, etc. Plant description Sect.2:3 PA User and Maintenance Manual CIFAMOOVE 30 • Sect.2:4 Ramp containment bulkheads for creating aggregate unit loading ramps with filler material. containment bulkheads filler material Sect.2:4 Plant description PA User and Maintenance Manual CIFAMOOVE 30 Sect.2:5 2.2 INTENDED USE OF THE MACHINE The plant has been built according to recognized technical safety standards. Despite this, dangers to the physical integrity and life of operators or others, or damage to the machinery/equipment or other assets may occur during its use. Use the machine/plant only in perfect technical conditions, in accordance with the provisions described in the manual, in full awareness of safety and dangers and in compliance with its instructions for use. In particular, be sure to eliminate any malfunctions that may affect safety. This plant has been designed for batching the components necessary for packaging concrete and cannot be used for any other purpose. ATTENTION Any use differing from the one described in this manual is not to be considered up to standard. The manufacturer is therefore not liable for any damage that any misuse may cause. Risk is borne exclusively by the user. For correct use of the plant, in addition to careful reading of this manual, users must have knowledge and experience in the field of concrete production. The plant is intended exclusively for industrial use. The workstation is provided in the cab. Access to other areas is limited to operations involving loading materials, checks and maintenance. The materials that can be added in the plant are: • Aggregates: natural or crushed with a granulometry of no more than 40 mm and a specific weight of no more than 1800kg/m³ • Cement: with specific weight of no more than 1400 kg/m³ • Water • Additives Maximum quantities that can be added for each component: • Aggregates: 1000 kg • Cement: 200 kg • Water: 100 kg The plant is prepared for outdoor installation and needs no special protection Plant description Sect.2:5 User and Maintenance Manual CIFAMOOVE 30 PA Sect.2:6 Maximum climate conditions to which the plant may be subjected are as follows: Earthquake • Wind • Nsnow S=9 ( DM96 ) Zone 4 ( Italian Law 'Testo Unico' / Eurocode 8) Zone 5 cat II (New Italian law ‘Testo Unico’ / Eurocode 1) - Wind speed 29 m/sec Zone 1 and elevation 500 m (Italian law ‘Testo Unico’ / Eurocode 1 ) Snow pressure 204 kg/m² IMPORTANT • The operating ambient temperature must be between +50 and -15. Machine/plant use in environments with temperatures higher or lower than this temperature interval can jeopardise proper operation of the machine/plant and limit performance, and therefore CIFA must be notified in advance of this type of use. • The positioning of the machine/plant should not exceed a height of 700 m above sea level, above 2000 m could compromise correct operation of the machine and most certainly affects performance and therefore CIFA must be notified in advance of this type of use. • In its standard version, the plant is not suitable for use in potentially explosive environments. Precise and accurate communication of the “Serial Number” and “Model” allows our service personnel to reply with fast, accurate answers. All operators must possess the necessary permits for operating the machine and must read and understand all safety instructions in this Manual. The allocation of duties and tasks must be carried out by the site safety manager in compliance with the requirements of European directives on safety in the workplace. Sect.2:6 Plant description User and Maintenance Manual CIFAMOOVE 30 PA Sect.2:7 2.3 REASONABLY FORESEEABLE MISUSES Any use other than the one mentioned in paragraph 2.2 INTENDED USE is to be considered an IMPROPER USE. CIFA spa is not liable for damages to persons and/or property resulting from incorrect, and therefore improper, use of the machine. The relative risks shall be borne entirely by the user. In particular, it is strictly forbidden to use the machine, even partially: • Without its protective guards and/or with its safety devices deactivated, malfunctioning or missing; • If it has not been correctly installed • In explosive atmospheres or in places where fire hazards may be present • For the mixing of aggregates of sizes other than those which have been defined in the technical specifications • Under hazardous conditions or in the case of machine malfunctions • For improper uses or on behalf of untrained personnel • In the case of defects with the machine’s intake plant • In the case of serious lack of maintenance • After any unauthorized modifications or interventions • In the case of partial or total negligence of the instructions Please refer also to all notes, cautions and prohibitions contained in the various chapters of this manual. Plant description Sect.2:7 PA User and Maintenance Manual CIFAMOOVE 30 Sect.2:8 2.4 TECHNICAL DATA Technical data for the plant CIFAMOOVE 30 Total weight 18000 kg Total weight in transport 16000 kg Power voltage 400 V Frequency 50 Hz No. of phases 3 Signals voltage 24 V Commands voltage 24 V Mixing motor power 18,5 kW Power of control unit to open cover 2,2 kW Belt engine power. 18,5 kW Pneumatic compressor motor power 3 kW Deduster Filter motor power 1,1 kW Power capacity 78 kW Power consumption 45 kW Maximum speed of belt. 1,2 m / min Minimum concrete mixing time 30 secondi Volume of concrete yield from mixer 0,5 m³ Theoretical production of vibrated concrete yield 30 m³ / h Height of aggregate feed ramp on 2 sides 3,6 m Quantity of aggregate compartments 4 Total capacity of aggregates hopper 32 m³ Maximum particle size of aggregates 40 mm Aggregates capacity 4000 kg Cement capacity 1000 kg Water capacity 500 kg Water hookup (customer’s responsibility) 2” male attachment with free discharge with Slump S3 - S4 - S5 (see flow diagram) (cap. 2.5) Capacity 300 l/minute Pressure 0.3 MPa Sect.2:8 Plant description User and Maintenance Manual CIFAMOOVE 30 PA Sect.2:9 2.5 OVERALL DIMENSIONS Plant description Sect.2:9 User and Maintenance Manual CIFAMOOVE 30 PA Sect.2:10 2.6 FLOW DIAGRAM Following is the theoretical production cycle of 50 m3/h, with batching and discharge times (indicated in seconds) for the various components provided by concrete with the following formula: AGGREGATES = 1000 kg/m3 CEMENT = 200 kg/m3 WATER = 100 l/m3 3600: 60=60 cycles/h Mixer = 0.5 m3 60 * 1.5 = 30 m3/h Production is considered in free discharge, considered in continuous cycles (except the start-up cycle) and does not include truck mixer handling times. Sect.2:10 Plant description User and Maintenance Manual CIFAMOOVE 30 PA Sect.2:11 2.7 DESCRIPTION OF MAIN UNITS 2.7.1 DESCRIPTION OF AGGREGATES BATCHING UNIT The aggregates batching unit is composed of the following: 1) Storage hopper for aggregates to be batched, divided into 4 compartments through internal bulkheads, for total storage capacity of approx. 32 m . 3 The aggregates unit can be equipped with an optional heating system. The loading outlet for each compartment is 3,1 meters. The hopper is loaded with a wheel loader from two access ramps, which can be made on concrete or on the ground. For the latter, containment bulkheads can be provided upon request in order to secure the support frame (refer to foundation drawings). 2) Aggregates batching system An aggregates batching system is located under the hopper for weighing different aggregates depending on the desired formula. It is composed of batching vents and a weighing system. The vents are activated by pneumatic cylinders. Vibrators and moisture probes can be applied on the rear vents (sand batching). The weighing system is composed of 4 load cells which support the mixer feeding conveyor. 3) Mixer feeding conveyor belt The task of the conveyor belt is to transport the correct quantity of aggregates to the mixer. Safety nets are located on the conveyor belt. Maintenance can be carried out without removal of nets. ATTENTION Refer to the manufacturer's manual included in the literature accompanying the product for information regarding proper assembly, use and maintenance. Plant description Sect.2:11 User and Maintenance Manual CIFAMOOVE 30 PA Sect.2:12 rear load cell Loading vents Motovibrator pneumatic cylinder discharge hopper Loading vents conveyor belt front load cell Support structure Sect.2:12 Plant description User and Maintenance Manual CIFAMOOVE 30 2.7.2 PA Sect.2:13 DESCRIPTION OF MIXING UNIT The mixing unit connected to the aggregates batching unit essentially consists of the following parts: • Supporting frame in structural steel, complete with ladders and walkways for access to the batching module and mixer. A cab from where the entire plant is supervised is present in the support structure. • Batching system, where the cement, water and additifs are batched. • Mixer, where the concrete is mixed. • Mixer unloading hopper to permit concrete to be unloaded into the concrete mixer. Batching module Mixer Access ladder discharge hopper Support structure Control cabin Compressor Plant description Sect.2:13 User and Maintenance Manual CIFAMOOVE 30 PA Sect.2:14 2.7.2.2 Batching group The batching group includes: • cement batcher with weighing system by load cells • water batcher with weighing system by load cells • pneumatic and electric service plant • Filter for dedusting the mixer • aggregates batching dedusting filter cement batcher additive batcher water batcher Mixer The position of the batching module is over the mixer and is accessible directly from the mixer level. Concrete is unloaded from the screw conveyors and weighed in the batcher, which is supported on three compression load cells. The batched concrete is unloaded into the mixer by means of two supplied electro-pneumatic Ø200 mm butterfly valves. To facilitate the descent of the material, the concrete batcher is equipped with an electric vibrator. The batcher is connected to the mixer with a small Ø110 mm spiral tube which allows venting during concrete batching. Sect.2:14 PA User and Maintenance Manual CIFAMOOVE 30 Sect.2:15 IMPORTANT In order to avoid distorting weighing, connections between the concrete batcher and the batching screw conveyors and between the batcher and the mixer are carried out with rubber sleeves, fastened with metal collars. The batching and water feeding unit is composed of a tank hanging on a load cell, of a batching valve (1”1/2 ball valve), of an exhaust valve (DN125 butterfly valve) and of a mixing distribution system. A rubber sleeve is set between the butterfly valve and the mixing distribution system. During material unloading (aggregates, concrete and water), air is sucked through the spiral tube in the mixer, connected to the removing air filter. The exhaust air is purified in the filter by the dust parts and with the aid of the fan is blown outward. Refer to the supplier instructions, which are an integral part of the documentation supplied with the machine, for information regarding correct use of the filter. Data and technical specifications are also contained in the relative instructions. The dust collection hopper located under the filter is connected to the mixer with a Ø200 mm spiral tube. Through this tube, during the suction phase, the air rises from the mixer to the filter, and during the sleeve cleaning phase, the dust descends and is recovered in the mixer. An electrical panel for filter, screw conveyor and concrete silo derivation box connection is also set on the batching level (fluidification and filters). 2.7.2.3 Filter for mixing Operation description A 12 m2 dedusting filter can be installed on the mixer to suction and dedust air loaded with concrete from the mixer and prevent dust emissions into the environment. Only air can pass through the filter pockets to reach the outside, while concrete dust is held back by the pockets and left to fall inside the mixer itself. Refer to the supplier instructions, which are an integral part of the documentation supplied with the machine, for information regarding correct use of the filter. Data and technical specifications are also contained in the relative instructions. 