pdfcoffee.com module-7-maintenance-practices-sub-module-717-aircraft-handling-and-storagepdf-pdf-free

реклама

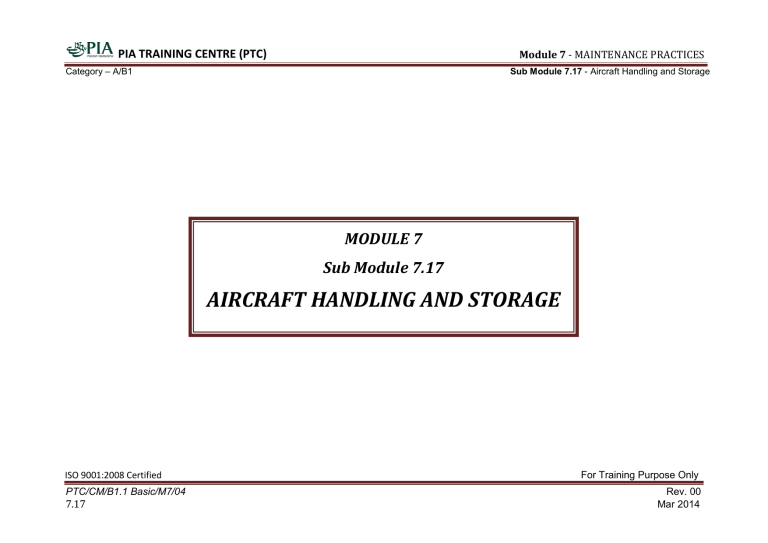

PIA TRAINING CENTRE (PTC) Module 7 - MAINTENANCE PRACTICES Category – A/B1 Sub Module 7.17 - Aircraft Handling and Storage MODULE 7 Sub Module 7.17 AIRCRAFT HANDLING AND STORAGE ISO 9001:2008 Certified PTC/CM/B1.1 Basic/M7/04 7.17 For Training Purpose Only Rev. 00 Mar 2014 PIA TRAINING CENTRE (PTC) Category – A/B1 Module 7 - MAINTENANCE PRACTICES Sub Module 7.17 - Aircraft Handling and Storage Contents AIRCRAFT HANDLING AND STORAGE .................................. 1 MOVING METHODS................................................................. 2 AIRCRAFT TOWING ................................................................ 2 AIRCRAFT TAXIING ................................................................. 2 PRECAUTIONS WHEN TOWING / TAXING AIRCRAFT .......... 3 AIRCRAFT JACKING................................................................ 4 JACKING PRECAUTIONS ........................................................ 7 PARKING AND MOORING AIRCRAFT .................................. 11 CHOCKING OF AIRCRAFT .................................................... 15 AIRCRAFT STORAGE............................................................ 16 AIRCRAFT FUELLING PROCEDURES .................................. 20 DEFUELLING ......................................................................... 22 DE-ICING/ANTI-ICING OF AIRCRAFT ................................... 23 GROUND ELECTRICAL SUPPLIES ....................................... 31 GROUND HYDRAULIC SUPPLIES ........................................ 33 GROUND PNEUMATIC SUPPLIES ........................................ 34 EFFECTS OF ENVIRONMENTAL CONDITIONS ON AIRCRAFT HANDLING AND OPERATION ............................ 35 ISO 9001:2008 Certified PTC/CM/B1.1 Basic/M7/04 7.17 - i For Training Purpose Only Rev. 00 Mar 2014 PIA TRAINING CENTRE (PTC) Category – A/B1 AIRCRAFT HANDLING AND STORAGE Aircraft need to be moved on the ground, between flights, for a variety of reasons, which can include: Moving aircraft into, or within hangars for maintenance Re-positioning aircraft for ground running or storm protection Emergency removal of aircraft from a taxi-way. It is important that the aircraft be moved safely, using the correct equipment, to avoid injury to personnel or damage to aircraft. Small aircraft, generally require little preparation but, with larger aircraft, some or all of the following points may be relevant: Preparation for the reception of the aircraft should be made in advance of its arrival. There should be adequate space available for the aircraft, with consideration given, as appropriate, to clearances for jacking, access for cranes etc. All equipment required for servicing should be available and serviceable. Module 7 - MAINTENANCE PRACTICES Sub Module 7.17 - Aircraft Handling and Storage The members of the moving team should be fully conversant with their assigned tasks. The person controlling the move should adequately brief them all, as to their individual responsibilities. This applies equally to the re-positioning a light aircraft in a hangar or to the moving of a giant airliner around a large, international airport. The equipment and method of move should be as stated in the relevant aircraft maintenance manual. All towing limitations should be observed. These should be stated in the maintenance manual under "Ground Handling". Examples of limitations include minimum turning radii and disconnection of nose-wheel steering system on certain aircraft. Clearance from the local Air Traffic Control may be required for the move. The aircraft should be in a satisfactory condition to move. The brakes should be serviceable and electrical power should be available, if required, for lights and indications in dark or poor light. The route of the proposed move should be free from obstructions, such as servicing platforms, passenger steps, vehicles and any other servicing equipment. Consideration should also be given to sources of F.O.D. along the route. ISO 9001:2008 Certified PTC/CM/B1.1 Basic/M7/04 7.17 - 1 For Training Purpose Only Rev. 00 Mar 2014 PIA TRAINING CENTRE (PTC) Category – A/B1 Module 7 - MAINTENANCE PRACTICES Sub Module 7.17 - Aircraft Handling and Storage MOVING METHODS AIRCRAFT TAXIING Normal moving methods of moving aircraft on the ground are by means of: When aircraft are to be moved under their own power, whether for ground movements or prior to flight, a fully certified flight crew must be on the flight deck and in command of the aircraft. It is usual for the aircraft to have received a daily inspection before the taxi operation, which ensures items such the oil and fuel levels and brake pressures are sufficient for the task. Hand: by pushing and using a steering arm Tractor: using a bridle and steering arm or with a purposemade towing arm Taxiing: moving the aircraft, using its own power. When an aircraft has to be moved from one place to another, either by man-handling, by the use of a tractor (also called a towing ‘tug’) or by taxiing, there are a number of safety precautions which have to be applied every time. AIRCRAFT TOWING This is the normal method used on large aircraft. The aircraft is normally towed with a suitable tractor (or tug) and using the correct, purpose-made towing arm for the specific aircraft. A person familiar with, and authorised to operate, the aircraft brake system should be seated in the cockpit (or on the flight deck) to apply the brakes in an emergency. The brakes should not normally be applied unless the aircraft is stationary. The relevant maintenance manual will normally specify details of the towing arm and any limitations on the towing procedure. On many aircraft with nose-wheel steering, it is normal practice to disconnect or depressurise the aircraft steering system before towing. ISO 9001:2008 Certified PTC/CM/B1.1 Basic/M7/04 7.17 - 2 It will be necessary for a ‘Starter Crew’ to be present before engine starting. This crew should include a supervisor (who will be in visual and/or verbal communication with the aircraft crew), a fireman with a suitable extinguisher and a tractor driver to pull any ground power unit clear after engine starting. Once the aircraft is moving under its own power, the flight crew has responsibility for the safety of the aircraft. The ground team should give assistance to the crew, via the intercom and/or standard marshalling hand signals (refer again to the ‘FlightLine Safety’ section of the earlier Safety Precautions topic), until the flight crew no longer require their services. When approaching its parking spot, providing it is not using the automatic parking indicating system, found on many parking stands, the pilot may be dependent upon the ground team for clearance indications and stopping cues. Once stopped, the aircraft wheels must be chocked, given ground power, if required, and generally taken control of, by the engineers, prior to its next maintenance procedure. For Training Purpose Only Rev. 00 Mar 2014 PIA TRAINING CENTRE (PTC) Category – A/B1 Module 7 - MAINTENANCE PRACTICES Sub Module 7.17 - Aircraft Handling and Storage PRECAUTIONS WHEN TOWING / TAXING AIRCRAFT Towing speed should be kept to a safe level at all times (walking pace is a safe limit). A steering limit is often imposed, so that the radii of turns are kept within specified limits, thus minimising tyre scrubbing and reducing the twisting loads on the undercarriage. It is usual to tow the aircraft forwards in a straight line after executing a turn, in order to relieve stresses built up in the turn. The steering limit is often shown by marks painted on the fixed part of the nose leg, but may, sometimes, be overcome by the disconnection of a pin, joining the torque links. Suitably briefed personnel should be positioned at the wing tips and tail when manoeuvring in or around confined spaces, so that obstructions may be avoided. Large, multi-engined aircraft will usually be towed with specialpurpose tug and a suitable towing arm that includes a shear pin, designed to shear if a pre-determined towing load is exceeded. In an emergency it may be necessary to move an aircraft from the runway if it has one or more deflated tyres. Provided there is one sound tyre on the axle the aircraft may be towed to the maintenance area, but sharp turns must be avoided and towing speed kept to a minimum. If there are no sound tyres on an axle, the aircraft should only be moved the shortest distance in order to clear an active runway and serviceable wheels should be provided before towing. After any tyre failure, the associated wheel and other wheels on the same axle should be inspected for signs of damage. One person shall be supervising the aircraft movement (NOT the tractor driver) and should be positioned so that all members of the team can be observed. Particular care should be given, when towing swept wing aircraft, to "wing tip growth". This is the tendency of the swept wing to "grow" in a turn and was discussed in ‘Flight-Line Safety’, which is contained in the early topic concerning Safety