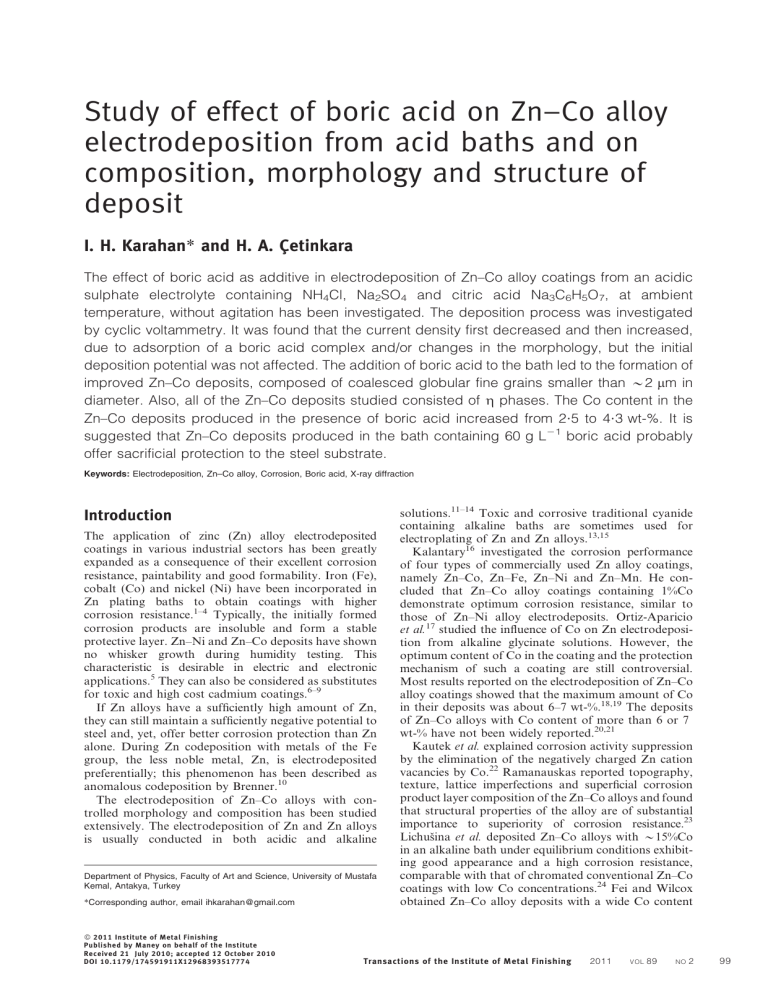

Study of effect of boric acid on Zn–Co alloy electrodeposition from acid baths and on composition, morphology and structure of deposit I. H. Karahan* and H. A. Çetinkara The effect of boric acid as additive in electrodeposition of Zn–Co alloy coatings from an acidic sulphate electrolyte containing NH4Cl, Na2SO4 and citric acid Na3C6H5O7, at ambient temperature, without agitation has been investigated. The deposition process was investigated by cyclic voltammetry. It was found that the current density first decreased and then increased, due to adsorption of a boric acid complex and/or changes in the morphology, but the initial deposition potential was not affected. The addition of boric acid to the bath led to the formation of improved Zn–Co deposits, composed of coalesced globular fine grains smaller than y2 mm in diameter. Also, all of the Zn–Co deposits studied consisted of g phases. The Co content in the Zn–Co deposits produced in the presence of boric acid increased from 2?5 to 4?3 wt-%. It is suggested that Zn–Co deposits produced in the bath containing 60 g L21 boric acid probably offer sacrificial protection to the steel substrate. Keywords: Electrodeposition, Zn–Co alloy, Corrosion, Boric acid, X-ray diffraction Introduction The application of zinc (Zn) alloy electrodeposited coatings in various industrial sectors has been greatly expanded as a consequence of their excellent corrosion resistance, paintability and good formability. Iron (Fe), cobalt (Co) and nickel (Ni) have been incorporated in Zn plating baths to obtain coatings with higher corrosion resistance.1–4 Typically, the initially formed corrosion products are insoluble and form a stable protective layer. Zn–Ni and Zn–Co deposits have shown no whisker growth during humidity testing. This characteristic is desirable in electric and electronic applications.5 They can also be considered as substitutes for toxic and high cost cadmium coatings.6–9 If Zn alloys have a sufficiently high amount of Zn, they can still maintain a sufficiently negative potential to steel and, yet, offer better corrosion protection than Zn alone. During Zn codeposition with metals of the Fe group, the less noble metal, Zn, is electrodeposited preferentially; this phenomenon has been described as anomalous codeposition by Brenner.10 The electrodeposition of Zn–Co alloys with controlled morphology and composition has been studied extensively. The electrodeposition of Zn and Zn alloys is usually conducted in both acidic and alkaline Department of Physics, Faculty of Art and Science, University of Mustafa Kemal, Antakya, Turkey *Corresponding author, email [email protected] ß 2011 Institute of Metal Finishing Published by Maney on behalf of the Institute Received 21 July 2010; accepted 12 October 2010 DOI 10.1179/174591911X12968393517774 solutions.11–14 Toxic and corrosive traditional cyanide containing alkaline baths are sometimes used for electroplating of Zn and Zn alloys.13,15 Kalantary16 investigated the corrosion performance of four types of commercially used Zn alloy coatings, namely Zn–Co, Zn–Fe, Zn–Ni and Zn–Mn. He concluded that Zn–Co alloy coatings containing 1%Co demonstrate optimum corrosion resistance, similar to those of Zn–Ni alloy electrodeposits. Ortiz-Aparicio et al.17 studied the influence of Co on Zn electrodeposition from alkaline glycinate solutions. However, the optimum content of Co in the coating and the protection mechanism of such a coating are still controversial. Most results reported on the electrodeposition of Zn–Co alloy coatings showed that the maximum amount of Co in their deposits was about 6–7 wt-%.18,19 The deposits of Zn–Co alloys with Co content of more than 6 or 7 wt-% have not been widely