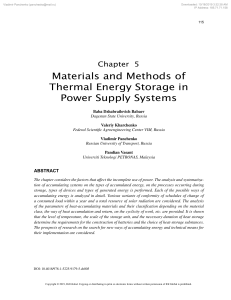

Journal of the European Ceramic Society 36 (2016) 189–202 Contents lists available at www.sciencedirect.com Journal of the European Ceramic Society journal homepage: www.elsevier.com/locate/jeurceramsoc Theoretical and experimental determination of the major thermo-mechanical properties of RE2 SiO5 (RE = Tb, Dy, Ho, Er, Tm, Yb, Lu, and Y) for environmental and thermal barrier coating applications Zhilin Tian a,b , Liya Zheng a,b , Jiemin Wang a , Peng Wan a,b , Jialin Li a , Jingyang Wang a,∗ a High-performance Ceramics Division, Shenyang National Laboratory for Materials Science, Institute of Metal Research, Chinese Academy of Sciences, 110016 Shenyang, China b University of Chinese Academy of Sciences, Beijing 100049, China a r t i c l e i n f o Article history: Received 29 June 2015 Received in revised form 7 September 2015 Accepted 12 September 2015 Available online 26 September 2015 Keywords: Rare-earth silicates Environmental barrier coating Mechanical property Thermal property a b s t r a c t X2-RE2 SiO5 orthosilicates are promising candidate environmental/thermal barrier coating (ETBC) materials for silicon-based ceramics because of their excellent durability in high-temperature environments and potential low thermal conductivities. We herein present the mechanical and thermal properties of X2-RE2 SiO5 orthosilicates based on theoretical explorations of their elastic stiffness and thermal conductivity, and experimental evaluations of the macroscopic performances of dense specimens from room to high temperatures. Mechanical and thermal properties may be grouped into two: those that are sensitive to the rare-earth (RE) species, including flexural strength, elastic modulus, and thermal shock resistance, and those that are less sensitive to the RE species, including thermal conductivity, thermal expansion coefficient, and brittle-to-ductile transition temperature (BDTT). The orthosilicates show excellent elastic stiffness at high temperatures, high BDTTs, very low experimental thermal conductivities, and compatible thermal expansion coefficients. The reported information provides important material selection and optimization guidelines for X2-RE2 SiO5 as ETBC candidates. © 2015 Elsevier Ltd. All rights reserved. 1. Introduction Silicon-based ceramics such as SiC, Si3 N4 , and SiC-matrix composites, exhibit excellent high-temperature mechanical properties, good stability in dry air, and potential applicability in gas turbines [1]. However, when exposed to combustion environments containing water vapor, silicon-based ceramics fail promptly because of volatilization of gaseous silicon hydroxide [2]. The unsatisfactory environmental durability is the bottleneck to their technological applications in combustion environments [3]. Two chemical degradation mechanisms are commonly observed: recession, which involves loss of the silicon-based ceramics because of repeated oxidation and volatilization in the presence of high-velocity water vapor moving through the turbine [4,5], and hot corrosion, which involves formation of pits in the silicon-based ceramics because of liquid silicate formation in the presence of alkali salts commonly present in combustion atmospheres [4]. To address these issue and ∗ Corresponding author. E-mail address: [email protected] (J. Wang). http://dx.doi.org/10.1016/j.jeurceramsoc.2015.09.013 0955-2219/© 2015 Elsevier Ltd. All rights reserved. protect silicon-based ceramics and composites, environmental barrier coating (EBC) must be developed. Great progress has been achieved in developing functionally graded thermal barrier coating/environmental barrier coating (TBC/EBC) systems [4,6]; these technologies are hybrid coating systems wherein the multifunctional EBC layer prevents recession and hot corrosion and the TBC layer reduces thermal conduction. However, considering the mechanical and thermal mismatches between TBCs and EBCs as well as the chemical incompatibility of some multifunctional coatings, trial-and-error is necessary to determine proper coating components. Therefore, developing advanced ETBC coating candidates possessing the integrated functions of EBCs and TBCs is crucial to protect silicon-based ceramics and composites from chemical attack and suppress thermal conduction simultaneously; these properties are believed to enable significant and efficient increases in the performance of protective components in gas turbines. Rare-earth (RE) silicates are acknowledged as third generation of EBC materials, and a number of silicates also have been identified as low-thermal conductivity ceramics [7,8]. RE2 SiO5 , for example, has attracted extensive research attention because of its hightemperature stability and water vapor corrosion resistance [5]. This 190 Z. Tian et al. / Journal of the European Ceramic Society 36 (2016) 189–202 2. Theoretical calculation methods and experimental procedure 2.1. Theoretical calculation methods Fig. 1. Crystal structure of X2-RE2 SiO5 . orthosilicate can be screened as a low-thermal conductivity material according to Clarke’s criteria for thermal insulators [9], which suggests that RE2 SiO5 is an excellent and promising ETBC candidate. RE2 SiO5 silicates present two monoclinic polymorphs. Compounds containing RE elements from La to Gd crystallize with a space group of P21 /c, and are called X1 phases, while those with RE elements from Dy to Lu feature a space group of C2/c, and are called X2 phases. The X1 and X2 phases represent the lowtemperature and high-temperature phases, respectively [10], and RE2 SiO5 specimens with Tb and Y have been reported to appear in both phases. As shown in Fig. 1, the unit cell of X2-RE2 SiO5 contains 32 atoms, including two different RE3+ sites, RE1 and RE2, one Si site, and five O sites labeled O1–O5. Four O (O1–O4) atoms form a Si-centered distorted tetrahedron, while atom O5, with no Si atom as the nearest neighbor, is loosely bonded to four RE ions, thereby forming a distorted polyhedron. X2-RE2 SiO5 consists of rigid [SiO4 ] tetrahedra and relatively soft [REO6 ] and [REO7 ] polyhedra [11]. X2-RE2 SiO5 orthosilicates possess smaller thermal expansion coefficients and lower thermal conductivities, making them suitable for use as coating materials for silicon-based ceramics. Considering their beneficial properties, X2-RE2 SiO5 silicates were selected as the representative material in the present investigations. Mechanical and thermal properties, as well as property matching among substrates, are of great importance when selecting ETBC materials with high reliability in harsh environments. Two main obstacles prohibited the efficient evaluation of X2-RE2 SiO5 silicates as ETBC. First, the mechanical and thermal properties of X2-RE2 SiO5 change with the RE elements incorporated into it; thus, guidelines require extensive information of mechanical and thermal properties. Second, integrated ETBC candidates must satisfy important criteria, such as low thermal conductivity, no phase transformation, good thermal shock resistance (TSR), and excellent mechanical stability in the harsh service environments. Unfortunately, obtaining accurate intrinsic properties through investigations of X2-RE2 SiO5 coating samples is difficult. As a convenient and reliable alternative, evaluating the mechanical and thermal properties of bulk and dense X2-RE2 SiO5 samples is recommended. We herein present theoretical predictions and experimental evaluations of the mechanical and thermal properties of X2-RE2 SiO5 . The room-temperature mechanical properties of X2-RE2 SiO5 samples were studied, and their dynamic Young’s moduli and brittle-to-ductile