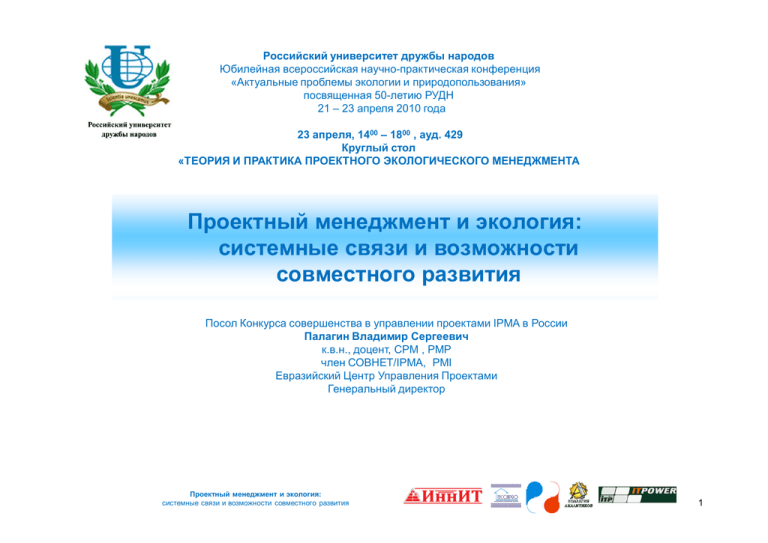

Доклад "Проектный менеджмент и экология: системные связи и

реклама

» 5021 – 23 2010 , 1400 – 1800 , 23 . 429 : IPMA ., , CPM , PMP /IPMA, PMI : 1 1. 2. 3. 4. : 2 ,( . óikos - , ), , , , .( ( ), ) , .( ) – , , (PMI, – ( ); ), (DIN 69901, ); , . . , . , . : 3 IPMA International Project Excellence Award IPMA International Project Excellence Award : 4 4 IPMA International Project Excellence Award 2009 Well Modernisation Program. Member of OMV Group ( ) Petrom EP, Beijing T3 Airport Expansion Project. Ltd China, Siemens Industry Sector - Mobility Division ( Siemens ) 2008 Lomellina 2 Project Foster Wheeler Italiana SpA ( ) 2007 Technological Revamping Project of 150,000 t/a Acetic Acid Jiangsu Sopo (Group) Co. Ltd., China 2006 TDN REWE IP-VPN 2 T-Systems International ( ) Shenzou 6-Manned Spaceship Chinese Academy of Space Technology ( ) 2006 : 5 PMI 2007: FLUOR & n Fernald Feed Materials Production Center FLUOR closed a cold war nuclear facility in less time and with less money than anyone thought possible - but first the company had to gain the trust of the community. It was an unwelcome reminder of a time long since passed—and residents weren’t happy about having it in their backyard. Located in a rural area northwest of Cincinnati, Ohio, USA, the Fernald Feed Materials Production Center had delivered high-grade uranium metal products to the U.S. military throughout the Cold War. Long shrouded in secrecy, even from community members, the facility ceased production in 1989. It was the end of one era—and the beginning of another. Three years later, the U.S. Department of Energy (DOE) hired Dallas, Texas, USA-based Fluor Corp. to launch one of the largest environmental cleanup operations in the country’s history. When Fluor took over, the site had suffered widespread contamination, primarily through soil and groundwater pathways. With extensive news coverage prompting attention from both regulators and the public, the company was operating in a contentious social and political environment. Given the stakes, the cleanup project could have easily succumbed to turf battles and warring priorities between the DOE and Fluor. But they showed a dogged willingness to work together and embrace enormous change. : 6 The site contained 31 MILLION POUNDS of nuclear product. A BIG MESS The scope of the Fernald project was massive—and downright dangerous. The site contained: 1. Two concrete silos with 8,900 cubic yards of radium-bearing sludge 2. One concrete silo holding 5,100 cubic yards of cold metal oxides 3. Six waste pits containing more than 1 million tons of low-level radioactive waste 4. 6 million cubic feet of containerized low-level waste 5. 174,912 gallons of low-level liquid mixed waste 6. 31 million pounds of nuclear product 7. 224 process-related and administrative structures 8. 400 acres of contaminated soil 9. 225-acre plume of contamination in an underground aquifer. During its production years, Fernald was closed off to both the public and regulators. Not surprisingly, those 37 years of secrecy resulted in an angry and suspicious attitude from the surrounding community and the press. : 7 TIME LINE December 1992 - The U.S. Department of Energy (DOE) awards Fluor Corp. the first environmental remediation contract of the Fernald Feed Materials Production Center outside of Cincinnati, Ohio, USA. 1993 - Aware of public hostility toward the project, Fluor launches a “public participation strategy” to engage local stakeholders. 1994 - A safety program is initiated. 2000 - DOE awards Fluor a reworked contract aimed at closing the site in 2010. 2003 - Fluor accelerates the project’s target completion date to December 2006. 