2.7.2.4 Fume exhaust tube Dedusted air comes out from the filter through the fan output, to which a chimney with a mouth for fume exhaust can be applied by the competent authorities. Plant description Sect.2:15 PA User and Maintenance Manual CIFAMOOVE 30 Sect.2:16 2.7.2.5 Filter for concrete silos – Silotop type Operation description One or more 25m3 dedusting filters can be installed on the silos to suction and dedust air loaded with concrete during silo loading and prevent dust emissions into the environment. Only air can pass through the filter pockets to reach the outside, while concrete dust is held back by the pockets and left to fall inside the silo itself.. Refer to the supplier instructions, which are an integral part of the documentation supplied with the machine, for information regarding correct use of the filter. Data and technical specifications are also contained in the relative instructions. 2.7.2.6 Dual shaft mixer This is a planetary type mixer, in which mixing is carried out by rotation around the central vertical axis of the mixer, distributing the intense action of mixing and transferring all mixing energy directly into the concrete. This mixing technology ensures complete and even mixing in the shortest time possible. A power motor with a robust gearbox is assembled over the mixing tank and moves the rotor with the side scraper blades. The mixing stars are assembled off-centre with respect to the rotor. The star axis rotates and turns around the planetary gearbox. 1, 2 or 3 mixing stars are provided depending on the size of the mix. The planetary transmission is fully sealed against dust contamination. It is easily accessed and is also continuously self-lubricated. The motor assembled at the top and the transmission technology do not limit the mixing tank, allowing fast mixing and easy cleaning. Refer to the supplier instructions, which are an integral part of the documentation supplied with the machine, for information regarding correct use of the mixer. 2.7.3 Discharge hopper The mixer discharge hopper is generally covered in rubber or other material to ensure that the concrete slides easily and to protect the hopper walls. The rubber stocking is located in the lower part of the hopper, fastened by a collar. Sect.2:16 Plant description PA User and Maintenance Manual Sect.2:17 CIFAMOOVE 30 2.7.4 Pneumatic system The pneumatic system is composed of: compressor solenoid valves pneumatic panel with filter, pressure reducer, lubricator and pressure switch piping and fittings for sending compressed air to the various components The various devices connected to the compressor include: • solenoid valves for activating aggregate vent cylinders • cement silo fluidification and filters (1 filter at a time) • pneumatic panel on the mixing unit (see §2.7) Note: The compressor assembled on the plant is able to provide cleaning of 1 filter per cement silo. This means that one silo should be loaded at a time, selecting the filter to be cleaned. A second compressor must be installed (optional) in order to load multiple silos at the same time. Plant description Sect.2:17 User and Maintenance Manual CIFAMOOVE 30 2.8 PA Sect.2:18 DESCRIPTION OF CONTROL PANEL Inside the control cabin is the electric control panel, for automatic, or manual operation by computer. 2.8.1 Control panel Electromechanical CONTROL PANEL is able to manage all the loading and discharging operations of the existing scales, with PC and PLC. It is composed of an aggregate, water and additive weighing indicator set inside the panel, of a main switch and of an emergency push button. This panel includes the PLC appropriately connected to the manual system in order that the entire system can also operate in automatic mode. Control panel accessories Programmable Logic Controller (PLC) inside the control panel, with the function of executing commands sent from the PC to activate motors, valves, etc. and to receive system signals from limit switches, sensors, load cells and humidity probes, etc. Personal Computer (PC) : the machine is used only for data management, and it serves as an operating terminal and memory for formulas, customers, delivery notes, etc. It’s equipped with an HD (hard disk) where the control programs and data are stored. By means of the PC it is possible to communicate with other systems such as PLC, HOST COMPUTER, MODEM, etc. Printer for delivery notes (optional) and printer for reports. The power, supplied by the main power source (e. g. diesel generator) goes from the CONTROL PANEL to the Uninterruptible Power Supply unit (UPS) . Inside the UPS the power is converted to achieve the ideal characteristics, appropriate for power supply of CONTROL PANEL components, PLC, PC and PRINTERS (if connected). Refer to the “UPS Connections” page of the electric diagram. Basic system composition n°1 PLC; n°1 Powerware UPS n°1 PC industrial colour monitor; n°1 Printer for notes; (optional) n°1 Printer for various documents; n°1 Hardware key with serial number; n°1 User manual. The hardware key is identified by a serial number that must be identical to the number on the licence form; if the numbers are different please contact the assistance immediately to regularize the supply. Sect.2:18 PA User and Maintenance Manual CIFAMOOVE 30 Sect.2:19 2.8.2 Automatic operation Automation has the following principal functions:: • Intuitive graphic interface for ease of operation • Control of plant in manual with computer or completely automatic operation • Management and control of complete production cycle, with batching of solid and liquid components and set-up of discharge sequences • Storage of concrete recipes based on 1m³ of dry components • Optimizing the m³ for each cycle, based on the quantity required • Wattmeter to indicate absorption of the mixer during the mixing phase • Management of alarms and events, with printing possible, if a printer is installed • Storage of production data, with production print possible, if a printer is installed (only with PC) • Print of production reports for each cement truck load • 2 monitors 19”. Automation is designed to control the following components: • Batching up to 4 aggregates on the cumulative scale through individual nozzles • Set-up of quantity of material “on the way “ for batching precision • Automatic control of vibrators in 2 batching nozzles (sand compartments) • Ability to manually set humidity for all aggregates • Automatic acquisition of humidity value for 2 sands, through capacity sensors • Offset of aggregate and water batching based on humidity detected or set • Batching up to 4 types of cement on a single cumulative scale • Automatic control of 4 systems: fluidification, cement, silos and vibrator, for cement balance • Water batching from network by weight. • Batching up to 2 types of additives with separate scales. For use and maintenance of the control panel, consult the specific manual attached included in the delivery. Plant description Sect.2:19 User and Maintenance Manual CIFAMOOVE 30 2.9 LOCATION OF CONTROL EQUIPMENT (1) Main electrical control panel (inside the control cabin) (2) Electrical panel for remote control of mixer (Manual operation) (3) Lever for manual opening of mixer discharge door (to be used only if there is no electrical power) Sect.2:20 Plant description PA Sect.2:20 PA User and Maintenance Manual Sect.2:21 CIFAMOOVE 30 2.10 LOCATION OF SAFETY EQUIPMENT The plant is equipped with safety equipment, operation and emergency limit switch and protection for moving parts, either fixed or mobile. Fixed guards (nets or casing) have been set to prevent accidental contact with moving parts that do not require frequent maintenance. In the even that periodic access to a hazardous area is necessary, interlocked moveable guards (doors) have been provided. Opening of these doors requires the use of a key that interrupts power. Thus, for plant safety it is indispensable to keep these protections maintained, by remounting the fixed protection after intervention and periodically checking the functioning of the safety limit switches. 2.10.1 SAFETY DEVICES AND LIMIT SWITCH 1 EMERGENCY MUSHROOM push button 1a-on main panel in booth 1b-on remote mixer panel 2 SIREN (warns for about three seconds that the conveyor loading the mixer is about to move) 3 2 CONVEYOR/LOCK DEVICES. (Show where limit switches are) 2.10.2 Fixed and moveable guards. 4 Belt transmission COVER, front conveyor part. 5 SAFETY NETS ON CONVEYOR BELT 6 SAFETY SYSTEM on Mixer DOOR composed of lock. Plant description Sect.2:21 User and Maintenance Manual CIFAMOOVE 30 2.11 LOCATION OF SAFETY SIGNS Sect.2:22 Plant description PA Sect.2:22 User and Maintenance Manual CIFAMOOVE 30 Pos. 1 2 3 4 Signal PA Sect.2:23 Description ATTENTION: Cut off electricity before performing any works on machines or electrical parts. CAUTION ELECTRICAL HAZARD: Do not activate the machine if guards are not completely in place. DO NOT APPROACH - Automatic start-up machines PNEUMATIC SYSTEM WARNINGS 5 1) Discharge compressed air before performing maintenance 2) Check pressure daily 3) Check oil weekly 6 Skip ropes must be replaced every 50000 m3 7 ATTENTION: Disconnect power every night before exiting Plant description Sect.2:23 User and Maintenance Manual CIFAMOOVE 30 PA Sect.2:24 2.12 SCHEME FOR NOISE EMISSIONS 2.12.1 Main component noise emissions table The noise produced by each individual component is reported below. Pos. Quantity description theoretical noise level a 1 Electric vibrator on cement batcher = 80 dB (A) b 2 Electric vibrator on aggregates batch feeders = 80 dB (A) c 1 Filter fan 1.1 kW = max 82 dB (A) d 1 Skip belt = <80 dB (A) e 1 Mixer = <80 dB (A) f 1 Truck mixer during loading = <80 dB (A) g 1 Electrocompressor 3 kW = max 85 dB (A) h 1 Mixer cleaning unit (optional) = max 85 dB (A) 2.13 AIR EMISSIONS DIAGRAM DEDUSTED POINTS FILTER CHARACTERISTICS EMISSION CHARACTERISTICS No° filters Filter Filter speed m/min m2 filter Flow rate Mixer 1 DUST211 1,5 12 1200 m3/ h Cement silos 1-4 SILOTOP 1 24.5 1600 m3/ h Pos. Plant component A B Note: filter B have no fan. Sect.2:24 Plant description Theoretical emission <10 mgNm3 <10 mg/ Nm3 Emission height 12 m 16 m User and Maintenance Manual CIFAMOOVE 30 PA Sect.3:1 Use and Maintenance Manual CIFAMOOVE 30 Chapter 3 SAFETY REGULATIONS Sect.3:1 PA User and Maintenance Manual CIFAMOOVE 30 Sect.3:2 3 SAFETY REGULATIONS 3.1 TERMINOLOGY AND DEFINITIONS Apply: WORK AREA: means those areas of the machine where the operator runs the commands required to operate in accordance with the machine intended use the same as described in this manual. INTENDED USE: Use of the machine according to the information provided in the instructions for use. Reasonably foreseeable misuse: Use of the machine in a manner not foreseen at design and different from the one indicated in the user’s manual, but that may result from readily predictable human behaviour. DANGER: a potential source of injury or damage to health DANGEROUS ZONE: any zone within and / or around machinery in which the presence of a person constitutes a risk to the safety and health of such person RISK: A combination of the likelihood and severity of an injury or harm to health that can arise in a dangerous situation EXPOSED PERSON: any person wholly or partially in a danger zone OPERATOR: The person or persons installing, operating, adjusting, cleaning, repairing and moving machinery, or performing routine maintenance. Before using the machine the operator must have read and understood the instruction manual and learn about all operations for the first start. If it was appropriate to CIFA engineers