transition temperatures (BDTT) were explored at different temperatures. Thermal conductivities were systemically investigated through analyses of crystal structures, theoretical predictions, and experimental measurements. The thermal expansion coefficients of X2-RE2 SiO5 were obtained from 500 to 1473 K, and their TSR parameters were derived from measured properties. The results obtained provide important guidelines for the design and evaluation of X2-RE2 SiO5 as potential ETBC materials. For X2-RE2 SiO5 (RE = Tb, Dy, Ho, Er, Tm, Yb, Lu and Y), firstprinciples calculations were performed using the VASP (Vienna Ab-initio Simulation Package) code based on density functional theory (DFT) [12]. Electron–ion interactions were represented by using the projector augmented wave method [13], and the electronic exchange correlation energy was treated as a generalized gradient approximation [14]. The plane wave basis cut off was set to 450 eV, and special -point sampling integration was used over the Brillouin zone by applying the Monkhorst–Pack method with a 3 × 3 × 3 -point mesh [15]. The lattice parameters and internal freedom of the unit cell were fully optimized until the total energy difference was smaller than 1 × 10−6 eV. Elastic constants were determined from the linear fits of stress as functions of applied homogeneous elastic strains [16]. The criterion of convergences for total energy was selected as 1 × 10−6 eV in the elastic constant calculations. X2-RE2 SiO5 crystallizes in the C2/c space group and features 13 independent elastic constants. The polycrystalline bulk modulus B, shear modulus G, and Young’s modulus E of the orthosilicate were determined based on Voigt, Reuss, and Hill approximations [17–19]. According to Voigt approximation, the bulk and shear moduli can be calculated from elastic constants as: BV = 2 1 (c11 + c22 + c33 ) + (c12 + c13 + c23 ) 9 9 GV = 1 1 (c11 + c22 + c33 − c12 − c13 − c23 ) + (c44 + c55 + c66 ) (2) 15 5 (1) According to Reuss approximation, the bulk and shear moduli are calculated from compliance matrix components as: BR = 1 (s11 + s22 + s33 ) + 2 (s12 + s13 + s23 ) GR = 1 (4) 4 (s11 + s22 + s33 ) − 4 (s12 + s13 + s23 ) + 3 (s44 + s55 + s66 ) (3) The Voigt and Reuss averaging methods respectively assume that strains and stresses are continuous in polycrystal and present the upper and lower bounds of the effective bulk and shear moduli for polycrystals. The Voigt–Reuss–Hill (VRH) approach combines the upper and lower bounds by assuming the average Voigt and Reuss elastic moduli to be a good approximation of the macroscopic elastic moduli: BVRH = 1 (BR + BV ) 2 (5) GVRH = 1 (GR + GV ) 2 (6) Young’s modulus E can be calculated using VRH’s shear and bulk modui: EVRH = 9GVRH BVRH 3BVRH + GVRH (7) Longitudinal and transversal sound velocities, l and s , are derived from the shear modulus GVRH and bulk modulus BVRH : l = s = BVRH + 4GVRH 3 G VRH (8) 1/2 (9) Z. Tian et al. / Journal of the European Ceramic Society 36 (2016) 189–202 Average sound velocity m is calculated as follows: m = 3(s l )3 2l 3 + s 3 1/3 (10) Using the average sound velocity m , the Debye temperature D is obtained as follows [9]: D = 1/3 h 3n NA M kB 4 m (11) where h is Planck’s constant, kB is the Boltzmann’s constant, n is the number of atoms in the primitive cell, NA is Avogadro’s number, is the density, and M is the molecular weight. Based on the elastic constants obtained, the directional dependence of Young’s modulus (for monoclinic crystals) in 3D representation can be calculated by Nye [20]: t/L. The internal friction Q−1 corresponding to the flexural vibration mode was calculated as Q−1 = k/ff , where k is the exponential decay parameter of the amplitude of the flexural vibration component. The bulk moduli of X2-RE2 SiO5 were evaluated from the relationship between E and G, B= GE 3 (3G − E) 2.2. Material preparation Bulk X2-RE2 SiO5 samples were prepared by using a two-step processing method. First, pure X2-RE2 SiO5 powders were synthesized from a 1:1 molar ratio of commercially available powders of RE2 O3 (Rear-Chem. Hi-Tech. Co., Ltd., Huizhou, China) and SiO2 (Sinopharm Chemical Reagent Co., Ltd., Shanghai, China). The powders were mixed by wet ball milling for 24 h in a Si3 N4 jar, and the slip obtained was dried at 60 ◦ C for 24 h, and then passed through a 120 mesh sieve to obtain the desired powders. The powder mixture was thermally treated at 1550 ◦ C for 1 h to synthesize pure X2-RE2 SiO5 powders. Dense X2-RE2 SiO5 ceramics were obtained through hot pressing using pure X2-RE2 SiO5 powders. Hot pressing was performed at 1600 ◦ C at a heating rate of 10 ◦ C/min for 1 h under 30 MPa in a flowing Ar atmosphere. The densities of the as-synthesized samples were determined by using the Archimedes method, and the phase compositions of the samples were identified using an X-ray diffractometer (XRD) with CuK␣ radiation (D/max-2400, Rigaku, Tokyo, Japan). Microstructures were observed with a SUPRA 55 scanning electron microscope (LEO, Oberkochen, Germany) and grain size distributions were analyzed using Image-Pro Plus software. 2.3. Mechanical properties The dynamic Young’s modulus and internal friction of the samples were evaluated through an impulse excitation technique using samples with dimensions of 3 mm × 15 mm × 40 mm. The samples were measured in a graphite furnace RFDA-HTVP-1750-C (IMCE, Diepenbeek, Belgium) at a heating rate of 4 ◦ C/min in an Ar atmosphere. Vibration signals captured by a laser vibrometer were analyzed by a resonance frequency and damping analyzer, and Young’s modulus was calculated from the flexural resonant frequency, ff , according to ASTME 1876-97: E = 0.9465 mff w 2 L3 t3 T1 (13) where E is the dynamic elastic modulus in Pa, m is the mass of the specimen in kg, ff is the fundamental flexural resonant frequency in Hz, and w, L and t are the width, length and thickness, respectively, of the specimen in meters. T1 is a correction factor, that depends on the Poisson ratio v and the thickness/length ratio (14) Bending strength was measured in samples with dimensions of 3 mm × 4 mm × 36 mm, and all tests were performed in a universal testing machine (CMT4204, SANS, Shenzhen, China). The three-point bending method with a crosshead speed of 0.5 mm/min was applied, and three samples for each X2-RE2 SiO5 specimen were measured. Prior to testing, the surfaces of the samples were polished with diamond paste of 1.5 m to minimize machining flaws. Fracture toughness was measured using the single-edge 1 3 2 2 2 2 2 2 2 4 4 2 2 2 2 3 4 2 2 2 = l1 s11 + 2l1 l2 s12 + 2l1 l3 s13 + 2l1 l3 s15 + l2 s22 + 2l2 l3 s23 + 2l1 l2 l3 s25 + l3 s33 + 2l1 l3 s35 + l2 l3 s44 + 2l1 l2 l3 s46 + l1 l3 s55 + l1 l2 s66 E where sij are the elastic compliance coefficients that can be obtained through the inversion of the elastic constants (sij = cij −1 ) and l1 , l2 and l3 are the directional cosines to the x-, y- and z-axes, respectively. 