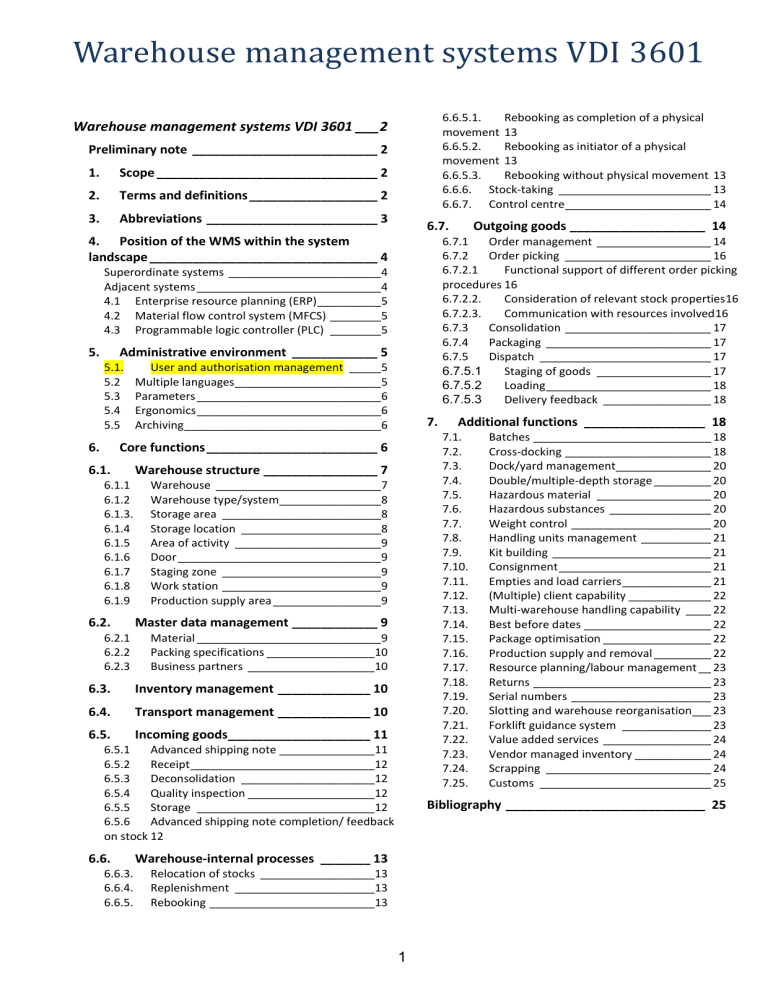

Warehouse management systems VDI 3601 6.6.5.1. Rebooking as completion of a physical movement 13 6.6.5.2. Rebooking as initiator of a physical movement 13 6.6.5.3. Rebooking without physical movement 13 6.6.6. Stock-taking ________________________ 13 6.6.7. Control centre _______________________ 14 Warehouse management systems VDI 3601 ___ 2 Preliminary note __________________________ 2 1. Scope _______________________________ 2 2. Terms and definitions __________________ 2 3. Abbreviations ________________________ 3 6.7. 4. Position of the WMS within the system landscape ________________________________ 4 Superordinate systems ________________________4 Adjacent systems _____________________________4 4.1 Enterprise resource planning (ERP) __________5 4.2 Material flow control system (MFCS) ________5 4.3 Programmable logic controller (PLC) ________5 5. Administrative environment ____________ 5 5.1. 5.2 5.3 5.4 5.5 6. User and authorisation management _____5 Multiple languages _______________________5 Parameters _____________________________6 Ergonomics _____________________________6 Archiving _______________________________6 7. 6.1.1 6.1.2 6.1.3. 6.1.4 6.1.5 6.1.6 6.1.7 6.1.8 6.1.9 6.2. 6.2.1 6.2.2 6.2.3 Warehouse structure ________________ 7 Warehouse __________________________7 Warehouse type/system________________8 Storage area _________________________8 Storage location ______________________8 Area of activity _______________________9 Door ________________________________9 Staging zone _________________________9 Work station _________________________9 Production supply area _________________9 Master data management ____________ 9 Material _____________________________9 Packing specifications _________________10 Business partners ____________________10 6.3. Inventory management _____________ 10 6.4. Transport management _____________ 10 6.5. Incoming goods____________________ 11 6.5.1 Advanced shipping note _______________11 6.5.2 Receipt _____________________________12 6.5.3 Deconsolidation _____________________12 6.5.4 Quality inspection ____________________12 6.5.5 Storage ____________________________12 6.5.6 Advanced shipping note completion/ feedback on stock 12 6.6. 6.6.3. 6.6.4. 6.6.5. Additional functions _________________ 18 7.1. 7.2. 7.3. 7.4. 7.5. 7.6. 7.7. 7.8. 7.9. 7.10. 7.11. 7.12. 7.13. 7.14. 7.15. 7.16. 7.17. 7.18. 7.19. 7.20. 7.21. 7.22. 7.23. 7.24. 7.25. Core functions ________________________ 6 6.1. Outgoing goods ___________________ 14 6.7.1 Order management __________________ 14 6.7.2 Order picking _______________________ 16 6.7.2.1 Functional support of different order picking procedures 16 6.7.2.2. Consideration of relevant stock properties16 6.7.2.3. Communication with resources involved16 6.7.3 Consolidation _______________________ 17 6.7.4 Packaging __________________________ 17 6.7.5 Dispatch ___________________________ 17 6.7.5.1 Staging of goods __________________ 17 6.7.5.2 Loading __________________________ 18 6.7.5.3 Delivery feedback _________________ 18 Batches ____________________________ 18 Cross-docking _______________________ 18 Dock/yard management_______________ 20 Double/multiple-depth storage _________ 20 Hazardous material __________________ 20 Hazardous substances ________________ 20 Weight control ______________________ 20 Handling units management ___________ 21 Kit building _________________________ 21 Consignment ________________________ 21 Empties and load carriers ______________ 21 (Multiple) client capability _____________ 22 Multi-warehouse handling capability ____ 22 Best before dates ____________________ 22 Package optimisation _________________ 22 Production supply and removal _________ 22 Resource planning/labour management __ 23 Returns ____________________________ 23 Serial numbers ______________________ 23 Slotting and warehouse reorganisation___ 23 Forklift guidance system ______________ 23 Value added services _________________ 24 Vendor managed inventory ____________ 24 Scrapping __________________________ 24 Customs ___________________________ 25 Bibliography ____________________________ 25 Warehouse-internal processes _______ 13 Relocation of stocks __________________13 Replenishment ______________________13 Rebooking __________________________13 1 Warehouse management systems VDI 3601 Preliminary note The content of this standard has been developed in strict accordance with the requirements and recommendations of the standard VDI 1000. All rights are reserved, including those of reprinting, reproduction (photocopying, micro copying), storage in data processing systems and translation, either of the full text or of extracts. The use of this standard without infringement of copyright is permitted subject to the licensing conditions specified (www.vdi.de/richtlinien) in the VDI Notices. We wish to express our gratitude to all honorary contributors to this standard. 1. Scope The present standard describes task and performance areas that define an IT system as a warehouse management system (WMS). To this end, it defines the necessary terms and acronyms, describes the administrative and functional environment and addresses customary ways of integrating a WMS into superordinate or subordinate IT systems. In current language, the term “warehouse management” is used to describe the management, control and optimisation of storage and distribution systems. The fundamental functions of warehouse managementcover quantity and storage location management and control as well as disposition of conveying means. In addition the scope of a WMS as per this view also comprises complex methods and means for controlling system statuses as well as various operational and optimisation strategies. Thus, the task of a WMS is to manage and optimise intra-company storage systems. See ISO/IEC 2382 for definitions on concepts related to the technical environment of a WMS (operating systems, servers, clients, databases, etc.). Warehouse management systems necessitate that these subordinate system layers ensure throughput, data quality, and data stability as required for the WMS to perform its tasks. 2. Terms and definitions For the purposes of this standard, the following terms and definitions apply: Storage Booking process for ^incoming goods at the storage location, comprising storage location finding, transport to storage location, and checking the storage location coordinates. Stock-taking Recording of all assets, especially of the entire warehouse stock, to correctly determine a company’s floating capital. Order picking Logistic task for compiling partial quantities from a total of goods (assortment of goods) based on delivery orders by means of warehouse tasks. Logistics control centre Technical installation that continuously visualises and analyses key figures and logistic processes, identifies deviations from the target, and recommends actions to the user. 2 Master data management System for handling and storing condition-oriented data (usually with redundancy). Note: The most important master data objects are customers, suppliers, products, capital goods, personnel and accounts. The master data also includes movement data on material in the warehouse, from ^incoming goods to ^outgoing goods. Dispatch Part of the intra-company logistics where the entire outgoing movement of goods is managed physically and IT-based. Outgoing goods Area of a company where the goods to be delivered are physically released and booked out from stock and checked against advised quantities regarding contents and quantity. Incoming goods Area of a company where incoming goods are physically taken over, booked in and checked against advised quantities regarding contents and quantity. 3. Abbreviations The following abbreviations are used throughout this standard: ASN ERP HU IPC advanced shipping note enterprise resource planning handling unit industrial PC MDE MFCS BBD MIS NSU PPC QA Stock SRM RFID PLC SSCC TMS VAS mobile data entry material flow control system best before date management information system number of shipping unit production planning and control quality assurance stock storage and retrieval machine radio-frequency identification programmable logic controller serial shipping container code transport management system value added services VMI WMS vendor managed inventory warehouse management system 3 4. Position of the WMS within the system landscape As part of the system landscape of a company, the WMS communicates with adjacent systems via interfaces (Figure 1). The position of such systems within the IT hierarchy is geared towards the tasks and main functions of the software systems involved. The precise differentiation and/or layout of the individual systems and their system boundaries result from the individual project requirements. This means that alternative configuration options are possible. Advantages and disadvantages of specific alternatives can therefore not be defined globally within the framework of this standard. Figure 1. Plane model of system landscape (from WMS’s perspective) Superordinate systems The WMS communicates “upwards” with systems ranked at a higher hierarchical level. Typically, these are ERP systems, see also VDI 3969. Subordinate systems The WMS communicates “downwards” with systems ranked at lower hierarchical levels (subsystems) such as material flow control systems (MFCS) or programmable logic controllers (PLC) that directly control automatic conveying or storage equipment such as rack vehicles and conveying paths, sorters, order picking robots and packing facilities. This group also comprises systems that support manual handling such as barcode and RFID scanners, pick-by-light and pick-by-voice devices. Standard series VDI/ VDMA 5100 describes a possible design approach to this topic. Adjacent systems The WMS communicates “sidewards” with systems hierarchically ranked neither at superordinate nor at subordinate levels, e.g. dispatch systems, transport management systems (TMS), management information systems (MIS) and data warehouse systems. The systems are part of the same operational plane within the plane model. 