древесиноведение. механическая обработка древесины

реклама

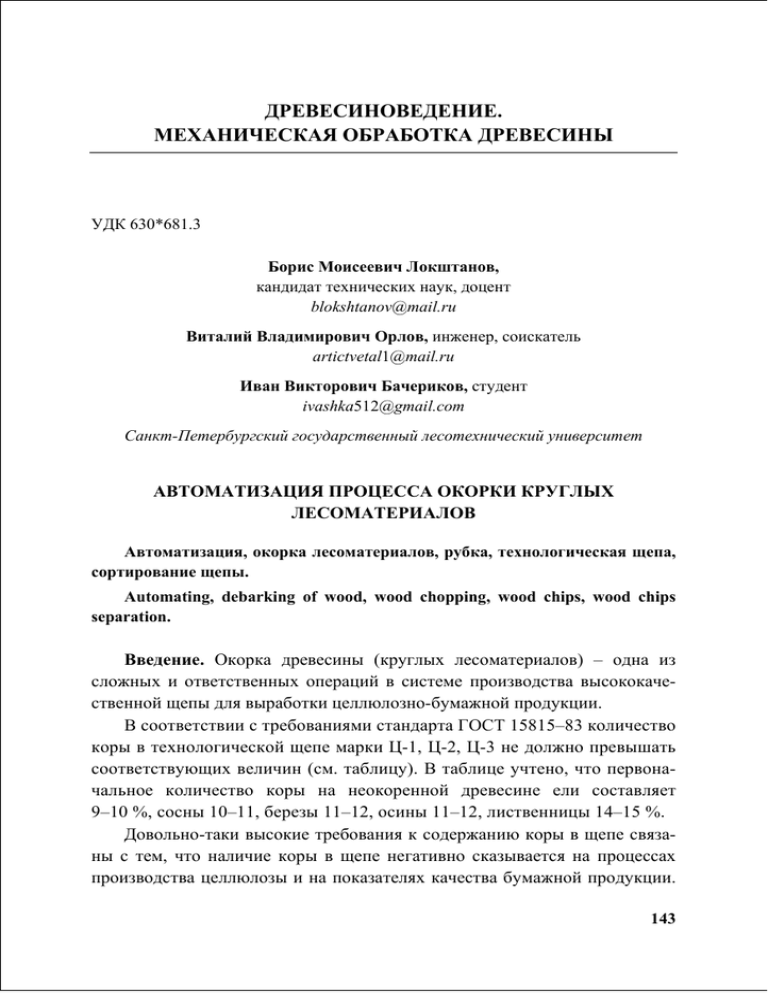

ȾɊȿȼȿɋɂɇɈȼȿȾȿɇɂȿ. ɆȿɏȺɇɂɑȿɋɄȺə ɈȻɊȺȻɈɌɄȺ ȾɊȿȼȿɋɂɇɕ 630*681.3 Ȼɨɪɢɫ Ɇɨɢɫɟɟɜɢɱ Ʌɨɤɲɬɚɧɨɜ, , [email protected] ȼɢɬɚɥɢɣ ȼɥɚɞɢɦɢɪɨɜɢɱ Ɉɪɥɨɜ, [email protected] , ɂɜɚɧ ȼɢɤɬɨɪɨɜɢɱ Ȼɚɱɟɪɢɤɨɜ, [email protected] ɋɚɧɤɬ-ɉɟɬɟɪɛɭɪɝɫɤɢɣ ɝɨɫɭɞɚɪɫɬɜɟɧɧɵɣ ɥɟɫɨɬɟɯɧɢɱɟɫɤɢɣ ɭɧɢɜɟɪɫɢɬɟɬ ȺȼɌɈɆȺɌɂɁȺɐɂə ɉɊɈɐȿɋɋȺ ɈɄɈɊɄɂ ɄɊɍȽɅɕɏ ɅȿɋɈɆȺɌȿɊɂȺɅɈȼ Ⱥɜɬɨɦɚɬɢɡɚɰɢɹ, ɨɤɨɪɤɚ ɥɟɫɨɦɚɬɟɪɢɚɥɨɜ, ɪɭɛɤɚ, ɬɟɯɧɨɥɨɝɢɱɟɫɤɚɹ ɳɟɩɚ, ɫɨɪɬɢɪɨɜɚɧɢɟ ɳɟɩɵ. Automating, debarking of wood, wood chopping, wood chips, wood chips separation. ȼɜɟɞɟɧɢɟ. ( ) – - . 15815–83 ( 9–10 %, 10–11, - . 11–12, -1, ). -2, -3 , 11–12, 14–15 %. - , . 143 Ɍɪɟɛɨɜɚɧɢɹ ɤ ɫɬɟɩɟɧɢ ɨɤɨɪɤɢ ɤɪɭɝɥɵɯ ɥɟɫɨɦɚɬɟɪɢɚɥɨɜ ɪɚɡɥɢɱɧɵɯ ɩɨɪɨɞ ɞɪɟɜɟɫɢɧɵ ɞɥɹ ɩɪɨɢɡɜɨɞɫɬɜɚ ɬɟɯɧɨɥɨɝɢɱɟɫɤɨɣ ɳɟɩɵ ɩɨ ȽɈɋɌ 15815–83 , %, , ,% -1 1,0 90 92 93 93 95 -2 1,5 85 87 88 88 90 -3 3,0 70 74 78 78 80 , . ( ) . , , , , , , - . , 9463–88), 0276385-404–89, ( 134-0273685-405–89), ( 9462–88, 13-0273685-402–89, 13, . - , . : – 2,5 – 3 , –6 12 ; 4, 5, 5,5, 6 , – 20, 25, 30, 35, 40 . , ( 1,5, 2, 3, 5 , 144 . .). - , , ( , , - ). - . ( ), , . 6–20 3 / , - – 60–400 3 / . . : , , , , , - . Ɇɟɬɨɞɢɤɚ ɢ ɪɟɡɭɥɶɬɚɬɵ ɢɫɫɥɟɞɨɜɚɧɢɣ. Y 100e Y– ; – c a t bM 2 (1) , , %; e – , ɤ = f (d, w, t), d– (2) ,w– ,b– ,t– - , b = f(d); t – (3) , t = f (l, d, ), , – l – ; c– , ;a– ( , , - , 145 ); M – , , D M 1 , D 2 D1 – (4) (4 ); D – - . . , - . , ( , ), . 60 , , 3 / - . - , . - . 3D ( . 1), , . . , , , - . Y Y– , , 146 ; Ski – 2 . 2 S Ski 100, S , %; S – (5) 4 3 1 5 2 Ɋɢɫ. 1. 3D 1– 4– ;2– ;3– ; ;5– S d l , d – (6) ( ), ; l – - , . , . , 5–7 , . , 13 ( ( . 2) , . 3), Y. t( . 4) , Y Q ( . 4). , - 147 ( . 5). ( , . 6), , - , , [1]. 18 17 16 15 4 14 13 3 5 12 11 6 8 9 10 1 2 7 20 21 22 19 Ɋɢɫ. 2. 0,2 0,4 0,6 0,8 1,0 Ɋɢɫ. 3. () (N, ), (4×20) – Q 148 . 