191 (12) notched beam method from specimens with dimensions of 4 mm × 8 mm × 36 mm. Notches were introduced by diamondcoated wheel slotting. The thickness of the blade was 0.15 mm and the width of the notches was 0.2 mm. The saw depth was nearly half of the specimen height (8 mm). The specimens were fractured in a three-point bending test with a crosshead speed of 0.05 mm/min. 2.4. Thermal properties Thermal diffusivity was obtained using a laser flash analyzer (Netzsch LFA 457, Bavaria, Germany) in an Ar atmosphere from room temperature to 1273 K. Prior to the thermal diffusion test, the two sides of the samples were coated with a Ti adhesion layer through multi-arc ion plating to minimize thermal irradiation through the sample and achieve a thin colloidal graphite layer to ensure complete and uniform absorption of the laser pulses. Thermal expansion coefficients were obtained from temperaturedependent changes in the length of the specimens from room temperature to 1473 K in air as determined using a vertical hightemperature optical dilatometer (ODHT, Modena, Italy). Sample for this test measured 3 mm × 4 mm × 14 mm. 3. Results and discussion 3.1. Phase composition and microstructure The two-step synthesis method yielded X2-RE2 SiO5 samples with relative densities higher than 97%. Fig. 2 compares the standard XRD spectrum of Dy2 SiO5 (ICDD PDF No. 40-0289) with the experimental XRD patterns of X2-RE2 SiO5 and shows that single X2-RE2 SiO5 phases are generally formed. Minute amounts of impurities (RE2 O3 or RE2 Si2 O7 ) are detected in Dy2 SiO5 , Ho2 SiO5 , Tm2 SiO5 and Yb2 SiO5 because of the narrow X2-RE2 SiO5 phase region in the RE2 O3 -SiO2 system, and the diffraction peaks shift toward higher angles as the atomic radius of the RE element decreases. Fig. 3 shows the morphologies of X2-RE2 SiO5 samples obtained after thermal etching at 1300 ◦ C for 30 min; here, most grains are equiaxial. The average grain size of the X2-RE2 SiO5 samples is approximately 1 m, and their grain size distributions are listed in Table 1. 3.2. Room temperature mechanical properties The mechanical properties of the X2-RE2 SiO5 samples, including its elastic constant, Young’s modulus, shear modulus, bulk modulus, Poisson ratio, and flexural strength, are listed in Tables 2 and 3. 192 Z. Tian et al. / Journal of the European Ceramic Society 36 (2016) 189–202 icant anisotropy in the elastic moduli of the X2-RE2 SiO5 silicates is observed. The maximum and minimum Young’s moduli of the X2RE2 SiO5 samples are summarized in Table 4, and the ratio of the maximum to the minimum values is approximately 2. Planar mappings of the Young’s moduli of the samples on the (0 0 1), (0 1 0), and (1 0 0) atomic planes are also presented in Fig. 4 to provide more details on the variation in Young’s modulus. Mappings on the (0 1 0) and (0 0 1) atomic planes show strong anisotropic properties, whereas those on the (1 0 0) atomic plane display relatively weak anisotropy. To quantify the anisotropic elastic stiffness, we used the anisotropy index AU [24], which is defined by: AU = 5 GV BV + −6 GR BR (15) For an isotropic system, AU is identically equal to zero and the deviation from zero reflects the degree of anisotropy. In addition, the anisotropy of the bulk and shear moduli can be obtained from Voigt and Reuss approximations. The indices are defined as follows [25]: AB = BV − BR BV + BR (16) AG = GV − GR GV + GR (17) Fig. 2. XRD patterns of prepared X2-RE2 SiO5 . Elastic constants (cij ) were initially obtained by DFT calculations, and the results are shown in Table 2. The theoretical elastic moduli of the X2-RE2 SiO5 polycrystals are derived from the elastic constants obtained and compared with the experimental data in Table 3, thereby demonstrating that the theoretical Young’s and shear moduli match the experimental values very well. The calculated Young’s moduli of all of the X2-RE2 SiO5 polycrystals are less than 170 GPa; Lu2 SiO5 presented the highest Young’s modulus (169 GPa) while Tb2 SiO5 presented the lowest (146 GPa). A similar trend may be observed in terms of shear moduli. Except for the Young’s modulus of Yb2 SiO5 and the flexural strength of Ho2 SiO5 , the elastic moduli and flexural strengths of the samples typically increase with decreasing atomic radii of the RE elements. Yb-containing materials have been reported to exhibit abnormal properties [21]; for example, the density, melting and boiling points of Yb differ from those of other lanthanides. This finding may be attributed to the closed-shell electron configuration of Yb ([Xe] 4f14 6s2 ), which provides only two 6s valance electrons available for chemical bonding. By contrast, three valence electrons are available in most of the other lanthanides. The abnormal flexural strength of Ho2 SiO5 may be attributed to the strong anisotropy of elastic stiffness, as discussed in the following section. The elastic moduli and flexural strengths of the X2-RE2 SiO5 samples demonstrate a clear dependence on the atomic number of the RE element. This finding may be explained by enhancements in RE O bonding strength with decreasing ionic radius of the RE species. Wu et al. [8] found electronegativity and RE O bonding strength enhancements with increasing RE3+ radius in RE9.33 (SiO4 )6 O2 silicate oxyapatites. The cation field strength (CFS) can be used to represent bond strengths in RE silicates [22,23]. Hampshire proposed that the CFS can be calculated using the equation: CFS = Zc /rc 2 , where Zc is the cationic charge and rc is the cationic radius. The ionic radius of lanthanides decreases with increasing of atomic number because of lanthanide contraction. Using the ionic radius of RE3+ , the calculated CFS values of the X2-RE2 SiO5 samples are also listed in Table 3; the values obtained suggest strengthening of RE O bonding in X2RE2 SiO5 with the decrease of ionic radii of RE elements. The directional dependence of the Young’s moduli of the X2RE2 SiO5 samples was calculated using Eq. (12) and the results are plotted in Fig. 4. This figure demonstrates the variation of elastic modulus along different crystallographic directions. Signif- For isotropic structures, the Voigt and Reuss approximations must have the same values of B or G. The AB and AG must be zero, and deviations from zero indicate anisotropy. The anisotropy indices AU , AB , and AG of X2-RE2 SiO5 are calculated and shown in Table 5. For AU , Ho2 SiO5 and Y2 SiO5 respectively possess the greatest and least anisotropy indices. The values of AB of Ho2 SiO5 and Y2 SiO5 are similar in magnitude, whereas the AG of Ho2 SiO5 is more than twice that of Y2 SiO5 . Therefore, the large anisotropy of the elastic stiffness of Ho2 SiO5 mainly comes from the significant anisotropy of its shear modulus. 3.3. Temperature-dependent Young’s modulus and internal friction During the start-up or shut-down operation of turbine followed by oxidation or corrosion of the substrates, cracks may form and coating may spall off as a result of severe thermal cycling. Thus, the temperature dependence of elastic stiffness and the BDTT of coating materials need to be determined [26]. Temperature-dependent Young’s modulus and internal friction of the samples were measured by using the resonant frequency method, and the BDTT and Debye temperature were derived from the experimental data obtained. Fig. 5 shows the temperature-dependent Young’s moduli and internal friction of the X2-RE2 SiO5 samples. The Young’s moduli decrease nearly linearly from room temperature to relatively high temperatures and then rapidly dropped at certain critical temperatures; these phenomena are accompanied by exponential increases in internal friction. The X2-RE2 SiO5 samples also maintain over 80% of their room-temperature Young’s moduli at 1500–1800 K, thereby demonstrating excellent retention of the high-temperature Young’s moduli. The Young’s modulus could not be measured at higher temperatures, because the noise observed under this condition is too high to resolve the resonance frequency of the samples. Internal friction, which is also referred to as the mechanical loss spectrum, can be used to determine the BDTT. Internal friction of X2-RE2 SiO5 orthosilicates maintain low magnitudes from room temperature to at least 1400 K and abruptly increase thereafter. Exponential increases in internal friction are accompanied by decreases in Young’s moduli at high temperatures, thus