are available to provide all information necessary for the proper use of the machine. SHELTER, HOUSING: part of a machine used specifically to provide protection by means of a physical barrier PROTECTION DEVICE: Device, other than a guard, which reduces the risk, either alone or in conjunction with a guard PERSONAL PROTECTIVE EQUIPMENT : It is intended for personal protective equipment all equipment designed to be worn and held by the worker to protect him against one or more sources of risk to health or safety at work, and any addition or accessory designed for this purpose. PERSONAL PROTECTIVE EQUIPMENT must be used when the risks cannot be avoided or sufficiently reduced by technical measures of prevention, by means of collective protection, measures, methods or procedures for organizing the work. Sect.3:2 Safety requirements User and Maintenance Manual CIFAMOOVE 30 PA Sect.3:3 PERSONAL PROTECTIVE EQUIPMENT must: • be appropriate for the risks involved, without itself a major risk; • be adapted to existing conditions at the workplace; • take account of ergonomic requirements or health of the worker; • be adaptable to the user according to his needs. In case of multiple sources of risk, requiring the simultaneous use of multiple PPE, they must be compatible and able to maintain, even when used simultaneously, their effectiveness against the corresponding risks Safety requirements Sect.3:3 User and Maintenance Manual CIFAMOOVE 30 PA Sect.3:4 3.2 DPI - INDIVIDUAL PROTECTIVE DEVICES The DPI are divided according to the parts of the body or the human functions they protect. Therefore there are protective devices: • of the head • of the hearing • of the eyes • of the respiratory tract • of the hands and arms • Of the feet and legs in the particular case of use of truck mixer must be protected: The hearing, during the phases in which the engine of the machine turns at maximum and that is, at the loading moment in the head-firm and at the unloading moment in the building yard. In the building yard the safety device is necessary if there are strong . noises made from other people by operating machines, motocompressors, demolishers and when the concrete is unloaded in the pump. The respiratory tract if the head-firm does not have suitable equipment for the picking up of concrete dusts, in particular way in the dry load of the mix and during the pneumatic unload of the concrete. The head: in the building yard is compulsory the use of the protective helmet. The habit of wearing it always, also during the drive, has often protected and saved from hard injuries. The hands: wearing protective gloves is always good because the mix of concrete that is often touched can irritate and provoke dermatitis. Moreover is better to protect our hands defending them from scratches and small cuts or abrasions because of the contact with metallic parts. The feet: in the building yard maybe there are nails or other material that can perforate the sole. The safety shoes must have a no-slip sole. Eyes: must be protected from dust and above all from squirts of concrete mix during the washings. Sect.3:4 Safety requirements PA User and Maintenance Manual CIFAMOOVE 30 Sect.3:5 3.3 GENERAL WARNINGS • The employer must ensure that employees understand the instruction manual. • Personnel using the machine (authorised operators) must be previously trained and must have read the manual. • Keep a copy of the manual in the control cab of the system. • For proper use, the working environment must comply with the legal provisions in force in the country of use. • In particular, workers must be provided with suitable changing areas and a place of shelter during work breaks within the site area. These premises shall be equipped with artificial lighting, seating, furniture for personal belongings and a first aid cabinet. • A toilet must be set adjacent to the changing room. ATTENTION Compliance with all instructions and precautions below is essential as failure to do so may create problems with serious consequences for persons and property. 3.3.1 PREREQUISITES FOR EMPLOYEES RESPONSIBLE FOR PLANT ASSEMBLY, USE AND MAINTENANCE • Plant employees must meet the psychological and physical requirements set forth by law. • Works on/with the machine/plant can be performed by reliable personnel only. • Comply with the minimum age prescribed by law. • Employ only trained or instructed personnel, clearly define the personnel tasks for control, installation, maintenance and repair. • Make sure that the machine is only operated by duly authorised staff. • Personnel in training, who are in the learning and education phase or are employed as part of general training can operate the machine/plant only under the constant supervision of an experienced person. • Loose clothing is prohibited. • All employees must be provided with individual protection devices with the EC label (protective helmets, accident-prevention footwear, noise reducing earphones, earplugs, gloves, protective goggles, safety harness) and the Worksite Head must instruct them in their proper use. Safety requirements Sect.3:5 User and Maintenance Manual CIFAMOOVE 30 • PA Sect.3:6 The Worksite Head shall require workers to comply with company regulations, rules, and the appropriate use of individual and collective protective devices. 3.3.2 Protection against noise Avoid spending long periods in very noisy areas: if this is not possible, use personal protective devices such as earphones, earplugs, etc. ATTENTION If the operator is exposed to more than 85 dB(A) per day in noise, periodic medical examinations are required. Sect.3:6 Safety requirements PA User and Maintenance Manual CIFAMOOVE 30 Sect.3:7 3.3.3 RULES OF CONDUCT • Concentrate properly and take all precautions before any action. Do not become distracted, but rather act prudently when performing hazardous work. • During work, carefully check equipment movements in order to avoid striking anything or being struck. • Always keep a clear view of the entire work area. Do not work under poor lighting conditions: use all lights available and ensure that they are efficient. • Fully comply with all warnings to be attentive, watch for hazards and take precautions as indicated in the manual, and obey the safety lights on the plant. • Immediately disinfect all wounds, cuts or abrasions, even minor ones: often small scratches cause local infections that could be serious, as well as tetanus infections that may be deadly. • When perspiring, avoid sudden shifts in temperature. • Do not leave the plant unattended when it is in operation. • Keep the control station orderly and clean, avoiding any dust collection on control devices. • Always keep steps, walkways, the booth and shoes free of oil and grease, to avoid slipping. • Before the start of the work shift, check all safety devices, and note any deficiencies found. • Immediately advise the employer, manager or person in charge of any deficiencies in equipment and safety and protection equipment, as well as any hazardous conditions of which you become aware. • In case of emergency, insofar as you are competent and capable of such, eliminate or reduce said • deficiencies or risks. • Advise your service head and the co-worker who will take over the shift of the status of work and measures to be taken to safely continue it. • Do not touch any moving parts or live parts of the plant (or the electrical cabinet), sources of heat, pressurized pipes, areas where you may be cut (for example, sharp edges), and do not lean or sit on any part of the plant when it is in operation. • Do not walk on any uncovered pipes or cables, and do not walk on weak edges, pipes or surfaces. • Do not leave tools, nuts or bolts on conveyor belts or walkways, as they could be hazardous if they fall off. Do not abandon waste materials, especially if they have sharp edges or protrusions. • Do not use cracked wrenches or other equipment, because if subjected to force they may break. • Do not jump from the plant, but instead use the ladders to climb up or down, and hold on to the handrail. • Do not remove the labels or signs on the machine. • If they are damaged, immediately replace them with new signs. Safety requirements Sect.3:7 User and Maintenance Manual CIFAMOOVE 30 PA Sect.3:8 PROHIBITIONS • It is prohibited to come near the aggregate feed openings and the skip for cleaning or maintenance, while they are in motion. • It is prohibited to enter in the aggregate group during plant operation. • It is absolutely prohibited to enter in the mixer for cleaning or maintenance during plant operation. • Do not remove or modify the mesh or safety and protection devices unless you are authorized to do so. • Do not remove barriers that prevent people from entering dangerous areas. • Do not change the program settings to obtain higher performance than what was anticipated during planning and inspection. • All operations that may alter the stability of the structure are prohibited. In particular: • It is prohibited to construct containment sides that increase the capacity of the store of aggregates . • It is also prohibited to place any structure supporting the cover of the aggregates storage unit on top of the sides if this has not been supplied by CIFA. 3.3.4 WARNING - EXTINGUISHER • We recommend installing a carbon dioxide or dry chemical product fire extinguisher (not included in CIFA supply) in the control booth or its immediate vicinity. • All personnel responsible for maintenance and operation must be instructed in the use of the fire extinguisher. • The fire extinguisher must be inspected regularly to ensure that it is completely functional at all times. 3.3.5 LIGHTING - RECOMMENDATIONS • The plant is located outdoors, and thus it is subject to environmental conditions. • The covered portions (booth, aggregates batching unit, etc.), must have lighting equivalent to 300 lux (normal environmental conditions). • The control booth is equipped with a lighting system. • Installation of a lighting system in the other areas (which CIFA usually does not provide) must be done using an appropriate electrical circuit dedicated to it, by a specialized electrician who issues the legal documents required (declaration of the system’s conformity). • To perform maintenance operations, a mobile source of light may be useful. Sect.3:8 Safety requirements PA User and Maintenance Manual CIFAMOOVE 30 Sect.3:9 3.4 INFORMATION FOR GENERAL USE In the event of an anomaly or emergency, press the mushroom “STOP” button located on the machine. (For location, see paragraph 2.10) During plant operation, no other person except the operator should be anywhere on the worksite or at the control station. Danger: aggregate falling from side walls - Safety helmet compulsory near cabin and aggregate group. Before positioning the truck mixer, the driver should ensure that there is no one near the loading point. The truck mixer can be loaded only if the vehicle is positioned correctly below the hopper, and after the operator has ensured that no other persons are near the loading point. Always operate under good lighting conditions. During use of the plant, the operator is responsible for the entire area that constitutes the work environment, and this must be delimited in a very visible way. ATTENTION: before leaving your control station, lock the stopping device in the off position and remove the key. Safety requirements Sect.3:9 User and Maintenance Manual CIFAMOOVE 30 PA Sect.3:10 3.5 MAINTENANCE INFORMATION • Before performing any maintenance or leaving the machine unguarded, lock the stopping device in the off position. STOPPING DEVICE on control panel ON Lock the stopping device with a padlock. OFF Position of switched on tension Plant ON Position of switched off tension Plant OFF • In addition, you must have the key needed to access the appointed place. • The keys for reactivating