3 / , –t Ɋɢɫ. 4. (t, ) (Q , %) (4×20) Q, 3 (Y, %) / n, Ɋɢɫ. 5. / (n, / (420) (Q, 3/ ) ) 149 n, / 2,5 3,0 3,5 4,0 4,5 5,0 5,5 6,0 D, Ɋɢɫ. 6. (n, / ) (D, ) (– –) – ; (—) – ( , , , ), . . t = 130…140 1 3 , ( (t = 150…200 ) t = 40…60 , . , 25–50 ( 15–20 / 3. 15–40 3/ 3. ) 75 % ), 1,5–2 ( 3 / 3. ), . , № 108001 [2]. . 2. . 1 3 , 4. 5 6, 150 11 3D. - 11 17 18. 12 7 3 - 4. 13 16 5, 3 14 15 . , ( . 1), 8. 10. 9 , , , - 20, 22, 21 13, 14, 16. ȼɵɜɨɞɵ. 3D , , - , , . , , 15815–83 - . Ȼɢɛɥɢɨɝɪɚɮɢɱɟɫɤɢɣ ɫɩɢɫɨɤ 1. ]. – 3 . – . 1, . 1. , 2002. – 432 . 2. № 108001. – . 25. – 10.09.2011 . . [ ]: [ . .– [ .: ]: - , , , 151 , - . . - D . , , , . , . *** This paper describes the principles of automatisation of the process of debarking of roundwood in barking drums. It is stated that the quality of debarking wood is currently being carried out visually, in addition, removal of badly barked logs from the flow of timber requires a great effort, including manual labor. We offer the technology of debarking of roundwood with the automation system of selection process of badly barked logs and parameter control of the process of debarking wood in a continuous reel. The automation system is based on the usage of scanning unit of barked logs on 3D technology and weighing instruments. According to the operation of these plants we may determine the amount of debarking wood, assess the quality of log barking, to automate the separation badly barked logs from the main stream, to determine the amount of waste wood, and automatically adjust the parameters of the process of debarking in the barking drum in the long run. The proposed system of automation of the process of debarking of roundwood in the barking drum allows to produce wood chips of high quality with a minimum content of the bark, suitable for the production of high-quality cellulose and wood pulp. 152