accounting for the so-called “brittle-to-ductile” transition in ceramic materials Z. Tian et al. / Journal of the European Ceramic Society 36 (2016) 189–202 193 Fig. 3. Surface morphologies of X2-RE2 SiO5 after thermal etching at 1300 ◦ C for 30 min. Table 1 Average grain size and grain size distributions of X2-RE2 SiO5 (in m). Average grain size 2–1.5 1.5–1 1–0.5 0.5–0 Tb2 SiO5 Dy2 SiO5 Ho2 SiO5 Er2 SiO5 Tm2 SiO5 Yb2 SiO5 Lu2 SiO5 Y2 SiO5 0.73 6.5% 19.4% 41.9% 32.2% 0.77 6.7% 16.7% 56.6% 20.0% 0.76 6.9% 13.8% 51.7% 27.6% 0.98 10.5% 36.8% 31.6% 21.1% 0.84 4.0% 20.0% 56.0% 20.0% 1.02 16.7% 27.8% 44.4% 11.1% 0.51 1.6% 3.3% 42.6% 52.5% 0.74 3.1% 18.8% 40.6% 37.5% Table 2 Elastic constants of X2-RE2 SiO5 (in GPa). Tb2 SiO5 Dy2 SiO5 Ho2 SiO5 Er2 SiO5 Tm2 SiO5 Yb2 SiO5 Lu2 SiO5 Y2 SiO5 C11 C12 C13 211 215 220 225 225 223 240 224 51 54 58 61 66 55 67 92 80 81 83 84 78 102 86 55 C15 17 16 15 14 8 16 9 5 C22 C23 C25 C33 C35 C44 C46 C55 C66 169 179 190 201 214 185 221 208 37 40 44 47 49 49 49 29 −16 −16 −30 −17 −20 −18 −20 0 181 184 185 188 179 202 194 154 −18 −20 −24 −26 −20 −21 −35 0 43 45 47 49 52 46 52 47 10 10 11 11 10 15 11 10 75 76 76 77 72 83 81 64 57 62 63 65 67 62 71 65 194 Z. Tian et al. / Journal of the European Ceramic Society 36 (2016) 189–202 Fig. 4. Directional Young’s moduli of X2-RE2 SiO5 in: 3-D scenario, (1 0 0), (0 1 0), and (0 0 1) atomic plane. Z. Tian et al. / Journal of the European Ceramic Society 36 (2016) 189–202 195 Table 3 Young’s modulus E (GPa), bulk modulus B (GPa), shear modulus G (GPa), Poisson’s ratio , flexural strength f (MPa), Debye temperature D (K) and CFS (Å−2 ) of X2-RE2 SiO5 . Method Tb2 SiO5 Dy2 SiO5 Ho2 SiO5 Er2 SiO5 Tm2 SiO5 Yb2 SiO5 Lu2 SiO5 Y2 SiO5 Calc. Expt. Calc. Expt. Calc. Expt. Calc. Expt. Calc. Expt. Calc. Expt. Calc. Expt. Calc. Expt. B G E BV BR BH GV GR GH 100 86 103 92 107 86 111 93 112 99 114 94 118 105 104 86 96 98 61 59 63 62 65 61 66 64 67 67 66 65 71 70 62 65 55 58 99 101 107 108 109 101 104 109 110 111.5 111 114.5 97 100.5 58 146 144 152 151 153 148 159 157 161 163 158 158 169 172 152 155 60.5 58 61.5 60 63 62 64.5 58 62 64 67.5 59 60.5 f 155 ± 5 153 ± 3 236 ± 10 156 ± 4 200 ± 5 207 ± 20 214 ± 19 177 ± 3 D CFS 0.251 0.229 0.250 0.225 0.254 0.214 0.256 0.219 0.255 0.225 0.264 0.221 0.253 0.226 0.248 0.200 416 416 419 422 418 416 423 425 424 430 413 418 426 433 513 528 3.52 3.61 3.70 3.79 3.87 3.98 4.047 3.704 Table 4 Maximum Young’s modulus (Emax ), minimum Young’s modulus (Emin ) and the ratio of Emax /Emin of X2-RE2 SiO5 . Emax (GPa) Emin (GPa) Emax /Emin Tb2 SiO5 Dy2 SiO5 Ho2 SiO5 Er2 SiO5 Tm2 SiO5 Yb2 SiO5 Lu2 SiO5 Y2 SiO5 216 108 2.00 217 113 1.92 221 114 1.94 220 121 1.82 207 127 1.63 221 111 1.99 229 123 1.86 183 113 1.62 Table 5 Anisotropy indices AU , AG and AB of X2-RE2 SiO5 . U A AB AG Tb2 SiO5 Dy2 SiO5 Ho2 SiO5 Er2 SiO5 Tm2 SiO5 Yb2 SiO5 Lu2 SiO5 Y2 SiO5 0.587 0.020 0.052 0.558 0.020 0.049 0.663 0.029 0.057 0.537 0.018 0.048 0.360 0.018 0.031 0.639 0.022 0.056 0.610 0.031 0.052 0.326 0.035 0.025 Fig. 5. Temperature-dependent Young’s moduli and internal friction of X2-RE2 SiO5 . [27]. Kardashev [28] suggested that exponential increases in internal friction correspond to the BDTT. The BDTT can be determined by linear fitting of the internal friction data at various temperature ranges. As indicated in Fig. 5, the BDTTs of X2-RE2 SiO5 are determined using the method proposed by Kardashev [28], and the results are shown in Fig. 6. The BDTTs of X2-RE2 SiO5 generally decrease with decreasing ionic radius of the RE elements. The BDTTs of Tb2 SiO5 , Dy2 SiO5 , Ho2 SiO5 and Er2 SiO5 , for example, are between 1600 and 1700 K. By contrast, other X2-RE2 SiO5 samples with smaller RE elements possess lower BDTTs ranging from 1480 K to 1570 K. The largest difference between the values obtained is approximately 180 K. Damping mechanisms are positive factors for Fig. 6. Brittle-to-ductile transition temperatures of X2-RE2 SiO5 as a function of RE ionic radius. improving toughness in hard and brittle materials and illustrate the ability of a material to dissipate part of the vibrational energy locally, thereby improving toughness by crack blunting. Sufficient strain tolerance, which can extend the life of ETBC coatings, can be obtained at temperatures above the BDTT. Brittle-to-ductile transition is usually associated with the changing of fracture modes. In brittle fractures, cracks typically propagate by cleavage along specific crystallographic atomic planes or along weak grain boundaries that are embrittled by impurity 196 Z. Tian et al. / Journal of the European Ceramic Society 36 (2016) 189–202 Fig. 7. Fracture morphologies of Yb2 SiO5 after flexural strength tests at (a) room temperature, (b) 1473 K, and (c) 1573 K. segregation. For example, Fig. 7 shows the fracture surfaces of Yb2 SiO5 (BDTT = 1519 K) after testing of its flexural strength at room temperature, 1473 K, and 1573 K. While, transgranular fracture occurred at room temperature, as shown in Fig. 7(a), the fractures at 1473 K reflect a mixture of transgranular and intergranular modes, as shown in Fig. 7(b). At 1573 K, intergranular fractures are clearly observed, because the morphology of grains can be easily distinguished on fracture surface in Fig. 7(c). Schaller [27] suggested that brittle-to-ductile transition can be decomposed into two stages namely, brittle-to-tough transition and tough-to-ductile transition. As the cracks propagating along the grain boundary can dissipate more energy, fracture toughness must be enhanced at elevated temperatures. The fracture toughness of Yb2 SiO5 at 1573 K was measured to be 3.5 ± 0.3 MPa m1/2 , much higher than that at room temperature 2.0 ± 0.1 MPa m1/2 . Combining the current comprehensive information, the BDTT of Yb2 SiO5 was determined by the mechanical spectrum to be 1519 K. BDTT can provide reliable knowledge on the ductile performance of ductility of X2-RE2 SiO5 silicates and is helpful for aiding the selection of optimal ETBC candidates. Experimental Young’s moduli were used to deduce the experimental Debye temperatures of X2-RE2 SiO5 . Wachtman et al. [29] proposed an empirical formula describing the temperaturedependent Young’s modulus: E = E0 − F × T × exp −T 0 T l = s = min = 0.87kB E0 1 0 2 (1 + ) (20) where E0 is the fitted Young’s modulus at 0 K, 0 is the theoretical density, and is the experimental Poisson ratio. Thereafter, the Debye temperature can be obtained using Eqs. (19) and (20). The Debye temperatures of the X2-RE2 SiO5 samples (listed in Table 3) match those determined through DFT calculations well. In general, except for that of Y2 SiO5 , Debye temperatures change within 4% in magnitude and increase slightly with increasing RE atomic number. 