reported.20,21 Kautek et al. explained corrosion activity suppression by the elimination of the negatively charged Zn cation vacancies by Co.22 Ramanauskas reported topography, texture, lattice imperfections and superficial corrosion product layer composition of the Zn–Co alloys and found that structural properties of the alloy are of substantial importance to superiority of corrosion resistance.23 Lichušina et al. deposited Zn–Co alloys with y15%Co in an alkaline bath under equilibrium conditions exhibiting good appearance and a high corrosion resistance, comparable with that of chromated conventional Zn–Co coatings with low Co concentrations.24 Fei and Wilcox obtained Zn–Co alloy deposits with a wide Co content Transactions of the Institute of Metal Finishing 2011 VOL 89 NO 2 99 Karahan and Çetinkara Study of effect of boric acid on Zn–Co electrodeposition range of 10–90%.25 The use of additives in electrodeposition baths is vital due to their influence on the growth and structure of the deposits obtained.26–29 Generally, additives are added to a bath at very low concentrations; their presence in the electrolyte promotes the formation of smooth and shiny coatings. The specific activity of an additive is generally understood in terms of its absorption onto the cathode surface during electrodeposition. Additive molecules adsorbed on the cathode surface can affect the activation energy30 and the rate of charge transfer in the elecftrochemical reaction, and may also influence the mechanism of electrocrystallisation.31,32 In the authors’ previous study investigating the relation of corrosion properties with gelatin as additive in Zn–Fe alloys,33 the results indicated strong evidence of an increase in corrosion potential with addition of gelatin to the electrolyte. Mouanga et al.28 studied the influence of coumarin on Zn–Co alloy obtained from a sulphate bath. They found that well structured Zn–Co alloys with a finer grain size were obtained in the presence of coumarin and this additive affected the reduction of Zn, but it had no effect on the reduction of Co. They also noticed that the presence of coumarin in the electrolyte resulted in structural refinement of alloy deposits and increase in cathodic current efficiency. Barbosa and Carlos34 used sorbitol for electrodeposition of Zn–Fe as a complexing agent in an alkaline bath. They observed that it is useful for minimising the potential difference of Fe and Zn. Wu et al. introduced boric acid into an ammonia–citric acid plating bath of Ni–W alloys. They found that boric acid acted as a surfactant to impede the proton reduction.35 Heydari Gharahcheshmeh and Heydarzadeh Soh studied Zn–Co deposition from an alkaline bath in the presence of glycine. They showed that Co deposited at a potential near to that of Zn together with successful codeposition of Co and Zn. They also showed that reduction–oxidation reactions of Zn–Co alloy deposits were quasi-reversible and resulted in deviation of electrodeposited alloys from the equilibrium phase diagrams. The corrosion resistance of the deposits was also highly influenced by the composition and morphology of the coatings.36 In this paper, electrodeposition of Zn–Co alloys from a cyanide free alkaline bath in the presence of boric acid as a complexing agent was studied using the potentiostatic deposition method. Cyclic voltammetry was also used to study the codeposition of Zn and Co. Scanning electron microscopy, energy dispersive spectroscopy and X-ray diffraction (XRD) analyses of Zn–Co films were applied to determine the morphology, composition and structure of the coatings respectively. Finally, the corrosion resistance of electrodeposited Zn–Co alloy coatings has been investigated as a function of boric acid content in