Precautions. Before commencing the towing operation, the brake system should be checked and the brake accumulator charged as necessary. Brake pressure should be carefully monitored during the move. ISO 9001:2008 Certified PTC/CM/B1.1 Basic/M7/04 7.17 - 3 For Training Purpose Only Rev. 00 Mar 2014 PIA TRAINING CENTRE (PTC) Module 7 - MAINTENANCE PRACTICES Category – A/B1 Sub Module 7.17 - Aircraft Handling and Storage AIRCRAFT JACKING Aircraft may need to be jacked for a variety of purposes. These may include component changes, retraction tests, weighing of the aircraft and aircraft rigging checks. Care needs to be taken when jacking, to avoid damage to aircraft or equipment. Jacking points are provided in the wings and fuselage, at strong points, to enable the whole aircraft to be lifted, and there are, usually, other points, at the nose and main undercarriages, to enable individual wheels to be changed (refer to Fig. 1). Some aircraft require a jacking pad to be fitted to each jacking point, while in some, the jacking pads are built into the structure. Special jacking adapters and beams may be available to lift individual axles. Nose Jacking Point (Offset) Main Jacking Points In all instances, the Maintenance Manual should be consulted, so that the correct equipment and procedures may be used. Special Considerations Because of the position of the jacking points, the C.G. of some aircraft may be well behind, or in front of, the main jacking points. It may be necessary to add ballast forward or rear of the jacking points or to check the fuel load of the aircraft, to bring the centre of gravity within safe limits as specified in the Maintenance Manual. ISO 9001:2008 Certified PTC/CM/B1.1 Basic/M7/04 7.17 - 4 Nose Jacking Point (Offset) Typical Jacking Points Fig.1 For Training Purpose Only Rev. 00 Mar 2014 PIA TRAINING CENTRE (PTC) Category – A/B1 Each jacking point may have a load limit which, if exceeded, could result in structural damage. To avoid exceeding this limit it may be necessary to install hydraulic or electric load cells. Any special requirements should be listed in the Maintenance Manual. Micro-switches, attached to the undercarriage legs, and operated by the extension of the shock absorbers (weight-on switches), are used to operate various electrical circuits, This operation may not be desirable, so circuits should be isolated, by tripping circuit breakers or removing fuses as necessary. Aircraft should always be as structurally complete as possible before jacking, It is essential that any stressed panels which have been removed are re-installed. Failure to do this may result in distortion or failure of the structure. Module 7 - MAINTENANCE PRACTICES Sub Module 7.17 - Aircraft Handling and Storage The Pillar hydraulic jack consists of a cylinder assembly, a fluid container and a hydraulic pump which, when operated, forces fluid from the container into the cylinder and raises the ram. A release valve is provided which, when opened, causes the fluid in the cylinder to return to the container and the ram to descend. Because of possible hydraulic failure, some jacks are provided with a mechanical locking collar which, when wound down, will prevent the jack from lowering. An air/filler valve, which vents the return side to atmosphere, may also be provided. This should always be open when the jack is operated. Bipod, Tripod and Quadrupod jacks are used, to raise an aircraft for various servicing operations. Their methods of operation and hydraulic mechanisms are similar to the pillar jack. They consist of a hydraulic unit, supported by the relevant number of legs (two, three or four). Aircraft jacks Aircraft jacks are intended for raising and lowering loads and should not be used for supporting the loads for long periods. Where a load must remain raised for a long period, it should be supported on blocks or trestles after it has been jacked to the required height. The most common types of aircraft jacks are the pillar, trolley, bipod, tripod and the quadrupod hydraulic jacks. There are several sizes of jacks, with capacities ranging from 4000 kg and greater. ISO 9001:2008 Certified PTC/CM/B1.1 Basic/M7/04 7.17 - 5 Because of the problems involved in raising an aircraft and to avoid injury to personnel or damage to the aircraft, care should be taken to use the correct type of jack as stated in the Maintenance Manual. Each jack should be used with the correct adapter head. The tripod jack comprises a hydraulic unit with three equally spaced legs. The jack is designed for a vertical lift only and not for a lift involving lateral movement of the jack (such as when raising one side of the aircraft for a wheel change). For Training Purpose Only Rev. 00 Mar 2014 PIA TRAINING CENTRE (PTC) Category – A/B1 The resulting side thrust may cause any one of the following: Serious damage to the ram, due to the bending load Distortion of the jack legs Damage to the aircraft, due to the .jack head slipping out of the jacking pad Shearing of the jacking pad fastener Dragging sideways of the serviceable tyre. To change a single wheel, a pillar jack may be used, while two tripod jacks may be used to raise the complete aircraft (or a bipod jack may be used). The bipod arrangement overcomes the limitations of the tripod jack for an 'arc' lift. On this type of jack, two fixed legs provide the support and a third, trailing leg, follows the lift and steadies the load during the lift. The maximum angle of arc should not be more than 6º. Module 7 - MAINTENANCE PRACTICES Sub Module 7.17 - Aircraft Handling and Storage Jack Maintenance and General Notes Aircraft jacks should always be positioned correctly and the load raised and lowered gradually. All jacks should be stored in the fully retracted position, kept clean and free from corrosion. Moving parts should be lubricated regularly and the jack should be exercised if it is not used frequently. Jack replenishment is usually through the air valve, up to the level of the bottom of the air valve. Low oil level is indicated by inability to lift to maximum height, whilst over-filling is indicated by leakage of oil when the jack is fully extended. The quadruped jack is used more commonly as it possesses the advantages of both types of jack. Two legs are fixed and two are adjustable. This jack may be used as a bipod jack, by removing the adjustable legs, or as an adjustable, stable jack with one extra leg added. All four legs may be locked solid, by slight adjustment of both adjustable legs. Transportation wheels are often permanently attached to some jacks while they may be provided as detachable units on other jacks. The wheels facilitate easy movement of the jacks that would otherwise need to be dragged around the hangar. Jacks, alternatively, can be dismantled for easier transportation. ISO 9001:2008 Certified PTC/CM/B1.1 Basic/M7/04 7.17 - 6 For Training Purpose Only Rev. 00 Mar 2014 PIA TRAINING CENTRE (PTC) Category – A/B1 Module 7 - MAINTENANCE PRACTICES Sub Module 7.17 - Aircraft Handling and Storage JACKING PRECAUTIONS As a safety precaution, small aircraft should normally be jacked inside a hangar. Larger aircraft may be jacked outside, provided they are positioned nose into wind; the jacking surface is level and strong enough to support the weight, and that any special instructions, stated in the Maintenance Manual, are observed. A maximum wind speed, stated for jacking outside, can also be found within the Maintenance Manual. The aircraft to be jacked should be chocked fore and aft and the brakes positioned to OFF (brakes released). If the brakes are inadvertently left in the ON position (brakes applied) stress could be introduced to the landing gear or to the aircraft structure, due to weight redistribution as the aircraft is raised. Checks should be made on the aircraft weight, its fuel state, and centre of gravity, to ensure they are within the specified limits as detailed in the Maintenance Manual. The aircraft should be headed into wind (if it is in the open), the main wheels chocked fore and aft, the brakes released and the undercarriage ground locks installed. It is vital that the earth cable be connect to the earth point on the aircraft and it must be ensured that there is adequate clearance above every part of the aircraft and that there is clearance for lifting cranes or other equipment, which may be required. Jacking pads should be attached to the jacking points and adapters provided for the jacks as required. Load cells may also be included if needed. Jacking Procedures While the following procedures will, generally, ensure safe and satisfactory jacking of most aircraft, precedence must always be given to the procedures and precautions specified in the relevant Maintenance Manual. The jacks should be positioned at each jacking point and checks made, to confirm that the jacks are adjusted correctly (i.e. release valve closed, jack body vertical, weight evenly distributed about the legs when the adapters are located centrally in the jacking pads, and the weight of the aircraft is just being taken by the jacks). One person should co-ordinate the operation and one person should control each