the energy source and the control panel must be kept by the operations • • head. • When the machine is out of service for repair or maintenance, no one but the person responsible for operations underway should be able to put it into motion. • Place a “MAINTENANCE UNDERWAY” sign on the control panel. • Before starting up the system, ensure that no one is performing maintenance operations. Off position OFF Lock the stopping device with a padlock Sect.3:10 Safety requirements PA User and Maintenance Manual Sect.3:11 CIFAMOOVE 30 • The aggregates batching unit is comprised of moving parts, such as nozzles, cylinders and especially the bucket. For any cleaning or maintenance work to the aggregates unit, the electric power must be shut off. ATTENTION Inside aggregate group batching openings are low: knock danger – Safety helmet compulsory • The plant, in standard supply, is without winter cover. • In case of bad weather conditions, don’t go on cement and water batching group: sliding danger. • The screw conveyors should also comply with safety regulations; maintenance should be performed when the motor is off; the inspection doors cannot be opened and for no reason may the feed socks connecting to the batch feeder be removed if the screw feeder is in movement. • Cleaning and maintenance of the mixer are potentially very dangerous operations and must be performed only after the power is shut off. Follow the procedure described in §8.3. • Danger of sliding if the mixer is wet: wait until mixer is dry before enter for sheet or blades adjustment or replacement. • Any work on pneumatic or oil pressure plants should be done only after discharging the pressure within said plants. • Do not work below or near a linkage (for example, tipping hoppers or tilting channels) unless adequately supported and locked. • Repairs of electrical systems should be made with the power shut off and the emergency button inserted. Wait for at least 5/6 minutes before approaching the electronic equipment, to allow the condensers to discharge any remaining energy. • Before doing any work on electric motors, wait for them to cool: danger of burns! • Whenever units must be disassembled or installed, be certain that they are supported by a lifting device that is appropriate for the load to be sustained. Immediately transfer the load to adequate means of support or trusses. • Never use gasoline, solvents or flammable fluids to clean parts, instead use approved commercial detergents that are non-toxic and non-flammable. • Use tools (mechanical and electric) that comply with current safety regulations. Safety requirements Sect.3:11 User and Maintenance Manual CIFAMOOVE 30 PA Sect.3:12 3.6 INFORMATIONS FOR WELDING OPERATIONS (extraordinary maintenance) Before welding, physically DISCONNECT the LOAD CELLS. Danger of cells damaging. ATTENTION Do not weld pipes or parts containing hydraulic oil or flammable substances: “DANGER OF EXPLOSION.” ATTENTION In case of welding on zinc plated parts, toxic smoke could be emitted. If possible, remove zinc from the part to be welded. Use proper smell preventing masks. 3.7 INFORMATION ON USE OF LUBRICANTS ATTENTION 3.7.1 WARNING: Risks related to use of lubricant, toxic or irritant effects, slipping, fire. • When handling lubricants, do not smoke, eat or drink. Follow the instructions on handling mineral oils and greases. • Before handling lubricants, in order to prevent irritation or allergies, always wear goggles or an antispray mask, oil-proof gloves and an oil-proof suit. • Keep the lubricants in a place with natural ventilation, far from sources of heat (electrical panels, open flame, etc.). • We advise avoiding direct contact of lubricants with pure oxygen and acids. • All lubricants may be disposed of by turning them over to bodies which are authorized to collect used oils. • If there is a lubricant spill, to clean it up, scatter sawdust on the surfaces to absorb the product, then collect it with a spatula and send it to the incinerator at bodies authorized to collect special wastes. To wash surfaces, use solvents (chlorinated and aliphatic compounds) and be sure that their vapours do not remain in the work area. • For persons who are especially sensitive to lubricants, there is a possibility that they may have an allergic reaction or acne caused by oil, especially if the skin has been previously injured by a sticky or abrasive substance (pastes for washing hands or wounds) or a chemical substance (solvents, strongly alkaline detergents, etc.). Contact with the eyes may cause irritation. • If lubricants are improperly handled, effects due to overexposure may occur, such as, for example, a slight irritation of the eyes or skin; if this occurs, avoid further exposure and see a doctor. • If the skin comes in contact with lubricants, wash it with soap and water. • If the eyes come into contact with lubricants, rinse them with pure water. • If a lubricant classified as an “oil” is swallowed, do not cause vomiting and immediately see a doctor. Sect.3:12 Safety requirements PA User and Maintenance Manual CIFAMOOVE 30 • Sect.3:13 If a lubricant classified as a “grease” is swallowed, call a doctor if the quantity is small. If more than a half litre is ingested, drink 1 or 2 glasses of water and immediately call a doctor. If the person has lost consciousness, do not induce vomiting or give him anything by mouth. 3.8 INFORMATION OF THE USE OF ADDITIVES ATTENTION Be especially careful when handling additives used for concrete, as they are corrosive and hazardous to the health. Carefully follow the instructions on the additive safety charts provided by the manufacturer. In particular, use appropriate IPD (Individual Protection Devices) and ensure that there is no open flame in the case of flammable products. 3.9 FALL PROTECTION WARNINGS • For ordinary maintenance, use provided gangways with parapets. In case of maintenance on skip motorization group, use safety harness. • For extraordinary or ordinary maintenance in points without gangways, use aerial lift and safety harness. • The operator must always use all INDIVIDUAL PROTECTION DEVICES (such as safety shoes, safety harness, gloves, helmet, etc.). • In any case should be forbidden to climb onto the structures or use inappropriate equipment (for example, ladders simply placed against the structure). Safety requirements Sect.3:13 PA User and Maintenance Manual CIFAMOOVE 30 Sect.3:14 3.10 INFORMATION ON TRANSPORT AND ASSEMBLY 3.10.1 LIFTING EQUIPMENT Lifting equipment must be appropriate for the nature, form and volume of the loads for which it is to be used. The maximum load capacity must be indicated on the lifting equipment. Hooks must be equipped with locking devices at the entrance, to prevent the load from becoming unhooked. The maximum load capacity must be indicated on the hooks, and this must always be observed. Before lifting the load, be sure that the hook locking device is locked. Three U-bolt clamps must be mounted for a good connection of the metal cable: the first as close as possible to the thimble, and the others at a distance of six times the diameter of the cable. All accessories (chains, cables, hooks, rings, clamps, wire terminals, etc.) must be controlled before use. Be on the lookout for any cuts, elongation, crushing, deformation or loose pins. Replace any equipment that appears damaged. 3.10.2 DISTRIBUTION OF LOADS Uniformly distribute loads to avoid imbalance. Basket slings are preferable, with cables passing below the load. In case of especially long loads, a balancer should be used, especially if the centre of gravity is not immediately identifiable. Use corner protections for lifting cables. Also ensure that the load is fully balanced, by lifting it just a few centimetres. During transfer, it is important to avoid dangerous fluctuations in the load. EDGE PROTECTOR Sect.3:14 Safety requirements User and Maintenance Manual CIFAMOOVE 30 PA Sect.3:15 3.10.3 MANUAL MOVEMENT OF LOADS Loads must have a maximum weight of 30 kg. The lifting and depositing of loads should be carried out with your back straight, in a squatting position. Safety requirements Sect.3:15 User and Maintenance Manual CIFAMOOVE 30 Page intentionally left blank Sect.3:16 Safety requirements PA Sect.3:16 User and Maintenance Manual CIFAMOOVE 30 PA Sect.4:1 Use and Maintenance Manual CIFAMOOVE 30 Chapter 4 TRANSPORT Sect.4:1 User and Maintenance Manual CIFAMOOVE 30 PA Sect.4:2 4 TRANSPORT 4.1 INFORMATION The CIFAMOOVE plant is designed to be transported by road in a single module, with parts that can easily be lifted for operation. Additional accessories will, of course, require additional means of transport. Before moving the plant, the worker should check the weight and dimensions of the individual parts and verify the availability of the following: LIFTING MACHINERY (crane, overhead travelling crane, etc.) WITH AN ADEQUATE CAPACITY (50 -60 t) CHAINS, CABLES AND HOOKS in sizes based on the weight of the equipment ONE OR MORE MEANS OF TRANSPORT WITH ADEQUATE CAPACITY AND DIMENSIONS ATTENTION Important: before lifting, read the information in chapter 3, in particular § 3.4. Sect.4:2 Transport User and Maintenance Manual CIFAMOOVE 30 PA Sect.4:3 4.2 OVERALL DIMENSIONS DURING TRANSPORT N°2 Container High cube 40” Weight MEASUREMENTS Calibration 3800-4150 Kg Maximum load weight 26580-26600 Kg External Internal Door Opening Length 12192 mm 12020 mm - Width 2438 mm 2340 mm 2290 mm Height 2896 mm 2680 mm 2570 mm Volume 75.70 / 76.00 m3 Transport Sect.4:3 User and Maintenance Manual CIFAMOOVE 30 PA Sect.4:4 4.3 LIFTING To lift the equipment, use the hook-up points provided on the equipment, indicated in red or by indicator signals. The unit must be moved in a horizontal position: establish the exact length of the chains based on balancing the unit. Adjust before the four external chains, and then middle chains. If the modules must be lifted separately, carefully sling the individual items as necessary, complying with general safety rules for suspended loads. ATTENTION: no one should be standing within the load range of action. 4.4 TRANSPORT 1) During transport, the plant must be appropriately positioned on the means of transport on wooden blocks of an adequate height, and fastened to the means of transport by appropriate chains (wooden blocks and attachment chains are not included in the CIFA supply) 2) Check to see that loose parts have been solidly positioned and fastened. 3) Ensure that all connecting points and blocks for transport are properly fastened. Sect.4:4 Transport User and Maintenance Manual CIFAMOOVE 30 PA Sect.5:1 Use and Maintenance Manual CIFAMOOVE 30 Chapter 5 ASSEMBLY Sect.5:1 User and Maintenance Manual CIFAMOOVE 30 PA Sect.5:2 5 ASSEMBLY 5.1 ASSEMBLY PERSONNEL Assembly must be performed solely by specialized, adequately trained personnel following the instructions in this manual. • CIFA S.p.A. usually provides the following assembly solutions: • Turnkey assembly: assembly and inspection are performed entirely by CIFA personnel. • Assembly assistance: CIFA provides a specialized technician to coordinate assembly and inspection operations, which are performed by the customer’s personnel. • Customer assembly: assembly is performed entirely by the customer, to whom CIFA provides the necessary designs and instructions. If assembly is performed by the Customer or through assembly assistance, the following must be available at the worksite: • A plant operation and maintenance worker • At least 3 assemblers who can perform assembly and structural work • At least one specialized electrician for assembly and inspection of the electrical system. • At least 1 mobile crane with a 60 t capacity and the relative operator, with features appropriate for lifting and assembly of the various pieces that comprise the plant. The following telephone numbers must be readily available at the worksite: - Work Management Director - Worksite Director - First Aid - Fire Department - Emergency Services Sect.5:2 Assembly PA User and Maintenance Manual CIFAMOOVE 30 5.2 Sect.5:3 OPTIMAL ASSEMBLY CONDITIONS 5.2.1 Arrival of material at worksite Before the materials arrive at the worksite, the customer must have prepared an appropriate area that is not subject to collapse or flooding, where the pre-assembled units, crates and various structural components can be unloaded. This area must be fenced using a special chain and must prohibit access to unauthorized persons. The worksite director must indicate authorized personnel. 