4 4.1 Enterprise resource planning (ERP) Enterprise resource planning is an integrated software system for comprehensively planning and coordinating corporate and especially business-related tasks. It is aimed at utilising the resources available within a company (personnel, operating resources, etc.) in the most efficient way. In addition to comprising programs for virtually all tasks of a company (e.g. finance, accounting, controlling, HR management, product development, production), RP systems can also provide logistic applications (e.g. inventory management, disposition). 4.2 Material flow control system (MFCS) The implementation of partially or fully automated material flow operations is realised in the Material flow control system (formerly: material flow computer plane). It coordinates and, where necessary, optimises the sequence of tasks to be performed and controls the source-target relations of single (transport) tasks, processes, etc. being completed. To this end, subordinated controls are activated. Material flow control can be an integrated module of a WMS or installed as a separate system. A material flow control system performs all transport management tasks within the warehouse described in Section 6.4. The forklift guidance system described in Section 7.21 is a special form of transport management. 4.3 Programmable logic controller (PLC) A programmable logic controller is an electronic assembly at subsystem level used for open and closedloop control tasks of automated components, e.g. conveying equipment or storage and retrieval machines. Basically, this is a device with specialised input and output interfaces. Using sensors and actuators, it can control, monitor, and influence production and transportation processes. There are now controls available for the tasks described that are based on an industrial PC (IPC) or on software solutions. 5. 5.1. Administrative environment User and authorisation management In order to avoid unauthorised access to WMS data and functions, authorised system users are created and maintained in the user management. The regulations for the assignment and validity of passwords are also defined here. There are functions for maintaining users, e. g. creation, deletion, and password resetting. Permissions for accessing WMS objects (menus, dialogues, fields and functions) are set within the authorisation management. Usually, these permissions are combined into profiles or groups and then assigned to the user. A distinction is made between different permission levels: read/visible, execute/write, no permission. Depending on the specific setup, the user has permission to see, navigate within, enter data into or execute the relevant objects. Objects for which the user has no permissions can be hidden or greyed out. As part of permissions maintenance, the dialogues and functions required for individual employees or groups of employees are set and functions that are not required are deactivated. In addition to permissions for objects, permissions for data contents, e. g. for delivery orders of specific clients, can be set. This is especially necessary to limit data access in multi-client environments. 5.2 Multiple languages Based on the language selected by the user, all screen texts are displayed in that language. In addition to the dialogues, this also affects e.g. error and system messages, help systems, and descriptive master 5 data (e.g. material descriptions). Translations can either be provided by the WMS manufacturer or entered by the administrators themselves via the dialogue system. In addition, documents can be printed in languages other than the one set for the user, e.g. in the language of the goods recipient. To this end, information such as names of materials, other text elements and, if necessary, whole forms must be managed in multiple languages. Text administration is done using suitable character sets, e. g. Unicode. The language for print outputs can be selected e. g. based on warehouse, site, client, or goods recipient. Different units of measurement including conversion from one unit to another are supported to enable the correct units of measurement to be displayed based on the language setting. This refers to the display of screen dialogues and/or the printout of receipts and not to a change of the unit of measurement used in the system itself. The system’s unit of measurement needs to be set once during initial configuration of the system. 5.3 Parameters The configuration of the WMS is performed using editable parametersi. Some parameter changes take effect immediately, others only after a (partial) restart. Basic parameters usually are maintained within the system configuration only and thus can only be performed by configuration administrators (in most cases, these are key users defined by the WMS supplier’s customer). Other parameters can be modified by the application administrators. Usually, these parameters are maintained directly within the productive system. To this end, relevant dialogues are available in the WMS. 5.4 Ergonomics The WMS supports the warehouse processes using ergonomic, process-oriented dialogues. Frequent dialogue changes within one process are avoided. Verifications help to avoid wrong entries and any forbidden triggering of functions. The information required for the processes are presented clearly, any unnecessary information can be hidden. 5.5 Archiving Usually, a WMS is optimised for processing the required data volumes. Storing fully processed records (e.g. for research) requires considerably larger resources in terms of storage volumes and processing capacities. Therefore, data records ready for archiving and completed data records are exported from current data tables on a regular basis. Archiving these data records reduces the amount of data in the productive system to the level required for operation. The archive can be optimised for the queries usually performed to speed up research in these larger amounts of data. Depending on the requirements, archives can be sourced out so that productive operation is not impaired by the queries being performed. Usually, data retention periods within the productive and archiving systems are defined during the conception stage. If central data warehouses are used for archiving and researching across system borders, data is not usually archived within the WMS. Instead, the data warehouse is supplied with the relevant data via an interface. Cross-system information can then be compiled from a single data warehouse. 6. Core functions The core functions are part of the minimum scope of delivery of every WMSii. However, specific functionalities can differ. The core functionalities support - normally using modules provided by the WMS supplier only - the main area of application of every WMS, i.e. the processes from incoming goods 6 to outgoing goods as well as warehouse-relevant management processes. Figure 2 illustrates the structure of a WMS, focussing on the interaction between core and additional functions. The latter are described in Section 7. 6.1. Warehouse structure The warehouse structure is the basis for designing the processes. The warehouse structure consists of various organisational units that are partly organised hierarchically, partly linked to each other. Examples of typical organisational units: • warehouse warehouse type/system • storage area • storage location • area of activity • door • staging zone • work station • production supply area These are explained below. The contents can have different, project-specific designations. • 6.1.1 Warehouse A “warehouse” designates the logical aggregation of all storage facilities and areas managed by the WMS plus the transport facilities and traffic zones directly linked to them as well as any work stations, storage compartments, areas, silos, tanks and other facilities that can be used to hold goods for storage, handling or order processing purposes. This also includes facilities and areas for incoming and outgoing goods. Usually, a warehouse is assigned to a site, i.e. to a continuous property. In exceptional cases, continuous storage processes (e.g. storage and retrieval actions) can also extend across several properties. If several such warehouse sites are closely linked to each other on an organisational level, the system is referred 7 to as a warehouse network; it can be mapped in a WMS as one logical warehouse. 