the electrolyte. Experimental Electrodeposition of Zn–Co alloys Zn12xCox alloys were prepared by electrodeposition under potentiostatic conditions on aluminium and AISI 4140 steel disc substrates from a sulphate plating bath at room temperature (Table 1). The chemical composition of the AISI 4140 steel is 0?36C–0?80Mn–0?005Si–0?914Cr– 100 Transactions of the Institute of Metal Finishing 2011 VOL 89 0?30Ni–0?85Mo–0?075V–0?07S–0?143Cu–0?034P (wt-%). The electrolytes were prepared using (18 MV cm) twice distilled water. The pH value of the bath was adjusted to y5 with hydrochloric acid and NaOH. The dimensions of the deposits were y1?561?5 cm. Before the deposition, the substrates are prepared in the standard industrial way: chemical then electrolytic degreasing in sodium hydroxide solution (40 g L21; 64?5uC) for 2 min followed by water wash, mechanically grinding with silicon carbide papers from 3 to 0?5 mm and velvet, chemical pickling and activation in an acid medium (hydrochloric acid, 30% v/v) for 10 s, rinsed with the twice distilled water and then dried in air. Thus, the wettability and therefore the reactivity of the cleaned substrate surface were at an optimum. After these preparation steps, the substrates were ready to be electrodeposited. The counter electrode was platinum. The reference electrode used in all experiments was a saturated calomel electrode. The quantitative composition analysis of the electrodeposits was determined using a JEOL 6400 scanning electron microscope with an energy dispersive spectrometer working at 15–30 kV. The compositions of the films were determined using energy dispersive spectroscopy. The preferred orientations of the deposits were determined by XRD analysis, using a Siemens D500 Xray diffractometer with Cu Ka radiation. The 2h range of 0–90u was recorded at a rate of 0?02u 2h/0?5 s. The crystal phases were identified by comparing the 2h values and intensities and the thickness of the deposits was determined by an X-ray fluorescence spectrometer (Canberra Ultra Low Energy Germanium Detector GUL0035). Electrochemical measurements The electrochemical behaviours of the electrodeposited Zn–Co alloys were analysed in 3 wt-% NaCl aqueous solution at room temperature in a Pyrex glass cell. As above, the counter electrode was platinum and the reference electrode used in the electrochemical experiments was a saturated calomel electrode. The corrosion behaviours of the samples were investigated by potentiodynamic polarisation technique. Polarisation measurements were performed with an electrochemical analyser/workstation (model 1100; CH Instruments, Inc., Austin, TX, USA) with a three electrode configuration. The exposed areas of the specimens were y1 cm2. The specimens were embedded in a cold setting resin and immersed into the solution until a steady open circuit potential was reached. After equilibration (45 min later), polarisation was started at a rate of 1 mV s21. Table 1 Solution compositions electrodeposition for Zn–Co Solution compositions Levels ZnSO4/M CoSO4/M C6H5Na3O7.2H2O/g L21 H3BO3/g L21 NH4Cl/g L21 Na2SO4/g L21 Solution pH Temperature/uC Deposition time/min Voltage/V 0.5 0.1 25 0, 20, 40, 60 and 80 45 0.5 5 Room temperature 10 23 NO 2 alloy Karahan and Çetinkara Study of effect of boric acid on Zn–Co electrodeposition 2 Effect of H3BO3 on Co content of Zn–Co alloy electrodeposits in electrolyte at room temperature 1 Cyclic voltammograms for different H3BO3 values Cyclic voltammetry was carried out using a proprietary system (model 1100; CH Instruments, Inc.), a conventional three electrode cell with a steel plate as the working electrode, platinum as the counter electrode and saturated calomel as reference electrode at a sweep rate of 10 mV s21. The solution was