5.2.2 What to prepare before installation To assembly the plant properly in compliance with safety norms, the following conditions must be met before work begins: • Set-up of support surface of the CIAFAMOOVE plant before arrival of the assembly manager, depending on the type of anchorage to the ground. (See fixing). • The resting surface must be perfectly flat and level, and strong enough to support the loads indicated in the foundation design. • The ground must be prepared so that elements such as rain, ice etc. do not sink the structure; thus an appropriate sub-base must be laid (not supplied by CIFA ). • Any masonry work must be completed as per the project before the assemblers arrive, and the work area must be free from materials used for masonry work. • The assembly area must be level and delimited, with the necessary visual accident prevention signals. The area must prohibit access to unauthorized personnel. • All plant components must be available within the range of action of the lifting machinery. • There must be a deposit area for the assembly team’s container and its equipment. • The work area must be illuminated adequately to permit equipment assembly without risk to the operators. • The worksite must also provide electrical energy, water and compressed air for the equipment required for assembly (welders, drills, etc.) and to inspect the plant (according to the data listed on the foundation design). Assembly Sect.5:3 User and Maintenance Manual CIFAMOOVE 30 5.3 PA Sect.5:4 LIST OF EQUIPMENT NECESSARY FOR ASSEMBLY n° 1 Safety belt for each operator n° 1 Protective helmet for each operator n° 1 Set of gloves and safety shoes for each operator n° 1 Ladder that can be extended to 8 m n° 1 Level to check surfaces n° 4 Dowel pins with minimum diameter of 5 mm, maximum diameter of 30 mm , and length of 250 mm n° 1 Series of star wrenches (key 7-8-10-13-17-19-24-30) n° 1 Series of box spanners (key 7-8-10-13-17-19-24-30) n° 1 1/2” jack with bushings key 19-24-30 n° 1 3/4” jack with bushings key 19-24-30 n° 1 Electric or pneumatic starter for bolts with 19-24-30 key n° 1 Monkey spanner, maximum aperture 32 mm n° 2 Small Claw hammers n° 1 Chisel n° 1 Hacksaw with 5 blades for steel n° 1 Electric drill with points up to 13 mm n° 1 Complete electrician’s trusse n° 2 1500 kg chain lever hoist with chain width 3 - 4 m n° 1 5 kg sledgehammer n° 2 2 kg hammers n° 2 0.8 kg hammers n° 1 2” pipe wrench n° 1 Hemp cable piece diameter 16 mm length 30 m n° 1 Electric welder complete with accessories (power cable - cable with callipers length 30 mwelding mask - electrodes - etc.) n° 1 Clamp n° 1 Tester n° 1 Complete set of tools for electricians n° 1 Big levers series n° 1 Set of socket wrenches from 8 to 36 n° 1 Spanner to open up to 32 mm n° 1 Air Compressor n° 1 Crane 50 t*. handling and installation inert unit n° 2 Hydraulic jacks, with a capacity greater than 10-15 t Sect.5:4 Assembly User and Maintenance Manual CIFAMOOVE 30 n° 1 PA Sect.5:5 Oxyacetylene device for cutting with accessories (30 m long pipe, cutting torch, glasses, 1 oxygen bomb ,1 acetylene bomb, etc.) n° 1 Big grinder n° 1 Small grinder n° 2 Set of drill bits for concrete n° 2 Set of drill for steel hole n° 1 Series of saws for metal dia.16 up to 60 mm n° 2 Set of screwdrivers n° 2 Crimping Pliers n° 2 Pliers for end sleeves n° 2 Scissors ATTENTION: USE OF A SCREW MACHINE WILL GREATLY DECREASE ASSEMBLY TIME. ATTENTION: This list contains only the main equipment for the assembly it is possible that some equipment may be excluded. Assembly Sect.5:5 User and Maintenance Manual CIFAMOOVE 30 5.4 PA Sect.5:6 BOLT TIGHTENING TABLE During assembly operations, tighten bolts based on the tightening pairs indicated in the following table: Before tightening, ensure that the classes of resistance between screw and nut comply with the Screw and Nut association table Precarichi "P" e momenti di serraggio (coppia) "M" per bulloni con filettatura metrica ISO a profilo triangolare. Pre-loads "P" and driving torque "M" for bolts with metric thread ISO having triangular profile Vorbelastungen "P" und Anzugsmoment "M" für bolzenmit metrischen Gewinde ISO mit dreieckingem Precargas "P" y per de torsiòn "M" para pernos con roscado mètrico ISO con perfil triangular Pre-charges "P" et couple de serrage "M" pour boulons avec filetage métrique ISO avec profile triangulaire. Diametro e passo vite Area resistente Screw diameter and pitch Resisting area Classe vite Screw class Durchmesser und Abstand der Schraube Widerstandsbereich Schraubenklasse Diàmetro y paso del tornillo Diamètre et pas vis Area resistente Zone résistente Clase tornillo Classe vis dxp Sr mm mm2 M12 x 1.75 4.6 6.6 8.8 10.9 P M P M P M P M 84.3 16 39 24 58 38 91 47 113 M16 x 2 156.7 30 96 45 144 70 225 88 281 M20 x 2.5 244.8 47 188 71 282 110 439 137 548 M24 x 3 352.5 68 325 102 487 158 758 197 948 M30 x 3.5 560.6 108 646 M36 x 4 816.7 157 1129 235 1694 366 2634 457 3293 M42 x 4.5 1120.9 215 1808 323 2712 502 4218 628 5273 M52 x 5 1757.8 338 3510 506 5265 788 8190 984 TABELLA ASSOCIATIVA VITE E DADO 161 969 251 1507 314 1884 Normali ALTA RESISTENZA Standard Standard Estàndar Normale High resistance Hochwertige Alta resistencia Haute résistance Associative table of screw and nut Tabla asociativa tornillo y tuerca Tableau associatif vis et ècrou Vite Screw Schraube Tornillo Vis 4.6 6.6 8.8 10.9 4A 5D 6S 8G Dado Nut Tuerca Sect.5:6 Mutter Ecrou User and Maintenance Manual CIFAMOOVE 30 PA Sect.5:7 5.5 LIFTING AND POSITIONING THE CIFAMOOVE 30 5.5.1 Aggregates Unit Positioning 1- Lift the Aggregates Unit and position it on the floor of the foundation. Total Weight 9000 Kg. WARNING: THE AGGREGATES UNIT MUST BE HANDLED HORIZONTALLY: • CHOOSE THE EXACT LENGTH OF THE CHAINS BASED ON UNIT BALANCE. • WITH THE AID OF A LEVEL, CHECK THAT THE FRAME IS COMPLETELY FLAT, INSERTING SHIMS UNDER THE SURFACE IF NECESSARY Assembly Sect.5:7 User and Maintenance Manual CIFAMOOVE 30 PA Sect.5:8 5.5.2 Mixer Unit Positioning 2- Lift the Mixer Unit and position it on the floor of the foundation with the Aggregates Unit WARNING: The Mixer Unit must be handled horizontally. Choose the exact length of the chains based on unit balance. ATTENTION: With the aid of a level, check that the frame is completely flat, inserting shims under the surface if necessary. Total Weight 7000 Kg. Sect.5:8 Assembly User and Maintenance Manual CIFAMOOVE 30 PA Sect.5:9 5.5.3 Support bracket positioning 3 - Join the Aggregates Unit with the Mixer Unit and lock using bolts (See bolt tightening torque table). 4 - Using the lifting means, support the Mixer Unit and dismantle the brackets connecting the base of the control cabin to the mixing portal. Brackets Assembly Sect.5:9 User and Maintenance Manual CIFAMOOVE 30 PA Sect.5:10 5.5.4 Fastening the Aggregates and Mixer Units on the foundation 5 - Re-position the brackets between the Mixer Unit and the Aggregates Unit. Brackets 6 - Before starting start-up operations, make sure to secure the Mixer Units and the Aggregates Units on the foundation using chemical anchors. Sect.5:10 Assembly User and Maintenance Manual CIFAMOOVE 30 PA Sect.5:11 5.5.5 Landing Assembly 7 - With the aid of lifting means, lift the mixer portal to free up the space underneath to be able to overturn the landings. 8 - Overturn the landings on the portal and fasten with bolts. 9 - Overturn the discharge hopper and fasten it to the front landing. Landing Discharge hopper Assembly Sect.5:11 User and Maintenance Manual CIFAMOOVE 30 PA Sect.5:12 10 - Complete assembly with the side landings and safety guard-rails. 5.5.6 Mixer portal positioning 11 – Lift the mixer portal with the aid of lifting means, position the support tie rods to the cabin frame and fasten with relative pins (fig.A). Lock pins with safety pins FIG.A Sect.5:12 Assembly User and Maintenance Manual CIFAMOOVE 30 PA Sect.5:13 5.5.7 Ladder and landing completion 12 – Position the middle landing on the cabin frame (fig.A), assemble the ladder ramps, fastening them with pins at the top (fig.B) and with bolts at the bottom (fig.C). ATTENTION: Assemble using an aerial platform ATTENTION: Before going up to the mixer level, verify correct ladder fastening. Finish the ladder with guard-rails. B C A Assembly Sect.5:13 User and Maintenance Manual CIFAMOOVE 30 5.5.8 Extractor belt positioning 13 – Before lifting the belt, check for the presence of rotation pins at the rear of the belt. (fig.A) 14 – Fasten lifting ropes to corresponding belt connections. (fig.B) 15 – Remove the tie rod pins on the frame (fig.C) A B Sect.5:14 C Assembly PA Sect.5:14 User and Maintenance Manual CIFAMOOVE 30 PA Sect.5:15 16 – Lift the belt until it goes over the holes on the tie rod pins (fig.A). 17 – Re-position tie rod pins (fig.B). 19 – Unhook lifting ropes from belt connections. A B Assembly Sect.5:15 User and Maintenance Manual CIFAMOOVE 30 20 – Hook the belt at the front with ropes (fig. A). A 21 – Rotate the belt until it rests on the connecting flanges and fasten with bolts (fig. B). ATTENTION: See Tightening torque B Sect.5:16 Assembly PA Sect.5:16 User and Maintenance Manual CIFAMOOVE 30 PA Sect.5:17 22 – Position the rear load cells between the batcher belt and the aggregates frame. Assembly Sect.5:17 User and Maintenance Manual CIFAMOOVE 30 PA Sect.5:18 23 – With the aid of a connection means, lift the belt until it is detached 5 mm by the tie rod pin (fig.A), the position the front load cells. (fig. B) ATTENTION: Assembling safety bars on load cells is mandatory. B Safety bar Sect.5:18 Assembly User and Maintenance Manual CIFAMOOVE 30 PA Sect.5:19 5.5.9 Aggregate gate positioning 24 – With the aid of lifting means, lift and position the gates in the sequence indicated (from A to D). Use the type of eyebolts indicated in figure 1 for lifting. Fasten gates with bolts, referring to the tightening torque table. A- Central gate B- Rear central gate C- Front central gate D- Left side gate E- Right side gate F- Front front gate Assembly Sect.5:19 User and Maintenance Manual CIFAMOOVE 30 Figure 1 G- Rear front gate Sect.5:20 Assembly PA Sect.5:20 User and Maintenance Manual CIFAMOOVE 30 PA Sect.5:21 25 – With the aid of lifting means, lift and position the hutch in the sequence indicated. Fasten the hutches with bolts. Use the type of eyebolts indicated in figure 1 for lifting. A- Front side hutch B- Central side hutch C- Rear side hutch D- Front central hutch Figure 1 E- Rear central hutch Sect.5:21 User and Maintenance Manual CIFAMOOVE 30 PA Sect.5:22 26 – Verify correct assembly and fastening of front (Figure A) and rear (figure B) load cells and of tie rods under the belt (Figure C). Once verification has been completed, remove the rotation pins (figure D). B A D ATTENTION: Make sure safety bars are present. Sect.5:22 User and Maintenance Manual CIFAMOOVE 30 PA Sect.5:23 5.5.10 Mixer dedusting filter assembly 27 - Lift and position the dedusting filter over the mixer. Connect the spiral tube and relative electrical connections. Sect.5:23 User and Maintenance Manual CIFAMOOVE 30 5.5.11 Dirt recovery chute assembly 28- With the aid of an aerial platform, position the dirt recovery chute under the extractor belt. Chute 29- Complete electrical, pneumatic and water system connections. Sect.5:24 PA Sect.5:24 User and Maintenance Manual CIFAMOOVE 30 PA Sect.5:25 5.6 ELECTRICAL CONNECTIONS • Connect the electrical system according to the wiring diagram attached to the manual. • The electric lines to be carried out on site and the cable sections must be those permitted by current regulations. • Connect the electric line to the control panel positioned inside the control cab. The local mains voltage and the control panel voltage must coincide. ATTENTION No changes can be made to the panel without prior authorisation from CIFA S.p.A., with the penalty of annulment any liability on the part of the same. • All work on electrical equipment must be carried out by qualified electricians only. • Electrical system protection from weather elements (electric shock, lightning, etc.) is the responsibility of the customer. Plant grounding. ATTENTION PERFORMING OPERATIONS ON THE ELECTRICAL SYSTEM WITHOUT CUTTING OFF POWER IS PROHIBITED. Sect.5:25 User and Maintenance Manual CIFAMOOVE 30 PA Sect.5:26 5.7 RAMP CONTAINMENT BULKHEAD ASSEMBLY (OPTIONAL) 1. Assemble ramp containment bulkheads on the ground, connecting them to one another using bolts (A). 