2006 - The last of the contaminated materials to move offsite are shipped out. The on-site disposal facility is completed. The site is certified as meeting regulatory mandated cleanup levels. 2007 - A public ceremony is held to introduce the Fernald Preserve, a 1,050 10 years Fluor Fernald construction crew went without a lost workday injury - equal to more than 10 million safe work hours. In 2006, Fluor closed the project 12 years earlier and $7.8 billion below initial estimates. : 8 IPMA 2009: Software development for the IT system of the payments and intervention agency for agriculture and IACS SIVECO ROMANIA S.A. Starting with 2007, Romania benefits from EU funds for agriculture under the form of direct area payments. The direct payments represent the support granted by the European Union to the farmers in Romania under the conditions farmers are eligible and submit an area aid request. An essential condition the Romanian government had to fulfill in order to be able to absorb EU funds for direct payments was the creation of a system to ensure the administration and strict control of the farmers’ aid requests. This is the Integrated Administration and Control System (IACS), while its creation, implementation and management is the responsibility of the Payments and Intervention Agency for Agriculture (APIA). The development, implementation and finalizing by set deadlines of the integrated administration and control system for agriculture (IACS) in Romania by the realization of the IT components was a major stage in the process of Romania’s accession to the European Union. In 2007, Romania was allotted 440 Mln Euro worth of funds for granting direct payments per hectare, but the funds management according to EU regulations conditioned this. The Integrated Administration and Control System (IACS) are subordinated to APIA and manage the subsidies granted to farmers under the form of direct payments per hectare. Payments and Intervention Agency for Agriculture (APIA) is the institution responsible with the management of these funds and with the implementation of the aid measures for farmers. : 9 Unlike the other EU countries, Romania had only one year for the implementation and setting up of the IT system for APIA, which was a real challenge. Compared to other accession states where it took 3 to 4 years, in Romania the IT IACS system was developed and implemented in a very short period of time (a year and few months). Bulgaria launched the action in 2005, while Poland had 3 years to do it. Except for Romania and Bulgaria, these systems were realized prior to the integration of respective countries into the UE; Each EU member state is obliged to develop its own IACS system; the companies producing these systems are not allowed to sell it or give it away (even free of charge) to other EU member states; The solution developed by the consortium SIVECO Romania – ABG SPIN Poland is a very complex IT based system: as long as the system was developed, new updated and improved versions were produced, according to the beneficiary’s requirements and based on newly emerged regulations and legislation. For every country, the size of the agricultural area, numbers of farmers, degrees of division of the territory (to mention just a few factors to be taken into account) differ very much. Obviously, these requirements reflect in the different complexity that the management of situations implies. : 10 …… : 11 . . . : . : 12 : 13 PDCA ) : 14 1 ISO IPMA PMI Prince , * GAPPS , , , ? : * , , R0, " " : 15 1 , , , , , - , , , , , ( , ) , ) IPMA PMI : 16 5 9 1. 2. 3. 4. 5. 1. 2. 3. 4. 5. 6. 7. 8. 9. N. , . : 17 : . . , . . : 18 : 19 2010 : 20 E-Mail: [email protected] : 21