deaerated by bubbling argon gas for at least 45 min before each measurement. The temperature of the cell was kept at room temperature; the pH values of solutions were adjusted using a digital pH meter (¡0?1 accuracy). Results and discussion Figure 1 shows voltammetric curves for Zn–Co deposition from plating baths with various boric acid concentrations. In solutions, during the forward scan towards the negative direction, the cathodic current increased sharply when the deposition began. As can be seen, the deposition current density (CD) first decreased and then increased as boric acid was added to the bath. Comparing CD at the peak potential around 21?5 V, in the absence and presence of 40 g L21 boric acid, it can be seen that in the latter case, CD was reduced by y48%. It has been reported that boric acid, polyalcohols and mannitol react in the molar ratio 1 : 2 respectively, to form a boric–polyalcohol complex,37–39 so that the presence of boric acid in the solution hindered the diffusion of Zn2z and Co2z ions. The voltammograms suggest that initial codeposition of Zn and Co occurs on limiting current at around 21?11 V and does not change in any of the baths studied, implying that no complex was formed between Zn or Co ions and the boric anion. All the voltammograms show a gradual increase in the anodic current which results in the formation of ‘humps’ on the anodic peaks. These ‘humps’ are considered as the results of the dissolution of Co and Zn, which form on the surface of the deposit during the cathodic scan. Only at the cyclic voltammogram obtained from the electrolyte containing 60 g L21 boric acid, was Co dissolution not observed. Addition of boric acid in the electrolyte caused an increase in both deposition and dissolution CD. Figure 2 shows the effect of H3BO3 concentration on the Co content of Zn–Co alloy deposits. The additive presence in the electrolyte is an important factor affecting film composition. The Co concentration in deposits depends on the electrodeposition CD, bath pH and addition of boric acid. The additive changes the formation mechanism of the film and thereby the film composition. At the boric acid concentration of 20 g L21 the Co concentration of the film decreased suddenly from 3?1 to 2?5%. Then Co content increased gradually from 2?5% to the maximum 4?3% with increasing H3BO3 concentration from 20 to 60 g L21 and decreased to 3?6% thereafter. It should be pointed out that higher concentration H3BO3 (.60 g L21) tended to raise the solution viscosity and then to impede the mass transportation of the metallic ions.35 Figure 3 shows XRD patterns of the electrodeposited Zn–Co alloys deposited at different boric acid concentrations, varying from 0 to 80 g L21. The XRD analysis showed that the films are polycrystalline in structure. The XRD patterns of the deposits, whether from the solution with boric acid or not, exhibit a preferred orientation along the (101), (102), (103), (110) and (112) planes. In Fig. 3, with increasing value of the boric acid in the electrolyte from 20 to 80 g L21, the intensity of (101) preferred orientation was decreased, which led to the decrease in corrosion resistance of the alloys. It can be seen from the figure that increasing the boric acid content decreased the (101) peaks. As the boric acid value decreases the signals belonging to the g phase become less intense. Figure 4a–c shows the surface morphologies of Zn– Co alloy deposits obtained from the plating bath containing different concentrations of boric acid. 3 X-ray diffraction pattern obtained from Zn–Co coating from electrolyte containing 0, 20, 40, 60 and 80 g L21 boric acid Transactions of the Institute of Metal Finishing 2011 VOL 89 NO 2 101 Karahan and Çetinkara Study of effect of boric