6.1.2 Warehouse type/system Warehouses are classified into physical or logical warehouse types that are characterised by their storage technology, organisational structure, or function. Most warehouse types can also be operated automatically. Examples of warehouse types that are used for the actual storing of material: • classification based on physical characteristics: - pallet warehouse - high-bay warehouse - small-parts warehouse - bulk warehouse • outdoor storage space • classification based on logical characteristics: - hazardous substances warehouse - bonded warehouse - consignment warehouse Examples of warehouse types that fulfil a specific interface function within the processes: • incoming goods areas • outgoing goods areas • transfer locations (e.g. between halls or warehouse types/systems) • order picking areas • packing areas • consolidation areas Warehouse types have parameters defining their specific properties, e.g. storage and retrieval strategies, capacity checking methods, storage of handling units (HU), mixed storageiii. 6.1.3. Storage area Any warehouse type can be divided into logical or physical storage areas. Several storage locations with identical properties can be grouped together to form a single storage area. Often, storage areas are arranged based on the materials’ properties within a warehouse type, e.g. based on weight (heavy materials), volume (bulky materials), temperature (materials that need to be cooled), turnover frequency (fast moving goods).iv 6.1.4 Storage location The term “storage location” is used for a specific location in the storage area where a material stock is stored or can be stored. A storage location can be characterised by multiple attributes, e.g.: • x, y, z coordinates (e.g. aisle, column, level) • maximum weight • maximum volume • allocation to a fire sector • partition of storage location • storage location depth • fixed or random storage location storage locations are often designated based on a specific scheme that is in turn based e.g. on the coordinates of a grid. Often, the spatial allocation of storage locations such as “aisle”, “column”, or “level” is considered when creating a term. Since most warehouses comprise tens of thousands of storage locations, the storage location is a master data record that can be created via mass maintenance or an upload function in many WMS v. 8 6.1.5 Area of activity An area of activity groups together storage locations used for a specific activity, e.g. order picking, storage, or stock-taking.vi In contrast to warehouse types or storage areas, storage locations are thus mainly grouped together based on processes. Another difference is that activity areas for different activities can overlap. 6.1.6 Door The term “door” is used for a point in the warehouse where transport units such as trucks, wagons, or other vehicles deliver material to the warehouse or take over material from the warehouse. 6.1.7 Staging zone A staging zone is physically located within the warehouse in close proximity of a door. When a transport unit to be unloaded arrives at this door, the material is unloaded to the relevant staging zone before it is processed further. For a transport unit to be loaded, the staging zone serves as a buffer for the loading process. In some countries, the staging zone is also used as consolidation area. 6.1.8 Work station A work station is a point in the warehouse where tasks involving materials and HU are carried out, e.g. order picking, counting, quality inspection, packing, deconsolidation, VAS, kitting. 6.1.9 Production supply area A product supply area serves as an intermediate storage area in the production to provide material needed for production directly at the line or the production work station. The product supply area groups together production work stations that are close to production storage locations, taking into account the material staging type. Material staging types e.g. are staging for exactly one production order, cross-production order staging, or KANBAN staging. 6.2. 6.2.1 Master data management Material The material master data comprises a material’s data required for warehouse logistics. These data comprise general data that are not specific to a single warehouse only but relevant across all warehouse sites. Important data are e.g. an external material number (number from ERP), a material description, gross weight and volume, batch management requirement, serial number profile, information on storage life, and hazardous substance or hazardous material data. A material is always listed in a base quantity unit (e.g. piece) and can also have alternative quantity units (e.g. a sales quantity unit or an order quantity unit). In addition to the general data, the material master data also contain warehouse-specific information. These can differ from warehouse to warehouse and usually concern control indicators for storage and retrieval as well as for stock-taking within the entire warehouse. Some WMS provide a higher degree of detail by offering the possibility to maintain data for control within one warehouse type. These data comprise information e.g. on replenishment quantities or preferred storage areas. In practice and sometimes depending on the industry sector, the terms “article”, “item”, or “product” are used instead of the term “material”. 9 6.2.2 Packing specifications Packing specifications comprise information on how material is to be packed vii. In different storage processes, the packing specifications e.g. provide information on finding the appropriate packing material or pallets to be used. Moreover, they provide important information to the employee during the packaging process. 6.2.3 Business partners Business partners are goods recipients and/or consignors of goods who maintain a goods relationship with the warehouse. Goods consignors can themselves be recipients (e.g. in case of returns). These can be customers or suppliers, but also subcontractors, detailers, or any other kind of service provider. They not only include legal or natural entities maintaining business relations with the company (e.g. customers, suppliers or service providers), but also other organisational units of the same company. Several addresses can exist for one business partner (e.g. pickup address, delivery address, billing address). Business partner master data are mostly managed by the ERP and not by the WMS. 6.3. Inventory management Inventory management comprises functionalities and methods for managing and finding identical and differing warehouse inventory items. Warehouse stocks can be managed at storage locations, on resources (e.g. on forklifts, order picking trolleys, storage and retrieval machines) or on transport units (e.g. trucks, railway wagons). In order to differentiate stocks from each other, the WMS uses stock-differentiating properties that enable the stocks to be clearly differentiated, e.g. material, batch, client, country of origin, customer order, or project (see also Section 7.1, Section 7.8, Section 7.12, Section 7.14, Section 7.19). Another important stock-differentiating property is the stock type. Based on the stock type, a differentiation is made as to whether a stock is part of e.g. the stock readily available, the locked stock, the quality inspection stock or the customs stock. Furthermore, it is possible to determine whether the stock is in transport to or already at the storage location. If the stock-differentiating properties of two stocks are identical, the stocks’ quantities can be merged (e.g. with addition to existing stock at one storage location). viiiOtherwise, the stocks can clearly be differentiated from each other based on their stock-differentiating properties. Stocks with different stock-differentiating properties can also be grouped together on a project-specific basis. However, the properties for the new stock then have to be defined. Using the methods of stock determination, stocks can be selected for specific warehouse activities based on stock types and clients. Stock determination can be done separately for each material. A special case of inventory management applies for material that is requested in custom base quantity units (e.g. lengths, volumes, surface). Here, a classification into residual quantities and cut parts is done even before processing. Examples are wood, cable, and glass cuts. The cut material is therefore called “cut” Differing from this, the term “filling” is used for liquids and bulk material. The resulting requirements for inventory management and retrieval strategies must be taken into consideration. 