jacking point. On larger aircraft a levelling station will also need to be monitored and all members of the team may need to be in radio or telephone communication with the co-ordinator. ISO 9001:2008 Certified PTC/CM/B1.1 Basic/M7/04 7.17 - 7 For Training Purpose Only Rev. 00 Mar 2014 PIA TRAINING CENTRE (PTC) Category – A/B1 Module 7 - MAINTENANCE PRACTICES Sub Module 7.17 - Aircraft Handling and Storage Before jacking commences, the chocks must be removed and then the aircraft should be raised slowly and as evenly as possible. Whilst jacking is in progress, the locking collars should be continually wound down, keeping them close to the body of the jack. When the aircraft is raised to the correct height, the locking collar should be fully tightened down. The ‘Universal’ trestle is made up from lengths of angle iron, bolts and nuts, and has two jacking heads. By using different lengths of angle iron, trestles of various sizes can be produced. The wooden beam across the jacking heads may be replaced by a wooden former, which is cut to the curvature of the component it supports. When jacking is complete, then supports may be placed under the wings and fuselage as indicated in the Maintenance manual. Padding is normally attached to the former, to prevent damage to the aircraft finish. The two jacking heads, which are handoperated screw jacks, enable the beam to be adjusted to suit the angle of the component. Note: As previously stated, a pillar (bottle) jack and an adapter are often used for raising a single undercarriage for changing a single wheel. Alternatively a trolley jack or stirrup jack may be used. The remaining wheels should be checked to prevent aircraft movement, and it may be specified that a tail support be located when raising a nose undercarriage. The jack should be raised only enough to lift the unserviceable wheel clear of the ground. Trestles These are provided to support to aircraft structures (main planes, fuselages etc.) and may also be used to support the complete aircraft. Various types are available including plain wooden trestles that are purpose-built and not adjustable. Trestles should only be used at designated strong parts of the structure. It will normally be shown in the Maintenance Manual where they should be positioned. Lines are often painted on the aircraft to show where the trestle beam is positioned. ISO 9001:2008 Certified PTC/CM/B1.1 Basic/M7/04 7.17 - 8 Although the trestles have ‘jacking heads’, they should only be used for supporting a load, and not for attempting to raise parts of the aircraft. Damage may be caused to the aircraft if attempts are made to do any more than support the structure. The ‘Tail’ trestle is not suitable for heavy loads and must only be used for supporting a load vertically. Adjustment in height is made by a screw thread. In the same manner as a universal trestle, the beam can be made in the same shape as the contour of the aircraft. For Training Purpose Only Rev. 00 Mar 2014 PIA TRAINING CENTRE (PTC) Module 7 - MAINTENANCE PRACTICES Category – A/B1 Sub Module 7.17 - Aircraft Handling and Storage Lowering Aircraft off Jacks Slinging Before lowering the aircraft to the ground, all equipment, trestles, work stands etc. should be moved clear of the aircraft, to prevent collision or contact with the aircraft structure. The wheels should be rotated by hand, to ensure the brakes are off. The jacks should be lowered together, by opening their respective release valves, and the locking collars (if used) unscrewed (but kept close to the jack body), whilst the jacks are lowered. The jacks should be fully lowered after the aircraft is resting on its wheels and the release valves then closed. Slings may be required for lifting various parts of an aircraft during maintenance, repair, dismantling and assembly. Sometimes a complete aircraft may need to be lifted for transportation or to clear a runway quickly. On no account should the top of the jacks be handled until the jack is clear of the aircraft. It is common for the aircraft shock absorbers to stick and to suddenly collapse, resulting in damage to equipment or serious injury to parts that might be between the aircraft and jack. After the aircraft is lowered and the jacks removed, the jacking pads and adapters should be removed and the chocks placed in position. Any fuses or circuit breakers should be re-set in their correct position. ISO 9001:2008 Certified PTC/CM/B1.1 Basic/M7/04 7.17 - 9 The use of the correct equipment for lifting aircraft parts will minimise the risk of damage to the aircraft and personnel. A list of special equipment is usually in the front of the Maintenance Manual. This list will usually include special slings to be used on the aircraft and any other special equipment or tools required. Slings may be of the three-point type, as used for lifting-main planes, while other types, used for lifting engines, fuselages or other large items may be provided with spreader bars or struts. Before removing a main plane, the opposite main plane must be supported with trestles. To attach a sling, some aircraft have special slinging points with threaded holes in the airframe, which are used to accommodate the eye or fork-end bolts of the sling. These holes are normally sealed, with removable plugs, when not in use. As an alternative to screw-in devices, some slings are used in conjunction with strong straps that pass under the component to be lifted. For Training Purpose Only Rev. 00 Mar 2014 PIA TRAINING CENTRE (PTC) Category – A/B1 Lifting Tackle The following is a list of safety precautions that must be used when using lifting tackle: Do not exceed the safe working load of the lifting devices Do not leave a suspended load unattended at any time Do not walk or work under a suspended load Do not tow the hoist at greater than walking pace Do not tow the hoist, other than by hand, when a load is suspended from the lifting hook Do not allow the load to swing, especially when it is being hand-towed Do not using a hoist or crane on soft ground Do not use a crane or hoist if the lifting tackle shows signs of damage. Wire rope, chain or fibre rope may be used for lifting purposes. Before use, the tackle should be inspected to ensure that it is serviceable, is of the correct type and, when used, that the Safe Working Load (SWL) is not exceeded. The SWL should be stated on an identification plate, attached to the lifting sling, and should never be removed from the sling. Wire Rope is used with cranes, hoists, gantries and various slings. Before use, the wire rope, splices and attachments should be inspected for damage such as wear, corrosion and broken wires. ISO 9001:2008 Certified PTC/CM/B1.1 Basic/M7/04 7.17 - 10 Module 7 - MAINTENANCE PRACTICES Sub Module 7.17 - Aircraft Handling and Storage In use, care should be taken that the rope does not kink under load. Before multiple leg wire rope slings are used, they should be laid out on the floor to ensure shackles are correctly attached and the fittings are not twisted. Knotting of ropes, to shorten them, is prohibited. Wire rope slings may be treated against corrosion by immersion in oil and the surplus oil wiped off, but this treatment must not be applied to slings used for oxygen cylinders. They must always be free from oil or grease. Chains are used with cranes and various types of sling. Before use, all chains must be inspected for damage such as cracks, distortion, excessive wear and ‘socketing’. Socketing is the name given to the grooves, produced in the ends of links, when the links wear against each other. Any reduction in diameter will render the chain unserviceable. Fibre rope slings may be used for lifting lighter components, and are made from natural fibres such as sisal, hemp or nylon fibres. They must be inspected for frayed strands, pulled splices, excessive wear and deterioration. When not in use, fibre rope slings should be hung on pegs, in a sheltered position, and free from dampness. Immediately before use, the rope should be opened up, by slightly untwisting the strands, to ensure they are not damaged or mildewed internally. For Training Purpose Only Rev. 00 Mar 2014 PIA TRAINING CENTRE (PTC) Category – A/B1 A damaged or mildewed fibre rope sling should not be used, and it must be destroyed, by cutting into small, unusable sections, before final disposal. In addition to before-use checks on the rope, all loaded components such as pulley blocks, shackles, pins, spreader bars and hooks are to be inspected for excessive wear, cracks and flaws. Moving parts must be lubricated periodically. PARKING AND MOORING AIRCRAFT When an aircraft is out of service and in the open it should be secured against inadvertent movement and protected against adverse weather conditions. The operations recommended in the relevant Maintenance Manual depend on the type of aircraft, the length of time it will be out of service and the prevailing or forecast weather conditions. Parking Between flights it is usually sufficient to apply the parking brakes, lock the control surfaces and chock the wheels but, in a strong wind, light aircraft should be headed into the wind. Light aircraft without