2. Peg bulkheads against the sliding with chemical anchors (not included in CIFA supply) (B). 3. Connect safety ropes to bulkheads (C). A B C 4. Create two ramps with suitably compacted filler material in compliance with permitted loads on the ground of 3.5 Kg/cm2. filler material Sect.5:26 User and Maintenance Manual CIFAMOOVE 30 PA Sect.5:27 Page intentionally left blank Sect.5:27 User and Maintenance Manual CIFAMOOVE 30 PA Sect.6:1 Use and Maintenance Manual CIFAMOOVE 30 Chapter 6 START-UP Sect.6:1 PA User and Maintenance Manual CIFAMOOVE 30 Sect.6:2 6 START--UP For the cement silos and cement screw conveyors, perform the operation start-up indicated in the specific manuals. 6.1 START-UP 1) Aggregates scale • Loosen the locking plates of the aggregates scale and the lateral contrasts. These devices must keep the bucket in position without interfering with weighing. ATTENTION: PLANT SWITCHED OFF 2) Cement batch feeder • Loosen the nuts on the threaded safety rods below the flange of the cement batch feeder to leave a maximum play of 5 mm between the nut and the plate. ATTENTION: PLANT SWITCHED OFF 3) Water batcher feeder • Loosen the lower nuts of the threaded safety rod to leave a maximum play of 5 mm between the nut and the plate of the water batch feeder. ATTENTION: PLANT SWITCHED OFF 4) Connect the hydraulic system on-board the machine with the tubes (responsibility of customer) to the water mains or the water cistern. 5) Connect the additive tanks (responsibility of customer) with the batcher by means of the tubes supplied by CIFA. Provide installation and verification of the following where required: 1) Ice batcher in the appropriate supports, verifying that, after weighing system assembly, they are free from obstructions. batcher feeding systems (such as an screw conveyor or belt) are not included in Cifa supply. 2) Verify connection to the pneumatic system and the opening and closing of the discharge vents. Sect.6:2 Commissioning - Start-up PA User and Maintenance Manual CIFAMOOVE 30 6.2 Sect.6:3 CALIBRATIONS AND CONTROLS 1) Aggregate feed openings. • The aperture of the aggregates feed opening valve may be regulated (based on the type of aggregate) by moving the limit switch located on the pneumatic cylinders along its housing. • Adjust the electric vibrator on the aggregates nozzles to minimum, with the two masses counterpoised(if supplied). • (Consult the specific manual attached). • If vibration is not enough, increase it rotating the masses. • Factory setting • Aggregate batcher 100% 2) Calibrate the pressure reducers on the pneumatic plant of the aggregates unit and on the pneumatic panels: • maximum pressure for movement of cylinders, valves and filters = 5 to 7 bars. • maximum pressure for fluidification of cement silos = 2 bars. 3) Verify the proper functioning of the pneumatic butterfly valvesfor cement batching and water discharge. 4) Verify the proper functioning of the ball valves for water batching. 5) Verify the proper functioning of the fluidification nozzles applied to the cement silos. Verify that non-lubricated air arrives for fluidification. 6) Adjust to minimum the vibrator on the cement batch feeder, with the two masses counterpoised. (Consult the specific manual attached). Factory setting 10% 7) Verify the proper functioning of the manual butterfly valves below the cement silos If foreseen. 8) Start up the mixer and the washing plant, if applicable. Verify wear plates bolts. Verify the distance between blades and mixer. (Consult the specific manual attached). 9) Start up the filter (consult the specific manual attached). 10) Calibrate the magneto-thermal protection devices. (see wiring diagram). Commissioning - Start-up Sect.6:3 PA User and Maintenance Manual CIFAMOOVE 30 Sect.6:4 11) Verify the safety and protection devices (for location see § 2.10): • Verify that all protective casings are mounted and securely attached. • Verify that the mushroom emergency stop button is functioning (figure). • Verify that the acoustic warning (siren) is functioning. 12) Verify the proper functioning of the electrical system. • Before starting the compressor and before switching the plant ON, verify there is nobody inside aggregate group. 6.3 • CALIBRATING SCALES Aggregate weighing system calibration must be carried out by a specialised and certified company who must issue an inspection certificate in accordance with reference norms (where required). • Calibrated weights are supplied by the client. Following are some instructions necessary to avoid damaging the cells. • The cells have a breaking load (static) of no less than 3 times normal capacity. • Each load cell must be insulated by stranded copper applied to the upper and lower supports. Then connect to the grounding network. • Under no circumstances should you remove the safety bars in weighing systems that use cells. If a cell breaks, these bars will prevent the batch feeder and extractor belt from breaking. These bars are also meant to limit side to side wobbling. • Avoid making welds to the structure when the load cells are mounted. • Use sheaths and waterproof fittings to protect cell cables. This protection is already included in the CIFA supply. It is nevertheless a good idea to periodically verify that these protections are intact and properly assembled. • If any condensation occurs within the equipment, the equipment should always be kept powered. • Do not cut the cell cables, even if they are longer than necessary. 6.4 START-UP Plant start-up must be performed following the procedure of “START-UP PROCEDURE - CHECK LIST”, delivered with the plant. Check-list must be filled in by Start-up Tester and sent to CIFA SpA. Sect.6:4 Commissioning - Start-up User and Maintenance Manual CIFAMOOVE 30 PA Sect.6:5 Page intentionally left blank Commissioning - Start-up Sect.6:5 User and Maintenance Manual CIFAMOOVE 30 PA Sect.7:1 Use and Maintenance Manual CIFAMOOVE 30 Chapter 7 USE OF THE PLANT Sect.7:1 User and Maintenance Manual CIFAMOOVE 30 PA Sect.7:2 7 USE OF THE PLANT 7.1 • LOADING MATERIALS IN THE PLANT 1) Fill the aggregates storage hopper with various grades of aggregates (up to 4 different sizes) suitable for the production of concrete. • Load the aggregates with a wheel loader, ascending up along the access ramps. • Load the sands into two compartments equipped with electric vibrator (back compartments), while larger particles (gravel) have to be loaded into the compartments on plant. ATTENTION Do not load aggregate hopper over the capacity indicated at §2.3, in order to avoid material outflow from ramp. ATTENTION During aggregate loading, nobody must stay near the hopper. Danger: falling material 2) Cements are loaded by connecting the conduit exiting from the cement tank truck used for transport to the silo loading pipe. Once the connection is made, begin loading, using the vehicle’s compressor. Sect.7:2 Commissioning - Start-up User and Maintenance Manual CIFAMOOVE 30 PA Sect.7:3 7.2 AUTOMATIC CYCLE START-UP The control panel is installed in the cab with a relative PC. The plant is displayed on the screen, as well as scale displays and a series of buttons and selectors on the panel for emergency unloading of components. IMPORTANT Given the complexity of the cycle, use of the plant in manual is allowed only to individually activate some components for verification or maintenance, always via computer. For the meaning and use of selectors, see the specific panel manual or instructions on corresponding plates. It is possible to run single components via the manual selector. The cycle is carried out automatically by means of the PC installed inside the cab. During automatic operation, the plant is completely managed by the PC and, once the desired program has been set, the operator is only responsible for supervising. An example of a flow diagram (with batches considered to calculate theoretical production) is shown in §2.5. Based on the quantity of concrete desired, the plant software optimizes production, dividing the quantity set into a certain number of cycles (based on the mixer’s capacity). E.g. 10m³ - mixer capacity 1.5m³ - 7 batches, 1.43m³ each ATTENTION Before beginning batching, be sure that there is no one under the aggregates unit 7.2.1 Flow chart sequence 1) Batching and weighing aggregates unloaded into the bucket from the feeding openings, which open in sequence. a) For proper functioning, first the sands are batched, then the gravel. b) The weight detected by the load cells is displayed on the instrument mounted in the installed panel (Or see the weight on the monitor) 2) Batching and weighing water, cement and any additives. 3) Aggregate transport phase via conveyor belt. The operator can follow the lifting of material on the monitor. Note: a limit switch is present and, in the event that the previous cycle has not yet been completed, the belt stops. Commissioning - Start-up Sect.7:3 User and Maintenance Manual CIFAMOOVE 30 PA Sect.7:4 4) Unloading materials into the mixer. While the mixer is running, aggregates are unloaded into the mixer, while concrete, water and additives are unloaded via valve opening (butterfly or ball). Normally, unloading is carried out as follows: aggregates, partial water discharge, concrete. And final water discharge. 5) Mixing phase, at zero on scales, the mixing time starts for about 30 seconds according to standard DIN 1045. Time can vary according to the type of concrete set. 6) Concrete discharge from the mixer. When the mixing phase is complete, the door under the mixer opens and discharges the concrete into the concrete mixer, positioned as shown in the figure. • Following the absorbency value of the mixer, the door opens to full opening. • As the absorption value of the mixer decreases, the door opens totally. ATTENTION Before discharging the concrete, be sure that the truck mixer is in position and that no one is in the loading area. Sect.7:4 Commissioning - Start-up User and Maintenance Manual CIFAMOOVE 30 PA Sect.7:5 Page intentionally left blank Commissioning - Start-up Sect.7:5 User and Maintenance Manual CIFAMOOVE 30 PA Sect.8:1 Use and Maintenance Manual CIFAMOOVE 30 Chapter 8 MAINTENANCE Sect.8:1 PA User and Maintenance Manual CIFAMOOVE 30 Sect.8:2 8 MAINTENANCE 8.1 INTRODUCTION Prompt, careful maintenance is an indispensable prerequisite for ensuring efficiency, reliability and longevity of the machine. Plant maintenance includes just a few operations. Nevertheless, as this is a plant with many moving parts that operate in often unfavourable environmental conditions, it is important to follow maintenance instructions. ATTENTION: Before doing any maintenance work, carefully read the safety instructions in chapter 3, in particular §3.3. The following figure is intended to set out the most important precautions. Electric power disconnected, plant OFF MAINTENANCE UNDERWAY OFF The keys must be kept by the operations head. Lock the stopping device with a padlock. Sect.8:2 Maintenance PA User and Maintenance Manual Sect.8:3 CIFAMOOVE 30 8.2 ORDINARY PLANT MAINTENANCE Keep in mind that over the course of time, the plant will gradually show wear as a result of age, use and the environment. It is thus the user’s task to periodically examine the equipment to decide which parts, either functional or structural, must be repaired or replaced. ATTENTION : Use only original CIFA replacement parts ATTENTION Operations of ordinary maintenance must be performed by trained technicians. 