6.4. Transport management The movements of storage aids/transport aids within the warehouse from a starting point to a destination are managed using transport orders. Usually, a transport order contains at least the following information: • transport order number • starting point of transport 10 destination of transport • type of transport (e.g. storage, relocation of stocks, replenishment, special transports) • type of transport aid (or storage aid) • identification number of transport aid • transport group (for classifying the permitted means of transport, e.g. forklift) • transport status In addition, the following information regarding the transport order is logged: • creation of transport order (date/time) • planned/actual start of transport order (date/time) • receipt of transport order (date/time) • resource and user who carried out the transportix For transport management, all available transport subsystems are defined, e.g. conveying technology systems, forklifts, mobile data entry units (for manual transports). The route parameters determine which transport systems using which transport aid types can carry out the transports between the starting points and destinations of the warehouse. For transport order planning and execution, outstanding transports are compared with the available resources and assigned to an order backlog based on strategies (capacities/priorities). The assigned and available resources retrieve the transport orders from this order backlog for execution. All movements are logged. Arrival at the transport destination is reported by transport management to the ordering entities (e.g. inventory management). • 6.5. Incoming goods Incoming goods is the area where incoming goods are physically taken over, booked in and checked against advised quantities regarding contents and quantity. The following sub-processes are possible: • advanced shipping note • receipt • deconsolidation • quality inspection • storage • advanced shipping note completion/feedback on stock Parts of these processes can also be executed within the ERP, their level of detail can vary. The sequence of the listed sub-processes can also vary. 6.5.1 Advanced shipping note The announcement of a delivery of goods from a supplier to the recipient is called “advanced shipping note” (ASN). An advanced shipping note should at least provide information on the estimated time of arrival at the warehouse, the orders and order items covered by the delivery, material (material number, quantity), and possibly weight and/or volume. The advanced shipping notification is carried out e.g. • by the supplier feeding advanced shipping note information directly into the ERP system and from there to the WMS, • through a load carrier-specific advanced shipping note, e.g. in the form of an NSU (number of shipping unit) or an SSCC (serial shipping container code), • without actually transmitting an advanced shipping note, i.e. by transmitting order items to the WMS, or • without actually transmitting an advanced shipping note, i.e. the goods are booked in the WMS only based on shipping note information; the references to the purchase/purchase item must then be created manually. 11 6.5.2 Receipt During discharge, the goods are checked against the waybill and the carrier is relieved. During receipt, the advanced shipping note, accompanying papers (e.g. shipping note) and actually delivered goods are compared and booked. In doing so, the stock is created in the WMS. Usually, identification of material and papers is done using barcodes or RFID. Deviations must be taken account of (e.g. excess deliveries or underdeliveries, wrong material). 6.5.3 Deconsolidation During deconsolidation, the delivered containers are singularised so as to obtain individual storage units based on the different storage areas or warehouse tasks. Sometimes, partial quantities are separated for additional processes (e.g. quality inspection, cross-docking, master data control) at this stage already. 6.5.4 Quality inspection Depending on the operational requirements, inspections of supplier and material qualities can become necessary. These can range from a simple inspection of type and quantity to a comprehensive quality inspection. A visual or laboratory inspection of either a random sample or of the entire quantity can be carried out. Usually, the specifications for random sampling (quantity, scope, inspection regulations) are managed in the ERP system or in separate quality assurance systems. Quality inspections impact on inventory management in the WMS (e.g. rebooking, relocation of stocks, scrapping). 6.5.5 Storage The functional support of storing incoming goods comprises storage location finding, transport to storage location, and checking the storage location coordinates after completion of the warehouse task. Numerous storage strategies can be applied in this context that may vary significantly depending on process requirements.x A prerequisite for this is warehouse-relevant master data of sufficiently high quality. The following aspects can be relevant for storage: • physical material criteria (e.g. material dimensions, net/gross weight, shape) • material group (e.g. special material, hazardous substances) • (admissible) load carrier types (e.g. based on physical material criteria) • material characteristics (e.g. fast/medium/slow moving goods based on access frequency) • dedicated storage areas for specific material assortments or storage aids • handling during storage and retrieval (e.g. for selecting appropriate means of transport) • existing stock situation (e.g. for equal distribution to different lanes) Once completion of storage has been confirmed in the WMS, the stock of a material is booked from incoming goods to the storage location. 6.5.6 Advanced shipping note completion/ feedback on stock Once the quantitative registration of all goods of one delivery has been completed, the received quantities for the individual advanced shipping note item are reported back to the ERP, which then is responsible for accounting. For stock synchronisation purposes, it must be decided when and to what level of detail which stock changes will be communicated to the ERP system. At the very latest, the stock quantities are communicated to the ERP system as available stock once storage and advanced shipping note have been completed. 12 6.6. Warehouse-internal processes 6.6.3. Relocation of stocks The term “relocation of stocks” is used to describe the warehouse-internal process of transporting stock from one point in the warehouse to another. Relocation of stocks can be unplanned but also planned, xie.g. as part of a reorganisation (through slotting, see Section 7.20). 6.6.4. Replenishment Replenishment is a special form of relocation of stocks. In the replenishment process xii, a quantity of one material is e.g. repositioned from a reserve area to an order picking area. The order picking area is replenished based on the required quantities. Likewise, replenishment can be carried out between different order picking areas (e.g. from a pallet rack to a shelf storage system) or between different reserve areas (e.g. from a complete pallet storage system to a buffer area and from there to an order picking area in small quantities). Replenishment can e.g. be planned based on consumption data, or it can be triggered unplanned through the action of an order picker. The quantity to be replenished can be determined based on different strategies (e.g. based on the results of an analysis of minimum and maximum quantities, or considering outstanding orders or available container sizes). 6.6.5. Rebooking A rebooking can be initiated in the WMS or in the ERP. During a rebooking, at least one attribute of a stock is changed. 6.6.5.1. Rebooking as completion of a physical movement A rebooking can take place following a relocation of stocks, e.g. after storage is completed (upon acknowledgement at the destination storage location, a rebooking of the stock from “being stored” to “freely available” takes place). 6.6.5.2. Rebooking as initiator of a physical movementxiii A rebooking to change the stock status, e.g. from “freely available” to “locked”, can result in a relocation of stocks, e.g. to the quarantine warehouse. 6.6.5.3. Rebooking without physical movement A rebooking does not necessarily entail a relocation of stocks, i.e. the status of a stock can also change within one storage location without stock being moved. Examples are rebookings of “quality” to “freely available” or “locked”. 6.6.6. Stock-taking The term “stock-taking” describes the recording of all assets, especially of the entire warehouse stock, to correctly determine a company’s floating capital. The WMS supports the stock-taking process while evaluation of the stock-taking results is usually carried out using an ERP system. Various types of stock-taking are supported (e.g. end- of-period stock-taking, sample stock-taking, permanent stock-taking). The actual design of the required functionality depends on the customer’s legal and organisational framework conditions. A detailed description of the stock-taking procedure can be found in standard VDI 4492. 13 6.6.7. Control centre The logistics control centre is a tool for monitoring and controlling operational sequences. The WMS provides the user with key warehouse figures and information on the logistic and/or warehouse-relevant processes. In more complex situations, a control centre continually visualises and analyses the key figures and logistic processes, identifies deviations from the target and recommends actions to the user. A detailed description of the control centre functionality can be found in standard VDI 4493 Part 1. Relevant key figures for warehouse logistics are found in standard VDI 4490. 