wheel brakes should be headed into wind and their wheels chocked front and rear. Module 7 - MAINTENANCE PRACTICES Sub Module 7.17 - Aircraft Handling and Storage A more positive method entails the use of external control surface locks that prevent control surface movement and, thus, prevent strain on the control system. All external locks should have suitable streamers attached, to make them more visible. If an aircraft is to be parked overnight or for longer periods in the open, then additional precautions should be taken, to guard against the effects of adverse weather. The undercarriage ground locks should be fitted, and all openings, such as static vents, engine and cooling air intakes, should be blanked, to prevent ingress of dirt, birds, insects and moisture. Items such as pitot head and incidence indicators should also be covered. When severe weather is anticipated it is recommended that covers for cockpit, canopy and wheel are fitted if available. Blanks and covers should not be left in position when the aircraft is prepared for service. Servicing instructions should include a pre-flight check to ensure that all covers etc, are removed. Flying controls, on many aircraft, are locked by movement of a lever in the cockpit/cabin. The lever is connected to locking pins at convenient positions in the control runs or at the control surfaces. When this type of control lock is not provided, locking attachments may have to be fitted to the control column and rudder pedals. ISO 9001:2008 Certified PTC/CM/B1.1 Basic/M7/04 7.17 - 11 For Training Purpose Only Rev. 00 Mar 2014 PIA TRAINING CENTRE (PTC) Module 7 - MAINTENANCE PRACTICES Category – A/B1 Sub Module 7.17 - Aircraft Handling and Storage Mooring (Picketing) In certain weather conditions, particular in high winds, it would be recommended that the aircraft be parked in a hangar. If they must be left outside, then smaller aircraft may need to be tied down. The aircraft may be provided with picketing rings or attachment points at the wings and tail or adjacent to the undercarriage legs (refer to Fig. 2). A B C View A View B View C Aircraft Picketing Points ISO 9001:2008 Certified PTC/CM/B1.1 Basic/M7/04 7.17 - 12 For Training Purpose Only Rev. 00 Mar 2014 PIA TRAINING CENTRE (PTC) Category – A/B1 If outside, the aircraft should always be parked nose into wind and secured, from the picketing points to suitable ground anchor points such as heavy concrete blocks or specialised screw pickets. Cable or nylon rope of adequate strength should be used where possible but, if a natural fibre rope is used (sisal or hemp), then sufficient slack must be left to allow for shrinkage in damp conditions. Additional picketing from the undercarriage legs may be recommended in strong winds and, if so, care should be taken not to damage any pipelines or equipment attached to the legs or wheels. Typical Small Aircraft Procedures When mooring small aircraft in the open, the aircraft, if possible, should be parked head into the wind. The control surfaces should be secured with the internal control lock and the brakes applied. Care must, however, be exercised in extremely cold weather and parking brakes must not be set if there is a danger that accumulated moisture may freeze the brakes. Another danger, in cold weather, exists when the brakes are overheated, because, if they are set in this condition, serious distortion and cracking of the brake (and wheel) components can occur as they cool down. ISO 9001:2008 Certified PTC/CM/B1.1 Basic/M7/04 7.17 - 13 Module 7 - MAINTENANCE PRACTICES Sub Module 7.17 - Aircraft Handling and Storage Ropes, cables, or chains should be attached to the wing mooring (tie-down) points, and their opposite ends secured to ground anchors. A tie down rope (no chains or cables) should be fastened to the exposed portion of the engine mount and the opposite end of the rope also secured to a ground anchor. The middle of a rope should be attached to the tail tie-down ring and each end of the rope pulled, at a 45º angle, and secured to a ground tie-down point either side of the tail. A control lock should be applied to the pilot’s control column. If a control lock is not available, then the control may be tied back with a front seat belt. These aircraft are usually equipped with a spring-loaded steering system that affords protection against normal wind gusts. However, if extremely high winds are anticipated, additional external locks may be installed. Large Aircraft Procedures These may only require picketing in very strong wind conditions. The maximum wind-speed will normally be stated in the Maintenance Manual (including gusting winds). The aircraft should be headed into wind and the parking brakes applied. For Training Purpose Only Rev. 00 Mar 2014 PIA TRAINING CENTRE (PTC) Module 7 - MAINTENANCE PRACTICES Category – A/B1 Sub Module 7.17 - Aircraft Handling and Storage Cables or chains should be attached from the aircraft picketing points to prepared anchorages. In some instances the picketing cables are special components and include a tension meter that is used to apply a pre-load to the cable. If an aircraft is to be parked for a longer period, then additional precautions must be taken. Landing gear down-locks must be installed (if so equipped) and all openings such as static vents and engine intakes should be covered or blanked off (refer to Fig. 3) to prevent the ingress of dirt, birds, insects and all forms of precipitation. Intake Blank Pitot-Static Blanks Exhaust Blank Nose Wheel Covers Main Wheel Covers Typical Aircraft Blanks Fig. 3 ISO 9001:2008 Certified PTC/CM/B1.1 Basic/M7/04 7.17 - 14 For Training Purpose Only Rev. 00 Mar 2014 PIA TRAINING CENTRE (PTC) Category – A/B1 Module 7 - MAINTENANCE PRACTICES Sub Module 7.17 - Aircraft Handling and Storage CHOCKING OF AIRCRAFT When aircraft are parked, it is normal to place a chock ahead and behind at least one wheel set. The parking brakes are usually left in the ‘off’ position once chocks are in position, to allow the heat, generated by the brakes, to dissipate evenly. At high wind speeds, it is normal to chock all the wheels and apply the brakes (if they have cooled). Some aircraft chocks can be chained together, to give a more secure hold. During ground runs (and especially those involving high power), it is common sense to place chocks at the front of all main wheel sets, to reinforce the parking brake. ISO 9001:2008 Certified PTC/CM/B1.1 Basic/M7/04 7.17 - 15 For Training Purpose Only Rev. 00 Mar 2014 PIA TRAINING CENTRE (PTC) Module 7 - MAINTENANCE PRACTICES Category – A/B1 Sub Module 7.17 - Aircraft Handling and Storage AIRCRAFT STORAGE If an aircraft is de-activated for an extended time it will need to be protected against corrosion, deterioration and environmental conditions during its period of storage. The following notes are based on the storage procedures applicable to BAe 146 aircraft that have been de-activated for periods in excess of 30 days and up to a maximum of 2 years. It is not intended for the information given here to be complete, but merely to give the student examples of some of the activities performed. Specific details of an aircraft’s storage procedures can be found in Chapter 10 of the relevant Maintenance Manual. Generally there would be an initial procedure, this being repeated at specified intervals, as shown in Tables 1 (a) and 1 (b). If no repeat interval is given, then the item is only done initially. Once the aircraft has been prepared, there are routine, weekly checks to keep it in good condition. A list of equipment and materials is normally given. This will, typically, include: Hydraulic fluid and lubricating oils and greases Specialised water-displacing fluids and preventative compounds Aircraft covers and blanks Plastic sheeting and adhesive tape. corrosion- Prior to the storage period certain tasks are completed. These may include replacing the tyres with ‘dummy’ tyres (those not suitable for flight), or the raising of the pressures of the normal ones. The various tanks are either filled (water), drained (toilet), or part-filled (fuel). If the aircraft has propellers, they must be feathered, to prevent them rotating in the wind. (they may also be restrained by straps). ISO 9001:2008 Certified PTC/CM/B1.1 Basic/M7/04 7.17 - 16 For Training Purpose Only Rev. 00 Mar 2014 PIA TRAINING CENTRE (PTC) Category – A/B1 ISO 9001:2008 Certified PTC/CM/B1.1 Basic/M7/04 7.17 - 17 Module 7 - MAINTENANCE PRACTICES Sub Module 7.17 - Aircraft Handling and Storage For Training Purpose Only Rev. 00 Mar 2014 PIA TRAINING CENTRE (PTC) Category – A/B1 ISO 9001:2008 Certified PTC/CM/B1.1 Basic/M7/04 7.17 - 18 Module 7 - MAINTENANCE PRACTICES Sub Module 7.17 - Aircraft Handling and Storage For Training Purpose Only Rev. 00 Mar 2014 PIA TRAINING CENTRE (PTC) Category – A/B1 To allow the circulation of air around the inside of the aircraft, all the doors and curtains are fixed open, whilst all the external doors and panels are shut. The battery will be removed from the aircraft and kept in the battery bay. More active checks might be done on the two-weekly checks. These checks will probably involve re-installing the