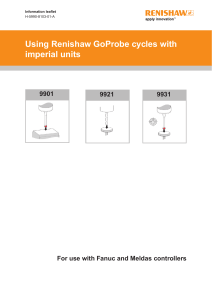

Probing systems for CNC machine tools technical specifications H 2000 3020 12

реклама