3.4. Minimum thermal conductivity Thermal conductivity is one of the key indices used to determine the feasibility of integrated ETBC materials. The thermal conductivity of insulation materials can generally be divided into two (21) 1 2 + 2 −3/2 + 1 2 + 3 − 6 3 + 2 −3/2 2/3 1/6 E 1/2 2/3 n M 2/3 × kB NA −1/3 (22) where v is Poisson ratio. Cahill et al. [31] calculated the min using a model of random walks among localized quantum mechanical oscillators and formulized min as follows: min (19) nNA 1 2 3 = (18) E0 (1 − ) 0 (1 + ) (1 − 2) M −2/3 E 1/2 where kB is the Boltzmann constant, NA is Avogadro’s constant, n is the number of atoms in the primitive cell, is the density, E is the Young’s modulus, and M is the molecular weight. To lower the min , large mass contrast, complicated structure, and small elastic stiffness are necessary. Liu et al. [30] modified Eq. (21) by introducing elastic anisotropy and calculated min from the crystal structural information and elastic parameters: min where E0 is the Young’s modulus at 0 K, T is absolute temperature, and F and T0 are fitting parameters. The temperature-dependent Young’s moduli of the X2-RE2 SiO5 samples are fitted by Eq. (18) (dash-dotted line in Fig. 5), and the fitted parameters are listed in Table 6. To calculate Debye temperatures, knowledge of the longitudinal l and transversal sound velocities s is necessary. These parameters can be obtained through the following relationship: regions from room temperature to high temperatures [9]: (1) thermal conductivity decreases with ∼1/T (T is temperature) because of anharmonic Umklapp phonon–phonon scattering; and (2) at high temperatures, thermal conductivity is independent of the temperature and approximates the minimum thermal conductivity ( min ). In most cases, min can be used as a qualitative material selection guideline for identifying low thermal conductivity ceramics. As suggested by Clarke, the phonon mean free path converges to the average interatomic distance at high temperature limits, and the average sound velocity m could be approximated as 0.87 E/ [9]. Hence, the min is calculated as follows: = 1/3 6 i kB n2/3 i T 2 i i 0 x 3 ex (ex − 1)2 dx (23) where n is the number density of atoms, i are the three speeds of sound (one longitudinal and two transverse), x is the distance that an atom is displaced from equilibrium, and i is the cutoff frequency for each polarization expressed in degrees using the following equation: i = i kB 1/3 62 n (24) where is the reduced Planck constant, kB is the Boltzmann constant, and n is the number density of atoms per unit volume. At extremely high temperatures, Eq. (23) can be simplified to: min = kB 2/3 n (2s + l ) 2.48 (25) The min of X2-RE2 SiO5 calculated by Eqs. (21), (22), and (25) are listed in Table 7. The min values of X2-RE2 SiO5 are very low in the vicinity of 1 W m−1 K−1 , thereby indicating their potential low Z. Tian et al. / Journal of the European Ceramic Society 36 (2016) 189–202 197 Table 6 Fitted parameters presented in Eq. (18) for X2-RE2 SiO5 . E0 F T0 Tb2 SiO5 Dy2 SiO5 Ho2 SiO5 Er2 SiO5 Tm2 SiO5 Yb2 SiO5 Lu2 SiO5 Y2 SiO5 143.72 0.02191 1359.75 151.88 0.02242 1408.22 147.60 0.01902 1070.57 155.70 0.01974 1061.82 160.78 0.02641 1387.69 157.99 0.02632 1596.06 171.31 0.01889 694.90 154.40 0.02094 1127.42 Table 7 Minimum thermal conductivities (W m−1 K−1 ) of X2-RE2 SiO5 . min (Clarke) min (Liu) min (Cahill) Tb2 SiO5 Dy2 SiO5 Ho2 SiO5 Er2 SiO5 Tm2 SiO5 Yb2 SiO5 Lu2 SiO5 Y2 SiO5 1.00 0.80 0.86 1.01 0.82 0.88 1.01 0.82 0.88 1.03 0.83 0.90 1.03 0.83 0.90 1.01 0.81 0.89 1.05 0.85 0.93 1.26 1.01 1.11 thermal conductivity. The min calculated using the three models demonstrates a dependence on the atomic number of the RE elements. In addition, the min values calculated using Clarke’s model are relatively high and the values calculated using other methods are close to each other. These phenomena may be explained by that fact that in Clarke’s model, all sound velocities are assumed to be pure modes even for systems with low symmetry. By contrast, in Liu’s and Cahill’s methods, minimum thermal conductivities are treated as the summation of three acoustic branches (one longitudinal mode and two transverse modes), which may make them more suitable for predicting the min of anisotropic materials [32]. Horai and Simmons [33] found that the silicon-oxygen network functions as the propagating path of heat in many silicate minerals. Because they are located inside the silicon-oxygen network, metallic atoms act as traps that consume part of the vibration energy to excite the vibrational motion of metallic atoms. Effective phonon transportation varies inversely with the mass of the metallic atoms. Because RE atoms possess large atomic masses and tend to capture large amounts of vibration energy, X2-RE2 SiO5 orthosilicates have very low min . Fig. 8. Temperature-dependent thermal diffusivities of X2-RE2 SiO5 . 3.5. Temperature-dependent thermal conductivity The above predictions of min indicate that X2-RE2 SiO5 orthosilicates are promising low-thermal conductivity materials. In this section, experimental thermal conductivities are measured at various temperatures and compared with the calculated ones. The temperature dependence of thermal conductivity provides crucial information for thermal transport throughout the specified temperature range. Thermal conductivity is experimentally determined from the measurements of thermal diffusivity a, heat capacity Cp , and density using the following equation: = aCp (26) Fig. 8 shows the temperature-dependent experimental thermal diffusivities of the X2-RE2 SiO5 samples. The thermal diffusivities of X2-RE2 SiO5 generally decrease with the increasing temperature, and the values are enhanced at high temperatures because of thermal radiation contributions. In terms of the constituent binary oxides (RE2 O3 and SiO2 ), the isobaric heat capacities CP of X2-RE2 SiO5 are determined from literature data [34] through the Neumann–Kopp rule, which may reliably reproduce the heat capacity of complex ternary oxides, such as RE9.33 (SiO4 )6 O2 [8], yttria-stabilized zirconia [35], and rare earth zirconates [36], with errors typically within ±3% compared with precise experimental measurements [36]. Fig. 9 plots the heat capacities of X2-RE2 SiO5 and shows that silicates with smaller molecular weights tend to present lower heat capacities. The experimental densities of X2RE2 SiO5 where the RE is Tb, Dy, Ho, Er, Tm, Yb, Lu, and Y are 6.35, 6.49, 6.56, 6.73, 6.90, 7.10, 7.24, and 4.22 g/cm3 , respectively. Fig. 9. Heat capacities of X2-RE2 SiO5 . The experimental thermal conductivities of X2-RE2 SiO5 are calculated using Eq. (26), and results are shown in Fig. 10. The experimental values range from 1.87 W m−1 K−1 to 3.48 W m−1 K−1 at room temperature, which is roughly twofold difference among the different RE elements. At 1273 K, differences among experimental thermal conductivities decrease, and values range from 1.1 W m−1 K−1 to 1.6 W m−1 K−1 , except for Lu2 SiO5 , which is evidently affected by thermal radiation [37]. Fig. 10 demonstrates that X2-RE2 SiO5 silicates have extremely low thermal conductivities, although the thermal conductivities vary irregularly with the RE 198 Z. Tian et al. / Journal of the European Ceramic Society 36 (2016) 189–202 Fig. 10. Experimental, theoretical and minimum lattice thermal conductivities of X2-RE2 SiO5 . Z. Tian et al. / Journal of the European Ceramic Society 36 (2016) 189–202 199 Table 8 Theoretical parameters for calculating intrinsic lattice thermal conductivities of X2-RE2 SiO5 using Slack’s model. T is absolute temperature in Kelvin. Tb2 SiO5 Dy2 SiO5 Ho2 SiO5 Er2 SiO5 Tm2 SiO5 Yb2 SiO5 Lu2 SiO5 Y2 SiO5 s (m/s) l (m/s) m (m/s) 3015 3028 3006 3027 3035 2941 3008 3641 5229 5248 5237 5287 5289 5190 5228 6290 3348 3362 3339 3363 3371 3270 3341 4041 1.50 1.50 1.52 1.53 1.52 1.57 1.50 1.49 species. Multiple phonon scattering mechanisms among the experimental samples may explain this phenomenon. According to the Debye model, lattice thermal diffusivity a is defined as [38,39]: 1 a = m 3 (27) where m is the average sound velocity and is the phonon mean free path. As m is nearly temperature independent, a is determined by the variation of at different temperatures. The phonon mean free path can be divided into several independent parts as follows [39–41]: 1 1 = + phonon 1 defect + 1 boundary + 1 i (28) i where phonon , defect , boundary , and i are the phonon mean free paths corresponding to anharmonic Umklapp phonon scattering, defect scattering, grain boundary scattering and other