battery, running the engines for a period and functionally testing a number of the aircraft’s systems that require the engines operating. The flight controls might require cycling throughout their ranges and, if dummy tyres are not fitted, the aircraft must be moved slightly to prevent ‘flat spots’ forming on the tyres. Module 7 - MAINTENANCE PRACTICES Sub Module 7.17 - Aircraft Handling and Storage All the tanks must be replenished to their correct levels and all pressure vessels will require their gases charging to their normal operating pressures. If the cabin furnishings, such as seats, carpets and galleys have been removed, they are to be inspected and, when serviceable, re-installed in the cabin. As already stated, the foregoing summaries are only examples of the form that a basic aircraft storage procedure might take. If the aircraft is smaller or larger and more complex it will require a different form of inspection and routine checking. The correct storage procedures will be found in Chapter 10 of the relevant aircraft’s Maintenance Manual. In addition, when power plants are stored separately, their fuel and oil systems must be inhibited and all their external mechanisms protected with grease or other suitable preservative. They must be stored in a clean, warm, dry atmosphere with inspections at intervals to check for deterioration. Some engines are stored in an airtight bag, which has moisture-absorbent crystals (a desiccant) inside. After the storage period all of the covers, blanks and preservative compounds will need to be removed. All of the systems will need to be restored to their original condition prior to aircraft use. A further set of procedures will be followed, similar to those previously discussed. When the aircraft is to be returned to service, it is simply a case of initially removing all covers, blanks and tie-downs. Once access to the inside of the aircraft is obtained and the battery re-installed, all of the systems must be checked and tested. ISO 9001:2008 Certified PTC/CM/B1.1 Basic/M7/04 7.17 - 19 For Training Purpose Only Rev. 00 Mar 2014 PIA TRAINING CENTRE (PTC) Module 7 - MAINTENANCE PRACTICES Category – A/B1 Sub Module 7.17 - Aircraft Handling and Storage AIRCRAFT FUELLING PROCEDURES The use of the term ‘fuelling’ can include both refuelling and defuelling procedures and these notes contain examples of the essential points to be considered when refuelling and defuelling aircraft. There may, however, be some further, local instructions, regarding the responsibilities of the various personnel involved in fuelling procedures and these will always take precedence in conjunction with the relevant Maintenance Manual. Fuelling Safety Precautions Particular care must be taken when fuelling aircraft, so that the operation may be accomplished in the safest possible manner. Whenever possible, aircraft should be fuelled in the open, and not in a hangar (although this is, sometimes, necessary as part of a maintenance programme). This will minimise the fire risk from high concentrations of flammable vapours. Fire appliances should be readily available during all fuelling operations. Carbon dioxide, or foam, extinguishers are recommended but, if there is a perceived increased fire risk, then fire-fighting vehicles should be standing by. Within the specified danger area, around an aircraft being fuelled, no sources of ignition or sparks should be allowed and no electrical power should be switched on or off during the fuelling operation. ISO 9001:2008 Certified PTC/CM/B1.1 Basic/M7/04 7.17 - 20 It is vital that the correct type and grade of fuel is used for the fuelling operation. Use of a turbine fuel in a piston aircraft will certainly cause an engine malfunction, or failure, that could lead to loss of an aircraft. The correct type and grade of fuel is always detailed in the Maintenance Manual and marked adjacent to the aircraft’s fuelling point(s). Care should also be exercised so as to avoid contamination of the fuel system with water or other contaminants. The fuel supply should be regularly checked for water contamination and a sample of fuel drained off after refuelling, so that a water check may be done. It will sometimes be necessary to filter the fuel during over-wing refuelling, particularly in dusty climates. Electrical bonding of the fuel system is vital during fuelling operations, as when fuel flows through the refuelling hose, static electricity may be generated. This may lead to potential differences at adjacent metal parts and initiate a spark, fire or explosion. To minimise this risk the following actions should be completed before fuelling operations commence The aircraft should be earthed The refuelling tanker should be earthed The nozzle of the fuel hose should be electrically bonded to the fuelling point. For Training Purpose Only Rev. 00 Mar 2014 PIA TRAINING CENTRE (PTC) Category – A/B1 Module 7 - MAINTENANCE PRACTICES Sub Module 7.17 - Aircraft Handling and Storage Refueling When refuelling the AMM should always be consulted so that the positions and capacities of the fuel tanks and also the type of fuel, position of the refuelling point(s) and refuelling procedures are known. There are two general re-fuelling methods: Gravity or over-wing refuelling: which is, essentially, the same method as used to refuel a motor car (automobile), with a similar type of refuelling hose being used. As the name suggests, the filler points are, generally, on the upper surface of the wing and the tank is open when refuelling is done. Pressure refuelling: in which the fuel may be pumped into the aircraft via a pressure refuelling coupling at very high rates. The refuelling pressures and the rates of fuel delivery may be quite different for individual aircraft types, so great care must be taken, to ensure no damage occurs to an aircraft through incorrect refuelling settings. The aircraft fuel gauges will normally be positioned on the flight deck, but they can, on some aircraft, be duplicated at a fuelling panel, adjacent to the pressure refuel coupling. The Relative Density (RD) of fuel will vary with temperature and so the weight of a certain quantity of fuel will also vary. For example, ten gallons (Imperial) of fuel, with an RD of 0.8, will have a weight of 80 lb, while ten gallons (Imperial) of fuel, with an RD of 0.78, will weigh 78 lb. It is crucial, for balance purposes, that the weight of fuel is known and this is the reason why many aircraft fuel gauges are calibrated in units of weight rather than in volume. When fuelling aircraft, it is essential that the technician is aware of the RD of the fuel, so that the necessary weight calculation may be done, if necessary. Checking fuel contents This is normally done, using the aircraft fuel gauges, which may be calibrated in kilograms (kg), gallons (Imperial or US) or pounds (lb). If a double check is required, then the contents may be determined, on the ground, by using ‘dip sticks’ (installed into the top of the tanks) or by ‘drip sticks’ (or magnetic ‘drop sticks’) which are installed in the bottom of some aircraft tanks. ISO 9001:2008 Certified PTC/CM/B1.1 Basic/M7/04 7.17 - 21 For Training Purpose Only Rev. 00 Mar 2014 PIA TRAINING CENTRE (PTC) Category – A/B1 Module 7 - MAINTENANCE PRACTICES Sub Module 7.17 - Aircraft Handling and Storage DEFUELLING Occasionally, it is necessary to remove fuel from an aircraft, to facilitate fuel tank maintenance, or because the aircraft is too heavily loaded for the next flight. Removing fuel from an aircraft can be accomplished by either the gravity or by the pressure defuelling method. The gravity method entails draining the fuel into a suitably earthed container, and this is typical of light aircraft, which are normally ‘gravity’ refuelled. The fuel removed must be disposed of in the correct manner, with regard to local instructions and to the environment. Aircraft that are normally pressure refuelled are normally equipped with a pressure defuelling facility. Pressure defuelling is achieved by utilising a small negative pressure (suction), which effectively draws the fuel out of the tank and returns it into the fuel tanker (bowser). Current rules will normally only allow the fuel, removed from an aircraft, to be placed into a dedicated defueller vehicle and the fuel will not be permitted to be used in another aircraft. This ensures that any contamination such as water or debris will not be transferred to other aircraft. ISO 9001:2008 Certified PTC/CM/B1.1 Basic/M7/04 7.17 - 22 For Training Purpose Only Rev. 00 Mar 2014 PIA TRAINING CENTRE (PTC) Category – A/B1 Module 7 - MAINTENANCE PRACTICES Sub Module 7.17 - Aircraft Handling and Storage DE-ICING/ANTI-ICING OF AIRCRAFT Ice Types There are three main types of ice/frost that can affect an aircraft’s performance, Hoar Frost, Rime Ice and Glaze Ice. The temperature and weather conditions will determine the type of ice that forms, but all three types can have a detrimental effect. The Dew Point is the temperature at which moist air becomes saturated and deposits dew if in contact with a colder surface or the ground. Above ground, condensation into water droplets takes place. Hoar