acid on Zn–Co electrodeposition a 40 g L21; b 60 g L21; c 80 g L21 4 Scanning electron microscopy images of Zn–Co films electrodeposited at different boric acid contents in electrolyte According to Fig. 4a and b, with the increase in boric acid content in the bath from 40 to 60 g L21, the grain size becomes more crystalline. However, further increase in the boric acid content from 60 to 80 g L21 has a reverse effect and causes finer grains (Fig. 4c). This can stem from the increase in CD as a result of boric acid increasing, due to the rise in the overpotential free energy for formation of new nuclei in Zn–Co alloy deposits that leads to higher nucleation rate, and hence formation of coatings with smaller grain size.14 Figure 5 shows the results corresponding to the influence of addition of 20, 40, 60 and 80 g L21 boric acid on the corrosion resistance of electrodeposited Zn– Co alloy from a sulphate bath in a 3 wt-% NaCl aqueous solution. Two stages of passivation are observed in Zn– Co alloy coatings. This can be an indication of the formation of protective film in two stages. When Zn–Co alloy is corroded, Zn begins to dissolve preferentially according to equations (1)–(4)26,40 corroded coatings and create areas in which CD is independent of potential. The presence of Co in the coating enhances dissolution of Zn in NaCl solution. Consequently, the increase in Zn dissolution causes its reaction with chloride ions in NaCl solution and formation of zinc hydroxy chloride according to equation (5)26,42 5Zn2z z8OH{ z2Cl{ zH2 O?Zn5 OH8 Cl2 :H2 O (5) Zinc hydroxy chloride has a very low product of solubility, and ensures higher protective ability for Zn– Co alloy coatings.41,42 It is noticed that the alloy coating from a bath containing 60 g L21 boric acid has the highest corrosion resistance among all coatings. While Zn–Co alloy coating from a plating bath containing 80 g L21 boric acid has the lowest corrosion resistance compared with other alloy coatings. An increase in boric acid content in the electrolyte up to 60 g L21 led to the formation of the best Zn–Co deposits, composed of coalesced globular fine grains smaller than y2 mm in diameter and Zn–Co alloys presenting a lower degree of corrosion. ZnðsÞ?Zn2z ðaqÞz2e{ (1) O2 ðgÞz2H2 OðlÞz4e{ ?4OH{ ðaqÞ (2) Zn2z ðaqÞz2OH{ ðaqÞ?ZnðOHÞ2 ðsÞ (3) Conclusions ZnðOHÞ2 ðsÞ?ZnOðsÞzH2 O (4) Compact and bright Zn–Co binary alloys were electrodeposited satisfactorily on steel sheet from baths containing cobalt sulphate, zinc sulphate, sodium sulphate, sodium citrate and boric acid (pH55). The effects of boric acid concentration on cathodic polarisation, composition and structure of the deposited alloys were investigated. The composition of the deposits is strongly dependent upon the added boric acid content. The Co content in the film increases with increasing boric acid content in the bath up to a limiting level (60 g L21), but decreases with the further increase in boric acid. These alloy deposits can be used for sacrificial protection of steels from corrosion. The deposited alloys formed from the currently studied bath consisted of a single solid solution phase with a hexagonal structure irrespective of the composition of the alloys. Thus, the protective films have complex compositions including Zn(OH)2 and ZnO that cover the surfaces of the References 5 Influence of boric acid concentration on corrosion properties of Zn–Co: AISI 4140 steel in 3 wt-% NaCl aqueous solution; BF, boric acid free bath 102 Transactions of the Institute of Metal Finishing 2011 VOL 89 1. İ. H. Karahan: J. Mater. Sci., 2007, 42, 10160. 2. S. M. Rashwan, A. E. Mohamed, S. M. Abd El-Wahaab and M. M. Kamel: J. Appl. Electrochem., 2003, 33, 1035. 