mechanisms, respectively. The values of defect , boundary and i are nearly temperature independent [42–44]; thus, the temperature dependence of phonon mean free path is dominated by the behavior of phonon at elevated temperatures, and phonon can be used to describe the intrinsic lattice thermal resistance throughout the whole temperature range. defect , boundary , and i relate to extrinsic effects and may be influenced by different microstructures and defect concentrations at low temperatures. Thermal radiation effects at high temperatures also contribute to the rise in thermal conductivity. So it can be concluded that thermal conductivities of X2-RE2 SiO5 were affected by different phonon scattering mechanisms in different temperature ranges which blocks the insight of intrinsic lattice thermal conductivities.With the help of reliable theoretical models, such as Slack’s model, the intrinsic lattice thermal conductivity can be predicted at different temperatures, which is necessary to eliminate extrinsic uncertainties from experimental thermal conductivity. For a typical perfect insulation ceramic, heat is conducted primarily by acoustic phonons because their group velocities are much larger than those of optical phonons. At temperatures above the Debye temperature, the interactions among acoustic phonons themselves are influenced by anharmonic Umklapp processes; thus, the relationship between intrinsic lattice thermal conductivity and temperature T may be well described by ∼1/T . Under these approximations, Slack derived the following expression for the intrinsic lattice thermal conductivity [45]: =A M̄ı 3 1/3 a n 2T (29) where A = 3.04 × 10−7 W mol kg−1 m−2 K−3 , M̄ is the mean atomic mass, ı3 is the average volume per atom, n is the number of atoms per primitive cell, a is the acoustic-mode Debye temperature, T is the absolute temperature, and is the high temperature limit of the acoustic phonon Grüneisen parameter. Typically, when considering new materials with complex crystal structures, phonon dispersion relationships cannot be used to determine a . Alternatively, the acoustic-mode Debye temperature ı (Å) n M (g) 2.40 2.39 2.38 2.37 2.37 2.36 2.33 2.35 32 32 32 32 32 32 32 32 53.250 54.125 54.719 55.313 55.719 56.75 57.25 35.75 lattice (W m−1 K−1 ) 1222/T 1273/T 1239/T 1274/T 1309/T 1158/T 1362/T 1533/T a is generally calculated from the “traditional” definition of the Debye temperature D using a = D n−1/3 . Thus, Eq. (29) can be rewritten to the common form as: =A 3 D 2 n2/3 T M̄ı (30) This expression emphasizes that ceramics with low Debye temperatures, strong anharmonicity and high complexity tend to have low thermal conductivities. Thus, our next goal is to calculate all of the material parameters in Eq. (30) precisely using first-principles calculations. Approximate formulations to calculate the Grüneisen paramdetermined from thermal eter , include the thermodynamic expansion coefficient, bulk modulus, molar volume and specific volumetric heat capacity [46], mode-specific calculated from the volume dependence of phonon frequency [46], and acoustic obtained from the longitudinal and transversal sound velocities [47–49]. In this study, we calculated the acoustic to depict anharmonic scattering among acoustic phonons. The acoustic is rooted in the original definition of the Grüneisen parameter, = −∂lnω/∂lnV, and formulized by equalizing the vibration energy of acoustic phonon to the energy of elastic wave propagation in a continuum approximation of polycrystals. Based on this approximation, the anharmonicity parameter was directly related to the pressure of thermal motion of phonon collection, which could be further expressed in terms of bulk modulus, density and velocity of elastic wave propagation [49]. Previous investigations have shown that acoustic Grüneisen parameter can be reliably calculated as follows [47–49]: = 1+ 3 = 2 9 l 2 − 43 s 2 2 l 2 − 2s 2 2 − 3 (31) where l and s are longitudinal and transversal sound velocities, respectively, and is the Poisson ratio. Using Slack’s model, the chemical composition, crystal structure, and elastic parameters of ceramics can be quantitatively related to their lattice thermal conductivity, and the results may provide guidelines on how to reduce intrinsic lattice thermal conductivity efficiently by tailoring chemical composition and crystal structure. Table 8 summarizes all of the theoretical parameters used to calculate the intrinsic lattice thermal conductivities of X2-RE2 SiO5 using Eq. (30). The theoretical lattice thermal conductivities lattice of X2-RE2 SiO5 are plotted in Fig. 10 and show decreases with the RE atomic number. lattice also varies with temperature T (in K) from 1526/T (Y2 SiO5 ) to 1158/T (Yb2 SiO5 ). However, the experimental results notably deviate from the theoretical data at both low and high temperatures, likely because heat conduction is only depicted by Umklapp scattering among acoustic phonons in the theoretical prediction. X2-RE2 SiO5 ceramics were fabricated by hot pressing, which introduces a considerable amount of defects and impurities to the result material. The phonon mean free paths evidently decrease by extrinsic scattering of defects, leading to lower thermal conductivities at low temperature range. 200 Z. Tian et al. / Journal of the European Ceramic Society 36 (2016) 189–202 Fig. 11. Thermal expansion coefficients of X2-RE2 SiO5 at different temperatures. At high temperatures, phonon scattering of native defects which exerts a weak effect on the measured thermal conductivities, is temperature-independent. However, thermal irradiation apparently enhances thermal transportation and dominates abnormal enhancements in the experimental thermal conductivities. We compare the parameters presented in Slack’s model to understand the origins of the different thermal conductivities of X2-RE2 SiO5 . X2-RE2 SiO5 species have the same number of atoms per primitive unit cell n, and similar average volumes of one atom in the primitive unit cell ı3 and Grüneisen parameter . However, Y2 SiO5 shows notably different magnitudes of Debye temperature D and mean atomic mass M. The M D 3 of Yb2 SiO5 is approximately 85% of that of Y2 SiO5 . This deviation leads to a significant difference in thermal conductivity, as thermal conductivity is proportional to D 3 , as shown in Eq. (30). The lower Debye temperature of Yb2 SiO5 leads to its smaller theoretical lattice thermal conductivity in comparison with that of Y2 SiO5 . is also relevant when evaluating the intrinsic low thermal conductivity. The is often referred to as a temperature-dependent anharmonicity parameter that reflects the deviation of phonon vibrations in a crystal lattice from harmonic oscillations. Anharmonicity of lattice vibrations drives the phonon–phonon Umklapp and normal processes that limit the latvalues of tice thermal conductivity. The Grüneisen parameter X2-RE2 SiO5 are calculated to be 1.50–1.54, which indicates a high degree of anharmonicity in the materials. Beyond the value of M D 3 , Yb2 SiO5 and Y2 SiO5 possess the largest and smallest Grüneisen parameters , respectively, which also contribute to their extreme low and relatively high theoretical lattice thermal conductivities. 