Frost is a deposit of ice crystals that form on an object when the dew point is below freezing point. High humidity will normally produce hoar frost, as these are similar to conditions that produce dew. Hoar frost can form when the air temperature is greater than 0°C, but the aircraft skin temperature is less than 0°C. This type of frost produces a very rough surface which leads to turbulent airflow. Glaze Ice can be either transparent or opaque and can form into a glassy surface due to liquid water flowing over a surface before freezing. It is the most dangerous type of ice found on an aircraft and is dense, heavy and tough. It adheres firmly to a surface, is difficult to shake off, and if it does breakaway, it does so in large chunks. During cold weather operations, it may be necessary to remove ice and snow from the aircraft, while it is on the ground, and to keep it clear long enough, to allow the aircraft’s systems to cope with snow or ice removal. This may not occur until the aircraft is flying. Rime Ice is a light coloured opaque rough deposit that has a porous quality. At ground level it forms in freezing fog from water droplets with very little spreading. It adds very little weight but it can disrupt the smooth flow of air over the wing, and block pitot and static vents. ISO 9001:2008 Certified PTC/CM/B1.1 Basic/M7/04 7.17 - 23 For Training Purpose Only Rev. 00 Mar 2014 PIA TRAINING CENTRE (PTC) Module 7 - MAINTENANCE PRACTICES Category – A/B1 Sub Module 7.17 - Aircraft Handling and Storage On the ground, the aircraft must be cleared of all snow and ice from its wings, tail, control surfaces, engine inlets and other critical areas (refer to Fig. 4) before the aircraft can take-off. Ice formation on an aircraft on the ground may result from a number of causes: Direct precipitation from rain, snow and frost Condensation freezing on external surfaces of integral tanks following prolonged flight at high altitude After taxing through snow or slush, ice may accumulate on landing gear, forward facing surfaces and under-surfaces. Rudder Ailerons VHF Antenna Elevator TCAS Antenna Flaps Pitot and Static Heads Slats Engine Nacelle Critical Surfaces for De-icing and Anti-icing Fig. 4 ISO 9001:2008 Certified PTC/CM/B1.1 Basic/M7/04 7.17 - 24 For Training Purpose Only Rev. 00 Mar 2014 PIA TRAINING CENTRE (PTC) Module 7 - MAINTENANCE PRACTICES Category – A/B1 The formation of ice on aircraft structures can produce many adverse effects, and if allowed to remain may result in some or all of the following: Decreased aerofoil lift Increased aerofoil drag Increased weight Decreased engine thrust Freezing of moisture in control hinges Freezing of micro-switches that affect systems such as the landing gear retraction Ingestion of ice into the engine. Definitions The terms ‘de-icing‘ and ‘anti-icing’ have specific definitions, and it is essential to know the differences. Sub Module 7.17 - Aircraft Handling and Storage De-Icing and Anti-Icing Methods The de-icing procedure for removal of ice, frost and snow from an aircraft’s surface can be achieved by mechanical or chemical methods. Mechanical methods use blowers, brushes and rubber scrapers whilst chemical methods utilise de-icing fluids. The anti-icing procedure provides protection against the formation of ice, frost and snow on aircraft surfaces for a short period known as the ‘Holdover Time’. This is achieved by applying an anti-icing fluid, but the aircraft must be either clean or de-iced prior to this anti-icing fluid application. There are two ways of aircraft de-icing and anti-icing: One Step Method Two Step Method. De-icing is the removal of ice that has already formed Anti-icing is the prevention of initial ice formation. ISO 9001:2008 Certified PTC/CM/B1.1 Basic/M7/04 7.17 - 25 For Training Purpose Only Rev. 00 Mar 2014 PIA TRAINING CENTRE (PTC) Module 7 - MAINTENANCE PRACTICES Category – A/B1 The One Step method utilises hot fluid to de-ice the aircraft, and this fluid remains on the aircraft surfaces to give a limited antiicing capability. The Two Step method consists of two separate fluid application procedures. The first step is the de-icing part and the second step the anti-icing. This second step must be done within three minutes of starting the first step, surface by surface if necessary. The second anti-icing step protects the aircraft surfaces for a holdover period. Whilst the AMM will detail the exact areas for de-icing and antiicing, particular attention should be paid to areas around probes, antennas, and pitot/static ports as well as control surfaces, landing gear and inlets and exhausts. Chemical De-Icing Freezing Point Depressant (FPD) compounds are often used in conjunction with mechanical methods, and there are two main types of FPD compounds: Sub Module 7.17 - Aircraft Handling and Storage These fluids have a minimum glycol content of approximately 50%, and due to a thickening agent, are able to remain on the aircraft surfaces for longer periods. The de-icing performance is good and provides protection against re-freezing and/or build up of further accretion, when exposed to freezing precipitation. Treatment of Frost Deposits Frost deposits are best removed by the use of a de-icing fluid such as Kilfrost ABC (Aircraft Barrier Compound). These fluids usually contain either: ethylene glycol and isopropyl alcohol di-ethylene glycol and isopropyl alcohol propylene glycol and isopropyl alcohol. This process is not lengthy and one application is usually sufficient provided it is applied within two hours of flight. Only fluids recommended by the manufacturer should be used and any instructions for their use should be strictly observed. Use of incorrect de-icing fluids may adversely affect glazed panels or paint finish. Type 1 (unthickened) These fluids have a high glycol content and a low viscosity. They provide good de-icing performance but only a limited protection against re-freezing. Type 2 (thickened) ISO 9001:2008 Certified PTC/CM/B1.1 Basic/M7/04 7.17 - 26 For Training Purpose Only Rev. 00 Mar 2014 PIA TRAINING CENTRE (PTC) Module 7 - MAINTENANCE PRACTICES Category – A/B1 Alcohol based de-icing fluids, may cause dilution or complete removal of oils and greases from joints or bearings. This may allow water ingress, which can subsequently freeze and jam controls. De-icing spray nozzles should not be directed at lubrication points or sealed bearings. Hot air blowers may be used to remove snow, ice or frost, and the liquid residue should be dried and not allowed to accumulate in places such as hinges or micro-switches as any re-freezing may cause damage. Sub Module 7.17 - Aircraft Handling and Storage Moderate to heavy ice deposits or residual snow should be cleared with de-icing fluid applied by spraying. The two methods of fluid spraying involve the: Cold Fluid Spray Hot Fluid Spray. When using these sprays, it is necessary to observe certain precautions, because of the risk of damage to the aircraft structure and associated components. With this in mind it is important to know that: Removal of Ice and Snow Deposits There are several methods of removing snow and ice from an aircraft, prior to applying liquids if required. Removal by hand can be accomplished by the use of soft brooms, hand brushes or rubber scrapers. The aircraft can be de-iced using cold air from a pressure supply unit, or by using hot air from a hot air blower designed for the purpose. Deep wet snow should be removed with a brush or rubber scraper, taking care not to damage components such as aerials and pitot probes, which may be covered in snow. The snow should also be cleared from items like vents and control hinges. Light dry snow should be blown off using a cold air blower. Hot air is not recommended as it may melt the snow which may accumulate and freeze requiring further treatment. ISO 9001:2008 Certified PTC/CM/B1.1 Basic/M7/04 7.17 - 27 High-pressure sprays may cause damage to pitot-static probes and other sensing devices Covers and bungs should be fitted during de-icing operations to prevent ingress of fluid into intakes and exhausts High-pressure sprays may cause erosion of the aircraft skin. Consult the AMM for recommended maximum impingement pressure No attempt should be made to remove ice by using an impact force to break the bond De-icing should proceed symmetrically, to prevent excess weight on one side of the aircraft. The Cold Fluid Spray method is the simplest method of applying de-icing fluid, but in severe conditions one application may not be sufficient to remove all deposits. Brushing followed by a second or third application may be required. For Training Purpose Only Rev. 00 Mar 2014 PIA TRAINING CENTRE (PTC) Category – A/B1 Module 7 - MAINTENANCE PRACTICES Sub Module 7.17 - Aircraft Handling and Storage The Hot Fluid Spray method has been adopted specifically to reduce turn-round time. The FPD fluid is mixed with water in proportion to suit prevailing weather conditions, and heated to between of 60ºC (minimum) and 85ºC (maximum). The fluid is normally sprayed onto the aircraft at a pressure of 100 psi (689.5 kN/m2) by use of spray lances. The nozzle of the lance is held close to