6.7. Outgoing goods The task of outgoing goods is to prepare a delivery or load creation. This comprises the following possible sub-processes: • order management • order picking • consolidation • packaging • dispatch • delivery feedback 6.7.1 Order management Order management serves to process customer orders on the IT level or to supply production by the warehouse. To this end, the WMS imports delivery orders from the ERP system via an interface or enables the entry of orders directly into the WMS. In special cases, the WMS allows for combining several delivery orders into one collective delivery order. Delivery orders consist of one or more delivery order items that are processed by means of warehouse tasks. A warehouse task in turn is processed based on a specific workflow. By processing all warehouse tasks for a delivery order item, packages are created. These packages form consignments. A consignment can comprise one or several packages (plus any load carriers) that are addressed to one goods recipient. Usually, a 1:1 relation between delivery order and consignment exists; some WMS also offer the possibility to split delivery orders into several consignments or to combine several delivery order items into a single consignment. Grouping together several consignments for transport, e.g. to one or more recipients, is referred to as creating a load.Figure 3 primarily illustrates the logical objects of order management within the WMS rather than the physical processes. Note: Usually, each package is assigned a unique number of shipping unit (NSU) and/or a serial shipping container code (SSCC) for unambiguous identification; see ISO/IEC 15459 for more information. As part of the interface communication between ERP and WMS, the transmitted delivery orders are checked forcompleteness and consistency. This is followed by the “schedule approval” of delivery orders for processing in the warehouse. This comprises: stock assignment Usually, access to freely available 14 stock and the Figure 3. Logical document and object structure in outgoing goods subsequent reservation of the quantities required to fulfil the scheduled delivery orders takes place using warehouse tasks. In more complex environments, special order types also allow access to other stock qualifications, e.g. access to customer single stocks, consignment stock or QA stock for returning to the supplier. In addition, strategies for optimised retrieval are implemented for assigning stocks (e.g. first-in-first-out, last-in-first-out, retrieval based on quantity, retrieval of goods not to be picked shortly before time of delivery, e.g. retrieval of entire containers). • package pre-calculation A pre-calculation for packages can be carried out during delivery order processing. Considering weight and volume and any hazardous material data or other factors, an algorithm is used to optimise the number and packing of packages. • consignment creation During creation of a consignment, a check is carried out to see if several packages for the same re15 cipient can be grouped together. Consignment creation takes place either continuously or subsequently. During continuous consignment creation, a check is carried out for each new package to see if a consignment for the same goods recipient already exists. If this is the case, the package is attached to the existing consignment if sufficient capacities are available. Where consignments are created subsequently, a check to determine which packages belong together is carried out during load creation. Accordingly, packages are only grouped together at that point. Once schedule approval has been given, the “approval for physical processing” of the warehouse tasks takes place. The latter are explained separately hereafter. 6.7.2 Order picking The objective of order picking is to compile partial quantities from a total of goods (assortment) based on delivery orders using warehouse tasks. This comprises both the singularising of material and the retrieval of entire containers from the assortment. The WMS supports completion of the warehouse task “order picking” by • applying different order picking procedures and optimising order picking notes, • accounting for relevant stock properties, and • communicating with the resources involved (e.g. employees, conveying technology, robots). 6.7.2.1 Functional support of different order picking procedures Usually, warehouse management systems support order picking based on the principles “person to goods” and “goods to person”. Depending on the principle, the WMS either guides the order picker to the goods (e.g. order picking in pallet rack) or it controls the transport of the goods to the person (e.g. order picking station of conveying technology). More complex systems support hybrid forms, e.g. pass-on systems with several zones defined as working area of the order pickers involved. In order to increase performance, the WMS optimises warehouse tasks for order picking. Common examples are: • splitting of delivery orders into warehouse tasks per storage area/activity area (parallel or sequential order picking) • grouping together of different warehouse tasks for simultaneous order picking in one storage area/activity area (multi-order picking) • grouping together of different delivery orders into one picking wave or picking batch for combined processing This allows e.g. multi-level order picking (material-based retrieval for several delivery orders on the first level, followed by sorting according to delivery order on the second level). Moreover, the WMS guides the resources required for order picking through the warehouse, taking into account order priorities and minimising the time required and distances to be covered. In addition to the manual approval of warehouse tasks by the warehouse personnel, rules set in the system enable automated approval of warehouse tasks relating to order backlogs. 6.7.2.2. Consideration of relevant stock properties Depending on delivery order or master data specifications, properties such as batch number, serial number or best before date must be considered during order picking. 6.7.2.3. Communication with resources involved (employees, conveying technology, robots, etc.) 16 The WMS controls the communication with the resources involved in order picking. For “person to goods” order picking, the information transfer to order picking employees takes place either with paper (printout of an order picking list) or without paper. Common procedures for paperless order picker guidance involve mobile data entry (MDE) devices or forklift terminals, optical methods (e.g. pick-by-light or put-to-light) or acoustic methods (e.g. pick-byvoice). For “goods to person” order picking and fully automated order picking, the WMS controls the connected storage and conveying technology via the material flow control system to transport the goods to the order picking stations for retrieval. 6.7.3 Consolidation Following order picking, the picked stocks for one delivery order are physically grouped together, i.e. consolidated. The task of the WMS is to manage the staging areas, organise the incoming stocks, and monitor completeness of the delivery orders. Once all parts of a delivery order have been consolidated, the subsequent process can be initiated. Different conveying and storage technologies can be deployed to support consolidation, e.g. conveying technology gyros or buffer storage systems. Also, consolidation can take place during the order picking stage (e.g. in a pick & pack scenario) or during the packaging process (grouping together packages for one goods recipient, if necessary also across delivery orders). 6.7.4 Packaging Typically, the packaging process is supported by the following WMS functionalities: • selection of the packaging type and size appropriate for the goods to be packed (based on material properties, volume and weight, dispatch route, hazardous material regulations, master data or delivery order-specific properties, packaging notes, etc.) • calculation and specification of packaging sequences and/or packaging schemes • repackaging functions for repackaging from warehouse-internal load carriers into the packaging used for shipping • weighing of package to determine/control weight • quality control (e.g. quantity check, scanning individual material) • printing out and/or attaching or including papers (e.g. list of package contents, shipping notes, shipping labels, hazardous goods documents, customs documents, advertising material) This necessitates proper maintenance of the required master data on packaging types and sizes and other information linked to these processes. Packaging, i.e. packing of the picked goods ready for shipment and the creation of the necessary documents and labels, is usually carried out after consolidation. However, parts of the process can also be completed earlier and even before starting the order picking, e.g. when orders are picked directly into the shipping containers (pick&pack). 6.7.5 Dispatch 6.7.5.1 Staging of goods The consignments packed ready for shipment are provided at dispatch and then transported to the recipient. The WMS assumes the following tasks: • management of dispatch areas and doors for staging • assignment of packages to dispatch areas 17 6.7.5.2 Loading A load/transport unit is created in the WMS prior to physical loading. During the loading process, the consignments and/or packages are assigned to the load/transport unit. This can be ensured by a scanning function at the door. The freight documents are created after loading. Possible additional functions and interfaces in this context are: • handover of data to the carrier (papers, waybill, export documents) • linking of shipping software/platforms (interfaces to forwarders) Furthermore, e.g. the following aspects of optimisation can be implemented: • consideration of stackability of pallets in the truck • consideration of loading sequence • re-storing of packed packages for retrieval shortly before shipping to optimise utilisation of the dispatch area In this context, some WMS can integrate functionalities for tour and route planning. This means that interfaces to or functionalities overlapping with ERP or TMS systems can exist. 