8.2.1 MAINTENANCE ON ELECTRIC PLANTS Technicians assigned to maintenance of electric plants must be professional qualified electricians. 8.2.2 EXTRAORDINARY PLANT MAINTENANCE Extraordinary maintenance must be performed by a specialized technician. Skilled technician is to be considered who has technical knowledge of plants for concrete production acquired through training, attendance to specific professional training courses, or experience. Technicians assigned to intervention to carpentry, electric motor and pneumatic plants must be acquainted with technical regulations, safety rules and regulations, accident prevention regulations and “good technique” rules. Maintenance Sect.8:3 User and Maintenance Manual CIFAMOOVE 30 8.3 PA Sect.8:4 MAINTENANCE OF MAIN UNITS Following is a list of maintenance operations to be performed, with the recommended frequency. For more complex operations, refer to §8.3 or the specific manuals attached. The specific manuals should always be consulted, because they may contain information in addition to what is reported in this list. Verify function of upper limit switches. Aggregate conveyor belt. Verify function of cable pull limit switches on the conveyor belt side. Check the functioning of the electric safety lock for opening and closing the covers. The mixer must be washed during prolonged periods without use (1-2 hours) and at the end of the day. Twin shaft mixer Wash the inside using a high pressure jet washer (excluded to provide cifa) at the end of the day. DAILY Check specific manual requirements. Concrete discharge hopper Wash with high pressure jet washer (excluded to provide cifa) during long pauses (1-2 hours) and at the end of the day. Discharge condensate and impurities from the air filters (near the compressor, on the batch feeder unit and on the silos) through the drain plugs. Pneumatic plant Discharge condensate and impurities from the compressor tank through the relative drain plug. Check to ensure that there is no air loss. Sect.8:4 Filter Check status Belt Check belt tensioning (see daily maintenance manual) Maintenance PA User and Maintenance Manual CIFAMOOVE 30 Sect.8:5 Check the safety equipment: mushroom button, safety limit switch, etc. (see location at §2.10 ) General Control the efficiency of the electrical system components (commands, acoustic signals and lights). Aggregate transport unit Check belt conditions. Control the condition of wear plates inside the mixer and the distance between paddles and plates(see specific manual attached). Mixer Control the functioning and quantity of grease in the automatic greasing device on the mixer (see specific manual attached). Consumption load 1 kg per day for 8 hours of work. WEEKLY Grease the manual greasing points on the mixer. Butterfly valves for cement batch feeder Verify that the area where material passes through is free from residues; if not, clean it carefully to avoid any obstruction of the valve. Control the oil level in the lubricator pan, and if necessary replenish it. If there is excessive oil consumption, regulate it by means of the special batching screws. An oil refill should last from 15 to 20 days, if the plant is operating normally. Pneumatic Plant Control to ensure that the air compressor stops and starts again automatically when it reaches MAX and MIN pressure values. If not, set the calibration values. Control the pressure gauge (5-7 bars for solenoid valves and filters, 2 bars for fluidification), or else adjust the pressure reducers. Clean the spiral pipe of cement filter, to avoid any accumulation of dust. Mixer dedusting filter and cement batcher Clean the spiral venting pipe (connecting cement batcher and venting pipe mixer), to avoid any accumulation of dust. Check fluidification nozzles on the concrete silos Maintenance Sect.8:5 PA User and Maintenance Manual CIFAMOOVE 30 Sect.8:6 Check the efficiency of the bolted joints. Tighten loose bolts and anchorings. Check the stability of the railings. General Verify the integrity of the rubber socks (cement batching and discharge, water discharge) and the hold of the collar bands. Control the integrity of wear cover s(mixer, concrete hopper, bucket, aggregate feed openings) where provided. Aggregate batching group Grease aggregate feed openings (greaser on the pins) Aggregate transport unit Grease bearings mounted on the belt. (see manual) Remove any material deposited on the load cells. Load cells weighing systems Control the efficiency of the insulating copper conductor and the grounding. MONTHLY Control to ensure that the safety bars are in the correct position (they should have a play of 4-5 mm, to limit fluctuations without interfering with weighing). Clean the water filter. Hydraulic plant Verify the integrity of the rubber hoses and the seal of the collar bands. Control the filtering elements. Mixer dedusting filter Verify the functioning of the filter cleaning system. Remove the plexiglas recipients of the air filter and lubricator and wash them with soap and water (washing with fuel oil is never recommended). Pneumatic plant Control the level and quality of the compressor’s lubricating oil. If there are changes in colour (whitish = presence of water dark = overheated) completely replace. In all cases replace the oil after the first 100 hours of work, and thereafter every 300 hours (see the specific manual attached). Clean the compressor suction filter. Control the tension of the compressor transmission belt (see specific manual attached). Verify the integrity of the pipes and the hold of the grips. Clean aggregate inlet zone between mixer cover and skip Mixer raceways. Verify any leaks from the door and adjust as necessary. Sect.8:6 Maintenance User and Maintenance Manual CIFAMOOVE 30 PA Sect.8:7 1 YEAR Replace the water filter cartridge. Hydraulic plant Hydraulic oil system. 2 YEARS Verify oil level/purity. Load cells weighing systems Every 2 years, have a weigher check the load cells weighing systems. (in countries where required) Maintenance Sect.8:7 User and Maintenance Manual CIFAMOOVE 30 PA Sect.8:8 8.4 INSTRUCTIONS FOR ORDINARY AND EXTRAORDINARY MAINTENANCE 8.4.1 SAFETY DEVICES • Check the limit switches - daily (recommended immediately, upon first cycle): • To verify the functioning of the lower, middle and upper proximity limit switch: Make a visual check to ensure that the three lights (on mimic panel or screen) are illuminated when the bucket passes. To verify the functioning of the loose cable limit switch: Make a visual check to ensure that, during loading of aggregates, the loose cable light is illuminated, and then turns off when the bucket starts. • Other devices • Checking of safety devices: act the device and check if plant stops. • Functioning of push button: push for starting, turn and pull to have it back in position. • Efficiency checking of sound and light signals: pay attention if, during functioning, lamp on synoptic are lighting and if siren is heard. 8.4.2 MIXER For maintenance of mixer parts, consult the specific use and maintenance manual attached. 8.4.2.1 Daily cleaning of mixer • At the end of working day or before any long stop, load the mixer with aggregate and water and mix for 1 minute. • At the end of the day clean with water under pressure. (hydro-cleaning machine excluded to provide CIFA) • The purchase by the client of a pressure washer is recommended. • Do not go inside in the mixer for washing operations: Danger of slipping, knock or injuries. • To reduce deposit, proper product could be used at work starting (contact your suppliers of specific additives) 8.4.2.2 Mixer washing with washing plant (optional) ATTENTION All washing operations with nozzles on the mixer have to be performed with the windows (on mixer cover) closed. The washing sequence may be set either from the panel in the control cabin. Sect.8:8 Maintenance PA User and Maintenance Manual Sect.8:9 CIFAMOOVE 30 IMPORTANT: See the specific manual attached for the operating sequence. • Discharge the wash water into the concrete mixer (or onto a wheel loader) to transport it and deposit it into a system for the recovery of concrete residues and wash water. 8.4.2.3 Opening of windows on mixer cover: ATTENTION To open doors on the mixer, stop the plant, cut off panel power in the cab, put the lock on the selector and remove the key, cut off power to the main switch and insert the red key in the mixer interlocking system. IMPORTANT: For more safety, each window should be LOCKED WITH AN INTERLOCK. Interlock should be opened with a special key in the control panel. This operation shuts off the power, and also makes it impossible to turn it back on (until the key is returned to the control panel). 8.4.2.4 Washing with a high pressure jet washer (optional) (excluded to provide cifa) • To perform this operation, mixer windows should be opened. IMPORTANT: Perform this operation out from the mixer. • Disconnect spiral pipes (cement batcher venting and filter connection) to avoid to wash them. • Open the window and wash the interior of the mixer, then wash the concrete discharge hopper with slots in the protective grid located on the sides of the mixer • Unload the wash water in the concrete mixer (or onto a wheel loader) to transport it and deposit it to a system that recovers concrete residues and wash water. Maintenance Sect.8:9 User and Maintenance Manual CIFAMOOVE 30 PA Sect.8:10 8.4.2.5 Cleaning the aggregate entrance area between the cover and aggregate belt. IMPORTANT: Switch off the plant before unscrew the nuts and open the window. • Clean the inside of the loading hopper with a lance. 8.4.2.6 Examination - replacement of wear plates and mixing paddles For these operations, it is necessary to enter the mixer. IMPORTANT: Before entering the mixer, wash it thoroughly and wait for it to dry, to avoid slipping! Wear strong clothing, accident prevention shoes, gloves. To check wear (see specific manual). IMPORTANT: When the wash-maintenance operations are completed, CLOSE THE COVERS, remove the keys from the locks and return them to the remote panel to power it up again. 8.4.2.7 Replacement or maintenance of mixer electric motors - extraordinary maintenance Execute with PLANT SWITCHED OFF To replace or repair the electric motors of the mixer, it is necessary to take them off the mixer and place them on the ground, as follows: • Disconnect the electric motors from the electrical part of the mixer (including the transmission) (see specific attached use and maintenance manual). • Bring the lifting equipment near the mixing unit and connect the motor to the lifting eye bolt.. • Using the lifting equipment, lower the electric motor to the ground so that it can be transported to an appropriate workshop for repair or replacement.. Sect.8:10 Maintenance User and Maintenance Manual CIFAMOOVE 30 PA Sect.8:11 8.4.3 CONCRETE DISCHARGING HOPPER • To wash the hopper with jet washer, and to check wearing conditions, use the grids at mixer sides. • For extra hopper cleaning, use a special vehicle for working at heights. • To change hopper wearing, hook the hopper with a crane and put it on the ground. 