the aircraft skin, to prevent heat losses. The heat transfers to the skin of the aircraft, breaking the ice bond, and large areas of ice may be flushed away by turning the nozzle sideways. The fluid film remaining on the skin, has only been slightly diluted beyond its original dilution and is effective in preventing further ice formation. Hot water de-icing is a method that must not be used below 70C and may need to be performed in two steps. Step 1: Snow and ice are normally removed initially with a jet of hot water not exceeding 95C Step 2: If necessary a light coating of de-icing fluid is then sprayed on immediately (within 3 minutes) to prevent refreezing. On some aircraft, not equipped with aerofoil or propeller deicing systems, the use of a de-icing paste may be specified. The paste is spread evenly, by hand, over wing, tail and propeller leading edges. It provides a chemically active surface on which ice may form but not produce a bond. Any ice, which forms, is blown away by the airflow. The paste should be re-applied before each flight in accordance with the AMM. ISO 9001:2008 Certified PTC/CM/B1.1 Basic/M7/04 7.17 - 28 For Training Purpose Only Rev. 00 Mar 2014 PIA TRAINING CENTRE (PTC) Category – A/B1 Module 7 - MAINTENANCE PRACTICES Sub Module 7.17 - Aircraft Handling and Storage Hold Over Times When used for anti-icing, the FPD fluid should be sprayed onto the aircraft cold and undiluted, before the onset of icing or after any hot de-icing. The fluid film will prevent ice and snow from sticking to the aircraft skin and, given time, will melt any fresh precipitation. Typical times for which the fluid remains effective are known as the ‘Hold Over’ time (refer Table 2). Under extreme cold conditions it may be necessary to heat the fluid (60C max) to give it sprayability. No significant increase in hold over time is achieved by strengthening the mix of type I (AEA) fluids. Stations using Kilfrost will normally provide a mix of 50/50 or 60/40. It may be difficult to get stronger mixes at short notice unless the temperature conditions at the stations involved are below limits for that mix. ISO 9001:2008 Certified PTC/CM/B1.1 Basic/M7/04 7.17 - 29 For Training Purpose Only Rev. 00 Mar 2014 PIA TRAINING CENTRE (PTC) Module 7 - MAINTENANCE PRACTICES Category – A/B1 Sub Module 7.17 - Aircraft Handling and Storage Certain precautions should be observed when applying chemical anti-icing fluids, and these are: Anti-icing fluid must NOT be applied on top of a similar, earlier coat If possible, the engines or the APU should not be operated during snow/ice removal The fluid should not be sprayed directly onto windscreens, windows, vanes, pitot heads or probes The minimum quantity of fluid should be used in the air conditioning intake areas If possible the fluid should not be sprayed onto lubricated parts, such as landing gear legs Inspection after De-Icing/Anti-Icing Procedures Tyres to ensure that they are not frozen to the ground. They should be freed by the application of hot air to the ice (not the tyre) and the aircraft moved to a dry area Engine air intakes for ice and snow deposits Gas turbine engines for freedom of rotation by hand. Restriction may indicate icing in the compressor region and the engine should be blown through with hot air immediately before starting until the rotating parts are free Shock absorber struts and hydraulic jacks for leaks caused by contraction of seals and metal parts Tyre pressures and shock absorber pressure and extension Following the inspections an entry should be made in the Tech. Log, indicating that the De-Icing/Anti-Icing procedure has been completed. The following inspections should be done on completion of a de-icing procedure: External surfaces, for signs of residual snow or ice, particularly in the vicinity of control surface gaps and hinges All protrusions and vents, for signs of damage Control surfaces for full and free movement by hand. Where this is not possible the pilot's controls should be used, bearing in mind that power-operated controls exert large forces and could cause damage if any part of the control surface is frozen Landing gear mechanisms, doors, bays and wheel brakes, for snow and ice deposits Up-locks and micro-switches, for correct operation ISO 9001:2008 Certified PTC/CM/B1.1 Basic/M7/04 7.17 - 30 For Training Purpose Only Rev. 00 Mar 2014 PIA TRAINING CENTRE (PTC) Category – A/B1 Module 7 - MAINTENANCE PRACTICES Sub Module 7.17 - Aircraft Handling and Storage GROUND ELECTRICAL SUPPLIES Ground electrical supplies are normally limited to either 28 volts dc or 115 volts ac, depending upon the systems of the aircraft. Most modern aircraft have at least one 115 volt ac system (as well as a 28 volt dc one), so they will normally be supplied with 115 volts ac from an external power supply. The 115 volt ac connection has six pins, with four pins being longer than the other two. The four longer pins provide the three phases and the neutral connection whilst the short pins provide the safety interlock. Airfields normally supply electricity to aircraft through external generators called Ground Power Units (GPUs), or have underground supplies, which are connected to the aircraft via the air-bridge, or from beneath the ramp surface. When an external electric supply is required inside the hangar, its generation will normally be through transformer rectifier units. An external power control box may be installed on the hangar wall and the required output for a particular aircraft can be selected. To prevent accidentally connecting-up of incorrect supplies, all aircraft have separately-shaped plugs and sockets. The 28 volt dc supply usually has a three-pin connection whilst the 115 volt ac utilises a much larger, six-pin plug and socket (refer to Fig. 5). The 28 volt dc connection has two pins which are longer than the third. The longer pins are the supply connections whilst the shorter pin acts as a safety interlock, to ensure that the power is cut-off, if the cable is inadvertently pulled out without the power being switched off first. ISO 9001:2008 Certified PTC/CM/B1.1 Basic/M7/04 7.17 - 31 For Training Purpose Only Rev. 00 Mar 2014 PIA TRAINING CENTRE (PTC) Module 7 - MAINTENANCE PRACTICES Category – A/B1 Sub Module 7.17 - Aircraft Handling and Storage 3 PIN EXTERNAL POWER RECEPTACLE EARTH dc Power Socket and Receptacle EXTERNAL POWER READY LIGHT SERVICE INTERPHONE CONNECTION NOSE WHEEL WELL LIGHTS EXTERNAL SUPPLY SOCKET A.C. PHASE “A” POSITIVE D.C. A.C. PHASE “B” 3 PIN PLUG POSITIVE D.C. ACCESS DOOR A.C. PHASE “C” A.C. NEUTRAL D.C. ac Power Receptacle Ground Electrical Supplies ISO 9001:2008 Certified PTC/CM/B1.1 Basic/M7/04 7.17 - 32 Fig. 5 For Training Purpose Only Rev. 00 Mar 2014 PIA TRAINING CENTRE (PTC) Module 7 - MAINTENANCE PRACTICES Category – A/B1 Sub Module 7.17 - Aircraft Handling and Storage GROUND HYDRAULIC SUPPLIES Hydraulic test rigs are available, to supply aircraft with a source of hydraulic power without the need for running the engines or APU. These test rigs are normally powered either by internal combustion, or by electric, motors. They must use the same type of hydraulic pump and fluid as the aircraft under test, to allow testing of items such as the timing of system operations. The aircraft has an access panel, behind which are a set of ‘quick-connect’ couplings, allowing the rig hoses to be easily connected to the aircraft’s system without the need for ‘bleeding’ the system of air. This is achieved by use of nonreturn valves, which only open when the couplings are fully tightened. Before connecting a hydraulic testing rig to an aircraft, it must be ensured that all of the lines and couplings are thoroughly clean, so that no dirt can get into the aircraft’s system. Safety, Health and Servicing Precautions Phosphate ester-based hydraulic fluids constitute a major health risk. Extreme care should be taken when handling this fluid and the following precautions should be taken: Eye protection is essential when the possibility of atomised spray exists. If fluid contacts the eyes, they should be flushed with large quantities of clean/sterile water and medical advice sought promptly Hands must be washed thoroughly after working with these fluids and particularly before eating or smoking Hydraulic fluid must not be allowed to contact the skin for excessive periods. Barrier cream and protective gloves must be put on before starting work Contaminated overalls should be changed as soon as possible after contact with the fluid. A typical hydraulic test rig might have a 75kW (100 hp) electric motor, driving the pump through a gearbox, clutch and a flexible coupling. The output could be in the region of 175 litres per minute (38 gallons per minute) at 200 kPa (3000 psi). The oil would be filtered to the standard required by the aircraft system, typically, 3 microns. A mask must be worn when the possibility of inhaling the fluid in an atomised form exists. The fluid irritates the respiratory passages and can cause sneezing and coughing ISO 9001:2008 Certified PTC/CM/B1.1 Basic/M7/04 7.17 - 33 For Training Purpose Only Rev. 00 Mar 2014 PIA TRAINING CENTRE (PTC) Category – A/B1 