6.7.5.3 Delivery feedback Within the delivery order processing in the WMS, different statuses can be carried forward and submitted to the ERP system to initiate follow-up processes (e.g. invoice printing). Possible statuses are: “order picking completed”, “packing completed”, “loading completed”. Usually, booking of outgoing goods takes place when the transport unit leaves the warehouse site. This is reported back to the ERP system, synchronising the stock situations in both systems. 7. Additional functions A WMS’s core functions are complemented by additional functions. They are installed or activated when the customer needs the relevant functionality (e.g. due to trade-specific requirements). Furthermore, some modules (e.g. dock/yard management or resource planning) are offered separately by specialised providers and linked to the WMS via an interface. In the following, common additional functions of a WMS are listed in alphabetical order. 7.1. Batches Batch management especially relates to the functional support of the traceability of batches required by law as per European Regulation 178/2002. To this end, the batch number needs to be captured at incoming goods (traceability from supplier). In addition, traceability must be ensured to the precise storage location when internal transports occur. The batch is considered a stock-differentiating characteristic. If the batch has already left the warehouse, it must be assigned to the customer it was supplied to (proof of use for customer). Using empty fields (e.g. best before date as batch number field) is usually not sufficient because it would then no longer be possible to manage batches with a best before date. 7.2. Cross-docking The term “cross-docking” is used to describe processes where stocks from incoming goods are not stored but instead are fed directly into the outgoing goods process. For cross-docking, a distinction is made between processing inventory-managed material and HU without inventory information. • For cross-docking of inventory-managed material, additional processes must often be initiated since the quantities available in incoming goods do not usually correspond exactly to the quantities required in outgoing goods. Example processes 18 are the storage of residual quantities, the retrieval of shortages and the cancellation of retrieval tasks that are replaced by cross-docking. • For cross-docking of HU without inventory information, no inventory management based on material takes place. Only the HU are identified, managed and controlled based on their destinations (customers/loads/deliveries). This means that material quantities are not relevant. In addition to inventory information, the process trigger is of crucial importance for cross-docking (Figure 4). Firstly, a distinction is made between: • unplanned cross-docking • planned cross-docking • In unplanned cross-docking, the WMS recognises whether the stock items in incoming goods qualify for cross-docking during the incoming goods process or the outgoing goods process. • unplanned cross-docking in the incoming goods process: During creation of the warehouse tasks for storage, a check is carried out to see if stock items can be used for deliveries. In case of a match, crossdocking takes place. • unplanned cross-docking in the outgoing goods process: During creation of the warehouse tasks for retrieval, a check is carried out to see if any matching stock is being delivered or available in incoming goods. In case of a match, cross-docking takes place. In planned cross-docking, the decision as to whether or not cross-docking will take place is taken prior to the material’s physical arrival. Planned cross-docking is subdivided into: • goods allocation During goods allocation, a decision is made in the ERP system to carry out a cross-docking. The deliveries and delivery orders affected by the crossdocking are communicated to the WMS. In direct cross-docking, the materials are distributed untouched. In flow-through, however, the material is relocated from the incoming goods area to a repacking area before being made available in the outgoing goods area. • transport cross-docking In contrast to the other cross-docking processes, transport cross-docking has no impact on the process within the warehouse. Instead, it impacts the transport process to the goods recipient. In this case, the WMS draws on route information to decide during the outgoing goods process whether goods are transported to a goods recipient directly or via one or several hubs. Figure 4. Cross-docking (schematic illustration) 19 7.3. Dock/yard management In dock management, the warehouse docks (ramps) are managed by the WMS. The WMS supports e.g. the assignment of a truck to a specific dock at a set target delivery time. Yard management manages the warehouse yard. The WMS manages the parking positions of the yard and controls and monitors transports between the individual points of the yard. Dock/yard management comprises functions such as planning and allocating time frames, checking in and out trucks, truck recognition, truck management, parking position management, dock planning, door allocation, calling up trucks, and relocation transports. 7.4. Double/multiple-depth storage This describes storage of two or more storage units (with or without load carriers) behind each other at a single storage location. If storage locations are not allocated to items of the same material or batch, strategies for the relocation of stocks are required. These strategies can be more or less complex depending on the layout of the warehouse and the conveying technology (channel storage system; high-bay warehouses; SRM with 1 to n single/multiple-depth load handling devices). In this environment, the management of stock sometimes takes place in separate sub-systems of the ware- house/conveying technology suppliers. This is mainly the case in storage systems with channel storage systems, storage systems with SRM with several load handling devices or automated vehicle storage and retrieval systems. In double or multiple-depth storage systems using SRM, warehouse management is often done without such sub-systems. The necessary relocation of stocks is then recognised by the WMS and the SRM is informed via the MFCS. In this case, the corresponding locations can be controlled based on the subsequent movements. 7.5. Hazardous material Hazardous material is defined as a substance, an item or a formulation that represents a hazard to humans, animals, or the environment when transported incorrectly. The tasks for hazardous materials management include safe transport of hazardous materials. To this end, specific arrangements are necessary to secure the goods for transport. These can include attaching safety signs to the transport unit, creating accompanying documents and checking quantity restrictions for hazardous materials based on the means and type of transport (transport by rail, road, air or sea). For multi-mode transports, the requirements for each individual transport section must be considered. 7.6. Hazardous substances The storage of hazardous substances is subject to special requirements stipulated by laws and regulations. On the one hand, these requirements relate to controlling storage in order to adhere to rules for storing substances together, and on the other to documenting stored substances. Therefore, storing substances with hazardous properties in warehouses in which many different substances are stored is extremely complex and challenging. In such warehouses, efforts must be made to optimise two areas: On the one hand, the logistical requirements for efficient processes and an optimum use of available resources and space must be met. On the other hand, all safety and environmental regulations for operating such a site must be strictly adhered to. 7.7. Weight control In some storage processes it can make sense to integrate weight checks to record the weight of stocks and to check it against any weight restrictions. During the storage process, the weight can e.g. be checked against the load bearing capacities of the storage locations; during the packing process, attention is paid to the weights of dispatch units to account for shipping/transport restrictions. During 20 stock-taking or order picking of material that is time-consuming to count, the weight of a material can be recorded instead to then calculate the number of items in stock. Especially in the food industry, goods often differ in terms of the weight of the individual items. This actually makes it impossible to determine a fixed conversion factor from piece to weight unit. Thus, each product has two units of quantity with equal significance, one logistical unit of quantity and one valuation unit of measure (catch weight management). The weight check serves to determine or check the valuation unit of measure. 7.8. Handling units management The term “HU” is used to designate a logical warehouse unit that consists of one or several packing materials (load carriers/packaging material), any materials stored on it and any additional HU. Typical load carriers for HU are e.g. pallets, wire-mesh pallets, containers, shelf boards, and cardboard boxes. Nesting allows for a clear hierarchy to be created. (In order to e.g. map the structure of a shelf board or of the package, it is important to know the HU’s spatial positioning as this must also be accounted for.) Each HU is assigned a unique number for identification and management in the WMS. This identifica tion allows for handling units to be traced so they can be used for storage, transport, or dispatch. 