8.4.4 BUTTERFLY VALVES VFS - cement batch feeder and VFF - cement silos IMPORTANT: Before performing any operation, SHUT OFF THE ELECTRICAL AND PNEUMATIC POWER. ATTENTION: The cement batcher valve will last significantly longer if it is cleaned regularly, in particular if the material tends to harden or compact if it is not used for prolonged periods. IMPORTANT: • No lubrication is necessary for moving parts. • No replacement of worn parts is anticipated EXTRAORDINARY MAINTENANCE (cement silo valve VFF) • Before removing the baffle, ASCERTAIN THAT THE BATCH FEEDER BELOW IT IS COMPLETELY EMPTY. • To replace the manual or pneumatic activator, see the specific use and maintenance manual attached. Maintenance Sect.8:11 User and Maintenance Manual CIFAMOOVE 30 8.4.5 PNEUMATIC PLANT The air used to command the pneumatic cylinders goes through a filter, which eliminates any impurities (complete with pressure reducer) and then through Adjustment screw a lubricator, whose function is to vaporize the oil inside it and inject it into the air plant. Adjustment of lubricator: a batcher screw makes LUBRICATOR it possible to regulate the quantity of drops of oil to be vaporized. A full supply of oil should last from 15 to 20 days, if the plant is operating correctly. Recommended type of oil: mineral oil or SAE 10. Adjustment knob Calibrating the pressure reducer: using a handle that must be either turned one way or the other as needed, checking the pressure on the pressure gauge. Pressure gauge The air utilized for fluidification (which does not run through the lubricator) runs through an additional pressure reducer (calibrated at 2 bars for 0.5 bars on the plates). FILTER PRESSURE REDUCER Batcher unit pressure gauge 7 5 bar 6 MAX bar bar Pressure gauge gauge Sect.8:12 2 Maintenance Silo gauge PA Sect.8:12 PA User and Maintenance Manual CIFAMOOVE 30 Sect.8:13 Recommended adjustment: • Main pressure gauge (nozzle cylinders): 7÷7.5 bars. • Pressure gauge of the batching module (batching and water discharge valves and cement discharge valves): 5÷6 bars. • Fluidification pressure gauge (for each silo): 2 bars. 8.4.6 ELECTRICAL SYSTEM • Check the efficiency of all electrical control components. • At least once a month, ensure that the cables are completely insulated, especially where they meet the cable locks and cable glands, in order to avoid short circuits that could damage other components. Screws may loosen due to vibrations or subsequent closing of contactors contained in the cabinet, causing excessive wire heating with resulting burning of the wire insulation itself and, consequently, short-circuiting between the wires and between wires and grounding. • Also check to ensure that the connection points are perfectly locked and have not oxidized. • Always ensure that there is a perfect connection to the electrical plant’s grounding system. • At least once every 6 months, verify the ground wires and relative clamps. Note: to replace any device contained in a control panel, the plant must first be isolated. If maintenance personnel is not qualified to make any replacements or modifications, the equipment manufacturer must perform the work Maintenance Sect.8:13 User and Maintenance Manual CIFAMOOVE 30 PA Sect.8:14 8.5 LUBRICATION ATTENTION: ALL LUBRICATION OPERATIONS SHOULD BE CARRIED OUT WITH THE PLANT STOPPED Give exposed mechanical parts a protective surface lubrication. If equipment is unused for long periods of time, generously lubricate all parts of the machine. If, while lubricating, it becomes necessary to remove a protection: • be especially careful during maintenance operations • reassemble the protection before using the machine 8.6 TROUBLESHOOTING Below is a list of problems (with causes and possible remedies) that can be resolved without consulting a specialist. To troubleshoot any problems regarding components not listed in this manual, refer to the specific manuals. Intervention in case of blocking of a moving element (opening, skip or screw): - Stop the plant. - Remove any foreign element and clean out any loose material and then try to re-start the plant. - In case of damages, call CIFA service. Note: Batching openings have a moving opening system. The falling of material with big dimension during batching operation can block the opening in open position: this could allow the falling of too much material and damaging of cylinder. In case of opening blocking, intervention can be carried out from control panel by trying to open and close the opening. Otherwise stop the plant, exhaust the air from pneumatic plant to avoid sudden closing of the door opening (because the cylinder tries to close the door opening). Remove, if possible, the foreign element and clean off eventual exceeding material. Screws can be blocked if cement has blocks or rags. Sect.8:14 Maintenance PA User and Maintenance Manual CIFAMOOVE 30 Sect.8:15 8.6.1 BELT Malfunction Cause Possible solutions Belt No electrical power. Check the power and electrical connections. Emergency Push button ON Check and possible emergencies reset Upper limit switch blocked Verify and reset limit switch as necessary Selector in manual mode Verify plant operating settings The mixer has not finished Check the operation settings of the plant. its previous cycle Upper limit switch triggered To completely finish the cycle and check if parameters of “delay” are correct for the type of production ( Slump ). The discharge gate was left open Verify that control devices are active for electric lifting hoist on electrical remote control placed on mixer flat. 8.6.2 OLEODINAMIC PLANT Malfunction Cause Possible solutions No electric power or Check the electric power and the electrocompreselecrocompressor switched off. sor. The pneumatic cylinder will not open. Solenoid valves are noisy. The feed openings keep closing Low air pressure Check the pressure reducer. Gaskets are worn Replace the gaskets Solenoid valves are fault. Replace the solenoid valve or only the coil, if burnt. Silencers damaged Replace silencers Gaskets are worn. Replace the gaskets. Pneumatic cylinder scratched Replace the pneumatic cylinder Maintenance Sect.8:15 PA User and Maintenance Manual CIFAMOOVE 30 Sect.8:16 8.6.3 CEMENT BUTTERFLY VALVES Malfunction Cause Possible solution The product inside has caused a The valve does not block. open or remains open all the time. The air pressure is insufficient. The valve always remains partially or The valve opens and completely open. closes with difficulty or leaks cement. The washer is worn. Sect.8:16 Maintenance Disassemble, clean and reassemble Check the pneumatic line and take necessary action. See solution proposed above. Replace the gasket User and Maintenance Manual CIFAMOOVE 30 PA Sect.8:17 Page intentionally left blank Maintenance Sect.8:17 User and Maintenance Manual CIFAMOOVE 30 PA Sect.9:1 Use and Maintenance Manual CIFAMOOVE 30 Chapter 9 DISASSEMBLING THE PLANT Sect.9:1 User and Maintenance Manual CIFAMOOVE 30 PA Sect.9:2 9 DISASSEMBLING THE PLANT 9.1 GENERAL INSTRUCTIONS before disassembling the various components, ensure that you have SHUT OFF THE ELECTRIC POWER. Follow the safety instructions previously indicated for assembly operations and wear personal protection devices. If the plant is sold to another user, advise CIFA of the change in ownership. If the installation location is changed, verify that it is appropriate in terms of the seismic, wind and snow parameters indicated in § 2.2. 9.2 OPERATIONS PRIOR TO DISASSEMBLY Before disassembling the plant, perform the following operations: 1) Empty the cement silos, the water tanks, and the aggregates storage hoppers. 2) Disconnect the hookup to the electrical and water lines at the worksite. 3) Assemble the aggregate batcher stroke locking plates on the aggregate feeding belt. 4) Tighten the lower nuts of the threaded safety rod against the water batch feeder sheet to lock in the load cell and thus avoid damaging the cells. 5) Tighten the lower nuts of the threaded safety rod against the sheet of the cement batch feeder to lock in the load cells. 9.3 DISASSEMBLY SEQUENCE At this point, proceed with disassembling the plant, performing operations in reverse order from what is indicated in chapter 5-assembly (to be consulted for details of the individual operations): 1) Disconnect the electrical system power cables. 2) Dismantle optional accessories (ramp containment bulkheads, mixer cleaning, silos and augers, etc.). 3) Disconnect skip ropes and wind them around the winch, releasing the brake and rotating the fan. 4) Dismantle gates. 5) Disconnect the rubber water hosing, batching and cement discharge sleeves, the water discharge sleeve, and the concrete discharge hopper sleeve. Sect.9:2 Removal and disposal PA User and Maintenance Manual Sect.9:3 CIFAMOOVE 30 6) Dismantle the concrete unloading hopper. 7) Dismantle the mixer dedusting filter. 8) Dismantle walkways, guard-rails and ladders. 9) Hook the crane to the mixing unit, un-bolt it, remove pins and, rotating it on the runway wheels, lower it to the ground. 10) Remove the pins and disconnect the mixing unit support structure. Dismantle any bases. 11) Remove the runway sliding wheel locking wedges. Slide the mixing unit to the transport position. Reassemble the wedges in the rear position to lock the runways. 12) Assemble the transport beams and bolt the mixing unit to the lower frame. 13) Dismantle the skip nets. 9.4 TRASPORT Please see chapter 4 for information on vehicle road transport. 9.5 DISPOSAL The plant can be dismantled and scrapped without any special precautions. • However, be sure to remove the lubricating oil from the reducers, plastic and rubber parts (venting hoses, rubber stockings, gaskets, wearing sheets, etc.), and dispose of everything through authorized companies. • Deliver control panel and electrics cables to specific authorized companies. • Deliver the structural work and metal components to collection centres. The metallic structure must be disposed of as old metal. • In case of maintenance, do not dispose of used oil or rubber parts in the environment, but rather through authorized companies. • Removal and disposal Sect.9:3 User and Maintenance Manual CIFAMOOVE 30 Page intentionally left blank Sect.9:4 Removal and disposal PA Sect.9:4 User and Maintenance Manual CIFAMOOVE 30 PA Sect.10:1 Use and Maintenance Manual CIFAMOOVE 30 Chapter 10 SPARE PARTS AND AFTER SALES Sect.10:1 PA User and Maintenance Manual CIFAMOOVE 30 Sect.10:2 10 SPARE PARTS AND AFTER SALES The supply includes a manual of recommended spare parts; for additional replacement parts, refer to the specific manuals for the various components, as well as overall designs provided, which, along with the use and maintenance instructions, you can use to identify the parts. 10.1 PROCEDURES FOR MAKING REQUESTS Requests for spare parts should be sent to: CIFA SpA. - Spare Parts Service Via Stati Uniti d’America, 26 20030 Senago (MI) Italia Telephone 0039-2-990131 e-mail [email protected] When requesting replacement parts, please include the following information: • Type and model (CIFAMOOVE 30); • Registration number or purchase order and year of manufacture (reported on the EC plate) • Description of replacement part • Replacement part code, if indicated • Number of parts desired • Means of shipment • Company name, address, and tax information of requesting party and shipping address. Requests for after sales Service, should be sent to: CIFA SpA. - After Sales Service Via Stati Uniti d’America, 26 20030 Senago (MI) Italia Telephone 0039-2-990131 Fax 0039-2- 99013335 [email protected] e-mail Sect.10:2 Spare parts and after sales User and Maintenance Manual CIFAMOOVE 30 PA Sect.10:3 Page intentionally left blank Spare parts and after sales Sect.10:3 Via Stati Uniti d'america, 26 - 20030 - SENAGO (MI) Tel.: (+39) 2 99013.1 Fax: (+39) 2 9980786 [email protected] - www.cifa.com