Most hydraulic rigs have a small header tank of system oil. It would utilise the aircraft’s oil for the majority of operations, with the header tank keeping the system primed during coupling and uncoupling operations. The flow valves, which are often integral parts the rigs, must be kept closed until all the hoses have been connected and the rig is ready to run. The motor is started and once the operating pressure is indicated on the rig gauges, the valves can be opened and the rig then forms part of the aircraft system. This will enable the functional testing of the aircraft’s hydraulic systems using the aircraft’s selector valves. The rigs may also be provided with special gauges, such as flow meters, which will allow the testing for internal system leakages. Rig Maintenance The rigs must have an equal or better filtration level than the aircraft being serviced. Oil samples of the rig are taken on a regular basis, and the following checks must be completed on a regular basis: Module 7 - MAINTENANCE PRACTICES Sub Module 7.17 - Aircraft Handling and Storage GROUND PNEUMATIC SUPPLIES Pressurised aircraft usually require an adequate supply of lowpressure air, for such tasks as engine starting, ventilation, heating and cooling, anti-icing and pressurisation testing. This air supply is, normally, provided by the aircraft’s engine/s or APU but, when these are unavailable, a ground supply unit can be used. Pneumatic units can supply air at the required pressure and flow rate and are powered by turbine engines, diesel engines or electrically powered units. The compressors used by these units are normally axial flow, centrifugal flow, or of the screw or lobe type. Depending on the size of the aircraft being serviced and the air requirements, the compressor can be mounted on a trailer chassis or on a self-propelled vehicle. To ensure the air produced is of a suitable quality, it is normally filtered and cleaned before being fed to the external air supply connection, which is located on the outside of the airframe. The rig must be kept clean and all hoses blanked when not in use The filters must be changed or cleaned All the gauges should be calibrated Any electrical equipment on the rigs should be checked. ISO 9001:2008 Certified PTC/CM/B1.1 Basic/M7/04 7.17 - 34 For Training Purpose Only Rev. 00 Mar 2014 PIA TRAINING CENTRE (PTC) Module 7 - MAINTENANCE PRACTICES Category – A/B1 Some aircraft have two separate connections for air supplies at different points on the airframe. The forward connection may be for low-pressure air, which is then fed directly to the conditioning system, allowing testing of the air conditioning system and also of the pressure hull. The aft connection may be for a higherpressure bleed air supply that is primarily used to start the engines if the APU is unserviceable. Whilst some units are dedicated air starter rigs, some can be used both for starting and also for functional testing of the air conditioning and de-icing systems. As with the electric and hydraulic ground power supply rigs, the output of a pneumatic unit must match the aircraft’s system for pressure and flow. Sub Module 7.17 - Aircraft Handling and Storage EFFECTS OF ENVIRONMENTAL CONDITIONS AIRCRAFT HANDLING AND OPERATION ON Previous notes have mentioned a range of precautions that need to be applied when the weather is anything less than perfect. This section will cover actions that the technician will need to take for prevailing situations when various weather conditions exist. Cold and Wet When the ramp is cold and wet, the friction between the aircraft’s tyres and the ramp can be reduced. This also applies to all self-propelled vehicles and, hence, all movements on the ramp should be at a slower speed than normal, with quick access to chocks, in the event of an emergency. During engine ground running, it is possible that there may be a maximum power limitation if the ramp is very wet or flooded. This will be covered in either the Airfield Operations Manual or the Ground Handling Procedures Manual (as will most other precautions and procedures). If large amounts of protective clothing are worn on the ramp, it is the technician’s responsibility to ensure that nothing can get sucked into a running engine. Also, during ground running, it is important that extra chocks are placed at the wheels of the aircraft to prevent slippage at the higher power settings. ISO 9001:2008 Certified PTC/CM/B1.1 Basic/M7/04 7.17 - 35 For Training Purpose Only Rev. 00 Mar 2014 PIA TRAINING CENTRE (PTC) Module 7 - MAINTENANCE PRACTICES Category – A/B1 Sub Module 7.17 - Aircraft Handling and Storage Falling rain (and fog) will demand that more care be taken, due to the reduced visibility, especially when towing is in progress. The use of all normal lights, day or night, when moving vehicles in rain, is most important. Most airfields that operate continuously have a plan to deal with excessive amounts of snow. This plan might include the application of heater units or allowing APUs to run for extended periods to keep the inside of the aircraft warm. Where there is a risk of rain and the aircraft is to be parked, then the appropriate aircraft blanks and covers must be used. It is also inadvisable to re-fuel aircraft by the ‘open line’ (over wing) method in rain, due to the high risk of water getting into the tank whilst the filler cap is removed. Great care must be taken, to protect the filler neck orifice, so that very little water enters the tank. For aircraft, which are to be left out on the ramp, in sub-zero temperatures, it may be necessary to drain the potable water tanks, to prevent them freezing overnight. This will involve some care, as they should not be drained onto the ramp, due to the risk of personnel slipping on the ice. If a task needs to be completed on the upper surface of a wet wing, it would be advisable to use a ‘safety raiser’ or ‘cherry picker’. This mobile craning device will allow safe access to the upper surfaces of a high wing and also provide the technician with a safety device, to hook onto, should the need arise. Snow and Ice Other items of equipment that use water, such as heaters and pipe-work, may also need protection in cold temperatures. High Winds High winds can cause loose objects to move across the ramp and strike the aircraft. These can be light items such as twigs and branches but, on occasions, heavy pieces of ground equipment, that have not been secured correctly, have been pushed into aircraft, causing major damage. Many of the precautions, already mentioned, also apply in conditions of snow and ice. Aircraft towing and taxiing may be restricted until all standing precipitation has been cleared from the area to be used. During very high wind conditions, the smallest objects can be lethal, due to the energy they contain. The loss of visibility during falling snow can be severe, especially at times of low light, so great care must be shown if it is considered essential that an aircraft movement must take place. This may require a larger than normal towing team and the use of extra lights. In certain environments, such as desert climates (or at airfields near seashores), sand and dust, driven by the wind, can enter small crevices, causing problems with aircraft systems and may also block filters. Where extreme conditions exist, such as during a sand storm, then the blanking of all orifices may have to be augmented with tape or other methods, to prevent the ingress of dust and sand. ISO 9001:2008 Certified PTC/CM/B1.1 Basic/M7/04 7.17 - 36 For Training Purpose Only Rev. 00 Mar 2014 PIA TRAINING CENTRE (PTC) Category – A/B1 Great care must be taken, to ensure suitable entries are made in the Technical Log, for the complete removal of all blanking material, after the storm has abated. Module 7 - MAINTENANCE PRACTICES Sub Module 7.17 - Aircraft Handling and Storage This facility is known as the ‘Hotel Mode’ and, effectively, enables an engine to operate in a similar manner to an APU, without the need to carry extra weight. High Temperature Certain items of equipment are temperature-sensitive and, when aircraft are operated in environments of extreme high temperature (+55C), then several extra precautions have to be taken. Some form of cooling must be provided to ensue that the crew does not suffer from heat exhaustion, and reduce their efficiency. The operating temperature electronic equipment must also be kept below a critical level, to ensure its continued serviceability. Most of the larger aircraft have an auxiliary power unit (APU), which can provide a supply of bleed air to allow the air conditioning system of the aircraft to operate on the ground. If an APU is not available, then external air conditioning units can be connected to the aircraft to keep the inside cool. These cooling rigs should have an air conditioning unit of suitable capacity for the size of the aircraft that requires cooling. Some turbo-propeller passenger aircraft have the facility to run an engine, without the propeller turning, to provide air conditioning on the ground. ISO 9001:2008 Certified PTC/CM/B1.1 Basic/M7/04 7.17 - 37 For Training Purpose Only Rev. 00 Mar 2014