3.6. Thermal expansion The thermal expansion coefficients (TECs) of polycrystalline X2-RE2 SiO5 measured by an optical dilatometer are illustrated in Fig. 11. The lengths of the X2-RE2 SiO5 samples expand with increasing temperature up to 1473 K. Because the as-sintered samples have no preferred orientation (Fig. 4), isotropic thermal expansion of the X2-RE2 SiO5 bulk materials is observed. The TECs are determined as a function of temperature during the heating process in terms of the slopes of thermal expansions and are found to approximately range from 6.94 × 10−6 K−1 to 8.84 × 10−6 K−1 at 1473 K. The TECs of RE silicates are only slightly modified by the RE3+ ionic radius but strongly depend on the crystal structures of different polymorphs. This finding can be explained by considering the two types of bonds present in the RE silicate structure, namely Si O and RE O bonds. Previous investigations indicate that the mean coefficient of thermal expansion of the [SiO4 ] tetrahedron is about ∼0 K−1 [50]. Therefore, X2-RE2 SiO5 mainly expand within the [REO6/7 ] polyhedron chains. Hazen and Prewitt [51] further found that the TECs of different polymorphs may be mainly determined by the charge and coordination of RE cations. X2-RE2 SiO5 orthosilicates have the same charge and coordination of RE ions, and therefore, the TECs weakly depend on the RE elements. The TEC is an important parameter for the property evaluation of ETBC materials. TEC mismatch between the substrate and ETBC presents a dominant effect on the performance of an RE orthosilicate and may result in coating cracking, and spalling because of high thermal stress. The TECs of X2-RE2 SiO5 samples are higher than those of SiC and SiC/SiC CMC (4.5–5.5 × 10−6 K−1 ) [5]. Two possible solutions can balance this TEC mismatch: addition of a gradient transition layer and enhancement of the porosity of the X2-RE2 SiO5 layer. The porosity of ceramic coatings produced via the plasma spray method typically ranges from 3% to 20% [52]. Pores provide spaces for expansion, which lowers the TECs of X2-RE2 SiO5 and residual stresses [53]. In addition, RE disilicates always form at the interface between silicon-based ceramic and X2-RE2 SiO5 coatings because of the presence of SiO2 , which can release thermal stress [54]. 3.7. Thermal shock resistance Rapid heating and cooling result in thermal stresses that can lead to damage or catastrophic failure of ceramics. The TSR of a material changes with its flexural strength, elastic modulus, Poisson ratio, and thermal expansion coefficient. Therefore, keeping these parameters at optimal levels and carefully identifying their relationship with each other are important [52]. The TSR parameters available in literature are “so-called figures of merit” that can facilitate the ranking and selection of materials for engineering designs involving thermal stress fracture. Kingery defined TSR parameters as [55]: R= f (1 − ) E˛ (32) where f is the flexural strength, is the Poisson ratio, E is Young’s modulus and ˛ is the thermal expansion coefficient. The thermal stress fracture resistance parameter represents the reliability of a material under significant thermal stress. If the stress exceeds the strength of a material, fracture will occur. Using the measured thermal and mechanical properties, the TSR parameters of X2-RE2 SiO5 are obtained and listed in Table 9, together with the values of Al2 O3 and SiC [56] for comparison. Among the samples surveyed, Ho2 SiO5 exhibits the best TSR at 165 K, which is even higher than that of the engineering ceramic Al2 O3 (150 K). Such a high TSR may be attributed to the excellent flexural strength of Ho2 SiO5 . In summary, the mechanical and thermal properties of X2RE2 SiO5 are systematically investigated by a combination of DFT calculations and experimental evaluations. The main experimental mechanical and thermal properties of X2-RE2 SiO5 are plotted in a radar chart for comparison, as shown in Fig. 12. The radar chart facilities easy comparison of all of the attributes of interest and provides overview information. The mechanical and thermal properties of X2-RE2 SiO5 are normalized with the highest values among these silicates. Therefore, every attribute is scaled between 0 and 1 for comparison. The mechanical and thermal properties are summarized into two groups. Young’s modulus, flexural strength, and TSR show correlations with the contraction of RE elements, while thermal conductivity, thermal expansion, and BDTT depend weakly on the RE atomic number. Therefore, mechanical and thermal properties based on the radar chart can easily be balanced during material selection for optimal designs of X2-RE2 SiO5 for ETBC materials. Z. Tian et al. / Journal of the European Ceramic Society 36 (2016) 189–202 201 Table 9 Thermal shock resistance parameters of X2-RE2 SiO5 with some engineering ceramics for comparison. Tb2 SiO5 Dy2 SiO5 Ho2 SiO5 Er2 SiO5 Tm2 SiO5 Yb2 SiO5 Lu2 SiO5 Y2 SiO5 Al2 O3 SiC 92 102 165 99 117 134 132 119 150 300 Fig. 12. Radar chart for comparison of the properties, including Young’s modulus, flexural strength, BDTT, thermal conductivity at 300 K, thermal expansion at 1473 K and thermal shock resistance of X2-RE2 SiO5 . Every attribute is normalized by the highest values among all silicates and is scaled between 0 and 1. 4. Conclusion Dense and pure X2-RE2 SiO5 ceramics are successfully synthesized using a two steps involving hot pressing sintering. The mechanical properties of the samples, including their Young’s modulus, shear modulus, bulk modulus, Poisson ratio, and Debye temperature, are studied through a combination of DFT calculations and experimental investigations. The calculated values are in agreement with the experimental results. The elastic moduli (B, G and E) of X2-RE2 SiO5 increase from Tb2 SiO5 to Lu2 SiO5 because of contraction of the RE3+ ionic radius. X2-RE2 SiO5 orthosilicates exhibit anisotropic Young’s moduli. The brittle-to-ductile transitions and Debye temperatures are derived from the temperature dependence of internal friction and Young’s modulus. In contrast to the mechanical properties, thermal properties show weak relationships with the RE element. X2-RE2 SiO5 silicates exhibit very low thermal conductivity; in fact, the thermal expansion coefficients of the samples are approximately 6.94–8.84 × 10−6 K−1 at 1473 K. Thermal shock resistance parameters are obtained based on the measured properties, and Ho2 SiO5 is determined to present the best TSR. The present work sheds light on the potential use of X2-RE2 SiO5 orthosilicates as advanced ETBC candidates and provides guidelines for the selection or optimization of X2-RE2 SiO5 as an ETBC material. Acknowledgment This work was supported by the Natural Science Foundation of China under Grant nos. 51032006 and 51372252. References [1] M.K. Cinibulk, G. Thomas, S.M. Johnson, Strength and creep behavior of rare-earth disilicate-silicon nitride ceramics, J. Am. Ceram. Soc. 75 (1992) 2050–2055. [2] Z.L. Hong, L.F. Cheng, L.T. Zhang, Y.G. Wang, Water vapor corrosion behavior of scandium silicates at 1400 ◦ C, J. Am. Ceram. Soc. 92 (2009) 193–196. [3] Y.C. Zhou, C. Zhao, F. Wang, Y.J. Sun, L.Y. Zheng, X.H. Wang, Theoretical prediction and experimental investigation on the thermal and mechanical properties of bulk -Yb2 Si2 O7 , J. Am. Ceram. Soc. 96 (2013) 3891–3900. [4] J. Xu, V.K. Sarin, S. Dixit, S.N. Basu, Stability of interfaces in hybrid EBC/TBC coatings for Si-based ceramics in corrosive environments, Int. J. Refract. Met. Hard Mater. 49 (2015) 339–349. [5] K.N. Lee, D.S. Fox, N.P. Bansal, Rare earth silicate environmental barrier coatings for SiC/SiC composites and Si3 N4 ceramics, J. Eur. Ceram. Soc. 25 (2005) 1705–1715. [6] C.M. Heveran, J. Xu, V.K. Sarin, S.N. Basu, Simulation of stresses in TBC–EBC coating systems for ceramic components in gas turbines, Surf. Coat. Technol. 235 (2013) 354–360. [7] Z.Q. Sun, M.S. Li, Y.C. Zhou, Thermal properties of single-phase Y2 SiO5 , J. Eur. Ceram. Soc. 29 (2009) 551–557. [8] R. Wu, W. Pan, X.R. Ren, C.L. Wan, Z.X. Qu, A.B. Du, An extremely low thermal conduction ceramic: RE9.33 (SiO4 )6 O2 silicate oxyapatite, Acta Mater. 