7.9. Kit building The term “kit building” (also “set building”) is used to describe the process of compiling a kit. A kit comprises a kit head and one or several kit components. The kit head is the material that is ordered. The kit components are the individual parts that form a kit by assembly in the warehouse either during the order picking process or separately at a work station. Kit building consists of three processes: • kit-to-order • kit-to-stock • reverse kitting Kit-to-order means that the kits are created individually for customer orders based on sales bills of materials if a sufficient number of assembled kits is not in stock. After the bill of materials is analysed, the kit components are assembled to kits as part of the outbound delivery processing. This is done either at a work station or directly during order picking into a HU. Kit-to-stock means that kits are created anonymously (i.e. independent of any customer orders). The process can be initiated both in the ERP (e.g. via a production order) and directly in the WMS based on production bills of materials. If no production bill of materials exists, kit head, kit components and their quantities can be entered into the WMS manually when the kit-to-stock order is created. Reverse kitting means that a kit can also be disassembled back to its original components. This process is used e.g. when kits are no longer required, when the bill of materials of a kit has changed or when a kit has been received as part of a customer return. Reverse kitting can be carried out with or without a bill of materials. 7.10. Consignment For consignment, the material is still owned by the supplier after receipt at the customer’s warehouse. The customer takes ownership when retrieving the material for consumption or resale, thus creating a liability towards the supplier. The WMS can manage and distinguish the ownership structures of the material stocks (including those of identical material from different suppliers), and control consumption so that own stocks are consumed or sold before any consignment stocks. 7.11. Empties and load carriers 21 The unambiguous identification of each load carrier, the functional support of empties/load carrier accounts, the generation of collection requests for empties and the calculation of the necessary transport capacities are all aspects of empties/load carrier management. 7.12. (Multiple) client capability A WMS offers client capabilities if several clients (e.g. customers of a logistics service provider) can be served by the WMS independently from each other. This requires that the data for all of these clients can be maintained completely separate from each other and that no unauthorised access is granted. This not only applies to stock data but also to supplier and customer data, user management, warehouse regulations, warehouse processes, accounting of logistics and other services, and the allocation of storage areas to clients. 7.13. Multi-warehouse handling capability The support of at least two warehouse sites that are separated on a spatial and organisational level by a single WMS is referred to as multi-warehouse handling capability. It is important that one stock overview per warehouse site and one overview of the total stock of all warehouse sites can be displayed. In addition, it must be possible to carry out replenishments or consolidations between the individual sites. 7.14. Best before dates The management of best before dates (BBD) comprises at least the storing of dates of expiry after which the goods shall no longer be delivered or sold. In this context, the best before date is a stock-differentiating characteristic. Complex functions can quickly become necessary especially in the food and pharmaceutical industries. For these industries, e.g. customised residual lives, ascending sorting of best before dates at dispatch or a consideration of best before dates and residual lives as part of the availability check can be required. Furthermore, consideration of the latest permissible delivery date and of the latest permissible date of sale are important in some industries. 7.15. Package optimisation A package is a compiled unit of products or packages for protection and transport purposes. Package optimisation is a function of a WMS that prepares a package based on certain restrictions. Examples for such restrictions can be that a package may not exceed a specific weight, that the existing space of a packing unit is to be utilised fully or that a packing pattern calculation including the required sequencing for order picking is necessary. 7.16. Production supply and removal Supply and removal of material for production usually require specific handling in the warehouse. Differences compared to the processing of delivery orders for distribution result e.g. regarding the following aspects: • separation or deliberate combination of distribution orders and production orders during order picking • simplified outgoing goods processes by avoiding packaging or staging in the dispatch area • deviating replenishment strategies or material staging processes for production, e.g. by staging based on production lot size or staging in fixed replenishment lot sizes (e.g. KANBAN) This can be followed by WMS-supported restorage of finished goods or of residual quantities that have not been consumed. Additional functionalities in the production supply and removal areas are: • mapping of production or assembly stations including staging areas and corresponding stocks in production, if necessary in multi-step processes • processing of one- or multi-step bills of materials 22 displaying production or assembly instructions for simple production activities More complex production requirements, especially those regarding planning activities, are usually managed using a production planning and control system (PPC) or corresponding modules in the ERP system. In addition, there are functional overlaps with or similarities to logistical added-value services (see Section 7.9 and Section 7.22). • 7.17. Resource planning/labour management Prior to the actual resource planning, the total processing time needs to be determined based on past data and/or standard times. In addition, a load forecast based on the total processing time needs to be created. Resource planning can be divided into employee-based and transport means-based resource planning and is a useful feature of a WMS. By its very nature, employee-based resource planning is based on personnel data such as working hours and working times of the relevant employee, qualifications and areas of deployment. For transport means- based resource planning, data such as key performance indicators, areas of deployment and availabilities are considered during planning. 7.18. Returns In industries/companies with low return rates, returns can be handled as “normal” deliveries. Additional functional support in this area can e.g. be the initiation of control works and any processing steps resulting from it (e.g. special storage, conditioning, scrapping). In industries/companies with high return rates, e.g. in the mail order business, the returns process becomes a core process of the logistical processing and can have retrospective effects on many process steps in the WMS. 7.19. Serial numbers Managing serial numbers is not limited to simply storing the serial number based on an individual material. It also involves registering serial numbers or serial number ranges at incoming goods based on individual deliveries (traceability from the supplier) and registering them at outgoing goods based on individual recipients (proof of use for customer). Using empty fields (e.g. best before date as serial number field) is usually not sufficient, it would then no longer be possible to manage series with a best before date. 7.20. Slotting and warehouse reorganisation Slotting (also called “warehouse disposition”) is a planning function for automatically determining a storage location for a material. Based on material packaging, and demand data, slotting calculates a suggestion of data relevant for storage and retrieval (e.g. area for storage, storage location properties, storage and retrieval strategies). An example for slotting is the allocation of storage locations based on an ABC analysis. In the context of warehouse reorganisation, the current stock situation of the products being stored at the storage locations is compared to the storage disposition data that was originally defined. In this way, it is possible to determine whether or not a product is stored at its optimum storage location. If the product is not stored at its optimum storage location, a warehouse reorganisation can initiate a relocation of stocks. Warehouse reorganisation can increase efficiency within the order picking process, boost warehouse capacity utilisation and minimise the number of replenishments. 