3. J. B. Bajat, M. D. Maksimovic, V. B. Miskovic-Stankovic and S. Zec: J. Appl. Electrochem., 2001, 31, 355. 4. İ. H. Karahan, O. Karabulut and Ü. Alver: Phys. Scr., 2009, 79, 5. NO 2 Karahan and Çetinkara 5. N. Zaki: ‘Corrosion potentials of zinc alloys’, www.pfonline.com/ articles/039902.html. 6. C. R. Tomachuk, C. M. A. Freire, M. Ballester, R. Fratesi and G. Roventi: Surf. Coat. Technol., 1999, 122, 6. 7. M. M. Abou-Krisha, H. M. Rageh and E. A. Matter: Surf. Coat. Technol., 2008, 202, 3739. 8. E. M. K. Hillier and M. J. Robinson: Corros. Sci., 2006, 48, 1019. 9. M. M. Abou-Krisha and A. M. Abushoffa: Int. J. Electrochem. Sci., 2007, 2, 418. 10. A. Brenner: ‘Electrodeposition of alloys’, Vol. 2, 194; 1963, New York, Academic Press. 11. R. Ramanauskas, L. Muleshkova, L. Maldonado and P. Dobrovolskis: Corros. Sci., 1998, 40, 401. 12. C. J. Lan, W. Y. Liu, S. T. Ke and T. S. Chin: Surf. Coat. Technol., 2006, 201, 3103. 13. M. G. Hosseini, H. Ashassi-Sorkhabi and H. A. Y. Ghiasvand: Surf. Coat. Technol., 2008, 202, 2897. 14. R. Ramanauskas, L. Gudaviciute and R. Juskenas: Chemija, 2008, 19, 7. 15. C. J. Lan, W. Y. Liu, S. T. Ke and T. S. Chin: Surf. Coat. Technol., 2006, 201, 3103. 16. M. Kalantary: Plat. Surf. Finish., 1994, 81, 80. 17. J. L. Ortiz-Aparicio, Y. Meas, G. Trejo, R. Ortega, T. W. Chapman, E. Chainet and P. Ozil: Electrochim. Acta, 2007, 52, 4742. 18. H. Yan, J. Downes, P. S. Boden and S. J. Harris: J. Electrochem. Soc., 1996, 143, 1577. 19. I. Kirilova and I. Ivanov: J. Appl. Electrochem., 1999, 29, 1133. 20. N. R. Short, A. Abibsi and J. K. Nennis: Trans. Inst. Met. Finish., 1989, 67, 73. 21. M. E. Bahrololoom, D. R. Gabe and G. D. Wilcox: J. Electrochem. Soc., 2003, 150, (3), C144. 22. W. Kautek, M. Sahre and W. Paatsch: Electrochim. Acta, 1994, 39, 1151–1157. 23. R. Ramanauskas: Appl. Surf. Sci., 1999, 153, 53–64. 24. S. Lichušina, A. Sudavičius, R. Juškenas, D. Bučinskiene and E. Juzeliunas: Trans. Inst. Met. Finish., 2008, 86, (3), 141–147. Study of effect of boric acid on Zn–Co electrodeposition 25. J.-Y. Fei and G. D. Wilcox: Electrochim. Acta, 2005, 50, 2693. 26. P. D. L. Neto, A. N. Correia, R. P. Colares and W. S. Araujo: J. Braz. Chem. Soc., 2007, 18, 1164. 27. M. Mouanga, L. Ricq, L. Ismaili, B. Refouvelet and P. Bercot: Surf. Coat. Technol., 2007, 201, 7143. 28. M. Mouanga, L. Ricq and P. Bercot: Surf. Coat. Technol., 2008, 202, 1645. 29. M. Mouanga, L. Ricq, G. Douglade, J. Douglade and P. Bercot: Surf. Coat. Technol., 2006, 201, 762. 30. D. J. MacKinnon and J. M. Brannen: J. Appl. Electrochem., 1982, 12, 21. 31. E. Michailova, M. Peykova, D. Stoychev and A. Milchev: J. Electroanal. Chem., 1994, 366, 195. 32. J. C. Ballesteros, P. Diaz-Arista, Y. Meas, R. Ortega and G. Trejo: Electrochim. Acta, 2006, 52, (11), 3686. 33. İ. H. Karahan, H. A. Çetinkara and H. S. Güder: Trans. Inst. Met. Finish., 2008, 86, (3), 157. 34. L. L. Barbosa and I. A. Carlos: Surf. Coat. Technol., 2006, 201, 1695. 35. Y. Wu, D. Chang, D. Kim and S.-C. Kwon: Surf. Coat. Technol., 2003,173, (2–3),259–264. 36. M. Heydari Gharahcheshmeh and M. Heydarzadeh Soh: J. Appl. Electrochem., 2010, 40, 1563–1570. 37. I. M. Kolthoff and J. J. Lingane: ‘Polarography’; 1952, New York, Interscience. 38. J. Bassett, R. C. Denney, G. H. Jeffery and J. Mendham: ‘Vogel’s textbook of inorganic quantitative analysis’, 4th edn; 1978, New York, Longman. 39. E. M. de Oliveira and I. A. Carlos: J. Appl. Electrochem., 2009, 39, 1849–1856. 40. K. M. S. Youssef, C. C. Koch and P. S. Fedkiw: Corros. Sci., 2004, 46, 51. 41. N. Boshkov, K. Petrov, S. Vitkova, S. Nemska and G. Raichevsky: Surf. Coat. Technol., 2002, 157, 171. 42. N. Boshkov, K. Petrov, D. Kovacheva, S. Vitkova and S. Nemska: Electrochim. Acta, 2005, 51, 77. Transactions of the Institute of Metal Finishing 2011 VOL 89 NO 2 103