60 (2012) 5536–5544. [9] D.R. Clarke, Materials selection guidelines for low thermal conductivity thermal barrier coatings, Surf. Coat. Technol. 163–164 (2003) 67–74. [10] J.G. Wang, S.J. Tian, G.B. Li, F.H. Liao, X.P. Jing, Preparation and X-ray characterization of low-temperature phases of R2 SiO5 (R = rare earth elements), Mater. Res. Bull. 36 (2001) 1855–1861. [11] J. Felsche, The crystal chemistry of the rare-earth silicates Rare Earths, vol. 13, Springer, Berlin, Heidelberg, 1973, pp. 99–197. [12] G. Kresse, J. Furthmüller, Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set, Phys. Rev. B 54 (1996) 11169–11186. [13] G. Kresse, D. Joubert, From ultrasoft pseudopotentials to the projector augmented-wave method, Phys. Rev. B 59 (1999) 1758–1775. [14] J. Perdew, K. Burke, M. Ernzerhof, Generalized gradient approximation made simple, Phys. Rev. Lett. 77 (1996) 3865–3868. [15] J.D. Pack, H.J. Monkhorst, Special points for Brillouin-zone integrations—a reply, Phys. Rev. B 16 (1977) 1748–1749. [16] V. Milman, M.C. Warren, Elasticity of hexagonal BeO, J. Phys.: Condens. Matter 13 (2001) 241. [17] W. Voigt, Lehrbuch der kristallphysik, Taubner Leipzig, 1928. [18] A. Reuss, Berechnung del fliessgrenze von mischkristallen auf grund der plasti- zitatbedingung fur einkristalle, Z. Angew Math. Mech. 9 (1929) 49–58. [19] R. Hill, The elastic behavior of a crystalline aggregate, Proc. Phys. Soc. Lond. Sect. A 65 (1952) 349–354. [20] J.F. Nye, Physical Properties of Crystals: Their Representation by Tensors and Matrices, Clarendon Press, 1985. [21] Z. Lü, J. Zhou, Z.M. Sun, R.S. Chen, Effect of rare earth elements on the structures and mechanical properties of magnesium alloys, Chin. Sci. Bull. 58 (2013) 816–820. [22] P.F. Becher, S. Hampshire, M.J. Pomeroy, M.J. Hoffmann, M.J. Lance, R.L. Satet, An overview of the structure and properties of silicon-based oxynitride glasses, Int. J. Appl. Glass Sci. 2 (2011) 63–83. [23] H.J. Choi, H.G. Kim, J.G. Lee, Y.W. Kim, Refined continuum model on the behavior of intergranular films in silicon nitride ceramics, J. Am. Ceram. Soc. 83 (2000) 2821–2827. [24] S.I. Ranganathan, M. Ostoja-Starzewski, Universal elastic anisotropy index, Phys. Rev. Lett. 101 (2008) 055504. [25] J. Feng, B. Xiao, R. Zhou, W. Pan, D.R. Clarke, Anisotropic elastic and thermal properties of the double perovskite slab-rock salt layer Ln2 SrAl2 O7 (Ln = La, Nd Sm, Eu, Gd or Dy) natural superlattice structure, Acta Mater. 60 (2012) 3380–3392. [26] M. Eskner, R. Sandström, Measurement of the ductile-to-brittle transition temperature in a nickel aluminide coating by a miniaturised disc bending test technique, Surf. Coat. Technol. 165 (2003) 71–80. [27] R. Schaller, Mechanical spectroscopy of the high-temperature brittle-to-ductile transition in ceramics and cermets, J. Alloy. Compd. 310 (2000) 7–15. [28] B.K. Kardashev, A.S. Nefagin, G.N. Ermolaev, M.V. Leont’eva-Smirnova, M.M. Potapenko, V.M. Chernov, Internal friction and brittle-ductile transition in structural materials, Tech. Phys. Lett. 32 (2006) 799–801. [29] J.B. Wachtman, W.E. Tefft, D.G. Lam, C.S. Apstein, Exponential temperature dependence of Young’s modulus for several oxides, Phys. Rev. 122 (1961) 1754–1759. [30] B. Liu, J.Y. Wang, F.Z. Li, Y.C. Zhou, Theoretical elastic stiffness, structural stability and thermal conductivity of La2 T2 O7 (T = Ge Ti, Sn, Zr, Hf) pyrochlore, Acta Mater. 58 (2010) 4369–4377. [31] D.G. Cahill, S.K. Watson, R.O. Pohl, Lower limit to the thermal conductivity of disordered crystals, Phys. Rev. B 46 (1992) 6131–6140. [32] J. Feng, B. Xiao, R. Zhou, W. Pan, Anisotropy in elasticity and thermal conductivity of monazite-type REPO4 (RE = La, Ce Nd, Sm, Eu and Gd) from first-principles calculations, Acta Mater. 61 (2013) 7364–7383. [33] K. Horai, G. Simmons, Thermal conductivity of rock-forming minerals, J. Geophys. Res. 76 (1971) 1278–1308. [34] I.I. Barin, Thermochemical Data of Pure Substances, VCH, New York, 2008. 202 Z. Tian et al. / Journal of the European Ceramic Society 36 (2016) 189–202 [35] A.M. Limarga, S. Shian, M. Baram, D.R. Clarke, Effect of high-temperature aging on the thermal conductivity of nanocrystalline tetragonal yttria-stabilized zirconia, Acta Mater. 60 (2012) 5417–5424. [36] J. Wu, X. Wei, N.P. Padture, P.G. Klemens, M. Gell, E. García, P. Miranzo, M.I. Osendi, Low-thermal-conductivity rare-earth zirconates for potential thermal-barrier-coating applications, J. Am. Ceram. Soc. 85 (2002) 3031–3035. [37] Z.L. Tian, L.C. Sun, J.M. Wang, J.Y. Wang, Theoretical prediction and experimental determination of the low lattice thermal conductivity of Lu2 SiO5 , J. Eur. Ceram. Soc. 35 (2015) 1923–1932. [38] R. Berman, The thermal conductivities of some dielectric solids at low temperatures (experimental), Proc. R. Soc. Lond. A: Math. Phys. Sci. 208 (1951) 90–108. [39] R.J. Bruls, H.T. Hintzen, R. Metselaar, A new estimation method for the intrinsic thermal conductivity of nonmetallic compounds: a case study for MgSiN2 , AlN and -Si3 N4 ceramics, J. Eur. Ceram. Soc. 25 (2005) 767–779. [40] F.R. Charvat, W.D. Kingery, Thermal conductivity: XIII effect of microstructure on conductivity of single-phase ceramics, J. Am. Ceram. Soc. 40 (1957) 306–315. [41] K. Watari, K. Ishizaki, F. Tsuchiya, Phonon scattering and thermal conduction mechanisms of sintered aluminium nitride ceramics, J. Mater. Sci. 28 (1993) 3709–3714. [42] M. Roufosse, P.G. Klemens, Thermal conductivity of complex dielectric crystals, Phys. Rev. B 7 (1973) 5379–5386. [43] P.G. Klemens, Thermal resistance due to point defects at high temperatures, Phys. Rev. 119 (1960) 507–509. [44] V. Ambegaokar, Thermal resistance due to isotopes at high temperatures, Phys. Rev. 114 (1959) 488–489. [45] G.A. Slack, Nonmetallic crystals with high thermal conductivity, J. Phys. Chem. Solids 34 (1973) 321–335. [46] B. Liao, S. Lee, K. Esfarjani, G. Chen, First-principles study of thermal transport in FeSb2 , Phys. Rev. B 89 (2014) 035108. [47] H.A. Badehian, H. Salehi, M. Ghoohestani, First-principles study of elastic structural, electronic, thermodynamical, and optical properties of yttria (Y2 O3 ) ceramic in cubic phase, J. Am. Ceram. Soc. 96 (2013) 1832–1840. [48] Y.L. Pei, J. He, J.F. Li, F. Li, Q. Liu, W. Pan, C. Barreteau, D. Berardan, N. Dragoe, L.D. Zhao, High thermoelectric performance of oxyselenides: intrinsically low thermal conductivity of Ca-doped BiCuSeO, NPG Asia Mater. 5 (2013) e47. [49] D.S. Sanditov, A.A. Mashanov, B.D. Sanditov, S.S. Sangadiev, Anharmonism of lattice vibrations and of acoustic wave propagation velocity in quasi-isotropic solids, Tech. Phys. 56 (2011) 632–636. [50] A.J. Fernández-Carrión, M. Allix, A.I. Becerro, Thermal expansion of rare-earth pyrosilicates, J. Am. Ceram. Soc. 96 (2013) 2298–2305. [51] R.M. Hazen, C.T. Prewitt, Effects of temperature and pressure on interatomic distances in oxygen-based minerals, Am. Miner. 62 (1977) 309–315. [52] A.C. Karaoglanli, K. Ogawa, A. Türk, I. Ozdemir, Progress in Gas Turbine Performance, InTech, 2013. [53] F.A. Costa Oliveira, J. Cruz Fernandes, Mechanical and thermal behaviour of cordierite–zirconia composites, Ceram. Int. 28 (2002) 79–91. [54] D.L. Poerschke, D.D. Hass, S. Eustis, G.G.E. Seward, J.S. Van Sluytman, C.G. Levi, Stability and CMAS resistance of ytterbium-silicate/hafnate EBCs/TBC for SiC composites, J. Am. Ceram. Soc. 98 (2015) 278–286. [55] W.D. Kingery, Factors affecting thermal stress resistance of ceramic materials, J. Am. Ceram. Soc. 38 (1955) 3–15. [56] M.F. Ashby, D.R.H. Jones, Engineering Materials 2, fourth ed., Butterworth-Heinemann, Boston, 2013, pp. 299–312.