7.21. Forklift guidance system A forklift guidance system is a system for efficient resource management using vehicle or ground conveyor disposition and guidance. The system treats the forklift just as any other conveying system. The forklift guidance system comprises: • stored transport matrix reflecting the material flow topology 23 It is possible to store route restrictions (drive- through widths or heights, admissible floor loads). • typification of forklifts based on usability (dedicated load handling devices, special functions, required drive-through heights) • list of forklifts available in the system including relevant type information • allocation of forklifts to guidance areas (if spatial allocation of forklifts to storage areas is to be restricted) • allocation of load carrier types to suitable forklift types The system’s task is to optimally allocate transport orders to avoid non-productive empty runs, search runs and dead times. In this way, it is possible to achieve even utilisation of the forklifts and to increase throughput. Transport orders are allocated to the appropriate vehicles directly to the terminal by radio data transmission and without paper and/or can be selected from the outstanding orders by the forklift driver A forklift guidance system can allocate transport orders e.g. based on the following optimisation criteria: • forklift availability • forklifts close to the source location (also possible via positioning systems) • forklift that is allocated to this storage area • vehicle types, transport aid types (forklift that has permission to transport these goods, e.g. due to load capacity or because it is equipped with a special attachment) • movement job types including order priorities Furthermore, hand-over locations with capacities must be managed and be considered during the transport order assignment. 7.22. Value added services The term “value added aervices” (VAS) is used to describe services provided in the warehouse that add value. To be able to charge for these activities separately, data relevant for accounting are recorded and provided as part of the VAS. A distinction is made between VAS like labelling such as price marking in trade, repackaging, and assembly work (see also Section 7.9). For the latter, it is often necessary to process bills of materials beforehand. The value-adding activity is very often carried out by the logistics service provider on behalf of its customer (the client). 7.23. Vendor managed inventory In vendor managed inventory (VMI), the supplier (or outsourcing partner) carries out the inventory management of their merchandise and goods at the customer (dealer or manufacturer). To this end, the supplier is continually provided with information, e.g. with sales or consumption data or with information on the estimated demand. Even though it is often the ERP system that disposes within the scope of the summary inventory management, there are areas of application where a corresponding functionality is provided by the WMS, e.g. if • WMS-specific material that is not managed in the ERP system (e.g. packing material) is to be provided via automated replenishment by the service provider/supplier, or • the supplier carries out material disposition without a superordinate ERP system (e.g. logistics service provider) and the WMS replaces this functionality. • From the WMS’s position, two VMI versions are possible: • For active VMI, the WMS disposes the stocks at a downstream level, e.g. by organising automated replenishment by generating a delivery order based on sales or consumption data. • For passive VMI, the WMS enables direct access to the inventory data in the warehouse by an upstream supplier who disposes a delivery when required. 7.24. Scrapping The scrapping process serves to destroy a warehouse stock. Scrapping of material becomes necessary when it is damaged or has become unusable in another way. A scrapping order can be created for tar24 geted disposal or destruction (maculature, disposal of problematic substances from the chemical, pharmaceutical, electrical, etc. sectors). The scrapping process can also follow on from a return process, e.g. when goods are returned by the customer due to insufficient quality. Usually, these orders relate to goods that are not tradeable (i.e. goods with quality defects). Scrapping is also used to free storage capacities. Scrapping can be initiated both from the ERP system and from the WMS. 7.25. Customs The additional function customs describes IT support of import and export consignments, different types of bonded warehouses, refining processes, consideration of the country of origin, and interfaces to state- run customs systems. Processing export consignments can necessitate the creation and handling of special documents. The exact scope and extent of customs functionalities depend on country-specific regulations, shipment characteristics and the material. Schrifttum / Bibliography Gesetze, Verordnungen, Verwaltungsvorschriften / Acts, ordinances, administrative regulations Verordnung (EG) Nr. 178/2002 des Europaischen Parlaments und des Rates vom 28. Januar 2002 zur Festlegung der allgemeinen Grundsatze und Anforderungen des Lebensmittelrechts, zur Errich- tung der Europaischen Behorde fur Lebensmittelsicherheit und zur Festlegung von Verfahren zur Lebensmittelsicherheit (ABl. L 31, 2002, S. 1-24) Technische Regeln / Technical rules ISO/IEC 2382 Information technology (Informationstechnik). Berlin: Beuth Verlag ISO/IEC 15459 Information technology; Unique identifiers for transport units (Informationstechnik; Eindeutige Identifizierung von Transporteinheiten). Berlin: Beuth Verlag VDI 1000:2010-06 VDI-Richtlinienarbeit; Grundsatze und Anlei- tungen (VDI Guideline Work; Principles and procedures). Berlin: Beuth Verlag VDI 3969:2003-12 Schnittstellen des Lagerverwaltungssystems zu ubergeordneten Systemen (Interfaces of the warehouse administration system with superordinate systems). Berlin: Beuth Verlag VDI 4490:2007-05 Operative Logistikkennzahlen von Warenein- gang bis Versand (Operational logistics key figures from goods receiving to dispatch). Berlin: Beuth Verlag VDI 4492:2006-08 Anwendung von Inventurverfahren in EDV-ge- fuhrten Lagern (Application of stocktaking procedures in IT-based warehouses). Berlin: Beuth Verlag VDI 4493 Blatt 1:2013-03 Leitstand fur die Intralogistik (Control centre for intralogistics). Berlin: Beuth Verlag VDI/VDMA 5100 Blatt 1:2011-07 (Entwurf/Draft) Systemarchi- tektur fur die Intralogistik (SAIL); Grundlagen (System Architecture for Intralogistics (SAIL); Fundamentals). Berlin: Beuth Verlag VDI/VDMA 5100 Blatt 2:2008-03 (Entwurf / Draft) Systemarchi- tektur fur die Intralogistik (SAIL); Beispiele zur Modellierung (System Architecture for Intralogistics (SAIL); Modelling examples). Berlin: Beuth Verlag Weitere technische Regeln / Further technical rules VDI 3628:1996-10 (Entwurf / Draft) Automatisierte Materialfluss- systeme; Schnittstellen zwischen den Funktionsebenen im Automa- tisierungsmodell (Automated material handling systems; Interfaces between the various function levels in the automation model). Berlin: Beuth Verlag VDI 3628:1985-03 Automatisierte Materialflusssysteme; Schnitt- stellen zwischen den Funktionsebenen (Automated material handling systems; Interfaces between the various function levels). Berlin: Beuth 25 Verlag VDI 3629:2005-03 Organisatorische Grundfunktionen im Lager (Basic organisational functions in warehousing). Berlin: Beuth Verlag VDI 3962:1995-02 Praxisgerechter DV-Einsatz im automatischen Lager (Practise proved computer installation in automated storage systems). Berlin: Beuth Verlag i The configuration of the WMS is performed using editable parameters ii The core functions are part of the minimum scope of delivery of every WMS iii Warehouse types have parameters defining their specific properties, e.g. storage and retrieval strategies, capacity checking methods, storage of handling units (HU), mixed storage Storage area Any warehouse type can be divided into logical or physical storage areas. Several storage locations with identical properties can be grouped together to form a single storage area. Often, storage areas are arranged based on the materials’ properties within a warehouse type, e.g. based on weight (heavy materials), volume (bulky materials), temperature (materials that need to be cooled), turnover frequency (fast moving goods). 6.1.3. iv v the storage location is a master data record that can be created via mass maintenance or an upload function in many WMS vi An area of activity groups together storage locations used for a specific activity, e.g. order picking, storage, or stock-taking. vii Packing specifications comprise information on how material is to be packed viii If the stock-differentiating properties of two stocks are identical, the stocks’ quantities can be merged (e.g. with addition to existing stock at one storage location). Usually, a transport order contains at least the following information: • transport order number • starting point of transport • destination of transport • type of transport (e.g. storage, relocation of stocks, replenishment, special transports) • type of transport aid (or storage aid) • identification number of transport aid • transport group (for classifying the permitted means of transport, e.g. forklift) • transport status In addition, the following information regarding the transport order is logged: • creation of transport order (date/time) • planned/actual start of transport order (date/time) • receipt of transport order (date/time) • resource and user who carried out the transport x The functional support of storing incoming goods comprises storage location finding, transport to storage location, and checking the storage location coordinates after completion of the warehouse task. ix Numerous storage strategies can be applied in this context that may vary significantly depending on process requirements. xi Relocation of stocks can be unplanned but also planned, 26 xii Replenishment is a special form of relocation of stocks. In the replenishment process xiii Rebooking as initiator of a physical movement 27